Dock Levellers

Dock Levellers

Dock Levellers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Dock</strong> <strong>Levellers</strong><br />

Technical Details<br />

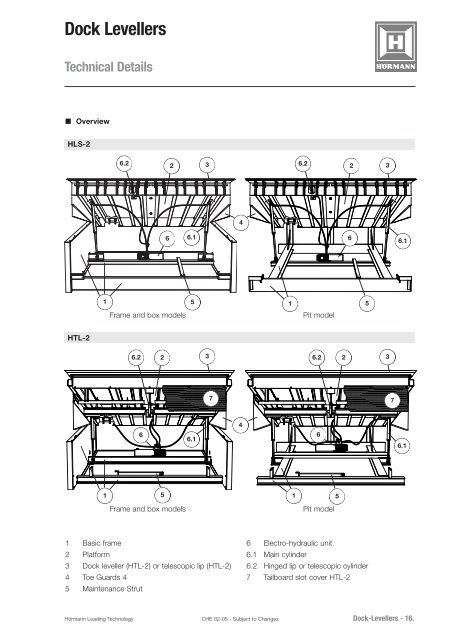

■ Overview<br />

HLS-2<br />

HTL-2<br />

1<br />

1<br />

6.2<br />

Frame and box models<br />

6.2<br />

6<br />

Frame and box models<br />

6<br />

2<br />

6.1<br />

1 Basic frame<br />

2 Platform<br />

3 <strong>Dock</strong> leveller (HTL-2) or telescopic lip (HTL-2)<br />

4 Toe Guards 4<br />

5 Maintenance Strut<br />

2<br />

5<br />

5<br />

6.1<br />

3<br />

3<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong> <strong>Levellers</strong> - 16<br />

4<br />

4<br />

6.2<br />

1 5<br />

Pit model<br />

6.2<br />

6<br />

1 5<br />

Pit model<br />

2 3<br />

6<br />

2 3<br />

7 7<br />

6 Electro-hydraulic unit<br />

6.1 Main cylinder<br />

6.2 Hinged lip or telescopic cylinder<br />

7 Tailboard slot cover HTL-2<br />

6.1<br />

6.1<br />

<strong>Dock</strong>-<strong>Levellers</strong> - 16.

<strong>Dock</strong> <strong>Levellers</strong><br />

Technical Details<br />

■ Basic Frame<br />

Self-supporting steel frame, welded with<br />

reinforcement profiles for the 2 main cylinders,<br />

matched to the respective load capacity.<br />

Calculation according to the Finite Element Method.<br />

Further execution dependent on the model:<br />

Frame and box models fitted with edge angles,<br />

closed at the sides, on box model also at the back.<br />

FR and box model with side adjustment angles<br />

and anchors all round, FA model with anchors at<br />

back only.<br />

■ Platform<br />

Profiled, slip-resistant steel (chequer plate), S 235 JR,<br />

standard material thickness 6/8 mm with<br />

reinforcement profiles S 355 JO. If required,<br />

e.g. when forklift trucks with PU tyres are involved,<br />

also available with 8/10 cm thick chequer plate.<br />

The construction conforms to EN 1398,<br />

being designed for handling equipment with<br />

a load on 1 axle over 2 contact surfaces,<br />

150 x 150 mm, at a distance of 1 m apart.<br />

Smaller contact surfaces, for example,<br />

as presented by so called reach trucks with<br />

hard PU tyres exert increased pressure on<br />

the platform which can cause permanent<br />

damage (deformation) to the platform<br />

surface.<br />

■ Hinges<br />

At the front end: 2 hinge axles, Ø 28 mm<br />

At the back end: 3 hinge axles in sockets<br />

Ø 60.3 x 14.2 mm.<br />

■ Safety marking<br />

Yellow/black markings applied to the lateral edge<br />

of the platform and the inside of the basic frame<br />

clearly show when the dock leveller has travelled<br />

up or down.<br />

■ Hinged lip / telescopic lip<br />

Made of profile, slip-resistant steel,<br />

Material S 355 JO, in a standard thickness of<br />

12/14 mm. The slightly inclined lip provides a good<br />

area of support when loading above the horizontal,<br />

thereby avoiding a "level crossing effect".<br />

Type R - straight: standard<br />

version for dock levellers up<br />

to 2000 mm wide<br />

Type S - tapered: standard<br />

version for dock levellers<br />

from 2100 mm wide<br />

Type SG - with separate<br />

segments: optional<br />

Hinged lip<br />

405 mm long, with open,<br />

self-cleaning<br />

orthotropically designed<br />

lip hinge, i.e. with<br />

150 mm long specially<br />

arranged supporting hinge<br />

strips (S355 JO).<br />

In the home position the<br />

hinged lip engages<br />

behind a locking device<br />

which also prevents<br />

intruders from using<br />

the dock leveller to gain<br />

access.<br />

Telescopic lip<br />

Reach 500 or 1000 mm long (short designation<br />

corresponding to HTL-2-5 or -10)<br />

The telescopic lip is guided by trapezoidal tubular<br />

profiles underneath the platform.<br />

The complete telescopic lip has a length of twice<br />

the reach + 350 mm. For this reason a 2 m long<br />

dock leveller HTL-2 with a reach of 1000 mm<br />

cannot be supplied.<br />

<strong>Dock</strong>-<strong>Levellers</strong> - 17.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong> <strong>Levellers</strong> - 17

<strong>Dock</strong> <strong>Levellers</strong><br />

Technical Details<br />

■ Toe guards<br />

Made of galvanized steel, telescopic.<br />

Toe guards prevent feet from getting trapped<br />

between the loading platform and the dock leveller.<br />

■ Maintenance strut<br />

Made of galvanized steel.<br />

The maintenance strut serves to secure and<br />

support the platform during maintenance<br />

checks and repairs.<br />

■ Front cover<br />

Hörmann HTL-2 dock levellers are supplied with<br />

a front cover in black flap material as a standard<br />

feature.<br />

■ Surface<br />

The steel surfaces are sand-blasted or stained<br />

and coated with a two-component PU paint,<br />

in a choice of traffic black (RAL 9017) or ultramarine<br />

blue (RAL 5002).<br />

On request, a galvanized version or one coated in<br />

a chosen colour to RAL is also possible.<br />

■ Electro-hydraulic unit<br />

Hörmann dock levellers feature an electro-hydraulic<br />

unit with 2 main cylinders which move the platform<br />

and a further cylinder for the hinged or telescopic<br />

lip. The main cylinders are attached to the left and<br />

right near the outer edge, whereby in the event of<br />

an emergency STOP any deforming can be<br />

counteracted as far as possible to do so.<br />

Power rating: 400 V / 50 Hz<br />

Motor output: 1.1 kW<br />

Safety elements: electronic emergency STOP<br />

valve, hose break valves,<br />

thermal and short-circuit fuse,<br />

restart lock following a power<br />

failure or emergency STOP<br />

■ Controls - from June 2005!<br />

Depending on requirements, Hörmann dock<br />

levellers can be equipped with<br />

- basic controls 420S/420T or<br />

- multiple controls 445S/445T or 460S/460T.<br />

All the controls are ideal for combining with<br />

Hörmann door controls:<br />

For the control of the dock door and dock<br />

leveller only 1 feeder cable is required!<br />

Housing identical in appearance and<br />

dimensions<br />

Uniform easy-to-follow menu prompting<br />

Same control for three-phase current and<br />

alternating current<br />

Same comprehensive accessories,<br />

e.g. signal lights, photocells<br />

All the dock leveller controls offer the option of<br />

mutual safeguarding of the dock door and dock<br />

leveller to prevent damage. For this, see section<br />

"<strong>Dock</strong> Leveller and <strong>Dock</strong> Door".<br />

The functions and options of the various controls<br />

are listed in the following overview as well as<br />

described in detail in the corresponding instructions.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong>-<strong>Levellers</strong> <strong>Dock</strong> <strong>Levellers</strong> - 18.<br />

18

<strong>Dock</strong> <strong>Levellers</strong><br />

Technical Details<br />

Overview of Basic controls Multiple controls<br />

4xxS: controls for HLS-2<br />

4xxT: controls for HLS-2<br />

1) Connection kit required<br />

420 S 420 T 445 S 445 T 460 S 460 T<br />

Separate control unit housing ✗ ✗ ✗ ✗ ✗ ✗<br />

Protection category IP 65 ✗ ✗ ✗ ✗ ✗ ✗<br />

Mains supply 400V / 230 V ✗ ✗ ✗ ✗ ✗ ✗<br />

Main switch / emergency-STOP switch ✗ ✗ ✗ ✗ ✗ ✗<br />

Membrane keypad integrated into<br />

the housing cover ✗ ✗ ✗ ✗ ✗ ✗<br />

Can be combined<br />

with Hörmann controls ✗ ✗ ✗ ✗ ✗ ✗<br />

Prepared for dock leveller<br />

release function ✗ ✗ ✗ ✗ ✗ ✗<br />

Prepared for door<br />

release function ✗ ✗ ✗ ✗<br />

Menu readout and programming<br />

via double 7 segment display ✗ ✗ ✗ ✗<br />

Service menu with maintenance<br />

cycles and operating hours counter<br />

as well as error analysis ✗ ✗ ✗ ✗<br />

Power-ON and error/malfunction<br />

display includes readout<br />

of last 5 error messages ✗ ✗ ✗ ✗<br />

Connection option<br />

for wheel chock with sensor ✗ ✗ ✗ ✗ ✗ ✗<br />

Connection option for proximity switch 1) 1) ✗ ✗ ✗ ✗<br />

Connection option for signal lights<br />

system, photocell, registering<br />

driver's arrival etc. ✗ ✗ ✗ ✗<br />

Option for control of an inflatable<br />

dock shelter/seal with or<br />

without roll-down flap. ✗ ✗<br />

Semi-automatic operation:<br />

door closes when the dock leveller<br />

is in the home position ✗ ✗<br />

<strong>Dock</strong>-<strong>Levellers</strong> - 19.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong> <strong>Levellers</strong> - 19

<strong>Dock</strong> <strong>Levellers</strong><br />

Technical Details<br />

■ Load capacity/rated load<br />

As standard 60 kN to EN 1398.<br />

Higher load capacities (for HLS-2 to180 kN,<br />

for HTL-2 to 150 kN) optional.<br />

The required load capacity is determined by the<br />

overall weight of<br />

• the handling equipment<br />

• the payload<br />

• the auxiliary devices used<br />

Never be tempted to take into<br />

account the supposed "actual"<br />

loading weight instead of the<br />

maximum load capacity of the forklift truck!<br />

We know from experience that the maximum load<br />

capacity of the forklift truck is always used to the full.<br />

Despite the short-term advantages when ordering<br />

a standard dock leveller, an undersized product will in<br />

the long term inevitably lead to complaints as a result<br />

of overloading.<br />

In addition to that, the type and quality of the<br />

forklift truck tyres is also a key factor.<br />

By way of comparison:<br />

In accordance with the European Standard 1398,<br />

the rated load stated on the type plate is based on<br />

handling equipment with<br />

- a load on one axle<br />

- 2 contact areas 150 x 150 mm<br />

- a distance of 1 m.<br />

These trucks have pneumatic tyres or “superelastic<br />

tyres”.<br />

Other, hard (PU) tyres, e.g. in Vulkollan, have<br />

smaller contact surfaces and therefore apply greater<br />

pressure to the platform. As a result, given the<br />

corresponding overall weight, this can cause the<br />

chequer plate of the dock leveller to deform. Such<br />

tyres are used, for e.g., on so called reach trucks.<br />

It should be made known in advance if forklift<br />

trucks with harder tyres are to be used.<br />

In such cases it may be necessary to choose a<br />

stronger platform or a dock leveller with a higher<br />

load capacity.<br />

Type Forklift truck Powered high-lift truck Reach truck<br />

with tandem rollers with single rollers<br />

Tyres inflated/ PU/ Vulkollan PU/ Vulkollan PU/ Vulkollan<br />

Super-elastic<br />

• Rated load 60 kN<br />

Permissible total weight* (dock leveller in operating position)<br />

Chequer plate 6/8 6t 5t 4t 3t<br />

Chequer plate 8/10 6t 6t 5t 5t<br />

• Rated load 90 kN<br />

Chequer plate 8/10 9t 6t 5t 5t<br />

* Note: When exceeded, there is a risk of tyre tracks. The rated load is not affected.<br />

<strong>Dock</strong>-<strong>Levellers</strong> - 20.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong> <strong>Levellers</strong> - 20

<strong>Dock</strong> <strong>Levellers</strong><br />

Technical Details<br />

■ Further technical features<br />

Height compensation<br />

DIN EN 1398 a well as ZH 1/156 permit a<br />

maximum gradient of 12.5%.<br />

Torsional flexibility / twist capability<br />

Thanks to precisely dimensioned profiles on the<br />

bottom platform edge and double cylinder<br />

hydraulics a high degree of twist can be achieved<br />

without impairing the stability.<br />

Temperature<br />

The dock leveller and the hydraulic oil used as<br />

standard are suitable for temperatures ranging<br />

between approx. –15°C and +50°C. In the case of<br />

lower temperatures, adjustments are necessary,<br />

above all it is important to use another type of oil.<br />

In doing so, bear in mind the effect of wind.<br />

Weights<br />

The weights of the dock leveller, depending on<br />

the type, installation model and size, are listed in<br />

the tables of the following drawings:<br />

V3042 HLS… Dimensions and Weights HLS-2<br />

V3042 HTL… Dimensions and Weights HTL-2<br />

■ Optional extras<br />

Weather seals<br />

A weather seal can be attached to the outside of<br />

the platform to prevent drafts entering the building<br />

through the gap between the base frame/pit and<br />

the platform.<br />

Anti-slip coating<br />

In certain circumstances, such as in meat<br />

processing, it may be necessary to provide<br />

special anti-slip protection.<br />

For this purpose, a special anti-slip coating is<br />

available which is applied to the platform.<br />

Made up of a two-component epoxy resin, it is<br />

particularly hard-wearing and chemically resistant<br />

which, in respect of goods traffic, is exactly what<br />

is called for.<br />

Note: on a galvanized surface the anti-slip coating<br />

does not adhere particularly well.<br />

In such cases, the surface must be pretreated.<br />

Thermal insulation<br />

Hinged lip dock levellers can be supplied with<br />

a 30 mm thick insulation layer underneath the<br />

platform. Providing thermal insulation for telescopic<br />

dock levellers is not quite so straightforward, so<br />

a specific enquiry must be made to establish the<br />

feasibility and costs.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong>-<strong>Levellers</strong> <strong>Dock</strong> <strong>Levellers</strong> - 21.<br />

21

<strong>Dock</strong> <strong>Levellers</strong><br />

<strong>Dock</strong> Leveller and Door<br />

■ Interlocking of door/dock leveller<br />

ALWAYS NECESSARY: Prevent the dock leveller<br />

being raised when the door is closed.<br />

Otherwise in the case of a manually operated door,<br />

the latching will be excessively strained or damaged.<br />

With a closed power-operated door, the operator<br />

would block the spring axle.<br />

The rise of the dock leveller could cause the cables<br />

to fall from the cable drum.<br />

On a door with door security kit, this would be<br />

considerably strained or damaged.<br />

Solution: the dock leveller<br />

release function<br />

The door's end-of-travel signalling<br />

ensures that the dock leveller<br />

cannot be operated when the<br />

door is closed.<br />

An additional PCB is required for<br />

the door controls.<br />

The dock leveller controls are<br />

already prepared for this function.<br />

Drawback: if the motor fails, no signal is issued<br />

and the dock leveller cannot be operated.<br />

The alternative would be to install a proximity<br />

switch in the door's clear opening. This would then<br />

guarantee release even without function of the<br />

controls and on manually operated doors.<br />

On manually operated doors a fuse-disconnecting<br />

switch can also be installed on the door. Careful<br />

consideration must, however, be given to where<br />

this will be positioned, e.g. on the shoot bolt or at<br />

the top.<br />

If it is installed at the very top of the door and the<br />

door travels back a short distance once having<br />

reached the end-of-travel position, it is possible that<br />

the switch will switch back on again unintentionally,<br />

thus preventing operation of the dock leveller.<br />

If it is installed lower down, there is a risk that forklift<br />

trucks will drive into a door that has not fully opened.<br />

OPTIONAL: Preventing the door from closing<br />

while the dock leveller is still in a working<br />

position.<br />

Depending on the site conditions, it can prove<br />

practical to fit a device to ensure that the door<br />

does not close until the dock leveller is in the home<br />

position.<br />

If, for e.g., the door is closed by central or remote<br />

control while loading is still taking place, there is a<br />

risk that the door will sustain collision damage.<br />

Solution: door release function<br />

This ensures that the door can<br />

only be closed when the dock<br />

leveller is in the home position.<br />

For this, a proximity switch is<br />

attached to the dock leveller.<br />

The door controls are not<br />

released until this has been<br />

activated.<br />

Hörmann multiple controls are<br />

already prepared for this door release function.<br />

Basic controls require a connection kit in order to<br />

allow connection of the proximity switch.<br />

This function is also necessary together with<br />

semi-automatic operation. With multiple controls<br />

using semi-automatic operation the door closes<br />

automatically following clearance of the dock<br />

leveller.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong>-<strong>Levellers</strong> <strong>Dock</strong> <strong>Levellers</strong> - 22.<br />

22

<strong>Dock</strong> <strong>Levellers</strong><br />

Particular Benefits<br />

■ TÜV-tested safety<br />

■ 28 standard sizes: 4 widths, 7 lengths<br />

■ As standard load capacity up to 60 kN<br />

■ Installation models for any situation: frame, box and pit model,<br />

renovation adapters for different pit sizes<br />

■ Extremely large working range above and below the horizontal<br />

■ Extended loading surface thanks to the inclination of the lip<br />

■ Open, self-cleaning lip hinge on HLS-2<br />

■ Long hinged lip on HLS-2, 405 mm<br />

■ HTL-2 telescopic lip supports with 132 mm high trapezoidal sections<br />

■ High-grade selection of materials and dimensioning on all hinges<br />

■ Effective telescopic toe guards<br />

■ Electric motor precabled and connected to the dock leveller<br />

■ Can be combined with door controls<br />

■ Door and dock leveller with mutual safeguard<br />

■ Expert testing and maintenance for the complete loading station<br />

including dock shelters/seals and doors possible<br />

<strong>Dock</strong>-<strong>Levellers</strong> - 23.<br />

Änderungen vorbehalten CHE 02-05 23

<strong>Dock</strong> <strong>Levellers</strong><br />

Special Solutions<br />

■ Hörmann DOBO System: first dock, then open the doors<br />

The Difference<br />

In contrast to conventional loading situations,<br />

with the DOBO system the lorry can dock while<br />

the doors are still closed. The doors can be<br />

opened after the vehicle has docked.<br />

Field of Application<br />

The DOBO System is the ideal solution<br />

- for the absolutely hygienic transportation of fish,<br />

meat and other chilled goods.<br />

- for customs purposes in those situations where<br />

the doors must remain closed until the customs<br />

officers arrive.<br />

- to prevent pilfering.<br />

In detail<br />

The Hörmann DOBO System (docking before<br />

opening) provides a cavity on the left and right of<br />

the dock leveller (pit model) for parking the lorry<br />

doors.<br />

When in the home position, the dock leveller is<br />

already at its lowest position below the horizontal<br />

plane. In this way the doors can be opened<br />

unimpeded.<br />

Hörmann dock levellers of the HLS-2 type with<br />

hinged lip are specifically modified for this purpose.<br />

For HTL-2 dock levellers with a telescopic lip no<br />

changes to the structural design are required.<br />

Combining the DOBO System with a loading<br />

house is recommended. The building itself then<br />

stays as it is - no structural alterations are<br />

necessary.<br />

Drawing<br />

405002 Pit dimensions for pit model<br />

“P” for the DOBO System<br />

<strong>Dock</strong>-<strong>Levellers</strong> - 24.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong> <strong>Levellers</strong> - 25

<strong>Dock</strong> <strong>Levellers</strong><br />

Special Solutions<br />

■ Hörmann <strong>Dock</strong> Leveller HTLV-2<br />

With multifunctional three-segment telescopic lip for lorries and delivery vans<br />

With HTLV-2 type dock levellers you have the<br />

choice: the three-segment telescopic lip can be<br />

extended to cover the entire width or simply<br />

switched over to allow use of the 1 metre wide<br />

middle section only.<br />

In a delivery van situation, the weight is compensated<br />

over the 1000 mm wide telescopic lip via an<br />

ingenious hydraulic system (patent pending).<br />

As a result, there is no overloading of the delivery<br />

van due to the combined weight on the dock<br />

leveller of the handling equipment and load.<br />

In a lorry situation, the 500 mm long<br />

three-segment telescopic lip can be infinitely<br />

extended over its full width (2000 mm).<br />

The dock leveller can now bear a dynamic load of<br />

up to 60 kN.<br />

The platform of the dock leveller therefore becomes<br />

a multifunctional loading station!<br />

Since the deck of the delivery van is lower than<br />

that of a lorry, the HTLV-2 dock leveller has a larger<br />

working area below the horizontal than conventional<br />

dock levellers. This is achieved by dispensing with<br />

the usual front girder with supporting members.<br />

Instead, 2 hydraulically controlled bolts at the sides<br />

support the platform in the home position.<br />

<strong>Dock</strong> <strong>Levellers</strong> of the HTLV-2 type are available as<br />

frame or box models.<br />

Dimensions and working range:<br />

Ordering size: 2000 x 3000 mm<br />

Overall height: 795 mm<br />

Width of<br />

telescopic lip: 2000: 500/1000/500 mm<br />

Working range: 565 mm below the horizontal,<br />

465 mm above the horizontal<br />

Rated load: 60 kN lorry<br />

20 kN delivery van<br />

<strong>Dock</strong>-<strong>Levellers</strong> - 25.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong> <strong>Levellers</strong> - 26

<strong>Dock</strong> <strong>Levellers</strong><br />

Special Solutions<br />

■ Hörmann <strong>Dock</strong> Leveller HTLP-2<br />

With parallel connection to lorries for forklift trucks and stacker lift trucks<br />

A reliable system<br />

With the HTLP-2 dock leveller, the transport vehicle<br />

always stands horizontal throughout the loading<br />

process.<br />

Thanks to the parallel guidance in the front section of<br />

the dock leveller, you can load high goods into the<br />

lorry using a forklift truck as well as access the very<br />

last pallet using a simple stacker lift truck.<br />

The 500 mm long telescopic lip with 2 separate<br />

slide-in segments is infinitely extendable, so precise<br />

positioning is guaranteed.<br />

The self-supporting base frame, the chequer-plated<br />

platform with a high degree of twist, 2 main cylinders<br />

with automatic emergency-STOP valves plus simple<br />

operation make loading a safe and straightforward<br />

procedure.<br />

Installation methods<br />

HTLP-2 dock levellers are available as a frame<br />

model, i.e. with self-supporting frame, or as a box<br />

model for particularly quick and straightforward<br />

installation.<br />

Dimensions and levelling:<br />

Ordering size: 2400 x 4700 mm<br />

Parallel section: 1200 mm<br />

Length of gradient: 3500 mm<br />

Overall height: 900 mm<br />

Length of<br />

telescopic lip: 500 mm<br />

Levelling: 440 mm below the horizontal<br />

400 mm above the horizontal<br />

Rated load: 60 kN<br />

<strong>Dock</strong>-<strong>Levellers</strong> - 26.<br />

Hörmann Loading Technology CHE 02-05 - Subject to Changes <strong>Dock</strong> <strong>Levellers</strong> - 27