Bonded Particle Filter - Pyrotek

Bonded Particle Filter - Pyrotek

Bonded Particle Filter - Pyrotek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

METAULLICS SYSTEMS<br />

Metaullics Systems, headquartered in Solon, Ohio, USA is a<br />

division of <strong>Pyrotek</strong>, Inc., which is a privately owned company with<br />

headquarters in Spokane,Washington, USA.<br />

<strong>Pyrotek</strong> specialises in the development, manufacture and supply of<br />

high temperature materials, technologies and engineered systems<br />

for liquid metal management and associated metallurgical<br />

applications. Manufacturing units and sales offices are located in<br />

more than 60 worldwide locations and allow <strong>Pyrotek</strong> to offer<br />

outstanding customer service and supply logistics. Products<br />

include launder systems, distribution bowls, tundishes and<br />

specialised insulating shapes and filters.<br />

Metaullics is a global supplier of molten metal pumps, distribution<br />

systems, alloying systems and scrap and waste recovery systems,<br />

filtration systems for all sectors of the Aluminium industry.<br />

Metaullics Systems Europe, with headquarters in The Netherlands<br />

provides local application engineering, customer service and<br />

warehousing facilities for Europe and The Middle East.<br />

1. SUPERIOR FILTER MEDIA<br />

FROM METAULLICS<br />

It gives you the benefits of clean aluminium – reliably and<br />

economically.<br />

Molten aluminium normally contains various solid-phase<br />

inclusions, such as oxides, borides, carbides and spinels, and<br />

refractory particles from vessel erosion. If allowed to remain,<br />

these contaminants adversely affect the characteristics of the<br />

metal in its final, solidified form.<br />

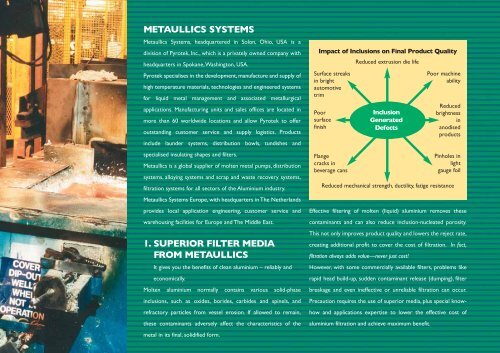

Impact of Inclusions on Final Product Quality<br />

Reduced extrusion die life<br />

Surface streaks<br />

in bright<br />

automotive<br />

trim<br />

Poor<br />

surface<br />

finish<br />

Flange<br />

cracks in<br />

beverage cans<br />

Inclusion<br />

Generated<br />

Defects<br />

Reduced mechanical strength, ductility, fatige resistance<br />

Effective filtering of molten (liquid) aluminium removes these<br />

contaminants and can also reduce inclusion-nucleated porosity.<br />

This not only improves product quality and lowers the reject rate,<br />

creating additional profit to cover the cost of filtration. In fact,<br />

filtration always adds value—never just cost!<br />

However, with some commercially available filters, problems like<br />

rapid head build-up, sudden contaminant release (dumping), filter<br />

breakage and even ineffective or unreliable filtration can occur.<br />

Precaution requires the use of superior media, plus special know-<br />

how and applications expertise to lower the effective cost of<br />

aluminium filtration and achieve maximum benefit.<br />

Poor machine<br />

ability<br />

Reduced<br />

brightness<br />

in<br />

anodised<br />

products<br />

Pinholes in<br />

light<br />

gauge foil