Bonded Particle Filter - Pyrotek

Bonded Particle Filter - Pyrotek

Bonded Particle Filter - Pyrotek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2.4 HIGH-EFFICIENCY FILTRATION<br />

Higher efficiency filtration is achieved with a lower-porosity, more tortuous path filter body - exactly what the Metaullics bonded<br />

particle filter provides. A tortuous flow path within the filter body permits the fluid stream to thoroughly remix, and each thorough<br />

re-mixing of the stream increases the amount of inclusions captured. This high filtration delivers aluminium clean enough for critical<br />

uses like aerospace, can stock, bright trim, thin foils, fine wire or intricate and highly machined castings.<br />

Deep-bed filters can be very efficient under best operating conditions and 95% average<br />

removal efficiency for all particles has been claimed. Data for ceramic foam filters show<br />

efficiencies greater than 80% for coarse particles (over 50), but only 30-60% for finer<br />

particles (25/50). Filtration efficiency for bonded particle filters compares very<br />

favourably in grade-for-grade comparison.<br />

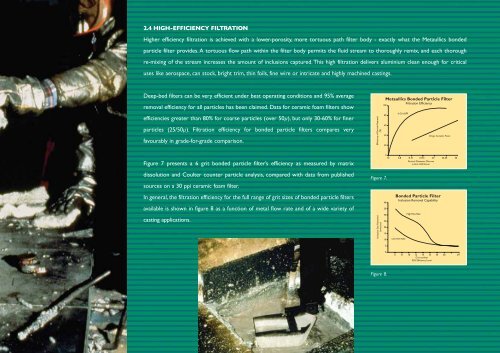

Figure 7 presents a 6 grit bonded particle filter’s efficiency as measured by matrix<br />

dissolution and Coulter counter particle analysis, compared with data from published<br />

sources on a 30 ppi ceramic foam filter.<br />

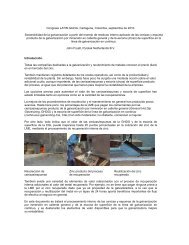

In general, the filtration efficiency for the full range of grit sizes of bonded particle filters<br />

available is shown in figure 8 as a function of metal flow rate and of a wide variety of<br />

casting applications.<br />

Figure 7.<br />

Figure 8.