Development and Functionalisation of Nanofibres Produced by ...

Development and Functionalisation of Nanofibres Produced by ...

Development and Functionalisation of Nanofibres Produced by ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Members <strong>of</strong> the examination commission:<br />

Chairman:<br />

Examination jury:<br />

Pr<strong>of</strong>. K. Strubbe<br />

(Universiteit Gent)<br />

Pr<strong>of</strong>. L. van Vaeck<br />

(Universiteit Antwerpen)<br />

Pr<strong>of</strong>. H. Nelis<br />

(Universiteit Gent)<br />

Dr. L. Ruys<br />

(Centexbel)<br />

Pr<strong>of</strong>. E. Schacht<br />

(Promotor, Universiteit Gent)<br />

Pr<strong>of</strong>. P. Dubruel<br />

(Promotor, Universiteit Gent)<br />

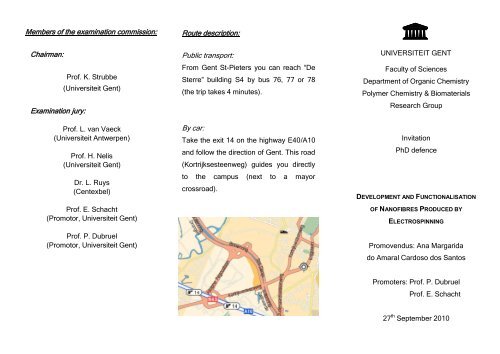

Route description:<br />

Public transport:<br />

From Gent St-Pieters you can reach “De<br />

Sterre” building S4 <strong>by</strong> bus 76, 77 or 78<br />

(the trip takes 4 minutes).<br />

By car:<br />

Take the exit 14 on the highway E40/A10<br />

<strong>and</strong> follow the direction <strong>of</strong> Gent. This road<br />

(Kortrijksesteenweg) guides you directly<br />

to the campus (next to a mayor<br />

crossroad).<br />

UNIVERSITEIT GENT<br />

Faculty <strong>of</strong> Sciences<br />

Department <strong>of</strong> Organic Chemistry<br />

Polymer Chemistry & Biomaterials<br />

Research Group<br />

Invitation<br />

PhD defence<br />

DEVELOPMENT AND FUNCTIONALISATION<br />

OF NANOFIBRES PRODUCED BY<br />

ELECTROSPINNING<br />

Promovendus: Ana Margarida<br />

do Amaral Cardoso dos Santos<br />

Promoters: Pr<strong>of</strong>. P. Dubruel<br />

Pr<strong>of</strong>. E. Schacht<br />

27 th September 2010

You are kindly invited<br />

to the public defence<br />

<strong>of</strong> the doctoral thesis<br />

Ana Margarida<br />

do Amaral Cardoso dos Santos<br />

DEVELOPMENT AND FUNCTIONALISATION<br />

OF NANOFIBRES PRODUCED BY<br />

ELECTROSPINNING<br />

<strong>and</strong> you are cordially invited<br />

to the reception<br />

Monday 27 th September 2010<br />

at 15.00<br />

“De Sterre” building S4<br />

Auditorium A<br />

Krijgslaan 281, 9000 Gent<br />

Samenvatting:<br />

Nan<strong>of</strong>ibres technology is an important field <strong>of</strong> the<br />

growing nanotechnology research. Nan<strong>of</strong>ibres provide<br />

ways to improve functionality <strong>of</strong> materials.<br />

Electrospinning is the most versatile process to fabricate<br />

ultra-thin fibres. This technique allows different<br />

materials like polymers, composites, ceramics <strong>and</strong> metals<br />

to be produced in various fibre assemblies. It is an<br />

attractive <strong>and</strong> versatile process to produce polymeric<br />

fibres <strong>of</strong> which the diameter ranges over several orders<br />

<strong>of</strong> magnitude. By controlling the process parameters<br />

fibrous structures with different diameters <strong>and</strong><br />

arrangements can be obtained to meet different<br />

applications. The simplicity <strong>of</strong> the process <strong>and</strong> the<br />

properties <strong>of</strong> electrospun fibres encourage the growing<br />

research on this field. Creative applications <strong>of</strong> this<br />

technology arise every day. A pr<strong>of</strong>ound knowledge <strong>of</strong> the<br />

process opens perspectives to practical applications <strong>of</strong><br />

nan<strong>of</strong>ibrous materials.<br />

In this work special attention was paid to up-scaling<br />

solutions <strong>of</strong> electrospinning technology. Challenges like a<br />

high production rate <strong>and</strong> commercial viability are<br />

objectives <strong>of</strong> the current research in this field.<br />

Manufacturing <strong>of</strong> electrospun structures is being studied<br />

through process modelling <strong>and</strong> engineering design to<br />

reach an adequate productivity <strong>and</strong> performance.<br />

Attention goes also to safety issues <strong>and</strong> environment<br />

friendly methodologies. Because <strong>of</strong> their dimensions<br />

traditional methodologies used for conventional non-<br />

woven materials may not be appropriate for<br />

electrospining <strong>and</strong> novel methods are constantly being<br />

developed. New technologies for characterization <strong>and</strong><br />

quality control <strong>of</strong> these materials constitute an important<br />

branch <strong>of</strong> the ongoing research in this field.<br />

This work demonstrates the versatility <strong>of</strong> electrospinning<br />

in processing highly porous materials composed <strong>of</strong> nano-<br />

scale to micron-scale diameter fibres. Different<br />

applications <strong>and</strong> strategies <strong>of</strong> functionalisation have<br />

been explored. It is expected that research in<br />

electrospinning will become even more multidisciplinary.<br />

As the use <strong>of</strong> this technique is extending to new<br />

materials <strong>and</strong> new applications, further development <strong>of</strong><br />

this technique requires extensive research <strong>and</strong> input<br />

from different fields. Researchers <strong>and</strong> investors<br />

anticipate that, in the future, electrospinning will<br />

become one <strong>of</strong> the most powerful tools for fabricating<br />

micro <strong>and</strong> nan<strong>of</strong>ibrous structures with the broadest<br />

range <strong>of</strong> functionalities <strong>and</strong> applications.