18 - Microglue

18 - Microglue

18 - Microglue

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The most critical factor ¡n controlling the<br />

paper stock being folded, ¡s the design and<br />

condition of the fold rolls.<br />

Worn rollers, or rollers manufactured from the<br />

wrong material or the wrong specifications,<br />

may prevent you from getting a good,<br />

consistent fold. Trying to control today's slick<br />

stock with worn rollers is like trying to drive<br />

your car on snow with bald tires. You will not<br />

have the grip to maintain positive control.<br />

Years ago, we could run almost anything<br />

using steel fold rolls. We learned that with the<br />

changes in paper and printing processes,<br />

steel rolls just didn't have enough grip for<br />

certain jobs.<br />

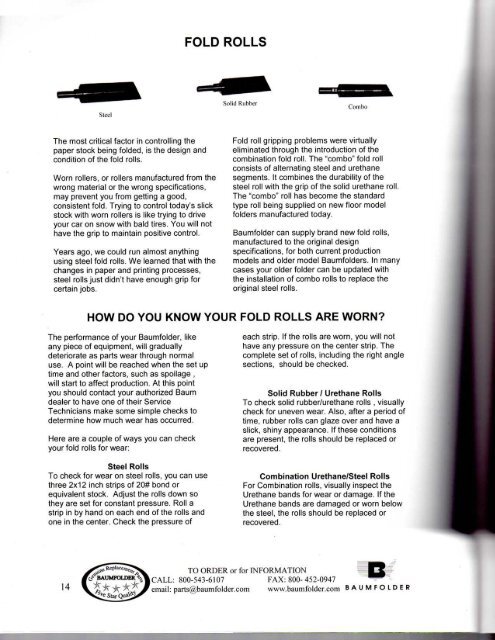

FOLD ROLLS<br />

Fold roll gripping problems were virtually<br />

eliminated through the introduction of the<br />

combination fold roll. The "combo" fold roll<br />

consists of alternating steel and urethane<br />

segments. It combines the durability of the<br />

steel roll with the grip of the solid urethane roll.<br />

The "combo" roll has become the standard<br />

type roll being supplied on new floor model<br />

folders manufactured today.<br />

Baumfolder can supply brand new fold rolls,<br />

manufactured to the original design<br />

specifications, for both current production<br />

models and older model Baumfolders. In many<br />

cases your older folder can be updated with<br />

the installation of combo rolls to replace the<br />

original steel rolls.<br />

HOW DO YOU KNOW YOUR FOLD ROLLS ARE WORN?<br />

The performance of your Baumfolder, like<br />

any piece of equipment, will gradually<br />

deteriórate as parts wear through normal<br />

use. A point will be reached when the set up<br />

time and other factors, such as spoilage ,<br />

will start to affect production. At this point<br />

you should contact your authorized Baum<br />

dealer to have one of their Service<br />

Technicians make some simple checks to<br />

determine how much wear has occurred.<br />

Here are a couple of ways you can check<br />

your fold rolls for wear:<br />

Steel Rolls<br />

To check for wear on steel rolls, you can use<br />

three 2x12 inch strips of 20# bond or<br />

equivalent stock. Adjust the rolls down so<br />

they are set for constant pressure. Roll a<br />

strip in by hand on each end of the rolls and<br />

one in the center. Check the pressure of<br />

14<br />

each strip. If the rolls are worn, you will not<br />

have any pressure on the center strip. The<br />

complete set of rolls, including the right angle<br />

sections, should be checked.<br />

Solid Rubber / Urethane Rolls<br />

To check solid rubber/urethane rolls , visually<br />

check for uneven wear. Also, after a period of<br />

time, rubber rolls can glaze over and have a<br />

slick, shiny appearance. If these conditions<br />

are present, the rolls should be replaced or<br />

recovered.<br />

Combination Urethane/Steel Rolls<br />

For Combination rolls, visually inspect the<br />

Urethane bands for wear or damage. If the<br />

Urethane bands are damaged or worn below<br />

the steel, the rolls should be replaced or<br />

recovered.<br />

TO ORDER or for INFORMATION<br />

CALL: 800-543-6107 FAX: 800-452-0947<br />

email: parts@baumfolder.com www.baumfolder.com BAUMFOLDER