CONDITION MONITORING AND CBM SERVICES - Wärtsilä

CONDITION MONITORING AND CBM SERVICES - Wärtsilä

CONDITION MONITORING AND CBM SERVICES - Wärtsilä

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

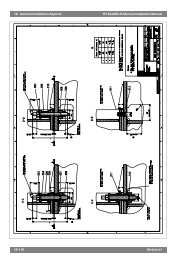

MAINTENANCE ONLY WHEN NEEDED<br />

A number of smart electronic technologies<br />

have opened up new engine maintenance<br />

opportunities over the last decade, and plug-in<br />

diagnostics systems are now part of modern<br />

engine maintenance.<br />

However, this tends to happen only on<br />

scheduled service dates. <strong>Wärtsilä</strong>’s condition<br />

monitoring and <strong>CBM</strong> services take the concept<br />

several steps further.<br />

By networking equipment sensors and<br />

automatically monitoring the equipment<br />

condition and logging the data, installation<br />

performance information is collected<br />

continuously and transmitted regularly back to<br />

our <strong>CBM</strong> centre. Feeding the information into<br />

the <strong>CBM</strong> system accurately determines the<br />

actual overall condition of the installation and<br />

ultimately the maintenance it needs.<br />

Our specially developed software analyses<br />

the installation’s operation data by comparing<br />

it against the engine’s ideal design values<br />

and other parameters. A <strong>Wärtsilä</strong> engine<br />

expert then provides predictions on engine<br />

performance and recommendations for<br />

optimizing the operation and maintenance<br />

profile. Detailed <strong>CBM</strong> reports are provided on a<br />

PLAN AHEAD – STAY AHEAD<br />

With the possibility it gives to balance the time<br />

between overhauls, minimize downtime and optimize<br />

the installation performance, <strong>CBM</strong> is becoming an<br />

industry standard. The aim is to find more than 90%<br />

of the critical cases 7 – 30 days in advance and to<br />

predict more than 90% of the required maintenance<br />

2 – 6 months in advance.<br />

regular basis to the technical staff, owner and<br />

operator of the installation.<br />

If required, a sensor-based network<br />

can also be used to monitor environmental<br />

emissions, which are usually closely related<br />

to engine operating efficiency. It is clear that<br />

more regulations will come into force, with a<br />

continuous drive for higher efficiency and lower<br />

emission levels. Tighter NO X, CO X and SO X<br />

standards mean condition monitoring and <strong>CBM</strong><br />

technology will play a key role.<br />

5