baling presses brochure - Strautmann Umwelttechnik

baling presses brochure - Strautmann Umwelttechnik

baling presses brochure - Strautmann Umwelttechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Baling <strong>presses</strong> for all industries<br />

Single-chamber <strong>baling</strong> <strong>presses</strong><br />

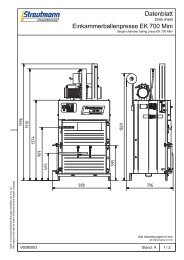

EK 700 Mini<br />

Multi-chamber <strong>baling</strong> <strong>presses</strong><br />

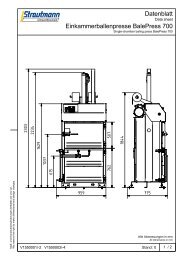

BalePress 700<br />

EK AutoLoadBaler<br />

800<br />

BaleTainer ®<br />

EK 1107<br />

EK 1109<br />

PP 1208<br />

PP 1208 Plus70<br />

Durable. Easy to operate. Reliable.

Market your recyclables<br />

Cardboard packaging Film PET<br />

Market your recyclables and dispose of them in a profitable manner!<br />

<strong>Strautmann</strong> <strong>baling</strong> <strong>presses</strong> can be installed directly at the<br />

place where the material is accruing. The material is no<br />

longer lying loosely on the premises but is thrown into the<br />

<strong>baling</strong> press, thus creating an atmosphere of order and<br />

cleanliness and saving space. The in-house logistics is<br />

improved and the costs for long transportation routes are<br />

reduced. Due to the compaction of the loose material, the<br />

trucks and containers can be charged at their optimum.<br />

<strong>Strautmann</strong> quality standards<br />

TopPlus ®<br />

The solid pressing plate guiding<br />

system TopPlus ® ensures a longer<br />

service life of the <strong>baling</strong> press.<br />

Holding-down devices prevent the<br />

pressed material from reexpanding.<br />

QuickDoor ®<br />

The QuickDoor ® swing door saves<br />

space and allows quick and safe filling<br />

of the pressing chamber.<br />

The conical bottom prevents<br />

transport cavities.<br />

Technical modifications reserved. Bale dimensions and weights depend on material. Version 03/2012.<br />

The number of journeys is reduced which leads to a proportionately<br />

less amount of CO2 emissions and a massive<br />

reduction of transport costs.<br />

<strong>Strautmann</strong> <strong>presses</strong> can be operated intuitively and easily.<br />

Apart from the machine quality, the quality of the bales is<br />

important for our customers. The higher the bale density,<br />

the higher the sales proceeds – no more costs for „waste“.<br />

® ® ®<br />

BaleMatic ®<br />

The hydraulic bale ejector BaleMatic ®<br />

helps to easily take the bales out of the<br />

<strong>baling</strong> press<br />

The control system enables<br />

easy and intuitive operation.

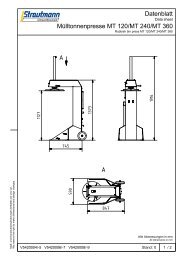

EK 700 Mini / BalePress 700 / BalePress 800<br />

Compact <strong>baling</strong> <strong>presses</strong> for small quantities<br />

Even our smallest <strong>baling</strong> <strong>presses</strong> offer major advantages:<br />

they reduce the volume of loose cardboard packaging and<br />

film by up to 90%.<br />

The <strong>presses</strong> are designed for mobile use and require little<br />

space. Easy and convenient operation of the <strong>presses</strong> as well<br />

as easy bale handling allow a wide application range. Even<br />

for a small quantity of material, using these <strong>baling</strong> <strong>presses</strong><br />

pays off.<br />

The small <strong>baling</strong> <strong>presses</strong> are equipped with a bale truck.<br />

Thus, the finished bales can be easily taken out of the pressing<br />

chamber.<br />

EK 700 Mini BalePress 700 BalePress 800<br />

Pressing force in kN 30 40 / 60 60 / 100<br />

Dimensions (W x H x D) 1,0 x 2,0 x 0,8 m 1,0 x 2,3 x 0,75 m 1,1 x 2,3 x 0,8 m<br />

Machinery weight 370 kg 380 kg 470 - 520 kg<br />

Electricity supply 230 V, 1 ph 230/400 V, 1/3 ph 400 V, 3 ph<br />

Bale weight up to 50 kg up to 60 kg up to 80 kg<br />

Bale dimensions 0,7 x 0,5 x 0,35 m 0,7 x 0,5 x 0,7 m 0,8 x 0,6 x 0,7 m<br />

EK 1107 / EK 1109<br />

Single-chamber <strong>baling</strong> <strong>presses</strong><br />

Baling <strong>presses</strong> for large-scale use<br />

These <strong>baling</strong> <strong>presses</strong> are used for cardboard packaging, film,<br />

cardboard and paper in various industries. Their high feed<br />

volume, large feed opening and easy operation make these<br />

<strong>baling</strong> <strong>presses</strong> your productive helpers for large-scale use.<br />

The EK 1107 and the EK 1109 are equipped with the spacesaving<br />

QuickDoor ® and the solid pressing plate guiding<br />

system TopPlus ® . The incorporated holding-down devices<br />

prevent the material from reexpanding and achieve high bale<br />

densities as well as high proceeds. The hydraulic bale ejector<br />

BaleMatic ® helps to easily take the bales out of the press.<br />

The bales can be tied up by means of tape or wire.<br />

Flexible and mobile Interior of pressing plate Interior of pressing plate Cardboard packaging in<br />

chamber<br />

EK 1107 EK 1109<br />

Pressing force in kN 220 280 / 350<br />

Dimensions (W x H x D) 1,8 x 2,8 x 1,1 m 1,7 x 3,0 x 1,4 m<br />

Machinery weight 1.600 kg 1.800 - 1.850 kg<br />

Electricity supply 400 V, 3 ph 400 V, 3 ph<br />

Bale weight up to 250 kg up to 320 kg<br />

Bale dimensions 1,1 x 0,7 x 1,0 - 1,2 m 1,1 x 0,9 x 1,0 - 1,2 m<br />

www.strautmann-umwelt.com

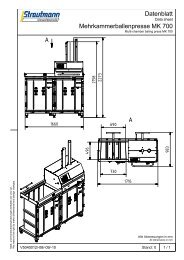

Multi-chamber <strong>baling</strong> <strong>presses</strong><br />

MK 700<br />

High flexibility in one press<br />

The multi-chamber <strong>baling</strong> <strong>presses</strong> MK 700 and MK 1100 help<br />

to separate out various materials. In two or more adjacent<br />

pressing chambers, different materials such as cardboard<br />

packaging and film can be collected in these <strong>baling</strong> <strong>presses</strong>.<br />

As soon as one chamber of the <strong>baling</strong> press is full, the mobile<br />

pressing head can be moved over this chamber and press<br />

the material into bales. According to the requirements, the<br />

multi-chamber <strong>baling</strong> <strong>presses</strong> MK 700 and MK 1100 can be<br />

equipped with one or several additional chambers.<br />

Film and cardboard packaging<br />

sorted in chambers<br />

MK 700 (with 2 chambers) MK 1100 (with 3 chambers)<br />

Pressing force in kN 40 / 60 220<br />

Dimensions (W x H x D) 1,7 x 2,4 x 1,1 m 4,0 x 2,6 x 1,25 m<br />

Machinery weight 800 kg 1.680 kg<br />

Electricity supply 230 V, 1 ph / 400 V, 3 ph 400 V, 3 ph<br />

Bale weight up to 60 kg up to 250 kg<br />

Bale dimensions 0,7 x 0,5 x 0,7 m 1,1 x 0,7 x 0,7 m<br />

MK 1100<br />

Additional chamber Interior of pressing<br />

chamber<br />

Filled pressing chamber<br />

Technical modifications reserved. Bale dimensions and weights depend on material. Version 03/2012.<br />

Extras of the MK 1100: The pressing plate guiding system<br />

TopPlus ® stabilizes the pressing plate during the pressing<br />

procedure and increases the service life of the components,<br />

while the hydraulic bale ejector BaleMatic ® ensures comfortable<br />

bale discharge.<br />

Multi-chamber <strong>baling</strong> press with 3 chambers

Direct marketing: Manual <strong>baling</strong> <strong>presses</strong><br />

„Direct marketing“ signifies: the bales have the right size and<br />

weight such that they can be directly sold to paper mills and<br />

recycling companies. If customers do not have any „directly<br />

marketable“ bales available, they will first have to have such<br />

bales pressed into the „directly marketable“ form by a waste<br />

disposal company. Only then can the bales be sold to paper<br />

mills or recycling companies.<br />

That means that the customer has to bear additional costs<br />

for pressing the bales into another form and for transport.<br />

The directly marketable bales save these costs and achieve<br />

higher proceeds.<br />

Baling twine and wire Easy bale ejection<br />

Incorp. twine drawing hooks<br />

Film in chamber<br />

Direct marketing: Manual <strong>baling</strong> <strong>presses</strong><br />

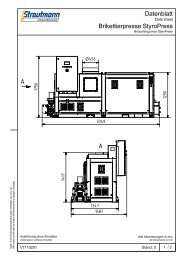

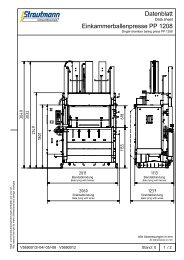

PP 1208 / PP 1208 Plus70<br />

The power packs<br />

The <strong>baling</strong> <strong>presses</strong> PP 1208 and PP 1208 Plus70 are the power<br />

packs among the large single-chamber <strong>baling</strong> <strong>presses</strong>. Large<br />

cardboard packagings and films or film bags can be easily<br />

thrown into the large feed opening. Due to the Quick-Door ®<br />

swing door, the pressing chamber is quickly and safely filled<br />

in a space-saving manner. With bale weights of up to 550 kg<br />

the bales can be directly sold to paper mills. The hydraulic<br />

bale ejector BaleMatic ® The <strong>baling</strong> <strong>presses</strong> PP 1208 and PP 1208<br />

easily ejects the bale and creates<br />

high operating convenience.<br />

Plus70 are the power<br />

packs among the large single-chamber <strong>baling</strong> <strong>presses</strong>. Large<br />

cardboard packagings and films or film bags can be easily<br />

thrown into the large feed opening. Due to the Quick-Door ®<br />

swing door, the pressing chamber is quickly and safely filled<br />

in a space-saving manner. With bale weights of up to 550 kg<br />

the bales can be directly sold to paper mills. The hydraulic<br />

bale ejector BaleMatic ® easily ejects the bale and creates<br />

high operating convenience.<br />

The pressing plate guiding system TopPlus ® The pressing plate guiding system TopPlus increases the<br />

service life of the <strong>baling</strong> <strong>presses</strong> and the retainer elements<br />

and holding-down devices reduce the reexpansion of the material<br />

after the pressing procedure, thus ensuring highest bale<br />

densities. The bales can be tied up by means of tape or wire.<br />

® increases the<br />

service life of the <strong>baling</strong> <strong>presses</strong> and the retainer elements<br />

and holding-down devices reduce the reexpansion of the material<br />

after the pressing procedure, thus ensuring highest bale<br />

densities. The bales can be tied up by means of tape or wire.<br />

Ergonomic doorlock<br />

handwheel<br />

Hydraulic doorlock<br />

Plus 70<br />

PP 1208 PP 1208<br />

Pressing force in kN 580 700<br />

Dimensions (W x H x D) 2,2 x 3,1 x 1,4 m 2,1 x 3,1 x 1,4 m<br />

Machinery weight 2.600 kg 2.800 kg<br />

Electricity supply 400 V, 3 ph 400 V, 3 ph<br />

Bale weight up to 400 kg up to 550 kg<br />

Bale dimensions 1,2 x 0,8 x 1,1 m 1,2 x 0,8 x 0,8 - 1,2 m<br />

www.strautmann-umwelt.com

Direct marketing: Automatic <strong>baling</strong> <strong>presses</strong><br />

AutoLoadBaler<br />

The AutoLoadBaler compacts cardboard packaging into<br />

directly marketable bales (industrial bales).<br />

The cardboard packaging can be collected in the salesroom,<br />

storeroom, production area, etc. by means of the collection<br />

cart. The cart is then pushed in at the side of the press and<br />

the bottom of the collection cart is moved upwards. Rotors<br />

convey the material into the pressing chamber where it is<br />

then pressed with a pressing weight of up to 53 tons.<br />

No pre-shredding of the cardboard packaging required,<br />

automatic filling and start of the pressing procedure. There is<br />

no waiting time for the staff, a second cart can be filled at any<br />

time.<br />

Insertion of cart Space-saving sliding door Operational principle AutoLoadBaler<br />

AutoLoadBaler<br />

Pressing force in kN 530<br />

Dimensions (W x H x D) 2,1 x 3,1 x 2,3 m<br />

Machinery weight 3.400 kg<br />

Electricity supply 400 V, 3 ph<br />

Bale weight up to 400 kg<br />

Bale dimensions 1,2 x 0,95 x 0,8 m<br />

AutoLoadBaler ready<br />

More time available for your core business - less time required for disposal<br />

Technical modifications reserved. Bale dimensions and weights depend on material. Version 03/2012.<br />

Our customers are also offered the option to purchase the<br />

AutoLoadBaler ready - without the collection cart assembly.<br />

The AutoLoadBaler ready is then equipped with an interface<br />

where the collection cart assembly can be subsequently<br />

mounted.<br />

Automatic filling Higher sales proceeds

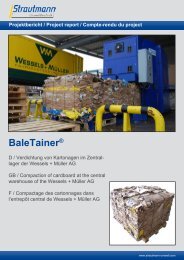

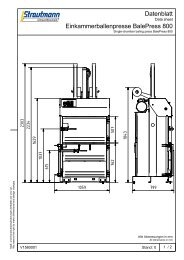

BaleTainer ®<br />

A new dimension for large-scale use<br />

The BaleTainer ® is a fully automatic <strong>baling</strong> press for the<br />

compaction of paper, cardboard packaging, film and empty<br />

PET bottles and easily handles large quantities of waste.<br />

The innovative BaleTainer ® takes you to the next dimension<br />

of disposal technology: Due to the large feed opening, large<br />

quantities of PET bottles and large cardboard packagings<br />

such as octabins and cardboard pallets can be easily thrown<br />

in without pre-shredding.<br />

Filling can be carried out manually, by means of a lift truck<br />

or via a conveyor belt. The bale is compacted according to<br />

the segmental principle. As soon as a segment has been finished,<br />

it is pushed out of the pressing chamber into the bale<br />

channel. After the third or fourth segment, the bale is fully<br />

automatically tied up by means of wire. The finished bales<br />

are discharged fully automatically.<br />

Direct marketing: Automatic <strong>baling</strong> <strong>presses</strong><br />

Ramp filling Manual filling Interior of swing hopper Bales - PET and cardboard<br />

packaging<br />

Operational principle BaleTainer ®<br />

The bales in industrial format offer all prerequisites for direct<br />

marketing. At 24 t, truck and sea containers are filled to their<br />

full capacity.<br />

Apart from the fully automatic filling of the pressing chamber,<br />

wire setting and bale discharge are also done fully automatically,<br />

thus saving manpower and working hours!<br />

Furthermore, due to the new pressing concept of the <strong>baling</strong><br />

press, less pressure force, less energy and less space are<br />

required.<br />

The BaleTainer ® is also available as a semiautomatic machine.<br />

In this case, the bale is manually tied up by means of<br />

wire.<br />

BaleTainer ®<br />

Pressing force in kN 600<br />

Dimensions (W x H x D) 1,85 x 2,8 x 6,5 m<br />

Machinery weight 6.000 - 8.000 kg<br />

Electricity supply 400 V, 3 ph<br />

Bale weight up to 400 kg (3 slices)<br />

Bale dimensions 1,1 x 1,1 x 0,8 m (with 3 slices)<br />

www.strautmann-umwelt.com

Further possible valuable substances<br />

Drums Beverage cans<br />

TetraPak ® EPS (Styropor ® )<br />

Electronic scrap Foam<br />

We will be pleased to give you individual advice free of<br />

charge with regard to your material and your disposal situation.<br />

<strong>Strautmann</strong> <strong>Umwelttechnik</strong> GmbH | 49219 Glandorf | Germany | Tel. +49 (0) 5426 80777-0 | www.strautmann-umwelt.com