NHG-70

NHG-70

NHG-70

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

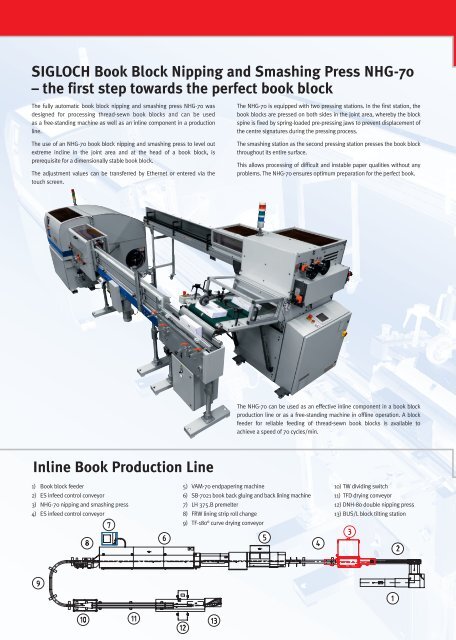

SIGLOCH Book Block Nipping and Smashing Press <strong>NHG</strong>-<strong>70</strong><br />

– the first step towards the perfect book block<br />

The fully automatic book block nipping and smashing press <strong>NHG</strong>-<strong>70</strong> was<br />

designed for processing thread-sewn book blocks and can be used<br />

as a free-standing machine as well as an inline component in a production<br />

line.<br />

The use of an <strong>NHG</strong>-<strong>70</strong> book block nipping and smashing press to level out<br />

extreme incline in the joint area and at the head of a book block, is<br />

prerequisite for a dimensionally stable book block.<br />

The adjustment values can be transferred by Ethernet or entered via the<br />

touch screen.<br />

Inline Book Production Line<br />

1) Book block feeder<br />

2) ES infeed control conveyor<br />

3) <strong>NHG</strong>-<strong>70</strong> nipping and smashing press<br />

4) ES infeed control conveyor<br />

The <strong>NHG</strong>-<strong>70</strong> is equipped with two pressing stations. In the first station, the<br />

book blocks are pressed on both sides in the joint area, whereby the block<br />

spine is fixed by spring-loaded pre-pressing jaws to prevent displacement of<br />

the centre signatures during the pressing process.<br />

The smashing station as the second pressing station presses the book block<br />

throughout its entire surface.<br />

This allows processing of difficult and instable paper qualities without any<br />

problems. The <strong>NHG</strong>-<strong>70</strong> ensures optimum preparation for the perfect book.<br />

The <strong>NHG</strong>-<strong>70</strong> can be used as an effective inline component in a book block<br />

production line or as a free-standing machine in offline operation. A block<br />

feeder for reliable feeding of thread-sewn book blocks is available to<br />

achieve a speed of <strong>70</strong> cycles/min.<br />

5) VAM-<strong>70</strong> endpapering machine<br />

6) SB-<strong>70</strong>21 book back gluing and back lining machine<br />

7) LH 375.B premelter<br />

8) FRW lining strip roll change<br />

9) TF-180° curve drying conveyor<br />

10) TW dividing switch<br />

11) TFD drying conveyor<br />

12) DNH-80 double nipping press<br />

13) BUS/L block tilting station