INT 9 - PaintInfo

INT 9 - PaintInfo

INT 9 - PaintInfo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

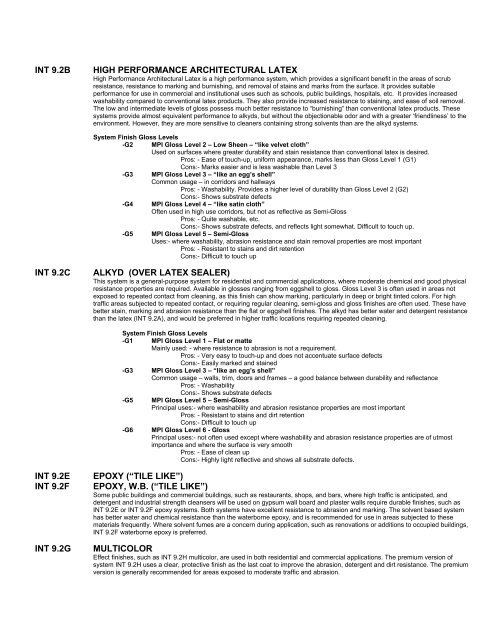

<strong>INT</strong> 9.2B HIGH PERFORMANCE ARCHITECTURAL LATEX<br />

High Performance Architectural Latex is a high performance system, which provides a significant benefit in the areas of scrub<br />

resistance, resistance to marking and burnishing, and removal of stains and marks from the surface. It provides suitable<br />

performance for use in commercial and institutional uses such as schools, public buildings, hospitals, etc. It provides increased<br />

washability compared to conventional latex products. They also provide increased resistance to staining, and ease of soil removal.<br />

The low and intermediate levels of gloss possess much better resistance to “burnishing” than conventional latex products. These<br />

systems provide almost equivalent performance to alkyds, but without the objectionable odor and with a greater ‘friendliness’ to the<br />

environment. However, they are more sensitive to cleaners containing strong solvents than are the alkyd systems.<br />

System Finish Gloss Levels<br />

-G2 MPI Gloss Level 2 – Low Sheen – “like velvet cloth”<br />

Used on surfaces where greater durability and stain resistance than conventional latex is desired.<br />

Pros: - Ease of touch-up, uniform appearance, marks less than Gloss Level 1 (G1)<br />

Cons:- Marks easier and is less washable than Level 3<br />

-G3 MPI Gloss Level 3 – “like an egg’s shell”<br />

Common usage – in corridors and hallways<br />

Pros: - Washability. Provides a higher level of durability than Gloss Level 2 (G2)<br />

Cons:- Shows substrate defects<br />

-G4 MPI Gloss Level 4 – “like satin cloth”<br />

Often used in high use corridors, but not as reflective as Semi-Gloss<br />

Pros: - Quite washable, etc.<br />

Cons:- Shows substrate defects, and reflects light somewhat. Difficult to touch up.<br />

-G5 MPI Gloss Level 5 – Semi-Gloss<br />

Uses:- where washability, abrasion resistance and stain removal properties are most important<br />

Pros: - Resistant to stains and dirt retention<br />

Cons:- Difficult to touch up<br />

<strong>INT</strong> 9.2C ALKYD (OVER LATEX SEALER)<br />

This system is a general-purpose system for residential and commercial applications, where moderate chemical and good physical<br />

resistance properties are required. Available in glosses ranging from eggshell to gloss. Gloss Level 3 is often used in areas not<br />

exposed to repeated contact from cleaning, as this finish can show marking, particularly in deep or bright tinted colors. For high<br />

traffic areas subjected to repeated contact, or requiring regular cleaning, semi-gloss and gloss finishes are often used. These have<br />

better stain, marking and abrasion resistance than the flat or eggshell finishes. The alkyd has better water and detergent resistance<br />

than the latex (<strong>INT</strong> 9.2A), and would be preferred in higher traffic locations requiring repeated cleaning.<br />

System Finish Gloss Levels<br />

-G1 MPI Gloss Level 1 – Flat or matte<br />

Mainly used: - where resistance to abrasion is not a requirement.<br />

Pros: - Very easy to touch-up and does not accentuate surface defects<br />

Cons:- Easily marked and stained<br />

-G3 MPI Gloss Level 3 – “like an egg’s shell”<br />

Common usage – walls, trim, doors and frames – a good balance between durability and reflectance<br />

Pros: - Washability<br />

Cons:- Shows substrate defects<br />

-G5 MPI Gloss Level 5 – Semi-Gloss<br />

Principal uses:- where washability and abrasion resistance properties are most important<br />

Pros: - Resistant to stains and dirt retention<br />

Cons:- Difficult to touch up<br />

-G6 MPI Gloss Level 6 - Gloss<br />

Principal uses:- not often used except where washability and abrasion resistance properties are of utmost<br />

importance and where the surface is very smooth<br />

Pros: - Ease of clean up<br />

Cons:- Highly light reflective and shows all substrate defects.<br />

<strong>INT</strong> 9.2E EPOXY (“TILE LIKE”)<br />

<strong>INT</strong> 9.2F EPOXY, W.B. (“TILE LIKE”)<br />

Some public buildings and commercial buildings, such as restaurants, shops, and bars, where high traffic is anticipated, and<br />

detergent and industrial strength cleansers will be used on gypsum wall board and plaster walls require durable finishes, such as<br />

<strong>INT</strong> 9.2E or <strong>INT</strong> 9.2F epoxy systems. Both systems have excellent resistance to abrasion and marking. The solvent based system<br />

has better water and chemical resistance than the waterborne epoxy, and is recommended for use in areas subjected to these<br />

materials frequently. Where solvent fumes are a concern during application, such as renovations or additions to occupied buildings,<br />

<strong>INT</strong> 9.2F waterborne epoxy is preferred.<br />

<strong>INT</strong> 9.2G MULTICOLOR<br />

Effect finishes, such as <strong>INT</strong> 9.2H multicolor, are used in both residential and commercial applications. The premium version of<br />

system <strong>INT</strong> 9.2H uses a clear, protective finish as the last coat to improve the abrasion, detergent and dirt resistance. The premium<br />

version is generally recommended for areas exposed to moderate traffic and abrasion.