English - ROLLVIS SWISS, Vis à rouleaux satellites

English - ROLLVIS SWISS, Vis à rouleaux satellites

English - ROLLVIS SWISS, Vis à rouleaux satellites

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

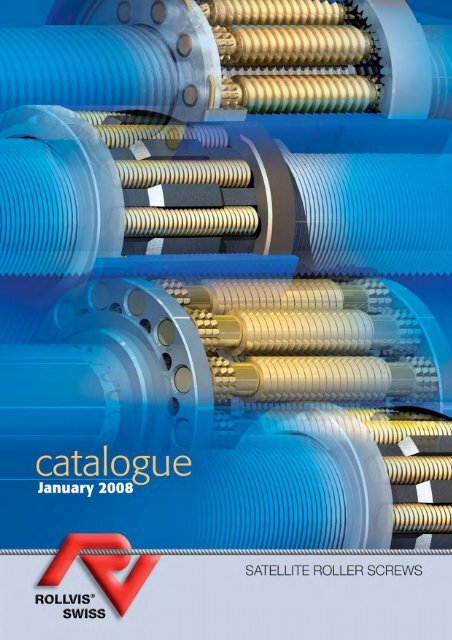

Who is <strong>ROLLVIS</strong> ?<br />

After its founding in 1970, <strong>ROLLVIS</strong> SA soon began to focus on the manufacture<br />

and marketing of satellite roller screws under the trademark « Rollvis swiss ».<br />

Now a benchmark in this highly specialised field, <strong>ROLLVIS</strong> SA has invested<br />

in the most powerful machines for the production of screws with low tolerance<br />

margins designed to individual specifications.<br />

A fast-growing company with a young and highly qualified workforce,<br />

<strong>ROLLVIS</strong> SA recently moved into new ultra-modern premises near to Geneva.<br />

It is structured to preserve its human scale and its capacity to listen and adapt<br />

perfectly to its customers’ requirements.<br />

Three decades and more of skills and experience combined with the latest<br />

high-end techniques ensure its products comply with the most stringent and<br />

demanding standards, notably in the following applications:<br />

aeronautics, space<br />

defence, car industry<br />

moulding, injection<br />

(plastics and metal)<br />

optical, graphics<br />

special machine tools<br />

medical<br />

electrical cylinders<br />

measuring machines<br />

and laser machines<br />

robotics, chemicals,<br />

and all other fields<br />

of high technology<br />

To ensure its satellite roller screws always gain by the latest progress in technology<br />

to make them ever more reliable, <strong>ROLLVIS</strong> SA has set up its own « Research<br />

and Development » department where its highly qualified engineers and<br />

technicians use the most recent and most powerful design software available<br />

in their unceasing quest for the control of avant-garde technologies.<br />

New processes are constantly reviewed to optimise the product, production<br />

system, quality control, tests and trials for individual requirements.<br />

Even the most exacting customers swear by the outstanding reliability and<br />

quality of <strong>ROLLVIS</strong> products.<br />

Present on all the continents, over time <strong>ROLLVIS</strong> SA has built up an excellent<br />

sales network, so that wherever you are in the world, there are experts to give<br />

you answers and advice.

contents<br />

Introduction - Satellite roller screws compared to ball screws 2<br />

- 1 -<br />

Types of roller screws 3 and 4<br />

Identification system 5<br />

Accuracy - Efficiency 6<br />

Geometry 7<br />

Preloading 8<br />

Preloading examples 9<br />

Mean speed and axial load 10<br />

Nominal lifespan 11<br />

Rigidity 12<br />

Rotation speed 13<br />

Driving torque 14 and 15<br />

Calculation example 16 and 17<br />

Lubrication 18 and 19<br />

Handling advice 20 and 21<br />

Preference program<br />

Type RV ........ diameters of 3.5 to 12 22<br />

Type RV ......... diameters of 15 to 23 23<br />

Type RV ......... diameters of 25 to 36 24<br />

Type RV ......... diameters of 39 to 48 25<br />

Type RV ......... diameters of 51 to 75 26<br />

Type RV ...... diameters of 80 to 150 27<br />

Type BRV ......... diameters of 8 to 44 28<br />

Type RVR ...... diameters of 8 to 125 29<br />

No liability can be accepted for any errors or omissions.<br />

We reserve the right to make changes in the interest of technical progress.<br />

Applications 30 to 32

Introduction<br />

<strong>ROLLVIS</strong> satellite roller screws are used to transform rotary movements<br />

into linear movements and vice versa. The bearing elements are threaded<br />

rollers between the screw and the nut. The high number of points of contact<br />

enables satellite roller screws to support very heavy loads.<br />

The <strong>ROLLVIS</strong> manufacturing programme comprises satellite roller screws<br />

without roller recycling (types RV and BRV) and with roller recycling (type RVR),<br />

in a range of accuracy classes.<br />

The <strong>ROLLVIS</strong> range also includes other types such as the reverse roller screw<br />

(type RVI) and the differential screw (type RVD).<br />

Satellite roller screws compared to ball screws<br />

The satellite roller screw is similar to the ball screw with the difference<br />

that the load transfer elements are threaded rollers.<br />

The main advantage of satellite roller screws is that they have a high<br />

number of points of contact to support the load.<br />

Load capacity and lifespan<br />

The main advantage of roller screws compared to ball screws is that their<br />

admissible static and dynamic load capacities are higher.<br />

The bearing function is ensured by threaded rollers instead of balls and<br />

the load is spread over a higher number of points of contact.<br />

- 2 -<br />

Satellite roller screws like ball screws<br />

use Hertz’s law.<br />

The admissible Hertz pressure is the same for satellite roller screws and<br />

ball screws. Satellite roller screws thus have a static load 3 times greater<br />

than that of ball screws and their lifespan is 15 times longer.<br />

Speed & acceleration<br />

Satellite roller screws can rotate much faster and support much greater<br />

acceleration.<br />

RV and BRV satellite roller screws are designed so that the rollers are not<br />

recycled. This means the mechanism can support twice the rotation speed<br />

of a ball screw. Acceleration can reach up to 3g.<br />

Lead & pitch<br />

Planetary roller screw can be achieved with smaller leads compared<br />

to ball screws.<br />

As the lead is a function of the pitch of the planetary roller screw, the lead<br />

can be very small (0.5mm and even less).<br />

Planetary roller screws can be achieved with entire or real numbers<br />

(i.e. lead of 3.32mm per revolution), which avoid reduction gears.<br />

This is an advantage compared to ball screws. The lead can be chosen and<br />

realised without any geometrical changes of both the screw shaft and the<br />

nut body, which allows updates with minor changes.<br />

In a ball screw the lead is limited by the dimension (OD) of the bearing<br />

ball, which is a standard feature.<br />

Rigidity & strength<br />

The many points of contact give a satellite roller screw greater rigidity and<br />

shock tolerance than a ball screw.

RV and BRV screws<br />

The main elements of RV and BRV satellite roller screws are the<br />

screw, the nut and satellite rollers.<br />

The screw has a multiple-start thread. The angle between the flanks is<br />

90° and the profile is triangular. The nut has an internal thread identical<br />

to that of the screw. The rollers have a single-start thread with an angle<br />

the same as that of the nut. This ensures there is no axial movement<br />

between the nut and the rollers. The rollers do not therefore need<br />

to be recycled.<br />

RV<br />

and<br />

BRV<br />

RVR screws<br />

RVR satellite roller screws have very fine threads and are used when<br />

very great positioning accuracy is required along with high rigidity and<br />

load-carrying capacity.<br />

The main elements of RVR satellite roller screws are the screw, the nut<br />

and the rollers which are guided and maintained at the correct distance<br />

in a cage.<br />

The screw has a single- or two-start thread with a triangular profile. The<br />

angle between the flanks is 90°. The nut has the same internal thread as<br />

the screw. The rollers are not threaded but have grooves perpendicular<br />

RVR<br />

Types of roller screws<br />

- 3 -<br />

The flanks of the roller thread are convex. At each end of the rollers there<br />

is a cylindrical pivot and gear teeth. The pivots are mounted in the holes<br />

of the end rings, thus ensuring the rollers are equidistant. The end rings<br />

are floated in the nut body and axially secured with circlips.<br />

The gear teeth engage in gear wheels fixed in the nut. This guides the<br />

rollers parallel to the axis to ensure perfect functioning.<br />

to the screw axis. The distance between the grooves matches the exposed<br />

thread of the screw and nut. The flanks are convex and the angle<br />

between them is 90°.<br />

When the screw or nut rotates, the rollers are axially displaced in the nut.<br />

After a complete revolution, each roller is returned to its initial position by<br />

two cams at the end of each nut. They can be recycled this way because<br />

there is a groove the length of the nut.<br />

The cage pockets are slightly longer than the rollers to enable them<br />

to move axially within the nut.

RVI<br />

RVI screws<br />

Types of roller screws (ctd.)<br />

RVI satellite roller screws work on the same principle as RV and BRV screws except that their<br />

nut system is reversed.<br />

This means the rollers themselves rotate around the screw (instead of the nut in RV and BRV<br />

screws) and move axially within the nut.<br />

Apart from the screw threading where the rollers orbit, the journal is smooth and can have a special<br />

shape (e.g.: antirotation).<br />

The nut is threaded along its entire length and is much longer than on RV and BRV screws.<br />

It governs the overall travel of the complete screw and therefore limits it if needed.<br />

RVD screws<br />

The RVD differential screw is actually a variant of the RV and BRV screws.<br />

Its components, expertly calculated and adjusted, are used to produce extremely fine threads<br />

(less than 0.02 mm).<br />

The movement of the rollers in this somewhat complex mechanism does however prevent<br />

a wide range of travel.<br />

The nuts are larger than on the RV and BRV types.<br />

- 4 -

Design RV = ground thread, non-recycling rollers<br />

BRV = rolled thread, non-recycling rollers<br />

RVR = ground thread, recycling rollers<br />

RVI = ground thread – reverse system<br />

RVD = ground thread – differential screw<br />

Nut types 1 = single nut<br />

2 = split nut<br />

3 = double nut<br />

Nut design 1 = cylindrical nut<br />

6 = nut with flange at one end<br />

7 = nut with central flange<br />

8 = special nut design<br />

Seal 0 = without wipers<br />

1 = with wipers<br />

Screw diameter d0 in mm<br />

Nominal lead P in mm<br />

Thread direction R = right<br />

B = right/left<br />

L = left<br />

Thread accuracy G1 = 6 µm/300 mm<br />

G3 = 12 µm/300 mm<br />

G5 = 23 µm/300 mm<br />

G9 = 200 µm/1000 mm (BRV only)<br />

6-digit number to identify customer’s specification<br />

Identification system<br />

- 5 -<br />

Example<br />

RV 210 / 30. 5. R3. 6-- ---

Satellite roller screws are divided into tolerance classes based on DIN<br />

69051, part 3 (ball screws). The determining factor is the lead error V300p<br />

referred to a thread length of 300 mm.<br />

The table opposite<br />

shows the tolerance<br />

classes:<br />

Tolerance Cl<br />

V300p<br />

G1<br />

6 µm/300 mm<br />

G3<br />

12 µm/300 mm<br />

G5<br />

23 µm/300 mm<br />

G9<br />

200 µm/1000 mm<br />

Positioning satellite roller screws are supplied in tolerance classes G1, G3<br />

and G5 and transport satellite roller screws (type BRV) in tolerance<br />

class G9.<br />

Lead error<br />

The lead error ep relative to effective travel Lu is calculated for the transport<br />

satellite roller screw by the following formula:<br />

ep = 2 . Lu . V300p<br />

1000<br />

Lead errors ep for positioning satellite roller screws are shown in the table<br />

opposite. For tolerance classes G1 and G3, the lead and torque diagrams<br />

are supplied with the screws.<br />

Lead is checked by a 3D measuring machine or on a measuring bench<br />

equipped with a laser interferometer.<br />

Efficiency in %<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

η 1<br />

η 2<br />

Machine tools<br />

Measuring machines<br />

Specific machines (benders)<br />

Robotics<br />

Aeronautics (aeroplanes and helicopters)<br />

Space (rockets and <strong>satellites</strong>)<br />

Satellite roller<br />

screw<br />

Trapezoidal<br />

thread screw<br />

1 2 3 4 5 6 7 8 9 10<br />

Helix angle ϕ in deg.<br />

Accuracy<br />

Efficiency<br />

Rollvis satellite roller screws achieve high rates of mechanical efficiency.<br />

The figure opposite shows efficiency rates η1 for the ascent and η2 for the descent,<br />

according to the helix angle. The efficiency of a trapezoidal thread screw is shown<br />

for comparison. Satellite roller screws, unlike friction screws, are not self-locking.<br />

Advantages<br />

High axial load capacity<br />

Long lifespan<br />

High efficiency<br />

No backlash<br />

Extremely high rigidity<br />

Defence (tanks, cannons, missiles, etc.)<br />

Oil industry<br />

Nuclear industry<br />

Medical<br />

Chemical industry<br />

Optical<br />

- 6 -<br />

Lead accuracy symbols according to DIN 69051/3<br />

P nominal lead<br />

e0 difference between required lead and nominal lead<br />

V300p difference between actual and nominal lead<br />

over 300 mm<br />

ep difference between actual and nominal lead<br />

over a length Lu<br />

Vup travel variation over a length Lu<br />

V2πp travel variation over one revolution<br />

effective travel<br />

Lu<br />

more than<br />

315 mm<br />

400 mm<br />

500 mm<br />

630 mm<br />

800 mm<br />

1000 mm<br />

1250 mm<br />

1600 mm<br />

2000 mm<br />

2500 mm<br />

Applications<br />

Rollvis satellite roller screws have proved their superior worth in many fields of applications such as:<br />

Lu<br />

315 mm<br />

400 mm<br />

500 mm<br />

630 mm<br />

800 mm<br />

1000 mm<br />

1250 mm<br />

1600 mm<br />

2000 mm<br />

2500 mm<br />

3150 mm<br />

Ep in microns<br />

for tolerance class up to<br />

G1 G3 G5<br />

6<br />

12<br />

23<br />

7<br />

13<br />

25<br />

8<br />

15<br />

27<br />

9<br />

16<br />

30<br />

10<br />

18<br />

35<br />

11<br />

21<br />

40<br />

13<br />

24<br />

46<br />

15<br />

29<br />

54<br />

65<br />

77<br />

93<br />

Accuracy greater than 6 µm/300 mm<br />

High rotation speed (RV and BRV systems)<br />

Small leads (from 0.25 mm)<br />

with wide diameters (system RVR)<br />

Fast acceleration and deceleration<br />

Telescopes<br />

Graphics<br />

Laser machines<br />

Injection moulding machines<br />

Car industry

Nut geometry and shape<br />

Standard satellite roller screws are available with 3 nut designs:<br />

• single nut (ES)<br />

• split nut (EF)<br />

• double nut (ED)<br />

Geometry<br />

Single nuts have low axial backlash of 0.01 to 0.03 mm. The split cylindrical nut is preloaded by clamping<br />

the two halves of the nut in a housing. A precision spacer ring is mounted between the two halves to maintain<br />

the required level of preloading. Split nuts with a flange at one end have a spacer ring designed to hold the<br />

halves apart. The halves are aligned by a parallel key. Double nuts are preloaded in the same way as split nuts.<br />

FLANGE SHAPES<br />

Shape A Shape B<br />

60° 60°<br />

- 7 -<br />

45° 30°<br />

SINGLE NUTS<br />

• Nuts in one piece<br />

with axial backlash<br />

• Wipers<br />

(if requested by the customer)<br />

SPLIT NUTS:<br />

• Nuts in two pieces, preloaded,<br />

without backlash<br />

• Same dimensions as single nuts<br />

• Reduced load capacities<br />

• Wipers<br />

(if requested by the customer)<br />

DOUBLE NUTS:<br />

• Two single nuts, preloaded,<br />

without backlash<br />

• Same load capacities as single nuts<br />

• About twice as long as single nuts<br />

• Wipers<br />

(if requested by the customer)

Preloaded nuts are used to eliminate backlash and increase rigidity.<br />

Preloading should be carefully calculated to achieve the highest rate of efficiency and the<br />

longest possible lifespan (see figure above).<br />

For preloaded nuts, in addition to the individual loads F1…Fn, preload Fv must also<br />

be taken into account to determine the mean load Fm. This yields new individual<br />

loads F1v…Fnv.<br />

If for example an absence of backlash is required for all operational loads, preload Fv must<br />

be selected according to the maximum load Fmax.<br />

Fv = Fmax [N]<br />

2.83<br />

If a satellite roller screw only needs to be backlash-free for a specific load, preload Fv<br />

should be selected according to the corresponding load Fn.<br />

Fv = Fn [N]<br />

2.83<br />

Unless the customer otherwise requests, split and double nuts are preloaded in the standard<br />

version to a maximum of 5% of the dynamic load capacity.<br />

F1…Fn [N] : individual loads<br />

Fv [N] : preloading force<br />

Preloading<br />

Fnv [N] : load resulting from the individual load and preloading<br />

Fma [N] : mean load taking into account preloading<br />

F1<br />

FV<br />

- 8 -<br />

F2<br />

Resulting load depending on preload Fv<br />

An axial load on a preloaded nut system increases<br />

the load of one of the halves and relieves the other from<br />

the preloading force. The resulting load can be estimated<br />

by the following equations:<br />

Loaded half of nut:<br />

Fnv(1) = Fv + 0.65 . Fn [N] if Fn < 2.83 . Fv [N]<br />

Fnv(1) = Fn [N] if Fn ≥ 2.83 . Fv [N]<br />

Relieved half of nut:<br />

Fnv(2) = Fv - 0.35 . Fn [N] if Fn < 2.83 . Fv [N]<br />

Fnv(2) = 0 [N] if Fn ≥ 2.83 . Fv [N]

Preloading examples<br />

Preloading with rigid spacer (thickness calibrated by Rollvis SA)<br />

Preloading with elastic washers<br />

Flange nut Cylindrical nut<br />

Elastic washers<br />

Flange nut Cylindrical nut<br />

- 9 -

For variable speed and load, lifespan should be calculated with mean<br />

values nm and Fm.<br />

For variable speed and constant load with speed n, the mean speed<br />

nm is used (figure below).<br />

nm = q1 .n1 + q2 .n2 + …[min -1 ]<br />

100 100<br />

Mean speed and axial load<br />

- 10 -<br />

For a variable load at constant speed, the mean load Fm is used<br />

(figure below).<br />

3<br />

Fm =<br />

3<br />

F1<br />

3<br />

. q1<br />

+ F2 . q2<br />

+ …[N]<br />

100 100<br />

For a variable load at variable speed, the mean load Fm is used.<br />

3<br />

Fm =<br />

3<br />

F1<br />

3<br />

. q1 n1<br />

. + F2 . q2 n2<br />

. + …[N]<br />

100 nm 100 nm<br />

For a variable linear load at constant speed, the mean load Fm is used<br />

(figure below).<br />

Fm = Fmin+ 2 . Fmax [N]<br />

3<br />

nm [min -1 ] : mean speed<br />

n1…nn [min -1 ] : individual speeds<br />

q1…qn [%] : time percentage<br />

Fm [N] : mean load<br />

F ; F1…Fn ; Fmin; Fmax [N] : actual forces

Nominal lifespan<br />

The nominal lifespan L10 or Lh of a satellite roller screw is attained with a probability of 90%.<br />

If greater reliability is required, the nominal lifespan L10 or Lh must be multiplied by the reliability factor fr<br />

(table opposite).<br />

Modified lifespan Ln = L10 . fr [revolutions]<br />

or Lhn = Lh . fr [h]<br />

Nominal lifespan of single nuts (with backlash)<br />

The nominal lifespan of single nuts is calculated by the following formula:<br />

or<br />

- 11 -<br />

L10 = ( C ) 3<br />

Lh =<br />

fm<br />

Reliability<br />

%<br />

90<br />

95<br />

96<br />

97<br />

98<br />

99<br />

L10 [h]<br />

nm . 60<br />

If the lifespan is predetermined, the dynamic load capacity is calculated as follows: C = Fm . L10 [N]<br />

106 3<br />

The lifespan in actual hours LhN is calculated by the following formula:<br />

The utilisation factor fN is calculated as follows:<br />

Nominal lifespan of preloaded nuts<br />

For preloaded nuts, it is first necessary to calculate the lifespan of each half of the nut<br />

with the corresponding dynamic load capacity C and the mean axial load Fma<br />

(including preload). The total lifespan L10 of the preloaded nut is obtained with<br />

the two lifespan values L10(1) and L10(2) (in revolutions).<br />

Ln [revolutions] : modified lifespan (revolutions)<br />

Lhn [h] : modified lifespan (hours)<br />

L10 [revolutions] : nominal lifespan (revolutions)<br />

Lh [h] : nominal lifespan (hours)<br />

LhN [h] : lifetime in actual hours<br />

fr [-] : reliability factor<br />

LhN =<br />

FN =<br />

Lh [h]<br />

fN<br />

fr<br />

1<br />

0.62<br />

0.53<br />

0.44<br />

0.33<br />

0.21<br />

.10 6 [revolutions]<br />

Lifespan of satellite roller screws<br />

Expected lifespan of the machine<br />

L10(1) = ( C ) 3<br />

Fma(1)<br />

L10(2) = ( C ) 3<br />

Fma(2)<br />

C [N] : dynamic load capacity<br />

Fm [N] : mean load (single nut with backlash)<br />

Fma [N] : mean load (preloaded nut)<br />

nm [min -1 ] : mean speed<br />

fN [-] : utilisation factor<br />

.10 6 [revolutions]<br />

.10 6 [revolutions]<br />

L10 = ( L10(1) -10/9 + L10(2) -10/9)<br />

-9/10<br />

[revolutions]

Satellite roller screw rigidity<br />

Rigidity<br />

Case 1 : fkn = 0.25 Case 3 : fkn = 2.0<br />

Case 2 : fkn = 1.0 Case 4 : fkn = 4.0<br />

The overall rigidity Cges of a satellite roller screw is made up of the<br />

following individual rigidity values:<br />

Cme nut rigidity<br />

CL bearing rigidity<br />

CSp screw rigidity<br />

Cu rigidity of the surrounding<br />

construction<br />

Nut rigidity Cme<br />

The rigidity Cme of a complete satellite roller screw nut can be approximated<br />

with the following formula:<br />

Cme = fm . fK . Fn 1/3 [N/µm]<br />

fm for single nut ES = 0.75<br />

fm for split nut EF = 1<br />

fm for double nut ED = 1.5<br />

The following condition is set for Fn for the Cme values shown in the<br />

table for standard preloading:<br />

Fn = 2.83 . FV [N]<br />

Fv [N] : preloading force<br />

Fn [N] : axial load<br />

Cme [N/µm] : nut rigidity<br />

Cs [N/µm] : screw rigidity<br />

[N2/3 /µm] : rigidity factor<br />

fk<br />

- 12 -<br />

Nut rigidity CS<br />

Nut rigidity CS can be determined by the following simplified formula:<br />

CS = 164 .<br />

d0 2<br />

L<br />

[N/µm]<br />

Permissible buckling force Fknzul<br />

at rotation speed n = 0<br />

Permissible buckling force can be calculated by the following formula:<br />

Fknzul = 0.8 . 101.6 . fkn .<br />

4<br />

d0<br />

L2 [kN]<br />

fm [-] : correction factor<br />

L [mm] : free screw length<br />

d0 [mm] : nominal diameter of screw<br />

Fknzul [N] : permissible buckling force<br />

fkn [-] : correction factor for bearing type

Permissible rotation speed<br />

and axial load<br />

Satellite roller screws are restricted by the internal<br />

configuration of the nut, the bearings at the<br />

end of the screw and the critical number of revolutions<br />

nkr due to flexural vibration.<br />

The value of the permissible speed applied<br />

can be:<br />

RV : d0 . n ≤ 140'000<br />

RVR : d0 . n ≤ 32'000<br />

Rotation speed<br />

Case 1 : fkr = 0,32 Case 3 : fkr = 1,55<br />

Case 2 : fkr = 1,0 Case 4 : fkr = 2,24<br />

n [min-1 ] : rotation speed<br />

nkr [min-1 ] : critical rotation speed<br />

nkrzul [min-1 ] : permissible critical rotation speed<br />

L [mm] : free screw length<br />

L<br />

L<br />

Critical speed nkr with axial load Fn = 0<br />

Critical speed is influenced by the axial load. It can be calculated on request for every satellite<br />

roller screw configuration.<br />

When the correct screw end bearings are chosen, their maximum speed will have no effect on the<br />

desired speed. All that needs to be determined is the critical speed nkr for flexural vibration.<br />

The critical speed nkr for flexural vibration can be calculated by the formula below. The correction<br />

factor fkr depends on the type of bearing and the clamping conditions (figure above).<br />

The calculation is based on the assumption that satellite roller screw nuts provide no guidance<br />

and the bearings at the screw end are considered rigid in the radial direction.<br />

nkr = 108 . 10 6 . d0 . 1<br />

L 2<br />

The permissible critical speed can be calculated by taking the bearing type into account:<br />

nkrzul = 0.8 . nkr . fkr [min-1 ]<br />

d0 [mm] : nominal diameter of screw<br />

fkr [-] : correction factor for bearing type<br />

0,8 [-] : safety factor<br />

- 13 -<br />

[min -1 ]<br />

L<br />

L

Driving torque<br />

All the values for motor rating can be calculated by the formulas below.<br />

Note that the load-free torque Mv must be taken into account for preloaded nuts (based on preloading Fv).<br />

For single nuts with backlash, the formula is: Mv = 0 [Nm]<br />

Motor driving torque MM at constant speed<br />

Load-free torque<br />

« Ascent » load torque ML1 =<br />

- 14 -<br />

Mv = Fv . P . i . c<br />

2000 . π<br />

P . i . F<br />

2000 . π . η1<br />

« Descent » load torque ML2 = P . i . F . η 2<br />

The frictional forces of the guide slideway<br />

must be taken into account in feed force F.<br />

Screw lead P<br />

2000 . π<br />

Motor driving torque MM = (MV + ML1,2 + MR . i) [Nm]<br />

If, as is possible in « Descent » mode, the motor driving torque is negative,<br />

the motor must have a brake.<br />

Motor driving power PM = MM . nM<br />

9.55<br />

d [mm] : external diameter of screw<br />

d2 [mm] : core diameter of screw<br />

P [mm] : screw lead<br />

L [mm] : length of satellite roller screw<br />

mT [kg] : mass to move<br />

D1 [mm] : diameter of driving wheel<br />

D2 [mm] : diameter of driven wheel<br />

i [-] : reduction ratio<br />

F [N] : feed force<br />

Fv [N] : preloading force<br />

J2<br />

Driving torque<br />

JM<br />

nM<br />

J1<br />

i = D1<br />

D2<br />

MM<br />

[Nm]<br />

[Nm]<br />

[Nm]<br />

[W]<br />

Fa [N] : acceleration force<br />

Mv [Nm] : load-free torque<br />

ML1 [Nm] : « ascent » load torque at constant speed<br />

ML2 [Nm] : « descent » load torque at constant speed<br />

MM [Nm] : motor driving torque<br />

MLa [Nm] : load torque on acceleration<br />

MB [Nm] : acceleration torque<br />

MMa [Nm] : motor driving torque on acceleration<br />

MR [Nm] : frictional torque of screw bearings<br />

[kgm2 ] : moment of inertia of motor<br />

JM<br />

v<br />

F

Motor driving torque MMa with acceleration<br />

The rotary moment of inertia of screw JR is a rough estimate.<br />

We shall be happy to calculate the exact value on request.<br />

Load torque MLa =<br />

Motor speed nM =<br />

Rotation speed reached after acceleration nM =<br />

JR [kgm2 ] : rotary moment of inertia of screw<br />

JT [kgm2 ] : translatory moment of inertia of screw<br />

J [kgm2 ] : moment of inertia<br />

J1 [kgm2 ] : moment of inertia of driving wheel<br />

J2 [kgm2 ] : moment of inertia of driven wheel<br />

PM [W] : driving power of motor at constant speed<br />

PMa [W] : driving power of motor on acceleration<br />

sB [mm] : acceleration path<br />

tB [s] : acceleration time<br />

v [m/s] : speed rate<br />

- 15 -<br />

P . i . (F + F2)<br />

2000 . π . η1<br />

Translatory moment of inertia JT = mT .( P 2 . π)<br />

Rotary moment of inertia (screw) JR = 4.8 . (d1 + d2) 4 . L . 10 -14 [kgm 2 ] (for steel)<br />

Sum of reduced moments of inertia J = JM + J1 + i 2 (JR + JT + J2) [kgm 2 ]<br />

v . 6 . 104<br />

P . i<br />

Acceleration torque MB = f (nM) MB = nM . J<br />

9.55 . tB . η<br />

Acceleration torque MB = f (sB) MB = 4 . π . sB . J<br />

P . i . tB 2 . η<br />

Acceleration time tB = f (nM) tB =<br />

Acceleration time tB = f (sB) tB =<br />

nM . J<br />

9.55 . MB . η<br />

4 . π . sB . J<br />

P . i . MB . η<br />

120 . sB<br />

P . i . tB<br />

Path travelled during acceleration sB = nM . tB . P . i<br />

120<br />

Motor driving torque MMa = (Mv + MLa + MR . i + MB) [Nm]<br />

Motor driving power PMa = Mma . nM<br />

9.55<br />

2<br />

[Nm]<br />

. 10 6 [kgm 2 ]<br />

[Min -1 ]<br />

[Nm]<br />

[Nm]<br />

[Min -1 ]<br />

[mm]<br />

[W]<br />

nM [min-1 ] : rotation speed of motor<br />

η [-] : mechanical efficiency of gearing<br />

η1 [-] : mechanical efficiency of satellite roller screw<br />

for « ascent » η1 = 0,71…0,89<br />

η2 [-] : mechanical efficiency of satellite roller screw<br />

for « descent » η2 = 0,61…0,85<br />

c [-] : coefficient of friction referred to preloading<br />

c = 0,1…0,5<br />

(for efficiencies η1 + η1 see page 6)<br />

[s]<br />

[s]

Satellite roller screws RV 20 x 5<br />

Nominal diameter : d0 = 20 mm<br />

Lead : P = 5 mm<br />

Nut : split nut (EF), preloaded<br />

Mounting position : horizontal<br />

Load direction : both sides<br />

Rapid mode : one side, opposite to working load<br />

Calculation example<br />

- 16 -<br />

N°<br />

1<br />

2<br />

3<br />

4<br />

Operating mode<br />

Peak load<br />

Roughing feed<br />

Finishing feed<br />

Rapid<br />

Time percentage<br />

q [%]<br />

q1 = 5<br />

q2 = 40<br />

q3 = 50<br />

q4 = 5<br />

Rotation speed<br />

n [min -1]<br />

n1 = 15<br />

n2 = 110<br />

n3 = 70<br />

n4 = 1700<br />

Axial load<br />

F n [N]<br />

F1 = 8300<br />

F2 = 4500<br />

F3 = 4200<br />

F4 = 1150<br />

Mean speed nm = 5 . 15 + 40 . 110 + 50 . 70 + 5 . 1700 = 165 min -1<br />

100 100 100 100<br />

Preloading<br />

Preloading is defined for the « finishing feed »<br />

operating mode (F3 = 4200 N).<br />

Load on nut half 1<br />

Nut half 1 is loaded in operating modes 1, 2 and 3.<br />

As F1, F2 eand F3 ≥ 2,83 Fv:<br />

Nut half 1 is only partly loaded in operating mode 4.<br />

As F4 = 1150 N < 2,83 FV:<br />

Load on nut half 2<br />

Half nut 2 is loaded in operating mode 4.<br />

Half nut 2 is not loaded in operating modes 1, 2 and 3.<br />

As F4 < 2,83 . Fv:<br />

Mean load<br />

Nut 1<br />

Nut 2<br />

Lifespan<br />

Dynamic load capacity of a nut C = 23 400 N<br />

Half nut 1<br />

Half nut 2<br />

3<br />

Fv = 4200 = 1484 N<br />

2.83<br />

Fnv = Fn hence F1V = 8300 N<br />

F2V = 4500 N<br />

F3V = 4200 N<br />

F4v = 1484 - 0,35 . 1150 = 1082 N<br />

F1v = F2v = F3v = 0<br />

F4v = 1484 + 0.65 . 1150 = 2232 N<br />

Fma(1) = 8300 3 . 15 . 5 + 4500 3 . 110 . 40 + 4200 3 . 70 . 50 + 1082 3 . 1700 . 5 = 3511 N<br />

165 100 165 100 165 100 165 100<br />

3<br />

Fma(2) = 2232 3 . 1700 . 5 = 1789 N<br />

165 100<br />

L10(1) = ( 23400 ) 3<br />

3511<br />

L10(2) = ( 23400 ) 3<br />

1789<br />

.10 6 = 296 . 10 6 revolutions<br />

.10 6 = 2237 . 10 6 revolutions

Total lifespan<br />

Lifespan in hours (with utilisation factor fN = 0,6)<br />

Nut rigidity Cme = 1 . 42.5 . 4200 1/3 = 686 N/µm<br />

Satellite roller screw rigidity<br />

Free length between fixed bearing and nut 1 = 1000 mm<br />

Nominal diameter of screw d1 = 20 mm<br />

Bearing rigidity C1 = 850 N/µm (assumed value)<br />

Driving torque<br />

Driving torque MM is calculated for the peak load of F1 = 8300 N.<br />

The screw is directly driven by the motor (i = 1).<br />

Load-free torque:<br />

Load torque:<br />

Frictional torque of bearings:<br />

Peak driving torque of motor at constant speed:<br />

Motor driving power reaches its peak in rapid mode with F4 = 1150 N.<br />

Load torque:<br />

Peak driving power of motor at constant speed:<br />

- 17 -<br />

L10 = [(296 . 10 6 ) -10/9 + (2237 . 10 6 ) -10/9 )] -9/10<br />

L10 = 270 . 10 6 revolutions<br />

LhN =<br />

270 . 106<br />

= 45 450 h<br />

165 . 0.6 . 60<br />

CS = 164 . 202<br />

1000<br />

Total rigidity of satellite roller screw system 1<br />

=<br />

1<br />

+<br />

1<br />

+<br />

1<br />

Cges 686 66 850<br />

Mv = 1484 . 5 . 1 . 0.43 = 0.5 Nm<br />

2000 . π<br />

ML1 = 5 . 1 . 8300 = 7.6 Nm<br />

2000 . π . 0.87<br />

MR = 0.2 Nm (assumed)<br />

= 66 N/µm<br />

MMmax = 0.5 + 7.6 + 0.2 = 8.3 Nm<br />

ML4 = 5 . 1 . 1150 = 1,05 Nm<br />

2000 . π . 0.87<br />

Cges = 56 N/µm<br />

PMmax = (1.05 + 0,5 + 0.2) . 1700 = 312 W<br />

9.55

Oil lubrication<br />

Circulating mineral oils with EP additives to enhance resistance to aging<br />

and corrosion in compliance with CL based on DIN 51517, part 2, are<br />

especially suitable for the lubrication of satellite roller screws. Speed,<br />

ambient temperature and operating temperature are determining factors<br />

in the choice of viscosity.<br />

The amount of oil required depends on the screw diameter, the number<br />

of supporting rollers and the amount of heat to dissipate. 1 cm 3 /h<br />

(for small screw diameters) to 30 cm 3 /h (for large screw diameters) can<br />

be used as reference values.<br />

The shortest possible lubrication intervals (…5 minutes) are recommended<br />

for high loads and longer intervals (5 minutes to 1 hr) for low loads.<br />

Automatic lubrication is recommended for high loads and speeds.<br />

For immersion lubrication, the oil level should be such that the bottommost<br />

roller is completely submerged in the oil. The amount of oil and the<br />

oil-change intervals depend on the loading and installation.<br />

The viscosity of the oil should be chosen to enable an adequate film of<br />

lubricant to form on the contact surfaces.<br />

Figure a shows the operating viscosity νκ to achieve for the mean speed<br />

of the satellite roller screw and screw diameter.<br />

<strong>Vis</strong>cosity νκ ensures a state of lubrication to fulfil the nominal lifespan<br />

provided the lubrication system is free of foreign bodies.<br />

Nominal viscosity can be calculated on the basis of viscosity νκ with the<br />

viscosity-temperature diagram (diagram ν-t, figure b) and the operating<br />

temperature. Nominal viscosity is the viscosity of oil at 40°C. <strong>Vis</strong>cosity<br />

classes ISO VG (DIN 51519) are plotted in diagram ν-t.<br />

Lubrication<br />

As a general rule, the same lubricants are used for satellite roller screws as for roller bearings, i.e. either oil or grease. The type of lubricant used mostly<br />

depends on operating and maintenance conditions. Unless the customer explicitly instructs otherwise, standard Rollvis grease is applied at the factory.<br />

Grease lubrication<br />

- 18 -<br />

Figure a shows the nominal diameters of RV satellite roller screws. The<br />

diameters of RVR satellite roller screws are slightly different. The requisite<br />

operating viscosity values can be obtained by interpolation.<br />

Intermediate values can be obtained from the steps. These must be rounded<br />

up to the nearest viscosity value.<br />

The operating temperature must be known or estimated to calculate<br />

nominal viscosity. The operating temperature must be measured on the<br />

nut after stabilisation. A suitable oil can be found in oil suppliers’ lists with<br />

the nominal viscosity at 40°C. In general, an operating temperature of<br />

30°C can be taken as a basis for selecting a lubricant.<br />

Example: Satellite roller screw RV 39 x 10<br />

Mean operating speed: nm = 1400 min -1<br />

Operating temperature (estimated): t = 25 °C<br />

In figure a, for a number of revolutions nm = 1400 min -1 and a<br />

nominal diameter of 39mm, the nominal viscosity is νκ= 33 mm 2 /s.<br />

In diagram ν-t (figure b), the 25°C temperature and 34 mm 2 /s viscosity<br />

lines intersect between ISO VG 15 and ISO VG 22. The oil to choose will<br />

be in viscosity class VG 22.<br />

A suitable CLP (DIN 51517) or HLP (DIN 51525) oil can be selected<br />

from this class.<br />

The best grease lubricants to use are KP (DIN 51825, part 3) with a consistency factor of 2.<br />

Lubrication intervals depend on the screw arrangement, size and operating conditions. Rollvis can provide recommendations for any type of application.

mm2 [ s ]<br />

ν κ operating viscosity<br />

Operating temperature t [°C]<br />

200<br />

150<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

15<br />

8000<br />

10000<br />

6000<br />

1000<br />

1400<br />

2000<br />

3000<br />

4000<br />

5000<br />

900<br />

800 700<br />

400<br />

500<br />

600<br />

Mean screw rotation speed nm [min -1 ]<br />

10<br />

10 12 15 20 23 27 30 36 39 48 60 80 100 120<br />

120<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

15<br />

22<br />

32<br />

46<br />

Nominal diameter d0 [mm]<br />

460<br />

320<br />

1500<br />

1000<br />

680<br />

10<br />

4 6 8 10 20 30 40 60 100 200 300<br />

mm2 νκ operating viscosity [ s ]<br />

100<br />

68<br />

150<br />

220<br />

- 19 -<br />

300<br />

150<br />

200<br />

Figure b<br />

Figure a

Assembly<br />

If possible, the nut and screw should not be dismantled. However,<br />

should this be necessary, an assembly sleeve must be used.<br />

External diameter d3 of assembly sleeve:<br />

0<br />

- 0,05<br />

d3 = d2<br />

(d2 = screw core diameter)<br />

Handling<br />

CAUTION<br />

RV screws always have a multiple-start thread. If the friction torque is different<br />

after the nut is reassembled, the nut must be taken off again and<br />

refitted on the next thread start until friction torque is correct!<br />

- 20 -<br />

Screw assembly<br />

The following points must be followed when assembling the screw:<br />

1 • Align the screw and slide guideways axially parallel.<br />

2 • Fix the nut in housing.<br />

3 • Run the nut along the entire length of the thread and check the screw<br />

for ease of movement.<br />

Please read the following handling instructions carefully.<br />

To ensure optimal operation and a long lifespan for satellite roller screws, the following points must be scrupulously complied with.<br />

If in doubt, please contact Rollvis.<br />

Lubrication<br />

Transport<br />

Installation<br />

Storage<br />

Bending<br />

Satellite roller screws are greased prior to shipment (unless oil lubrication is requested).<br />

Do not remove this grease. Only use this type of grease for relubrication.<br />

Handle screws with care: do not drop them or damage the thread.<br />

Do not unscrew the nut (or only with an assembly sleeve).<br />

Carefully align satellite roller screws parallel to the guideways.<br />

Alignment errors will damage satellite roller screws.<br />

Only remove satellite roller screws from their original packing just before installation.<br />

Avoid applying radial forces to the nut.<br />

Handling advice

Preference<br />

program<br />

- 21 -<br />

Type RV ........ diameters of 3.5 to 12 22<br />

Type RV ......... diameters of 15 to 23 23<br />

Type RV ......... diameters of 25 to 36 24<br />

Type RV ......... diameters of 39 to 48 25<br />

Type RV ......... diameters of 51 to 75 26<br />

Type RV ...... diameters of 80 to 150 27<br />

Type BRV ......... diameters of 8 to 44 28<br />

Type RVR ...... diameters of 8 to 125 29

Type D X P N d0 d1 d2<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

3.5 x 1<br />

5 x 1<br />

5 x 2<br />

5 x 3<br />

7 x 1<br />

7 x 2<br />

7 x 3<br />

7 x 4<br />

7 x 5<br />

8 x 1<br />

8 x 2<br />

8 x 3<br />

8 x 4<br />

8 x 5<br />

8 x 6<br />

10 x 1<br />

10 x 2<br />

10 x 3<br />

10 x 4<br />

10 x 5<br />

12 x 1<br />

12 x 2<br />

12 x 3<br />

12 x 4<br />

12 x 5<br />

12 x 8<br />

3<br />

3<br />

3<br />

3<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

5<br />

5<br />

5<br />

5<br />

4<br />

5<br />

5<br />

5<br />

5<br />

5<br />

[mm]<br />

3.5<br />

4.5<br />

4.5<br />

4.5<br />

7<br />

7<br />

7<br />

7<br />

7<br />

8<br />

8<br />

8<br />

8<br />

8<br />

8<br />

10.5<br />

10.5<br />

10.5<br />

10.5<br />

10.5<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

[mm]<br />

3.62<br />

4.62<br />

4.71<br />

4.78<br />

7.09<br />

7.16<br />

7.23<br />

7.28<br />

7.33<br />

8.09<br />

8.17<br />

8.24<br />

8.30<br />

8.35<br />

8.38<br />

10.59<br />

10.64<br />

10.70<br />

10.75<br />

10.79<br />

12.09<br />

12.14<br />

12.22<br />

12.25<br />

12.32<br />

12.42<br />

[mm]<br />

Efficiency<br />

Single nut,<br />

[kN]<br />

[kN]<br />

with backlash<br />

and double nut<br />

C Co<br />

[kN]<br />

Split nut,<br />

preloaded,<br />

without<br />

backlash<br />

[kN]<br />

C Co F K<br />

Maximum backlash of single nuts: 0.03mm (can be less on request).<br />

If possible, provide a lubrication hole in the nut (contact Rollvis for feasibility and position).<br />

Terms used in tables<br />

3.35<br />

4.35<br />

4.17<br />

3.97<br />

6.89<br />

6.76<br />

6.62<br />

6.47<br />

6.32<br />

7.89<br />

7.76<br />

7.63<br />

7.49<br />

7.33<br />

7.34<br />

10.38<br />

10.31<br />

10.21<br />

10.10<br />

9.98<br />

11.89<br />

11.81<br />

11.74<br />

11.65<br />

11.56<br />

11.13<br />

0.86<br />

0.85<br />

0.88<br />

0.88<br />

0.84<br />

0.88<br />

0.89<br />

0.89<br />

0.90<br />

0.83<br />

0.87<br />

0.89<br />

0.89<br />

0.89<br />

0.90<br />

0.80<br />

0.86<br />

0.88<br />

0.89<br />

0.89<br />

0.79<br />

0.85<br />

0.87<br />

0.89<br />

0.89<br />

0.90<br />

Type RV - Ground screws<br />

8.3<br />

10.3<br />

7.2<br />

5.3<br />

11.7<br />

9.3<br />

7.6<br />

6.6<br />

5.4<br />

11.5<br />

9.2<br />

7.5<br />

6.7<br />

5.8<br />

5.0<br />

18.7<br />

13.1<br />

11.3<br />

10.5<br />

9.6<br />

19.0<br />

12.8<br />

11.2<br />

10.0<br />

10.5<br />

8.3<br />

6.5<br />

7.8<br />

7.8<br />

7.5<br />

10.9<br />

11.4<br />

11.1<br />

11.0<br />

10.0<br />

10.7<br />

11.4<br />

11.0<br />

11.1<br />

10.7<br />

10.2<br />

17.6<br />

18.1<br />

17.9<br />

18.2<br />

17.9<br />

17.2<br />

18.0<br />

18.1<br />

17.8<br />

18.1<br />

15.7<br />

P ---------- Lead<br />

D --------- Reference diameter<br />

N --------- Number of starts<br />

d0 ------- Nominal diameter<br />

[N 2/3 /µm]<br />

F K<br />

32.6<br />

33.0<br />

23.0<br />

18.8<br />

46.3<br />

32.3<br />

26.2<br />

22.9<br />

19.6<br />

43.8<br />

30.4<br />

24.1<br />

21.4<br />

18.9<br />

17.1<br />

55.3<br />

46.4<br />

36.9<br />

32.6<br />

29.1<br />

51.6<br />

43.5<br />

34.9<br />

29.9<br />

27.3<br />

20.4<br />

5.2<br />

6.5<br />

4.5<br />

3.4<br />

7.4<br />

5.9<br />

4.8<br />

4.2<br />

3.4<br />

7.2<br />

5.8<br />

4.7<br />

4.2<br />

3.7<br />

3.2<br />

11.8<br />

8.3<br />

7.1<br />

6.6<br />

6.0<br />

12.0<br />

8.1<br />

7.1<br />

6.3<br />

6.6<br />

5.2<br />

- 22 -<br />

3.2<br />

3.9<br />

3.9<br />

3.7<br />

5.5<br />

5.7<br />

5.6<br />

5.5<br />

5.0<br />

5.4<br />

5.7<br />

5.5<br />

5.6<br />

5.3<br />

5.1<br />

8.8<br />

9.1<br />

9.0<br />

9.1<br />

9.0<br />

8.6<br />

9.0<br />

9.1<br />

8.9<br />

9.1<br />

7.8<br />

[N 2/3 /µm]<br />

20.5<br />

20.8<br />

14.5<br />

11.8<br />

29.2<br />

20.3<br />

16.5<br />

14.4<br />

12.4<br />

27.6<br />

19.1<br />

15.2<br />

13.5<br />

11.9<br />

10.8<br />

34.8<br />

29.2<br />

23.3<br />

20.5<br />

18.3<br />

32.5<br />

27.4<br />

22.0<br />

18.8<br />

17.2<br />

12.8<br />

Split nuts,<br />

preloaded,<br />

preloading<br />

torque<br />

[N]<br />

[Ncm]<br />

Fv Mv<br />

410<br />

520<br />

300<br />

210<br />

480<br />

300<br />

210<br />

170<br />

140<br />

570<br />

360<br />

260<br />

210<br />

170<br />

140<br />

600<br />

410<br />

300<br />

240<br />

200<br />

760<br />

520<br />

390<br />

310<br />

260<br />

170<br />

d1 ------- External diameter<br />

d2 ------- Thread bottom diameter<br />

C --------- Dynamic load capacity<br />

Co ------- Static load capacity<br />

3.0<br />

4.0<br />

4.0<br />

4.0<br />

4.0<br />

4.0<br />

4.0<br />

4.0<br />

4.0<br />

5.0<br />

5.0<br />

5.0<br />

5.0<br />

5.0<br />

5.0<br />

6.0<br />

6.0<br />

6.0<br />

6.0<br />

6.0<br />

8.0<br />

8.0<br />

8.0<br />

8.0<br />

8.0<br />

8.0<br />

[mm]<br />

D1<br />

15<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

21<br />

21<br />

21<br />

21<br />

21<br />

21<br />

26<br />

24<br />

24<br />

24<br />

24<br />

30<br />

26<br />

26<br />

26<br />

26<br />

26<br />

[mm]<br />

[mm] Without<br />

wipers<br />

With<br />

wipers<br />

[mm]<br />

[mm]<br />

[mm]<br />

[mm]<br />

D2 L1 L1 L2 L3 L4<br />

35<br />

39<br />

39<br />

39<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

48<br />

46<br />

46<br />

46<br />

46<br />

50<br />

46<br />

46<br />

46<br />

46<br />

46<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

41<br />

Fk -------- Rigidity factor<br />

Fv -------- Preloading force<br />

16.0<br />

20.3<br />

20.3<br />

20.3<br />

20.3<br />

20.3<br />

20.3<br />

20.3<br />

20.3<br />

22.3<br />

22.3<br />

22.3<br />

22.3<br />

22.3<br />

22.3<br />

27.3<br />

25.3<br />

25.3<br />

25.3<br />

25.3<br />

31.3<br />

27.3<br />

27.3<br />

27.3<br />

27.3<br />

27.3<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

2<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

Mv ------ Load-free torque due to preloading

Type D X P N d0 d1 d2<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

15 x 2<br />

15 x 3<br />

15 x 4<br />

15 x 5<br />

15 x 6<br />

15 x 8<br />

20 x 2<br />

20 x 3<br />

20 x 4<br />

20 x 5<br />

20 x 6<br />

20 x 8<br />

20 x 10<br />

21 x 2<br />

21 x 3<br />

21 x 4<br />

21 x 5<br />

21 x 6<br />

21 x 8<br />

21 x 10<br />

23 x 2<br />

23 x 3<br />

23 x 4<br />

23 x 5<br />

23 x 6<br />

23 x 8<br />

23 x 10<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

[mm]<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

19.5<br />

19.5<br />

19.5<br />

19.5<br />

19.5<br />

19.5<br />

19.5<br />

21<br />

21<br />

21<br />

21<br />

21<br />

21<br />

21<br />

22.5<br />

22.5<br />

22.5<br />

22.5<br />

22.5<br />

22.5<br />

22.5<br />

[mm]<br />

15.14<br />

15.22<br />

15.25<br />

15.32<br />

15.37<br />

15.46<br />

19.65<br />

19.71<br />

19.80<br />

19.83<br />

19.94<br />

19.98<br />

20.04<br />

21.14<br />

21.21<br />

21.28<br />

21.33<br />

21.39<br />

21.49<br />

21.58<br />

22.65<br />

22.72<br />

22.79<br />

22.87<br />

22.89<br />

23.00<br />

23.12<br />

[mm]<br />

14.81<br />

14.74<br />

14.65<br />

14.56<br />

14.47<br />

14.16<br />

19.32<br />

19.22<br />

19.15<br />

19.02<br />

18.97<br />

18.69<br />

18.62<br />

20.82<br />

20.72<br />

20.62<br />

20.52<br />

20.42<br />

20.19<br />

19.96<br />

22.32<br />

22.24<br />

22.15<br />

22.06<br />

21.97<br />

21.71<br />

21.62<br />

Efficiency<br />

0.84<br />

0.86<br />

0.88<br />

0.89<br />

0.89<br />

0.90<br />

0.82<br />

0.85<br />

0.87<br />

0.88<br />

0.88<br />

0.89<br />

0.90<br />

0.81<br />

0.84<br />

0.86<br />

0.87<br />

0.88<br />

0.89<br />

0.89<br />

0.80<br />

0.84<br />

0.86<br />

0.87<br />

0.88<br />

0.89<br />

0.89<br />

Type RV - Ground screws<br />

Single nut,<br />

[kN]<br />

[kN]<br />

with backlash<br />

and double nut<br />

C Co<br />

19.3<br />

17.4<br />

15.9<br />

15.0<br />

15.2<br />

13.9<br />

47.8<br />

43.7<br />

40.2<br />

37.1<br />

38.4<br />

38.2<br />

42.9<br />

51.1<br />

46.9<br />

43.2<br />

39.9<br />

41.5<br />

41.4<br />

46.7<br />

54.4<br />

50.0<br />

46.2<br />

42.7<br />

44.4<br />

44.6<br />

50.3<br />

26.3<br />

27.3<br />

27.6<br />

27.8<br />

27.3<br />

25.3<br />

59.7<br />

63.3<br />

64.3<br />

64.0<br />

64.0<br />

64.0<br />

61.9<br />

63.5<br />

67.7<br />

68.9<br />

68.8<br />

69.0<br />

69.3<br />

67.2<br />

67.2<br />

71.9<br />

73.5<br />

73.5<br />

73.9<br />

74.5<br />

72.4<br />

[N 2/3 /µm]<br />

F K<br />

51.1<br />

41.5<br />

35.7<br />

32.2<br />

29.2<br />

24.4<br />

80.3<br />

64.9<br />

55.7<br />

49.1<br />

44.8<br />

39.2<br />

34.7<br />

81.5<br />

65.7<br />

56.5<br />

49.8<br />

45.3<br />

39.7<br />

35.1<br />

82.7<br />

66.5<br />

57.2<br />

50.4<br />

45.9<br />

40.2<br />

35.6<br />

[kN]<br />

Split nut,<br />

preloaded,<br />

without<br />

backlash<br />

[kN]<br />

C Co F K<br />

12.2<br />

10.9<br />

10.0<br />

9.4<br />

9.6<br />

8.7<br />

30.1<br />

27.6<br />

25.3<br />

23.4<br />

24.2<br />

24.1<br />

27.0<br />

32.2<br />

29.6<br />

27.2<br />

25.2<br />

26.1<br />

26.1<br />

29.4<br />

34.3<br />

31.5<br />

29.1<br />

26.9<br />

28.0<br />

28.1<br />

31.7<br />

- 23 -<br />

13.2<br />

13.6<br />

13.8<br />

13.9<br />

13.6<br />

12.6<br />

29.8<br />

31.7<br />

32.2<br />

32.0<br />

32.0<br />

32.0<br />

30.9<br />

31.8<br />

33.8<br />

34.5<br />

34.4<br />

34.5<br />

34.6<br />

33.6<br />

33.6<br />

36.0<br />

36.8<br />

36.8<br />

36.9<br />

37.2<br />

36.2<br />

[N 2/3 /µm]<br />

32.2<br />

26.1<br />

22.5<br />

20.3<br />

18.4<br />

15.4<br />

50.6<br />

40.9<br />

35.1<br />

31.0<br />

28.2<br />

24.7<br />

21.9<br />

51.4<br />

41.4<br />

35.6<br />

31.4<br />

28.6<br />

25.0<br />

22.1<br />

52.1<br />

41.9<br />

36.1<br />

31.8<br />

28.9<br />

25.3<br />

22.4<br />

Split nuts,<br />

preloaded,<br />

preloading<br />

torque<br />

[N]<br />

[Ncm]<br />

Fv Mv<br />

600<br />

460<br />

370<br />

310<br />

270<br />

210<br />

1070<br />

840<br />

700<br />

590<br />

520<br />

410<br />

340<br />

1290<br />

1030<br />

850<br />

730<br />

630<br />

500<br />

420<br />

1490<br />

1200<br />

1000<br />

860<br />

750<br />

600<br />

500<br />

Maximum backlash of single nuts: 0.03mm (can be reduced on request).<br />

If possible, provide a lubrication hole in the nut (contact Rollvis for feasibility and position).<br />

Terms used in tables<br />

P ---------- Lead<br />

D --------- Reference diameter<br />

N --------- Number of starts<br />

d0 ------- Nominal diameter<br />

d1 ------- External diameter<br />

d2 ------- Thread bottom diameter<br />

C --------- Dynamic load capacity<br />

Co ------- Static load capacity<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

[mm]<br />

D1<br />

34<br />

34<br />

34<br />

34<br />

34<br />

34<br />

42<br />

42<br />

42<br />

42<br />

42<br />

42<br />

42<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

45<br />

[mm]<br />

[mm] Without<br />

wipers<br />

With<br />

wipers<br />

[mm]<br />

[mm]<br />

[mm]<br />

[mm]<br />

D2 L1 L1 L2 L3 L4<br />

56<br />

56<br />

56<br />

56<br />

56<br />

56<br />

64<br />

64<br />

64<br />

64<br />

64<br />

64<br />

64<br />

68<br />

68<br />

68<br />

68<br />

68<br />

68<br />

68<br />

67<br />

67<br />

67<br />

67<br />

67<br />

67<br />

67<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

55<br />

55<br />

55<br />

55<br />

55<br />

55<br />

55<br />

54<br />

54<br />

54<br />

54<br />

54<br />

54<br />

54<br />

55<br />

55<br />

55<br />

55<br />

55<br />

55<br />

55<br />

51<br />

51<br />

51<br />

51<br />

51<br />

51<br />

65<br />

65<br />

65<br />

65<br />

65<br />

65<br />

65<br />

64<br />

64<br />

64<br />

64<br />

64<br />

64<br />

64<br />

65<br />

65<br />

65<br />

65<br />

65<br />

65<br />

65<br />

Fk -------- Rigidity factor<br />

Fv -------- Preloading force<br />

35.7<br />

35.7<br />

35.7<br />

35.7<br />

35.7<br />

35.7<br />

43.7<br />

43.7<br />

43.7<br />

43.7<br />

43.7<br />

43.7<br />

43.7<br />

47<br />

47<br />

47<br />

47<br />

47<br />

47<br />

47<br />

46.7<br />

46.7<br />

46.7<br />

46.7<br />

46.7<br />

46.7<br />

46.7<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

Mv ------ Load-free torque due to preloading

Type D X P N d0 d1 d2<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

RV<br />

25 x 2<br />

25 x 4<br />

25 x 5<br />

25 x 6<br />

25 x 8<br />

25 x 10<br />

27 x 2<br />

27 x 4<br />

27 x 5<br />

27 x 6<br />

27 x 8<br />

27 x 10<br />

30 x 2<br />

30 x 4<br />

30 x 5<br />

30 x 6<br />

30 x 8<br />

30 x 10<br />

30 x 15<br />

30 x 20<br />

30 x 30<br />

36 x 2<br />

36 x 4<br />

36 x 5<br />

36 x 6<br />

36 x 8<br />

36 x 10<br />

36 x 15<br />

36 x 20<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

[mm]<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

27<br />

27<br />

27<br />

27<br />

27<br />

27<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

36<br />

36<br />

36<br />

36<br />

36<br />

36<br />

36<br />

36<br />

[mm]<br />

24.14<br />

24.28<br />

24.34<br />

24.40<br />

24.51<br />

24.60<br />

27.14<br />

27.29<br />

27.37<br />

27.40<br />

27.51<br />

27.62<br />

30.15<br />

30.29<br />

30.37<br />

30.40<br />

30.52<br />

30.63<br />

30.87<br />

31.05<br />

31.27<br />

36.15<br />

36.28<br />

36.37<br />

36.41<br />

36.54<br />

36.65<br />

36.80<br />

37.12<br />

[mm]<br />

Efficiency<br />

Single nut,<br />

[kN]<br />

[kN]<br />

with backlash<br />

and double nut<br />

C Co<br />

[kN]<br />

Split nut,<br />

preloaded,<br />

without<br />

backlash<br />

[kN]<br />

C Co F K<br />

Maximum backlash of single nuts: 0.03mm (can be less on request).<br />

If possible, provide a lubrication hole in the nut (contact Rollvis for feasibility and position).<br />

Terms used in tables<br />

23.82<br />

23.63<br />

23.53<br />

23.42<br />

23.21<br />

22.98<br />

26.82<br />

26.65<br />

26.56<br />

26.43<br />

26.22<br />

26.00<br />

29.82<br />

29.65<br />

29.56<br />

29.43<br />

29.22<br />

29.01<br />

28.44<br />

27.81<br />

26.41<br />

35.83<br />

35.63<br />

35.56<br />

35.44<br />

35.24<br />

35.12<br />

34.48<br />

33.88<br />

0.80<br />

0.85<br />

0.87<br />

0.87<br />

0.89<br />

0.89<br />

0.78<br />

0.85<br />

0.86<br />

0.87<br />

0.88<br />

0.89<br />

0.77<br />

0.84<br />

0.85<br />

0.86<br />

0.88<br />

0.89<br />

0.90<br />

0.90<br />

0.90<br />

0.75<br />

0.82<br />

0.84<br />

0.85<br />

0.87<br />

0.88<br />

0.89<br />

0.90<br />

Type RV - Ground screws<br />

78.0<br />

66.5<br />

62.5<br />

64.4<br />

75.3<br />

84.1<br />

87.8<br />

74.5<br />

70.3<br />

72.6<br />

85.3<br />

95.7<br />

112.4<br />

96.9<br />

90.7<br />

85.5<br />

80.0<br />

88.1<br />

91.6<br />

106.7<br />

49.1<br />

107.2<br />

91.9<br />

88.9<br />

83.3<br />

76.9<br />

70.9<br />

94.8<br />

105.1<br />

93.2<br />

102.6<br />

104.2<br />

103.9<br />

104.8<br />

103.6<br />

103.5<br />

114.2<br />

116.4<br />

116.4<br />

118.2<br />

117.4<br />

129.1<br />

145.4<br />

147.5<br />

148.2<br />

152.3<br />

150.6<br />

143.2<br />

153.8<br />

85.5<br />

124.1<br />

140.9<br />

147.4<br />

147.8<br />

150.5<br />

149.8<br />

151.4<br />

155.8<br />

P ---------- Lead<br />

D --------- Reference diameter<br />

N --------- Number of starts<br />

d0 ------- Nominal diameter<br />

[N 2/3 /µm]<br />

F K<br />

100.5<br />

69.5<br />

61.9<br />

55.9<br />

48.7<br />

43.6<br />

103.4<br />

71.0<br />

63.3<br />

57.1<br />

49.6<br />

44.5<br />

116.2<br />

79.8<br />

70.9<br />

64.1<br />

55.8<br />

49.6<br />

39.9<br />

35.2<br />

20.9<br />

107.1<br />

73.1<br />

65.5<br />

59.1<br />

50.8<br />

45.0<br />

37.4<br />

31.6<br />

49.1<br />

41.9<br />

39.4<br />

40.6<br />

47.5<br />

53.0<br />

55.3<br />

46.9<br />

44.3<br />

45.7<br />

53.8<br />

60.3<br />

70.8<br />

61.0<br />

57.2<br />

53.9<br />

50.4<br />

55.5<br />

57.7<br />

67.2<br />

31.0<br />

67.5<br />

57.9<br />

56.0<br />

52.5<br />

48.5<br />

44.7<br />

59.7<br />

66.2<br />

- 24 -<br />

46.6<br />

51.3<br />

52.1<br />

51.9<br />

52.4<br />

51.8<br />

51.7<br />

57.1<br />

58.2<br />

58.2<br />

59.1<br />

58.7<br />

64.5<br />

72.7<br />

73.8<br />

74.1<br />

76.2<br />

75.3<br />

71.6<br />

76.9<br />

42.8<br />

62.1<br />

70.5<br />

73.7<br />

73.9<br />

75.3<br />

74.9<br />

75.7<br />

77.9<br />

[N 2/3 /µm]<br />

63.3<br />

43.8<br />

39.0<br />

35.2<br />

30.7<br />

27.5<br />

65.2<br />

44.7<br />

39.9<br />

36.0<br />

31.2<br />

28.0<br />

73.2<br />

50.3<br />

44.6<br />

40.4<br />

35.2<br />

31.3<br />

25.1<br />

22.2<br />

13.2<br />

67.4<br />

46.1<br />

41.2<br />

37.2<br />

32.0<br />

28.3<br />

23.6<br />

19.9<br />

Split nuts,<br />

preloaded,<br />

preloading<br />

torque<br />

[N]<br />

[Ncm]<br />

Fv Mv<br />

1690<br />

1140<br />

980<br />

860<br />

690<br />

570<br />

1810<br />

1250<br />

1080<br />

950<br />

770<br />

640<br />

2130<br />

1500<br />

1300<br />

1150<br />

940<br />

790<br />

560<br />

440<br />

295<br />

2490<br />

1800<br />

1580<br />

1410<br />

1160<br />

980<br />

710<br />

560<br />

d1 ------- External diameter<br />

d2 ------- Thread bottom diameter<br />

C --------- Dynamic load capacity<br />

Co ------- Static load capacity<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

40<br />

40<br />

40<br />

40<br />

40<br />

40<br />

50<br />

50<br />

50<br />

50<br />

50<br />

50<br />

50<br />

50<br />

50<br />

65<br />

65<br />

65<br />

65<br />

65<br />

65<br />

65<br />

65<br />

[mm]<br />

D1<br />

53<br />

53<br />

53<br />

53<br />

53<br />

53<br />

53<br />

53<br />

53<br />

53<br />

53<br />

53<br />

62<br />

62<br />

62<br />

62<br />

62<br />

62<br />

62<br />

62<br />

62<br />

74<br />

74<br />

74<br />

74<br />

74<br />

74<br />

74<br />

74<br />

[mm]<br />

[mm] Without<br />

wipers<br />

With<br />

wipers<br />

[mm]<br />

[mm]<br />

[mm]<br />

[mm]<br />

D2 L1 L1 L2 L3 L4<br />

84<br />

84<br />

84<br />

84<br />

84<br />

84<br />

83<br />

83<br />

83<br />

83<br />

83<br />

83<br />

92<br />

92<br />

92<br />

92<br />

92<br />

92<br />

92<br />

92<br />

58<br />

110<br />

110<br />

110<br />

110<br />

110<br />

110<br />

110<br />

110<br />

64<br />

64<br />

64<br />

64<br />

64<br />

64<br />

65<br />

65<br />

65<br />

65<br />

65<br />

65<br />

71<br />

71<br />

71<br />

71<br />

71<br />

71<br />

71<br />

71<br />

71<br />

70<br />

70<br />

70<br />

70<br />

70<br />

70<br />

70<br />

70<br />

78<br />

78<br />

78<br />

78<br />

78<br />

78<br />

79<br />

79<br />

79<br />

79<br />

79<br />

79<br />

85<br />

85<br />

85<br />

85<br />

85<br />

85<br />

85<br />

85<br />

85<br />

84<br />

84<br />

84<br />

84<br />

84<br />

84<br />

84<br />

84<br />

Fk -------- Rigidity factor<br />

Fv -------- Preloading force<br />

55.5<br />

55.5<br />

55.5<br />

55.5<br />

55.5<br />

55.5<br />

55.2<br />

55.2<br />

55.2<br />

55.2<br />

55.2<br />

55.2<br />

64.7<br />

64.7<br />

64.7<br />

64.7<br />

64.7<br />

64.7<br />

64.7<br />

64.7<br />

64.7<br />

76.7<br />

76.7<br />

76.7<br />

76.7<br />

76.7<br />

76.7<br />

76.7<br />

76.7<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

28<br />

28<br />

28<br />

28<br />

28<br />

28<br />

28<br />

28<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

6<br />

6<br />

6<br />

6<br />

6<br />