44.7.13 AOAC Of fi cial Method 979.23 - AOAC International

44.7.13 AOAC Of fi cial Method 979.23 - AOAC International

44.7.13 AOAC Of fi cial Method 979.23 - AOAC International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

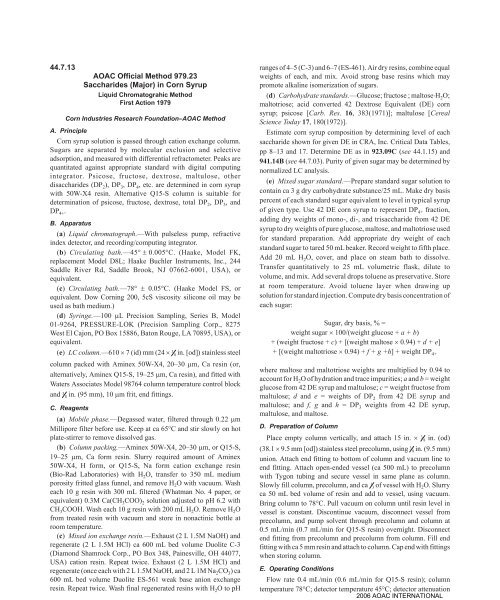

<strong>44.7.13</strong><br />

<strong>AOAC</strong> <strong>Of</strong> <strong>fi</strong> <strong>cial</strong> <strong>Method</strong> <strong>979.23</strong><br />

Sac cha rides (Ma jor) in Corn Syrup<br />

Liq uid Chromatograhic <strong>Method</strong><br />

First Ac tion 1979<br />

Corn In dus tries Re search Foundation–<strong>AOAC</strong> <strong>Method</strong><br />

A. Prin ci ple<br />

Corn syrup so lu tion is passed through cat ion ex change col umn.<br />

Sugars are sep a rated by mo lec u lar ex clu sion and se lec tive<br />

ad sorp tion, and measured with dif fer en tial refractometer. Peaks are<br />

quantitated against ap pro pri ate stan dard with dig i tal com put ing<br />

in te gra tor. Psicose, fruc tose, dex trose, maltulose, other<br />

disaccharides (DP 2), DP 3, DP 4, etc. are de ter mined in corn syrup<br />

with 50W-X4 resin. Al ter na tive Q15-S col umn is suit able for<br />

de ter mi na tion of psicose, fruc tose, dex trose, to tal DP 2, DP 3, and<br />

DP 4+.<br />

B. Ap pa ra tus<br />

(a) Liq uid chromatograph.—With pulseless pump, re frac tive<br />

in dex de tec tor, and re cord ing/com put ing in te gra tor.<br />

(b) Cir cu lating bath.—45 0.005C. (Haake, Model FK,<br />

re place ment Model D8L; Haake Buchler In stru ments, Inc., 244<br />

Sad dle River Rd, Sad dle Brook, NJ 07662-6001, USA), or<br />

equiv a lent.<br />

(c) Cir cu lating bath.—78 0.05C. (Haake Model FS, or<br />

equiv a lent. Dow Corning 200, 5cS vis cos ity sil i cone oil may be<br />

used as bath me dium.)<br />

(d) Sy ringe.—100 L Pre ci sion Sam pling, Se ries B, Model<br />

01-9264, PRES SURE-LOK (Pre ci sion Sam pling Corp., 8275<br />

West El Cajon, PO Box 15886, Ba ton Rouge, LA 70895, USA), or<br />

equiv a lent.<br />

(e) LC col umn.—610 7 (id) mm (24 3 8in. [od]) stain less steel<br />

col umn packed with Aminex 50W-X4, 20–30 m, Ca resin (or,<br />

al ter na tively, Aminex Q15-S, 19–25 m, Ca resin), and <strong>fi</strong>t ted with<br />

Wa ters As so ci ates Model 98764 col umn tem per a ture con trol block<br />

and 3 8 in. (95 mm), 10 m frit, end <strong>fi</strong>t tings.<br />

C. Re agents<br />

(a) Mo bile phase.—De gassed water, <strong>fi</strong>l tered through 0.22 m<br />

Millipore <strong>fi</strong>l ter be fore use. Keep at ca 65C and stir slowly on hot<br />

plate-stirrer to re move dis solved gas.<br />

(b) Col umn pack ing.—Aminex 50W-X4, 20–30 m, or Q15-S,<br />

19–25 m, Ca form resin. Slurry re quired amount of Aminex<br />

50W-X4, H form, or Q15-S, Na form cat ion ex change resin<br />

(Bio-Rad Lab o ra tories) with H 2O, trans fer to 350 mL me dium<br />

po ros ity fritted glass fun nel, and re move H 2O with vac uum. Wash<br />

each 10 g resin with 300 mL <strong>fi</strong>l tered (Whatman No. 4 pa per, or<br />

equiv a lent) 0.3M Ca(CH 3COO) 2 so lu tion ad justed to pH 6.2 with<br />

CH 3COOH. Wash each 10 g resin with 200 mL H 2O. Re move H 2O<br />

from treated resin with vac uum and store in nonactinic bot tle at<br />

room tem per a ture.<br />

(c) Mixed ion ex change resin.—Ex haust (2 L 1.5M NaOH) and<br />

re gen er ate (2 L 1.5M HCl) ca 600 mL bed vol ume Duolite C-3<br />

(Di a mond Sham rock Corp., PO Box 348, Painesville, OH 44077,<br />

USA) cat ion resin. Re peat twice. Ex haust (2 L 1.5M HCl) and<br />

re gen er ate (once each with 2 L 1.5M NaOH, and 2 L 1M Na 2CO 3) ca<br />

600 mL bed vol ume Duolite ES-561 weak base an ion ex change<br />

resin. Re peat twice. Wash <strong>fi</strong> nal re gen er ated res ins with H 2O to pH<br />

ranges of 4–5 (C-3) and 6–7 (ES-461). Air dry res ins, com bine equal<br />

weights of each, and mix. Avoid strong base res ins which may<br />

pro mote al ka line isomerization of sugars.<br />

(d) Car bo hy drate stan dards.—Glu cose; fruc tose ; malt oseH 2O;<br />

maltotriose; acid con verted 42 Dex trose Equiv a lent (DE) corn<br />

syrup; psicose [Carb. Res. 16, 383(1971)]; maltulose [Ce real<br />

Sci ence To day 17, 180(1972)].<br />

Es ti mate corn syrup com po si tion by de ter min ing level of each<br />

saccharide shown for given DE in CRA, Inc. Crit i cal Data Ta bles,<br />

pp 8–13 and 17. De ter mine DE as in 923.09C (see 44.1.15) and<br />

941.14B (see 44.7.03). Pu rity of given sugar may be de ter mined by<br />

nor mal ized LC anal y sis.<br />

(e) Mixed sugar stan dard.—Pre pare stan dard sugar so lu tion to<br />

con tain ca 3 g dry car bo hy drate sub stance/25 mL. Make dry ba sis<br />

per cent of each stan dard sugar equiv a lent to level in typ i cal syrup<br />

of given type. Use 42 DE corn syrup to rep re sent DP 4+ frac tion,<br />

add ing dry weights of mono-, di-, and trisaccharide from 42 DE<br />

syrup to dry weights of pure glu cose, malt ose, and maltotriose used<br />

for stan dard prep a ra tion. Add ap pro pri ate dry weight of each<br />

stan dard sugar to tared 50 mL beaker. Re cord weight to <strong>fi</strong>fth place.<br />

Add 20 mL H 2O, cover, and place on steam bath to dis solve.<br />

Trans fer quan ti ta tively to 25 mL vol u met ric flask, di lute to<br />

vol ume, and mix. Add sev eral drops to lu ene as pre ser va tive. Store<br />

at room tem per a ture. Avoid to lu ene layer when draw ing up<br />

so lu tion for stan dard in jec tion. Com pute dry ba sis con cen tra tion of<br />

each sugar:<br />

Sugar, dry ba sis, % =<br />

weight sugar 100/(weight glu cose + a + b)<br />

+ (weight fruc tose + c) + [(weight malt ose 0.94) + d + e]<br />

+ [(weight maltotriose 0.94) + f + g +h] + weight DP 4+<br />

where malt ose and maltotriose weights are mul ti plied by 0.94 to<br />

ac count for H 2O of hydration and trace im pu ri ties; a and b = weight<br />

glu cose from 42 DE syrup and maltulose; c = weight fruc tose from<br />

maltulose; d and e = weights of DP 2 from 42 DE syrup and<br />

maltulose; and f, g and h = DP 3 weights from 42 DE syrup,<br />

maltulose, and malt ose.<br />

D. Prep a ra tion of Col umn<br />

Place empty col umn ver ti cally, and at tach 15 in. 3 8 in. (od)<br />

(38.1 9.5 mm [od]) stain less steel precolumn, us ing 3 8 in. (9.5 mm)<br />

un ion. At tach end <strong>fi</strong>t ting to bot tom of col umn and vac uum line to<br />

end <strong>fi</strong>t ting. At tach open-ended ves sel (ca 500 mL) to precolumn<br />

with Tygon tub ing and se cure ves sel in same plane as col umn.<br />

Slowly <strong>fi</strong>ll col umn, precolumn, and ca 1 3 of ves sel with H 2O. Slurry<br />

ca 50 mL bed vol ume of resin and add to ves sel, us ing vac uum.<br />

Bring col umn to 78C. Pull vac uum on col umn un til resin level in<br />

ves sel is con stant. Dis con tinue vac uum, dis con nect ves sel from<br />

precolumn, and pump sol vent through precolumn and col umn at<br />

0.5 mL/min (0.7 mL/min for Q15-S resin) over night. Dis con nect<br />

end <strong>fi</strong>t ting from precolumn and precolumn from col umn. Fill end<br />

<strong>fi</strong>t ting with ca 5 mm resin and at tach to col umn. Cap end with <strong>fi</strong>t tings<br />

when stor ing col umn.<br />

E. Op er ating Con di tions<br />

Flow rate 0.4 mL/min (0.6 mL/min for Q15-S resin); col umn<br />

tem per a ture 78C; de tec tor tem per a ture 45C; de tec tor at ten u a tion<br />

2006 <strong>AOAC</strong> INTERNATIONAL

8; de tec tor out put 10 mV; re corder at ten u a tion 1, re corder range<br />

10 mV; chart speed 2 in./h. Pro gram in te gra tor to ob tain trap e zoidal<br />

base line cor rec tion for each peak and to pre vent er ro ne ous base line<br />

at val ley point be tween fused peaks or on pla teau cre ated by fused<br />

peak clus ter.<br />

F. Stan dard iza tion<br />

In ject 30 L (ca 3.5 mg sol ids) of stan dard so lu tion. In te grate<br />

stan dard sugar peaks in nor mal ized mode. Sum DP 4+ frac tions<br />

ob tained from nor mal ized print out to ob tain DP 4+ nor mal ized<br />

re sponse. Di vide known dry ba sis con cen tra tion by nor mal ized<br />

re sponse for each com po nent to ob tain ra tios. Di vide each<br />

com po nent ra tio by glu cose ra tio to ob tain Sys tem I KF val ues<br />

(cal i bra tion fac tors). Pro gram com po nent KF val ues in Sys tem I,<br />

B(c), us ing <strong>Method</strong> I and glu cose as ref er ence (KF glu cose = 1). En ter<br />

DP 3 KF at both DP 3 re ten tion time and at time 100 s less than DP 3<br />

time, to pro vide KF for panose, isomaltotriose, and lin ear DP 4 when<br />

50W-X4 resin is used. List DP 4+ KF as de fault KF for DP 5+<br />

cal cu la tion when 50W-X4 resin is used.<br />

G. Prep a ra tion of Test So lu tion<br />

De ter mine ap prox i mate dry sub stance as in 945.05C (see<br />

44.7.05). Di lute syrup by weight to ca 12% dry sub stance with H 2O.<br />

Add ca 0.3 g mixed ex change resin to ca 6 g di luted test portion and<br />

shake 10 min to re move pos si ble in ter fer ing ionic ma te rial which<br />

elutes in DP 4+ re gion.<br />

H. De ter mi na tion<br />

Rinse sy ringe with di luted test so lu tion 4 times be fore in jec tion.<br />

In ject 30 L di luted test so lu tion, G. Best ac cu racy is ob tained when<br />

dry sub stance sol ids in jected for test solution and stan dard are<br />

equiv a lent. In te grate eluted peaks, us ing Sys tem I and <strong>Method</strong> I.<br />

Af ter in jec tion, wash sy ringe 4 times with warm tap water, al low ing<br />

air bub bles to scrub sy ringe walls. Wash sy ringe twice with H 2O.<br />

I. Cal cu la tions<br />

Re sults are com puted au to mat i cally when us ing integrator. List<br />

fruc tose, glu cose, maltulose, and other DP 2 re sults. Com bine<br />

maltotriose, panose-isomaltotriose, and lin ear DP 4 re sults, and list<br />

sum as DP 3-4. Sum re main ing re sults and list as DP 5+. Re port re sults<br />

on ash-free, car bo hy drate dry sub stance ba sis. In ab sence of<br />

com put ing in te gra tor, list ar eas for fruc tose (f), glu cose (g),<br />

maltulose, other DP 2, sum of maltotriose, panose-isomaltotriose and<br />

lin ear DP 4, and sum of DP 5+, and com pute re sult by equa tion:<br />

Com po nent, % = [(area com po nent)(KF com po nent)]<br />

100/{[(area f)(KF f)] + [(area g)(KF g)] + . . .<br />

+ [(area 5+)(KF 5+)]}<br />

Ref er ences: J<strong>AOAC</strong> 62, 527(1979); 69, 258(1986).<br />

CAS-50-99-7 (dex trose)<br />

CAS-57-48-7 (fruc tose)<br />

CAS-50-99-7 (glu cose)<br />

CAS-17606-72-3 (maltulose)<br />

CAS-23140-52-5 (psicose)<br />

2006 <strong>AOAC</strong> INTERNATIONAL