110323-Triangle-Returns

110323-Triangle-Returns

110323-Triangle-Returns

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

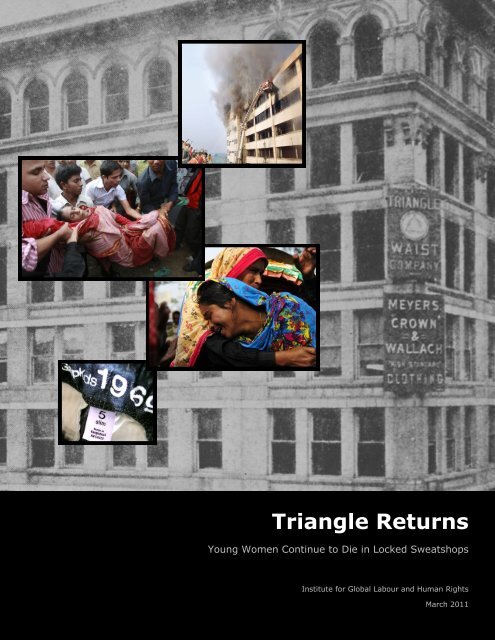

<strong>Triangle</strong> <strong>Returns</strong><br />

Young Women Continue to Die in Locked Sweatshops<br />

Institute for Global Labour and Human Rights<br />

March 2011

<strong>Triangle</strong> <strong>Returns</strong><br />

Young Women Continue to Die in Locked Sweatshops<br />

A Report by<br />

Institute for Global Labour and Human Rights<br />

(Formerly National Labor Committee)<br />

Author<br />

Charles Kernaghan<br />

Research<br />

Charles Kernaghan, Barbara Briggs, Sabrina Yow-chyi Liu<br />

Cassie Rusnak, Elana Szymkowiak, Robyn Roux, and Megan Will<br />

Design<br />

Sabrina Yow-chyi Liu<br />

March 2011

March 2011 1<br />

On the 100th Anniversary of the <strong>Triangle</strong> Shirtwaist Factory Fire<br />

Little Has Changed in the Global Sweatshop Economy<br />

<strong>Triangle</strong> Fire<br />

New York City<br />

March 25, 1911<br />

146 Died<br />

Exit Door Locked<br />

Referring to the locked exit gate, a floor manager<br />

responded: How else could you control so many<br />

young girls?<br />

Trapped workers jumped to their deaths from the<br />

9 th floor so their parents would have their bodies to<br />

bury.<br />

Fire fighters’ ladders could not reach the 8 th , 9 th and<br />

10 th floors of the building.<br />

Worked 6 days a week, often 14 hours a day, with<br />

an 8-hour shift on Saturdays.<br />

Institute for Global Labour and Human Rights<br />

Hameem Fire<br />

Savar, Bangladesh<br />

December 14, 2010<br />

29 Died, with over 100 injured,<br />

36 of them seriously<br />

Exit Door Locked<br />

At Hameen and other factories, workers told us that<br />

security guards are ordered to lock the exit gates<br />

during a fire to prevent garments from being stolen<br />

in the chaos.<br />

A hundred years later, workers trapped in the<br />

Hameem fire jumped to their deaths from the 11 th<br />

floor so that their parents would have their bodies<br />

to properly mourn and bury.<br />

Fire fighters’ ladders could not reach the 9 th , 10 th<br />

and 11 th floors of the building.<br />

Worked 7 days a week, 12 to 14 hours a day, with<br />

an 8-hour shift on Fridays.

March 2011 2<br />

Senior sewing operators earned 14 cents an hour,<br />

which in today’s dollars, adjusted for inflation,<br />

would be $3.18 an hour, $25.44 for an 8-hour shift.<br />

Starting in February 1909, garment workers in New<br />

York City struck and won union-only shops in<br />

hundreds of garment factories. <strong>Triangle</strong><br />

management fought to remain non-union.<br />

If the <strong>Triangle</strong> workers had had a union, it is<br />

possible the exit would not have been locked, and<br />

that far fewer or no workers would have died in the<br />

March 25, 1911 fire.<br />

The outrage over the deaths of 146 workers at the<br />

<strong>Triangle</strong> factory led to major reforms as dozens of<br />

new laws required factory improvements from<br />

sprinkler systems to exit doors that open outward<br />

and cannot be locked; a minimum wage, limits on<br />

working hours, the right to organize, and much<br />

more.<br />

Institute for Global Labour and Human Rights<br />

Senior sewing operators earn just 28 cents an<br />

hour, $2.24 a day for an 8-hour shift. 100 years<br />

after the <strong>Triangle</strong> fire, garment workers in<br />

Bangladesh earn just one tenth as much as the<br />

<strong>Triangle</strong> workers did in 1911.<br />

In July 2010, when garment workers in Bangladesh<br />

struggled for a 35-cent-an-hour wage, women were<br />

attacked, beaten with clubs, shot with rubber<br />

bullets and hosed down with powerful water<br />

cannons, using a dye so protesting workers could<br />

be identified and arrested.<br />

Hameem management had also busted a union<br />

organizing drive at their factory in September 2008,<br />

imprisoning the union leader and firing 19 of the<br />

lead activists. Well over 50 percent of the Hameem<br />

workers had signed onto the union’s demands.<br />

If Hameem management had not illegally busted<br />

the union, the 29 workers might not have died on<br />

December 14, 2010.<br />

Management continues to illegally outlaw unions at<br />

the Hameem factory. Less than 3% of<br />

Bangladesh’s garment workers are organized, and<br />

only a handful of workers have collective<br />

bargaining rights.<br />

After the Hameem fire led to the needless death of<br />

29 workers, there has been no serious investigation,<br />

nor is there likely to be one in the future. The<br />

owner, Mr. Azad, is a powerful businessman, who<br />

also owns a newspaper and TV station. Without<br />

the slightest evidence, Mr. Azad simply reported in<br />

his newspaper and TV station that the fire ―was the<br />

result of sabotage.‖<br />

Unless something changes, workers will continue<br />

to be paid starvation wages, forced to work<br />

grueling hours, denied the right to organize, and<br />

needlessly burned to death in unsafe factories<br />

producing major U.S. brands.

March 2011 3<br />

Hospitalized Hameem Workers Describe<br />

How They were Trapped by the Locked Exits<br />

Worker 1: ―Everyone rushed out and found both<br />

exit gates filled with smoke, so dense and dark<br />

that we couldn’t see oneself. As we could not<br />

pass through the other side gate we retreated and<br />

found this gate also locked. We broke open the<br />

[window] grill, climbed down from the 11 th floor<br />

to the ground with a rope [mostly fabric] – many<br />

died doing it… some of my coworkers fell down<br />

as the rope [fabric] tore off while they tried to<br />

climb down…‖<br />

Worker 2: ―Nobody told of any fire. The alarm<br />

rang 10 minutes later, long after the smoke<br />

arrived. Fire flaring up at every exit we rushed<br />

to. The gate at the west, leading to the sample<br />

room, was locked. Other open exits were<br />

inaccessible due to fire. We could not get out.<br />

Some jumped to [their] death, six workers. I<br />

thought it would take 10 minutes for the fire to<br />

burn me to death and my body could never be<br />

identified. Better if I jump, my family would at<br />

least have my corpse.<br />

To save myself… I did not know how or from<br />

where, Allah showed a way out. There was an<br />

Institute for Global Labour and Human Rights<br />

exhaust fan in the wall. We broke it, shoved with<br />

a bottle. By Allah’s grace, a fabric was found. I<br />

had no clue who tied it, who held it. I slowly<br />

began climbing down, reached the 9 th floor and<br />

the cord fell short. I was unable to climb down<br />

farther, nor could I climb up for the 10 th floor<br />

was blazing… Then somehow, I managed to rest<br />

my leg in the pit of an exhaust fan on the 9 th<br />

floor. My trousers caught fire, but I didn’t lose<br />

my grip. Later someone dragged me inside. I<br />

had no sense who was there and how many of<br />

them. Could not even shout, smoke was coming<br />

out of my mouth, could not breathe, my nostrils<br />

emitting smoke.<br />

Can’t tell how I was admitted to the hospital,<br />

who brought me, who led me. My eyes were<br />

open but I was senseless as I heard from my<br />

relatives. I could not recognize anybody. Later I<br />

regained my consciousness.‖<br />

Worker 3: ―Those who jumped off the 11 th floor<br />

did it thinking if they died there the fire would<br />

leave no trace of them. If they jumped to their<br />

death, their corpse would at least return home.‖

March 2011 4<br />

T<br />

he That’s It Sports, LTD Factory,<br />

located in Savar, about 16 miles from<br />

Dhaka, belongs to the powerful Hameem<br />

Apparel Group, which is one of Bangladesh’s<br />

largest garment exporters. The Hameem group<br />

is owned by Mr. AK Azad, who is also the<br />

President of the Federation of Bangladesh<br />

Chambers of Commerce and Industries, the<br />

most important trade association in the country.<br />

Mr. Azad owns several large garment factories,<br />

along with a newspaper and a television station.<br />

That’s It Sports, LTD<br />

Hameem Group Headquarters<br />

241 Tejgaon I/A, Dhaka 1208<br />

Bangladesh<br />

Phone: 880-2-8825232<br />

880-2-9885029<br />

E-mail: hameem@citechco.net<br />

The That’s It Sports Ltd. Factory is housed in<br />

a large 11-story building with 7,000 to 7,500<br />

workers, 80 percent of whom are mostly young<br />

women 20 to 25 years of age.<br />

Hameem Factory Fire<br />

Institute for Global Labour and Human Rights<br />

Grueling Working Hours<br />

at That’s It Sports Ltd / Hameem:<br />

12 to 14 hour shifts<br />

seven days a week<br />

with one day off a month<br />

Standard 12 to 14 hour shift, 7 days a week<br />

8:00 am – 1:00 pm (work / 5 hours)<br />

1:00 pm – 2:00 pm (lunch / 1 hour)<br />

2:00 pm – 5:00 pm (work / 3 hours)<br />

5:00 pm – 8:00 pm or 10:00 pm<br />

(overtime / 3 to 5 hours)<br />

The workers toil seven days a week, with at<br />

most one day off a month. In the month of<br />

January 2011, there was no day off at all. The<br />

workers are in the peak season now and are<br />

routinely at the factory 80 to 90 hours a week,<br />

while working at least 70 to 80 hours, including<br />

22 to 32 hours of mandatory overtime. Besides<br />

the hour lunch break, the workers receive a 15<br />

minute tea break from 7:00 to 7:15 pm.<br />

On Friday, which is supposed to be the weekly<br />

holiday, the workers are let out early at 5:00 pm.<br />

On average, workers receive one day off a<br />

month. It appears that on any given day, half the<br />

workers toil to 8:00 pm, while the other half is<br />

kept to 10:00 pm.

March 2011 5<br />

Starvation Wages<br />

Young women sewing $26.95 toddler denim shorts for GAP earn just 20 to 28 cents an hour.<br />

J.C.Penney and Phillips-Van Heusen are other major labels sewn at the Hameen Factory.<br />

Helpers Earn 20 Cents an Hour<br />

(3066 taka a month)<br />

20 cents an hour<br />

$ 1.60 a day (8 hours)<br />

$9.62 a week (48 hours)<br />

$41.67 a month<br />

$500.00 a year<br />

Junior Sewing Operators<br />

(With less than 3 to 5 years experience - 3860 taka a month)<br />

26 cents an hour<br />

$2.04 a day (8 hours)<br />

$12.37 a week (48 hours)<br />

$53.61 a month<br />

$643.33 a year<br />

Senior Sewing Operators<br />

(With more than five years experience -4218 taka a month)<br />

28 cents an hour<br />

$2.24 a day (8 hours)<br />

$13.52 a week (48 hours)<br />

$50.58 a month<br />

$703.60 a year<br />

Including all overtime and the attendance bonus, the most senior sewing operators can earn up to $23.24<br />

to $24.56 a week.<br />

(Exchange rate is 72 taka to $1.00 USD)<br />

Institute for Global Labour and Human Rights

March 2011 6<br />

GAP Accounts for 50 Percent of Production<br />

A<br />

ccording to worker estimates, at the<br />

time of the deadly Hameem fire in<br />

December 2010, GAP accounted for 50<br />

percent of total factory production. A<br />

knowledgeable source told us that 400,000 pairs<br />

of GAP’s children’s denim shorts were burned<br />

in the fire. GAP has also been sourcing<br />

production at Hameem for well over a decade.<br />

Institute for Global Labour and Human Rights<br />

J.C.Penney and Phillips-Van Heusen<br />

accounted for most of the remaining production.<br />

But, workers also mentioned sewing garments<br />

for Target, VF Corporation, and Abercrombie<br />

and Fitch. Only the U.S. apparel companies can<br />

inform the American people regarding how<br />

much production they had at the Hameem<br />

Factory.

March 2011 7<br />

Twenty-nine Workers Died<br />

in the Hameem Factory Fire in Bangladesh<br />

8 workers jumped to their death<br />

10 workers were burned to death<br />

5 died of smoke inhalation<br />

6 died in the hospital of burns<br />

Six of the dead had been working at Hameem for less than two weeks, including one worker who had<br />

been at the factory for only two days.<br />

Management gave just $2,083.33 in compensation to the families of the dead workers.<br />

Name of worker<br />

ID<br />

Card<br />

Position<br />

Institute for Global Labour and Human Rights<br />

Home District<br />

Date of<br />

Employment<br />

1 Md. Mozammel 9810 Loader Dinajpur 08/05/06<br />

2 Md. Maruf Hossain 18666 Operator(OP) Faridpur 12/04/10<br />

3 Ms.Tania Sultana 3001 OP Borguna<br />

4 Ms. Anjona 711 OP Jamalpur 01/12/10<br />

5 Md. Faridul Iron.Man Dinajpur<br />

6 Ms. Halima 913 OP B. Baria 02/17/07<br />

7 Md. Ruhul Amin 312 OP Bogura 01/10/08<br />

8 Md. Rasel Shekh Sample Man Madaripur 11/01/10<br />

9 Md. Babul 218 OP Jamalpur 12/08/10<br />

10 Md. Himel 6513 OP Nator 02/12/09<br />

11 Md. Rezaul 12171 Packer Man Gaibandha 12/20/09<br />

12 Ms. Runa 12025 OP Borishal<br />

13 Md. Delowar hossain 13258 OP Fharidpur 12/09/09<br />

14 Ms. Munsura 3068 OP Fharidpur<br />

15 Md. Masum khan Sample Man Bagherhat 10/11/10<br />

16 Md.Selim Reza Sample Man Sirajgong 05/09/09<br />

17 Md.Shah Alam Sample Man Sirajgong 07/18/10<br />

18 Md.Sohel 7116 Fe.Q.I Chuadanga 07/06/10<br />

19 Md.Rezaul Folding Man Sirajgong<br />

20 Mr.Ranju 5577 OP Sirajgong 02/11/09<br />

21 Md.Sujon Ahmed 762 OP Ranjpur 12/01/10<br />

22 Md.Chan Mia 29953 Iron.Man Manikgong 03/03/10<br />

23 Md.Imran Hossain Sample Man Jessore 10/16/10<br />

24 Md. Abu Sayed 607 OP Ranjpur 12/10/09<br />

25 Md. Ekamuddin 14 Sample Man Bagura 04/08/10<br />

26 Mukhlesur Rahaman 1568 OP Jamalpur 12/12/10<br />

27 Md. Babul 2744 OP Mymenshing 05/03/10<br />

28 Md. Shahinur 3007 OP Bagura 12/08/10<br />

29 Md. Al-Amin Shekh 8362 Assist. OP Pubna 11/24/10

March 2011 8<br />

Of the over 100 Workers Injured in the Hameem Fire<br />

Thirty-six were Hospitalized with Serious Injuries<br />

Management gave the seriously injured only $347.22 in compensation.<br />

Name of Worker (under<br />

medical treatment)<br />

Card No Designation District<br />

1. Md. Hasanur Rahman 33 Sample man Nilphamari<br />

2. Ms Josna Begum 10682 Assistant Operator Bogra<br />

3. Md. Rajib 2582 Operator Tangail<br />

4. Md. Shamim 12085 Packing man Narshindi<br />

5. Ms Amina Begum New Assistant Operator Madaripur<br />

6. Mr. Tushar Sarkar 1779 Operator Joypur hat<br />

7. Md.Shahed Hosain 12233 Operator Lakhipur<br />

8. Md. Tabibur Rahman Office A. O. Faridpur<br />

9. Md. Azizul Haq 4664 Quality Inspector Barisal<br />

10. Md. Ershad 1956 Iron man Rangpur<br />

11. Md. Anisur Rahman Packing Supervisor Gaibandha<br />

12. Md. Faruk Miah 7115 Q.I. Gaibandha<br />

13. Md. Zakir Hosain 1531 Iron mane Gazipur<br />

14. Md. Mojahar 5629 Operator Thakurgaon<br />

15. Md. Mohiuddin 3861 Q.I. Meherpur<br />

16. Md. Jainal 2022 Q.I. Tangail<br />

17. Ms Jabeda Khatun 1860 Assistant Operator Rangpur<br />

18. M/s Roksana 742 Operator Gazipur<br />

19. Md. Shakil 1557 Operator Rangpur<br />

20. Md. Oashim 741 Operator Kushtia<br />

21. Md. Azizul Haq 12274 Folding Man Dinajpur<br />

22. Md. Abdul Malek 654 Q.I. Kushtia<br />

23. Md. Mokbul Hosain 23 Sample man Bogra<br />

24. Md. Rasel 12169 Packing man Naogaon<br />

25. Md. Shafiqul 6101 Q.I. Tangail<br />

26. Md. Milon Hosain 2604 Sample man Rangpur<br />

27. Md. Badsha 764 Operator Bagerhat<br />

28. Happy 8169 Operator Netrakona<br />

29. Md. Hakim Security Guard Mymensingh<br />

30. Md. Habib 40 Sample Man Patuakhali<br />

31. Md. Akther Hosain Supervisor Munshiganj<br />

32. Md.Ariful Islam 768 Operator Khulna<br />

33. Mr. Shuvo 3308 Operator Netrakona<br />

34. Md. Manik Miah Line Chief Netrakona<br />

35. Md. Sujan 149 Operator Gaibandha<br />

36. Ms Shathi 3749 Operator Pabna<br />

Institute for Global Labour and Human Rights

March 2011 9<br />

Locked Exits Lead to Repeated Deaths<br />

in Bangladesh’s Garment Factories<br />

T<br />

he Hameem Factory Fire that resulted<br />

in the deaths of 29 workers on December<br />

14, 2010 is not alone in criminally<br />

locking emergency exits and recklessly<br />

endangering the lives of its workers.<br />

Emergency exits were also locked at the<br />

Garib and Garib Sweater Factory on<br />

February 25, 2010, where a fire broke out at<br />

9:30 p.m. killing 21 workers, with 31 others<br />

seriously injured. The Garib and Garib<br />

Sweater Factory was producing for H&M.<br />

On February 23, 2006, at 7:30 p.m., a fire<br />

engulfed the KTS Textiles Factory in<br />

Chittagong, leaving an estimated 60<br />

Institute for Global Labour and Human Rights<br />

workers dead, as the main exit gate was<br />

illegally locked.<br />

At the Chowdhury Knitwear and<br />

Garment Factory, 51 workers were burned<br />

to death on November 25, 2000, where a fire<br />

broke out at 7:30 p.m. The main exit gate<br />

was locked trapping the workers with no<br />

way out. Among the dead were 10, 12 and<br />

14 year olds.<br />

This will sound unbelievable, but garment<br />

workers across Bangladesh have told us<br />

managers often instruct security guards to<br />

lock the exit gates when a fire breaks out to<br />

prevent people from stealing garments in the<br />

chaos of the fire!<br />

U.S. Apparel Companies Flock to Bangladesh to Access Cheap Wages<br />

Bangladesh’s garment factories are booming, with 3.5 million mostly young women<br />

sewing clothing for export to the U.S. and Europe.<br />

Bangladesh is now the 3 rd largest apparel exporter to the U.S., following just China and<br />

Vietnam. In 2010, Bangladesh apparel exports to the U.S. surged 15.3 percent,<br />

reaching nearly four billion dollars ($3.93 billion).<br />

According to knowledgeable sources, apparel orders in Bangladesh are up nearly 30<br />

percent in just the last three months. Factory owners are speaking of adding another<br />

million workers or more.<br />

More than 97 percent of all apparel purchased in the United States is imported, often<br />

made under harsh sweatshop conditions.

March 2011 10<br />

A<br />

hundred years ago, the tragedy of the<br />

<strong>Triangle</strong> Shirtwaist factory fire struck a<br />

deep nerve in the American people, and<br />

they demanded reforms which would remake<br />

our industrial landscape and guarantee the rights<br />

of workers. Laws were passed demanding<br />

automatic sprinkler systems, exits that opened<br />

outward and could not be locked, and mandatory<br />

fire drills. Wall Street and the factory owners<br />

fought back, but they lost. The 146 workers<br />

killed at <strong>Triangle</strong> did not die in vain. The<br />

progressive reforms continued over the next 40<br />

years. By 1938, sweatshops were wiped out in<br />

the U.S. Minimum wage law were in place.<br />

There were limits on working hours and timeand-a-half<br />

for overtime work. By the 1950s, 34<br />

percent of all American workers were organized,<br />

and the middle class was built. We worked hard,<br />

and our lives improved.<br />

Now, 97 percent of all garments are made off<br />

shore, the vast majority under harsh sweatshop<br />

conditions. It is the same with auto parts,<br />

computers, cell phones and Barbie dolls. We are<br />

racing backward in the global economy, trapped<br />

in a Race to the Bottom, competing over who<br />

will accept the lowest wages and the most<br />

miserable living and working conditions.<br />

Just three months shy of the 100 th anniversary of<br />

the <strong>Triangle</strong> fire, on December 14, 2010, a fire<br />

broke out at the Hameem factory in Bangladesh,<br />

which was sewing garments for Gap. The fire<br />

alarms did not go off, and the emergency exits<br />

were locked on the 9 th floor, killing 29<br />

workers—many of whom jumped to their<br />

deaths—and injuring over 100. At Hameem, the<br />

workers toil 12 to 14 hours a day, seven days a<br />

week, with just a single day off a month. The<br />

Afterword<br />

By Charles Kernaghan<br />

Institute for Global Labour and Human Rights<br />

highest wage at Hameem is 28 cents an hour-less<br />

than one-tenth of what the <strong>Triangle</strong><br />

workers earned 100 years ago! (Adjusted for<br />

inflation, the 14 cents an hour they earned in<br />

1911 is worth $3.18 an hour today.) The<br />

garment workers in Bangladesh are trapped in<br />

misery, living in makeshift hovels.<br />

Hameem management busted a union organizing<br />

drive at their factory in September 2008,<br />

imprisoning the union president and firing all 19<br />

of the lead activists. It did not matter that well<br />

over half of the workers supported the union’s<br />

demands.<br />

When the workers in Bangladesh took to the<br />

streets in July 2010 demanding a 35-cent-anhour<br />

wage, they were beaten with clubs. The<br />

police shot rubber bullets and used powerful<br />

water cannons to sweep the workers off their<br />

feet. There was dye in the water so that<br />

demonstrating workers could be identified and<br />

imprisoned later.<br />

We are at a cross roads. We can stand back and<br />

allow the corporations to drive this Race to the<br />

Bottom. Or, we can fight back.<br />

The United States is still the largest economy<br />

and market in the world. This gives the<br />

American people a powerful voice, if we choose<br />

to use it.<br />

Corporations have demanded and won all sorts<br />

of laws—intellectual property and copyright<br />

laws—to protect their products, which are<br />

backed up by sanctions. Anyone making a<br />

knock-off of Gap’s toddler denim shorts, which

March 2011 11<br />

were made in the Hameem sweatshop, will be<br />

sued and end up in jail.<br />

However, when we ask the companies if we can<br />

have similar laws to protect the rights of the<br />

human being who makes the product, they<br />

respond, ―No! That would be an impediment to<br />

Free Trade!‖<br />

Something is wrong when the corporate product<br />

is legally protected, but not the human being<br />

who made it. And the corporate leaders must be<br />

laughing all the way to the bank.<br />

Working together with the United Steelworkers<br />

union, religious organizations, students and<br />

other activists, we drew up worker rights<br />

legislation which for the first time ever will hold<br />

corporations accountable to respect local labor<br />

laws in the U.S. and internationally.<br />

The legislation is very simple. Corporations<br />

must adhere to the local labor laws, including<br />

minimum wage levels, in the countries where<br />

they are producing. This should be no problem,<br />

as every company says they already do this.<br />

Have you ever heard a company say they are<br />

violating local labor laws? In addition, under<br />

the legislation, corporations will be held<br />

accountable to respect the core ILO<br />

internationally recognized worker rights<br />

standards—no child or forced labor, decent<br />

working conditions, freedom of association, the<br />

right to organize a union and bargain<br />

collectively. Here too, this should not be a<br />

problem, since the companies say they strictly<br />

adhere to the International Labor Organization’s<br />

worker rights standards.<br />

Institute for Global Labour and Human Rights<br />

The Decent Working Conditions and Fair<br />

Competition Act is very simple. Corporations<br />

can produce goods and services anywhere in the<br />

world. But if they violate local labor laws in the<br />

countries they are producing, then their goods<br />

cannot be imported to the U.S., sold here or<br />

exported. The same is true of the core ILO labor<br />

rights standards. If the ILO standards are<br />

violated, the product cannot be imported, sold or<br />

exported from the U.S.<br />

When the USW introduced the jobs bill in the<br />

110 th Congress, the were 175 co-sponsors in the<br />

House and 26 in the Senate, including Senators<br />

Obama, Biden and Clinton.<br />

A Harris Poll showed that 79 percent of the<br />

people surveyed supported the proposed<br />

labor rights legislation.<br />

There is even a precedent for such legislation.<br />

When Congress was alerted that garment<br />

manufacturers in China were producing winter<br />

jackets for sale at the Burlington Coat Factory<br />

stores, and that the fur collars were made of dog<br />

and cat fur, Congress went ballistic. No one<br />

would kill dogs and cats on their watch! In no<br />

time, they passed the Dog and Cat Protection<br />

Act of 2000, which prohibits the import, sale or<br />

export of dog and cat fur from the U.S. Now we<br />

need to give the same legal protections to<br />

workers in the global economy.<br />

This is our time to act, and the worker rights<br />

legislation is our vehicle.

Institute for Global Labour and Human Rights<br />

5 Gateway Center, 6th Floor<br />

Pittsburgh, PA 15232. USA<br />

412-562-2406<br />

inbox@glhr.org<br />

www.nlcnet.org