CONDITION MONITORING AND CBM SERVICES - Wärtsilä

CONDITION MONITORING AND CBM SERVICES - Wärtsilä

CONDITION MONITORING AND CBM SERVICES - Wärtsilä

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

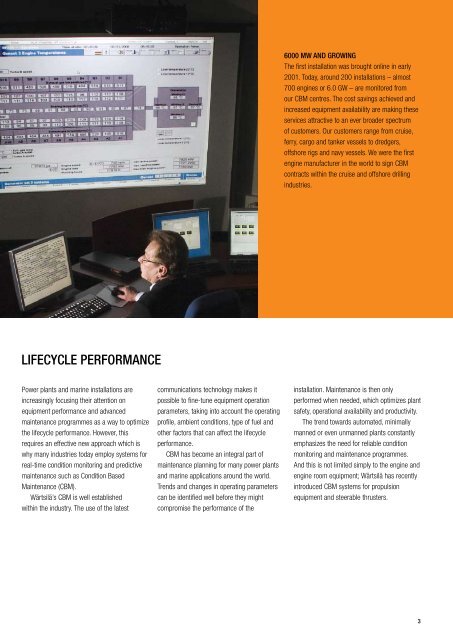

LIFECYCLE PERFORMANCE<br />

Power plants and marine installations are<br />

increasingly focusing their attention on<br />

equipment performance and advanced<br />

maintenance programmes as a way to optimize<br />

the lifecycle performance. However, this<br />

requires an effective new approach which is<br />

why many industries today employ systems for<br />

real-time condition monitoring and predictive<br />

maintenance such as Condition Based<br />

Maintenance (<strong>CBM</strong>).<br />

<strong>Wärtsilä</strong>’s <strong>CBM</strong> is well established<br />

within the industry. The use of the latest<br />

communications technology makes it<br />

possible to fine-tune equipment operation<br />

parameters, taking into account the operating<br />

profile, ambient conditions, type of fuel and<br />

other factors that can affect the lifecycle<br />

performance.<br />

<strong>CBM</strong> has become an integral part of<br />

maintenance planning for many power plants<br />

and marine applications around the world.<br />

Trends and changes in operating parameters<br />

can be identified well before they might<br />

compromise the performance of the<br />

6000 MW <strong>AND</strong> GROWING<br />

The first installation was brought online in early<br />

2001. Today, around 200 installations – almost<br />

700 engines or 6.0 GW – are monitored from<br />

our <strong>CBM</strong> centres. The cost savings achieved and<br />

increased equipment availability are making these<br />

services attractive to an ever broader spectrum<br />

of customers. Our customers range from cruise,<br />

ferry, cargo and tanker vessels to dredgers,<br />

offshore rigs and navy vessels. We were the first<br />

engine manufacturer in the world to sign <strong>CBM</strong><br />

contracts within the cruise and offshore drilling<br />

industries.<br />

installation. Maintenance is then only<br />

performed when needed, which optimizes plant<br />

safety, operational availability and productivity.<br />

The trend towards automated, minimally<br />

manned or even unmanned plants constantly<br />

emphasizes the need for reliable condition<br />

monitoring and maintenance programmes.<br />

And this is not limited simply to the engine and<br />

engine room equipment; <strong>Wärtsilä</strong> has recently<br />

introduced <strong>CBM</strong> systems for propulsion<br />

equipment and steerable thrusters.<br />

3