'DAF, a World of Applications' - Daf.com

'DAF, a World of Applications' - Daf.com

'DAF, a World of Applications' - Daf.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DAF in action<br />

Magazine <strong>of</strong> DAF Trucks N.V. September 2010<br />

DAF LF Hybrid<br />

in production<br />

by the end <strong>of</strong> 2010<br />

DAF Trucks at IAA 2010 in Hanover:<br />

‘DAF, a <strong>World</strong> <strong>of</strong> Applications’

www.zf.<strong>com</strong><br />

ZF technology –<br />

the intelligent choice.<br />

Automatically safer<br />

with AS-Tronic.<br />

For heavy long-distance transport, distribution traffi c, or special vehicles – trucks safely drive<br />

ahead <strong>of</strong> the pack with the N° 1 automatic transmission. The DAF AS-Tronic helps drivers bring<br />

their cargo safely to their destination, as it takes the stress <strong>of</strong>f the driver, enabling him to<br />

concentrate on the road. DAF AS-Tronic. Safe to say it’s N° 1<br />

Driveline and Chassis Technology<br />

ZF AST08-16 KE-COMMUNICATION

DAF in action<br />

In this issue<br />

DW14249303<br />

4. DAF in the news<br />

6. DAF Trucks at IAA 2010<br />

in Hanover: DAF, a <strong>World</strong> <strong>of</strong><br />

Applications<br />

10. DAF LF Hybrid in production<br />

by the end <strong>of</strong> 2010:<br />

‘Green in distribution’<br />

12. Harrie Schippers, President <strong>of</strong><br />

DAF Trucks N.V.: “Getting close<br />

to the customer is our greatest<br />

strength"<br />

16. Thick-skinned creatures<br />

in Europe<br />

19. Elst Transport pleased with<br />

DAF and Saxas<br />

20. Goodyear's ‘Mission<br />

Impossible’<br />

22. Meiller cooperates closely<br />

with the truck industry<br />

24. Municipality <strong>of</strong> Bottrop<br />

collects 800 tonnes <strong>of</strong><br />

household waste each week<br />

27. Hubert Knümann sen.<br />

Container Service in Bottrop,<br />

Germany<br />

Colophon<br />

DAF in action is a publication<br />

<strong>of</strong> DAF Trucks N.V.<br />

Edited by: Corporate Communications<br />

department<br />

P.O. Box 90065, 5600 PT Eindhoven,<br />

the Netherlands<br />

www.daf.<strong>com</strong><br />

Design and printing: GPB bv, Leiderdorp<br />

The power<br />

<strong>of</strong> an organisation<br />

In less than 8 years, DAF Trucks has grown from being one <strong>of</strong> the smallest truck<br />

producers in Europe to one <strong>of</strong> the largest. Last year, DAF reached the number one<br />

position in the tractor segment. That position has been further strengthened over<br />

the first six months <strong>of</strong> this year.<br />

In the 15 tonnes plus segment (the largest market segment in Europe) DAF is<br />

market leader in many countries including the UK, the Netherlands, Belgium, the<br />

Czech Republic, Poland, Romania and Hungary. In Germany we are the top<br />

imported truck brand and in many other European countries we have significantly<br />

improved our position in recent years. Indeed, we are <strong>of</strong>ten asked what this<br />

enormous success is down to.<br />

The principal reason, <strong>of</strong> course, is that we have a superb range <strong>of</strong> products that<br />

perfectly meet the needs <strong>of</strong> our customers. However, besides having excellent,<br />

reliable and efficient products, the success <strong>of</strong> DAF is also attributable to the<br />

efficient organisation behind the products. More than a thousand enthusiastic and<br />

pr<strong>of</strong>essional DAF dealers in Europe are on hand for our customers quite literally<br />

round the clock, giving sound advice before sales and optimal support once the<br />

truck is in service. DAF has consciously opted for a network <strong>of</strong> independent<br />

dealers. Apart from our three DAF-run dealer <strong>com</strong>panies, all DAF dealers are<br />

independent operators who are in touch with the market place and who do their<br />

utmost to keep their customers satisfied. DAF Trucks, PACCAR Parts and<br />

PACCAR Financial view their most important task as optimally supporting the<br />

dealers; so that—together with our dealers—we can be the best partner in the<br />

business. That is the power <strong>of</strong> DAF. That is the power <strong>of</strong> an organisation that<br />

has customer satisfaction as its most important starting point.<br />

Based on that philosophy and on our drive to provide customers with the best<br />

products and services, we will continue to build on our success in the years ahead.<br />

Not only in the tractor segment, where we are have already achieved a leading<br />

position, but also in the area <strong>of</strong> rigids and special vehicles. Because DAF also has<br />

much to <strong>of</strong>fer here: two, three and four axles, both single and double drive, in a<br />

wide range <strong>of</strong> different versions. We <strong>of</strong>fer efficient and durable transport solutions<br />

for a wide variety <strong>of</strong> transport segments. Together with partners from the superstructure<br />

industry, we will be presenting a number <strong>of</strong> different products at the<br />

IAA 2010 with the slogan: DAF, a <strong>World</strong> <strong>of</strong> Applications. Because the leader in<br />

tractors has more to <strong>of</strong>fer!<br />

Ron Bonsen<br />

Board <strong>of</strong> Management<br />

Marketing & Sales<br />

3 DAF IN ACTION

DAF in the news<br />

LF best imported<br />

7.5 tonner in Germany<br />

The DAF LF was recently named the ‘Best 7.5 tonner’ for<br />

trucks imported into Germany. The award was received by<br />

Hans Posthumus, Marketing Manager at DAF Germany.<br />

During a major annual event in Stuttgart, ETM Verlag, the publisher<br />

<strong>of</strong> the German technical journals Lastauto Omnibus, Fernfahrer and<br />

Trans Aktuell, handed out a large number <strong>of</strong> awards in an equally<br />

impressive number <strong>of</strong> categories covering trucks, buses and delivery<br />

vehicles. What was unique here is that the award winners were<br />

chosen by the readers <strong>of</strong> the German technical journals, namely the<br />

users themselves. Almost 8000 readers took part in the survey.<br />

Hans Posthumus (left) received the award from Matthias Rathmann,<br />

Editor-in-Chief <strong>of</strong> Trans Aktuell.<br />

Abbey Road Tanks, which uses DAF CF85 vehicles,<br />

was named ‘UK Haulier <strong>of</strong> the Year’.<br />

D A F I N A C T I O N 4<br />

Leyland Trucks wins<br />

Manufacturing Excellence<br />

Award<br />

For the second year in a row, Leyland Trucks was recently<br />

awarded the title <strong>of</strong> overall winner <strong>of</strong> the ‘Manufacturing<br />

Excellence Awards’, or the MX Awards. The MX Awards are an<br />

initiative by the leading association <strong>of</strong> mechanical engineers in<br />

the United Kingdom: the 160-year-old 'Institution <strong>of</strong> Mechanical<br />

Engineers’ (IMechE).<br />

In the 28-year history <strong>of</strong> these awards, no organisation has ever won<br />

the prize two years in a row. In addition to the overall award, Leyland<br />

Trucks – which also produces the DAF LF – also won in the ‘Business<br />

Development and Change Management’ category.<br />

Leyland Trucks has won awards in individual categories in previous<br />

years. Last year – in addition to the overall award – the <strong>com</strong>pany won<br />

in the ‘Customer Focus’ category and in 2008 in the ‘Best Financial<br />

Management’ and ‘Logistics and Resource Efficiency’ categories<br />

DAF's CF85 once again named ‘Fleet Truck <strong>of</strong> the Year’<br />

During the presentation <strong>of</strong> the prestigious ‘Motor Transport<br />

Awards 2010’ in London, the DAF CF85 was hailed the ‘Fleet<br />

Truck <strong>of</strong> the Year’ for the third year running. The ‘Motor<br />

Transport Awards’ are organised by the British magazine<br />

‘Motor Transport’.<br />

Never before in the history <strong>of</strong> the ‘Motor Transport<br />

Awards’ has a truck been ‘Fleet Truck <strong>of</strong> the Year’<br />

three years in a row. It is also the tenth time that the<br />

DAF CF85 or one <strong>of</strong> its predecessors has won this<br />

award.<br />

The award was presented to Ray Ashworth,<br />

Managing Director <strong>of</strong> DAF Trucks UK. “We are proud that the<br />

DAF CF85 has won this major award”, says Ashworth.<br />

“Everybody in the transport sector and in our DAF team recognises<br />

the importance <strong>of</strong> this award, because it is the choice <strong>of</strong> the fleet<br />

owners themselves.”<br />

“The fact that we won in 2008, 2009 and 2010 – the three most<br />

challenging years in the entire history <strong>of</strong> the British transport<br />

sector – underlines the value <strong>of</strong> this award. The award emphasises<br />

the extremely low fuel consumption and overall efficiency <strong>of</strong> the<br />

CF85, in <strong>com</strong>bination with the excellent support <strong>of</strong> our extensive<br />

network <strong>of</strong> devoted dealers.”

Ron Bonsen, member <strong>of</strong> the Board <strong>of</strong> Management <strong>of</strong> DAF Trucks N.V.<br />

and responsible for marketing and sales, hands over a memento to<br />

Roger O’Callaghan, Chief Executive Officer <strong>of</strong> Babcock International Group -<br />

Africa Division, at the signing <strong>of</strong> the contract with Babcock International.<br />

New DAF distributor<br />

in South Africa<br />

DAF Trucks N.V. recently signed a contract with the Africa<br />

division <strong>of</strong> Babcock International Group covering marketing,<br />

sales and service activities for DAF trucks on the South African<br />

market. Babcock will also represent PACCAR Parts in order<br />

to guarantee first class availability <strong>of</strong> parts for DAF vehicles<br />

throughout South Africa.<br />

Babcock International Group PLC is one <strong>of</strong> the leading UK <strong>com</strong>panies<br />

in the field <strong>of</strong> technical services and provides services to many<br />

sectors <strong>of</strong> industry such as energy, defence, tele<strong>com</strong>munications,<br />

education and transport.<br />

Babcock will set up three new sites for the sale and maintenance<br />

<strong>of</strong> DAF trucks. The first will be in Johannesburg, followed by sites<br />

in Durban and Cape Town. Ten existing service dealers will also<br />

form part <strong>of</strong> the network. “Our goal is to achieve a market share<br />

<strong>of</strong> 10% in the heavy truck segment within five years”, says Roger<br />

O’Callaghan, Chief Executive Officer <strong>of</strong> Babcock International Group<br />

- Africa Division.<br />

Comet's LFs have a very streamlined superstructure, which reduces fuel costs<br />

by 12%. In addition, the unique shape <strong>of</strong> the bodywork helps to make the<br />

<strong>com</strong>pany more recognisable.<br />

CF85s for HOYER<br />

In mid June HOYER Netherlands took delivery <strong>of</strong> nineteen CF85<br />

tractors. This was a major order from one <strong>of</strong> Europe’s largest<br />

bulk and tank transporters in the chemical industry.<br />

Sixteen <strong>of</strong> the CFs are being used internationally from bases in<br />

the Netherlands, and three from bases in Belgium. Each truck has<br />

been supplied with a MultiSupport repair and maintenance contract<br />

and also a contract with PACCAR Financial Europe, both with a five<br />

year term. HOYER’s Fleet Manager, Wim van Halum, and Johan<br />

Witteveen, Corporate Center<br />

Procurement Manager, have clear<br />

opinions about why the decision<br />

was made to purchase DAF<br />

tractors: “Low costs per kilometre,<br />

reliability and driver <strong>com</strong>fort<br />

played a key role”, says Wim van<br />

Halum. “However, our excellent<br />

relationship with the dealer<br />

was also a factor”, adds Johan<br />

Witteveen. “Our site in Rotterdam<br />

has its own workshop where we<br />

carry out routine work, but we go<br />

to the dealer for the bigger jobs.<br />

And the dealer is always available<br />

to help us.”<br />

Johan Doensen from International Fleet Sales (left), hands over the keys to one<br />

<strong>of</strong> the 19 CFs to Fleet Manager Wim van Halum.<br />

Comet opts for partnership<br />

Comet, the British retailer <strong>of</strong> white goods and home appliances,<br />

delivers its products using a fleet <strong>of</strong> no fewer than 174 DAF LFs.<br />

These trucks travel back and forth between 260 shops, 14 distribution<br />

points, five regional distribution centres and naturally<br />

thousands <strong>of</strong> customers all over the United Kingdom every day.<br />

"For our fleet operations we always need to find a balance between<br />

good customer service, our responsibility for the environment and<br />

the safety <strong>of</strong> drivers and road-users", says Ian Markham <strong>of</strong> Comet.<br />

"At the same time we need to ensure maximum efficiency and<br />

minimum costs. Long-term business partnerships are therefore<br />

essential for us. We are keen to work with people who can effectively<br />

help us achieve our goals, regardless <strong>of</strong> whether this is reducing<br />

emissions, improving safety or lowering costs. DAF understands<br />

our market and contributes towards our success.”<br />

5 D A F I N A C T I O N

DAF Trucks at IAA 2010 in Hanover:<br />

‘DAF, a <strong>World</strong> <strong>of</strong> Applic<br />

Hanover. 23 to 30 September. IAA 2010. One <strong>of</strong> the most important truck and transport exhibitions in<br />

Europe. DAF Trucks – a PACCAR <strong>com</strong>pany – is exhibiting the 12-ton LF45 hybrid truck, which is going<br />

into production at the end <strong>of</strong> this year. The stand <strong>of</strong> the leading manufacturer <strong>of</strong> tractor units in the<br />

European Union also places a major focus on the wide range <strong>of</strong> rigids, with a tailor-made vehicle for<br />

every application. Also at the IAA, DAF will be presenting a special edition <strong>of</strong> the XF105 Super Space Cab:<br />

the Blue Edition. And what's more, in a first for the truck industry, DAF is supplying all <strong>of</strong> its engine<br />

variants in ultra-clean EEV versions.<br />

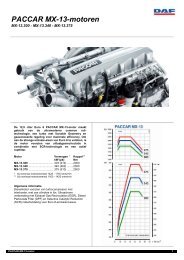

DAF is further expanding its leading position in<br />

the field <strong>of</strong> engine development by being the first<br />

truck manufacturer to <strong>of</strong>fer EEV versions <strong>of</strong> all <strong>of</strong><br />

its engine variants. Due to the optimisation <strong>of</strong> the<br />

engine management system, several versions <strong>of</strong><br />

the 12.9-litre PACCAR MX engine can now also<br />

<strong>com</strong>ply with the EEV standard without a soot<br />

particle filter.<br />

Even before this year is out DAF will <strong>com</strong>mence<br />

production <strong>of</strong> the DAF LF Hybrid, a 12-ton<br />

distribution truck with a parallel hybrid system.<br />

The system reduces fuel consumption and<br />

therefore CO2 emissions by between 10 and<br />

20%, depending on the application. DAF is one<br />

<strong>of</strong> the first European truck manufacturers to<br />

bring a hybrid truck into production.<br />

DAF IN ACTION 6<br />

Despite being the 'smallest' in terms <strong>of</strong><br />

volume <strong>of</strong> the seven truck producers in<br />

Europe as recently as less than ten years<br />

ago, with a market share <strong>of</strong> 16.3% for the<br />

first half <strong>of</strong> 2010 DAF has gained a very<br />

strong second position. DAF is the market<br />

leader in the Netherlands, Belgium, the<br />

UK, Poland, the Czech Republic, Romania<br />

and Hungary. In Germany – the largest<br />

truck market in Europe – DAF has further<br />

consolidated its position as the leading<br />

import brand with a market share <strong>of</strong> 12.1%.<br />

In the total European tractor segment<br />

(15 ton+) DAF has achieved a market share<br />

<strong>of</strong> more than 21% during the first six months<br />

<strong>of</strong> 2010, making the Dutch truck manufacturer<br />

the market leader within the European<br />

Union. Naturally the aim is to further reinforce<br />

this position, but further growth will also<br />

need to be achieved by the wide range <strong>of</strong><br />

2, 3 and 4-axled rigids with a tailor-made<br />

vehicle for every application. In order to<br />

underline this, a number <strong>of</strong> fully constructed<br />

vehicles are to be exhibited – in collaboration<br />

with leading partners from the body<br />

construction industry – on the DAF stand:<br />

a three-axle LF55 with Saxas bodywork<br />

for the drinks industry, a three-axle CF75<br />

refuse vehicle with HN Schörling bodywork,<br />

a two-axle CF65 with a cooling body by<br />

Schmitz Cargobull, a three-axle CF85 with<br />

VDL hook-arm system, a three-axle CF85<br />

with a container-loading system by Gergen,<br />

a four-axle CF85 with a Meiller tipper and a<br />

three-axle XF105 with the BDF bodywork<br />

which is very popular in Germany.<br />

LF Hybrid in production<br />

Even before this year is out DAF will<br />

<strong>com</strong>mence production <strong>of</strong> the DAF LF Hybrid,<br />

a 12-ton distribution truck with a parallel<br />

hybrid system. The <strong>com</strong>mencement <strong>of</strong><br />

production follows a very extensive field<br />

test, in which vehicles have been tested<br />

for two years in the most diverse practical<br />

applications in daily use with customers<br />

in both the UK and on the continent. The<br />

use <strong>of</strong> hybrid technology can reduce<br />

fuel consumption and therefore<br />

CO2 emissions by between<br />

10 and 20%, depending on<br />

the application. DAF is one <strong>of</strong><br />

the first European truck<br />

manufacturers to bring a<br />

hybrid truck into production.

ations’<br />

The DAF LF Hybrid uses a parallel diesel/<br />

electric hybrid system, in which the truck<br />

is driven by the diesel engine, the electric<br />

engine or a <strong>com</strong>bination <strong>of</strong> both. The truck<br />

is fitted with the 4.5-litre PACCAR FR diesel<br />

engine, which <strong>com</strong>plies with the ultra-low<br />

EEV emission requirements as standard,<br />

without a soot filter. In the LF Hybrid, this<br />

engine produces a maximum power <strong>of</strong><br />

118 kW/160 hp and is linked to an automated<br />

Eaton six-speed gearbox (Autoshift).<br />

An electric motor has been installed between<br />

the clutch and the gearbox, which can<br />

provide drive as well as functioning as a<br />

generator. Energy released during braking<br />

is stored in the lithium-ion batteries for<br />

re-use during acceleration. Depending on<br />

the degree <strong>of</strong> charge <strong>of</strong> the lithium-ion<br />

batteries, a central <strong>com</strong>puter determines<br />

when the diesel engine provides the drive<br />

and when and to what extent the electric<br />

engine is used.<br />

A first: all engine variants available in EEV<br />

In the spring <strong>of</strong> 2008, DAF was one <strong>of</strong> the<br />

first truck manufacturers able to supply<br />

EEV versions as an option for all its models<br />

(LF, CF and XF) and is now further extending<br />

its leading position in the field <strong>of</strong> engine<br />

development by being the first truck<br />

manufacturer to <strong>of</strong>fer EEV versions for all<br />

<strong>of</strong> its engine variants.<br />

XF105 Blue Edition<br />

Following on from the successful ‘White Edition’, the DAF stand will be displaying the XF105 Super Space Cab<br />

‘Blue Edition’ – a model that stands out due to its unique paint colour and extensive range <strong>of</strong> features. This<br />

XF105 ‘Blue Edition’ is available in a limited series, exclusively for the German market. The truck is powered<br />

by the 460 hp 12.9-litre PACCAR MX engine, linked to an automated AS-Tronic twelve-speed gearbox. The<br />

specification includes Skylights, Xenon lights, a full aerodynamics package, Alcoa aluminium rims and air<br />

horns. Exclusive features <strong>of</strong> the cab <strong>of</strong> the ‘Blue Edition’ include its leather steering wheel, refrigerator,<br />

cab heater, extensive audio<br />

equipment and <strong>of</strong> course<br />

DAF’s famous ‘Night Lock’ that<br />

protects the driver from breakins<br />

and burglary.<br />

The FAR XF105 6x2 chassis for the BDF<br />

applications that are popular in Germany<br />

has been improved further through adjustments<br />

to the ECAS air suspension. As a result, the lifting device<br />

for the swap bodies operates more swiftly and there is an extra<br />

reserve in the event <strong>of</strong> overloading.<br />

7 DAF IN ACTION

‘DAF, a <strong>World</strong> <strong>of</strong> Applications’<br />

PACCAR Winch forecasts<br />

growth in Europe<br />

With its brands Braden, Carco and Gearmatic, the<br />

PACCAR Winch Division is one <strong>of</strong> the leading<br />

manufacturers <strong>of</strong> winches in the world for use in<br />

construction and forestry, oil extraction and transport<br />

but also for use on mobile cranes and for<br />

military applications.<br />

Under the brand names Braden and Gearmatic, the<br />

PACCAR Winch Division first and foremost <strong>of</strong>fers a<br />

wide range <strong>of</strong> winches (planetary hoists) with lifting<br />

capacities <strong>of</strong> 1380 to 28,800 kilograms (3000<br />

- 64,000 lbs). In addition, a range <strong>of</strong> Magnum recovery<br />

hoists is available specifically for use in the<br />

oil extraction sector. These hoists feature pulling<br />

forces <strong>of</strong> up to 67,500 kilograms. Furthermore,<br />

hydraulically driven recovery hoists are available<br />

with pulling forces <strong>of</strong> up to 72,000 kilograms.<br />

Carco's winches have mainly been designed for<br />

use on tractors and bulldozers. The PACCAR Winch<br />

Division has a global network <strong>of</strong> independent and<br />

certified distributors, including sixteen in Europe.<br />

The presence <strong>of</strong> the PACCAR Winch Division at IAA<br />

2010 in September 2010 highlights the <strong>com</strong>pany's<br />

goal <strong>of</strong> significantly expanding its presence in<br />

Europe.<br />

In addition to the well-known tandem axle with<br />

hub reduction, the CF series is also available in<br />

some countries with a tandem axle with single<br />

reduction for use in 6x4 and 8x4 concrete mixer<br />

chassis. This means an extra load capacity <strong>of</strong> up<br />

to 800 kilograms.<br />

DAF IN ACTION 8<br />

Due to the optimisation <strong>of</strong> the engine<br />

management system, several versions<br />

<strong>of</strong> the 12.9-litre PACCAR MX engine can<br />

now also <strong>com</strong>ply with the EEV standard<br />

without a soot particle filter. This currently<br />

applies to the 265 kW/360 hp and 300 kW/<br />

410 hp versions and from the start <strong>of</strong> 2011<br />

will also include the 340 kW/460 hp version,<br />

which are installed in the DAF CF85 and<br />

XF105. The fact that the EEV emissions<br />

values will be achieved without a soot<br />

particle filter means a weight advantage<br />

<strong>of</strong> some 30 kilograms, whilst more room<br />

is left free on the chassis for the fitting <strong>of</strong><br />

larger fuel tanks.<br />

EEV specifications can also be met by the<br />

4.5-litre four-cylinder PACCAR FR and<br />

6.7-litre PACCAR GR engines in the LF<br />

and CF65 models without the use <strong>of</strong> a soot<br />

particle filter.<br />

More product news<br />

However, DAF will be presenting even<br />

more product news at the IAA 2010. For<br />

instance, further improvements have been<br />

made to the FAR XF105 6x2 chassis for<br />

the BDF applications that are popular in<br />

Germany. Adjustments to the ECAS air<br />

suspension mean that the lifting device<br />

for the swap bodies now operates more<br />

swiftly and there is an extra reserve in the<br />

event <strong>of</strong> overloading. In addition, the<br />

introduction <strong>of</strong> an adapted steering box<br />

has further improved steering properties,<br />

particularly during manoeuvres.<br />

In addition to the well-known HT1355T<br />

tandem axle with hub reduction (21 or<br />

26 tons), the CF series is also available in<br />

some countries with the lighter 1132 tandem<br />

axle (19 tons) with single reduction for use<br />

on 6x4 and 8x4 concrete mixer chassis for<br />

GVWs <strong>of</strong> 26 tons for the FAT CF75 6x4 up<br />

to 32 tons for the FAD CF85 8x4. Thanks<br />

to the lighter 1132 tandem axle and the<br />

adapted chassis frame, extra load capacity<br />

<strong>of</strong> up to 800 kilograms has been achieved.<br />

The DAF CF65 in the 19-ton version is also<br />

available with a 13-ton rear axle for extra<br />

reserve on the driven axle and less chance<br />

<strong>of</strong> overloading with partial loads.<br />

Services around the product<br />

take centre stage<br />

To underline the importance that DAF and<br />

its dealers (approx. 1000 sales and service<br />

dealers in Europe) place on excellent service<br />

to support their leading products, services<br />

such as PACCAR Financial, PACCAR Parts<br />

and TRP are being given a prominent place<br />

on the DAF stand, as will DAF’s unsurpassed<br />

International Truck Service (ITS), Multi -<br />

Support Repair and Maintenance Contracts<br />

and DAF Connect, a <strong>com</strong>plete management<br />

system that optimises maintenance <strong>of</strong> the<br />

vehicle fleet and efficiency in the workplace<br />

for <strong>com</strong>panies who carry out their own<br />

repairs.<br />

DAF dealers apply the "one-stop shopping"<br />

formula: all services and support under one<br />

ro<strong>of</strong>, so that customers can concentrate on<br />

their core business.<br />

DAF Telematics new functionalities<br />

The DAF Telematics System is a data<br />

<strong>com</strong>munication system that allows a

At its stand at the IAA, DAF also places particular<br />

emphasis on the facilities and services that<br />

support the product, such as the PACCAR Parts<br />

Max Card. Max Card holders can take advantage<br />

<strong>of</strong> exclusive <strong>of</strong>fers on parts, accessories and<br />

services.<br />

transport operator to further optimise the<br />

management <strong>of</strong> its fleet and business processes.<br />

Features <strong>of</strong> the DAF Telematics<br />

System are very easy access to data and<br />

extreme ease <strong>of</strong> use. A unique aspect is<br />

that all functionalities <strong>of</strong> the DAF Telematics<br />

System are integrated into one unit for<br />

maximum reliability and efficiency. A new<br />

web portal <strong>of</strong>fers even more options for<br />

usage and reporting. One <strong>of</strong> the new<br />

functions is "ge<strong>of</strong>encing". This involves<br />

sending a report when a truck is within a<br />

previously specified radius <strong>of</strong> the delivery<br />

address, so that the recipient is notified<br />

that the load will soon be arriving. From<br />

the home base, it is now possible to put<br />

together the most economical route and<br />

send it through to the truck. The number <strong>of</strong><br />

reporting options has also been expanded.<br />

Not only does DTS provide a detailed overview<br />

<strong>of</strong> the fuel consumption for a given<br />

truck, it can also issue other reports, for<br />

instance on the number <strong>of</strong> hours that the<br />

engine was running while stationary – all<br />

with the aim <strong>of</strong> optimising efficiency even<br />

further. There is now also an interface<br />

available to link the DAF Telematics system<br />

to the customer's existing back-<strong>of</strong>fice<br />

system for an efficient and 'real-time’<br />

exchange <strong>of</strong> data between transport<br />

management systems and the vehicle.<br />

PacLease<br />

With a fleet <strong>of</strong> almost 4000 vehicles,<br />

PacLease, a PACCAR <strong>com</strong>pany just like<br />

DAF, is one <strong>of</strong> the largest truck and trailer<br />

hire <strong>com</strong>panies in Germany, which stands<br />

out due to its extensive and varied range <strong>of</strong><br />

vehicles, with tractors, rigids and a wide<br />

variety <strong>of</strong> trailers. The network <strong>of</strong> locations<br />

where PacLease is established recently<br />

expanded from 8 to 24, as 14 DAF dealers<br />

now also <strong>of</strong>fer PacLease's services.<br />

DAF Components<br />

DAF Components is the fastest growing<br />

independent manufacturer <strong>of</strong> bus and<br />

coach engines in Europe and was granted<br />

the prestigious ‘Award for the Alternative<br />

Plaza 2010’ at 'Bus <strong>World</strong> Asia' in Shanghai<br />

earlier this year. DAF received this award<br />

for the first-class reliability and durability<br />

<strong>of</strong> its engines, along with the low fuel<br />

consumption <strong>of</strong> the 9.2-litre PACCAR PR<br />

engine and 12.9-litre PACCAR MX engine.<br />

The fact that DAF is the first <strong>com</strong>pany<br />

to <strong>of</strong>fer ultra-clean EEV engines for use<br />

in buses and coaches in Asia played a<br />

significant role in the judging <strong>of</strong> the award.<br />

Thanks to close cooperation with a number<br />

<strong>of</strong> prominent partners, the DAF stand<br />

provides added value in terms <strong>of</strong> information.<br />

These partners include Alcoa (light alloy<br />

rims), Total (fuels and lubricants), Goodyear<br />

(tyres), DuPont (paints), BASF (emission<br />

technologies), Eaton (hybrid technology)<br />

and Cummins (engine technology).<br />

To highlight the fact that DAF also has the right<br />

rigid vehicle for every situation, the DAF stand,<br />

in cooperation with leading partners from the<br />

construction industry, will be displaying a number<br />

<strong>of</strong> fully-built vehicles including this three-axle<br />

CF75 refuse vehicle with HN Schörling bodywork.<br />

New functionalities within the DAF Telematics data<br />

<strong>com</strong>munication system. One <strong>of</strong> the new functions<br />

is "ge<strong>of</strong>encing". This involves sending a report<br />

when a truck is within a previously specified<br />

radius <strong>of</strong> the delivery address, so that the recipient<br />

is notified that the load will soon be arriving.<br />

The number <strong>of</strong> reporting options has also been<br />

expanded.<br />

9 DAF IN ACTION

DAF LF Hybrid in production by the end <strong>of</strong> 2010:<br />

‘Green in distribution’<br />

Even before this year is out DAF will <strong>com</strong>mence production <strong>of</strong> the DAF LF Hybrid,<br />

a 12 ton distribution truck with a parallel hybrid system. The <strong>com</strong>mencement<br />

<strong>of</strong> production follows a very extensive field test, in which vehicles have been<br />

tested for two years in the most diverse practical applications in daily use with<br />

customers in both the UK and on the continent. The use <strong>of</strong> hybrid technology<br />

can lead to a reduction in fuel consumption and therefore CO2 emissions by<br />

between 10 and 20%, dependent upon the application. DAF is one <strong>of</strong> the first<br />

European truck manufacturers to bring a hybrid truck into production.<br />

DAF IN ACTION 10<br />

PACCAR – DAF’s parent <strong>com</strong>pany – is<br />

leading the way in the field <strong>of</strong> hybrid technology.<br />

In the United States, the Kenworth<br />

and Peterbilt brands <strong>of</strong>fer various models<br />

whereby significant reductions in fuel<br />

consumption and emissions can be achieved<br />

through the use <strong>of</strong> diesel/electric hybrid<br />

technology. As part <strong>of</strong> PACCAR's international<br />

hybrid programme, the DAF LF hybrid<br />

truck was developed in close cooperation<br />

with organisations and <strong>com</strong>panies such as<br />

Eaton, the Netherlands Organisation for<br />

Applied Scientific Research, Eindhoven<br />

University <strong>of</strong> Technology and Leyland<br />

Trucks Ltd, also a PACCAR subsidiary.<br />

EEV diesel technology<br />

The DAF LF Hybrid uses a parallel diesel/<br />

DAF is one <strong>of</strong> the first European truck manufacturers<br />

to bring a hybrid truck into production. As part <strong>of</strong><br />

PACCAR's international hybrid programme, the<br />

LF Hybrid was developed in cooperation with Eaton,<br />

Eindhoven University <strong>of</strong> Technology and Leyland<br />

Trucks Ltd, where the distribution truck will also be<br />

built.<br />

electric hybrid system, in which the truck<br />

is driven by the diesel engine, the electric<br />

engine or a <strong>com</strong>bination <strong>of</strong> both. The truck<br />

is fitted with the 4.5 litre PACCAR FR diesel<br />

engine, which <strong>com</strong>plies with the ultra-low<br />

EEV emission requirements as standard,<br />

without a soot filter. In the LF Hybrid this<br />

engine produces a maximum <strong>of</strong> 118 kW/<br />

160 hp and is linked to an automated Eaton<br />

six-speed gearbox (Autoshift). An electric<br />

motor has been installed between the clutch<br />

and the gearbox, which can provide drive as<br />

well as functioning as a generator. Energy<br />

released during braking is stored in the<br />

lithium-ion batteries for re-use during acceleration.<br />

Depending on the degree <strong>of</strong> charge<br />

<strong>of</strong> the lithium-ion batteries, a central <strong>com</strong>puter<br />

determines when the diesel engine<br />

provides the drive and when and to what<br />

extent the electric engine is used.<br />

Lithium-ion batteries<br />

The battery pack <strong>of</strong> the hybrid system<br />

weighs around 100 kilos and consists <strong>of</strong> 96<br />

lithium 3.4-Volt cells. When these batteries<br />

are fully charged, the LF Hybrid truck can<br />

travel about two kilometres electrically<br />

without needing the diesel engine to drive<br />

it. In practice, this is sufficient for driving in<br />

and out <strong>of</strong> the 'green zones' <strong>of</strong> city centres.<br />

In circumstances such as these, the diesel<br />

engine remains idle in order to drive various<br />

<strong>com</strong>ponents (such as the steering pump<br />

and the air <strong>com</strong>pressor). The LF hybrid is<br />

also fitted with a start/stop system.<br />

In addition to the battery pack, DAF hybrid<br />

technology also consists <strong>of</strong> a current transformer<br />

that converts the alternating current<br />

supplied by the generator to direct current<br />

for the batteries. A cooling unit is also fitted<br />

to the chassis to cool this current transformer.<br />

In total, the DAF LF45.160 Hybrid is<br />

some 300 kilograms heavier than the standard<br />

model with only a diesel engine.

An electric motor has been installed between the<br />

clutch and the Eaton gearbox, which can provide<br />

drive as well as functioning as a generator. Energy<br />

released during braking is stored in the lithiumion<br />

batteries for re-use during acceleration.<br />

Because the DAF LF series is famous for its<br />

favourable unloaded weight, the 12-ton LF<br />

Hybrid nevertheless <strong>of</strong>fers a very useful<br />

load capacity <strong>of</strong> some 7.5 tons.<br />

Field tests prove reliability<br />

As is DAF standard practice, the development<br />

programme for the LF Hybrid was<br />

concluded with an extensive field test. In<br />

addition to the test programmes using our<br />

own test vehicles, ten vehicles were used<br />

to gain practical experience by customers<br />

in the UK and on the Continent for various<br />

distribution applications over a two-year<br />

period. First and foremost the field test<br />

demonstrated the reliability <strong>of</strong> DAF hybrid<br />

technology but also – depending on the<br />

application – that average savings in fuel<br />

consumption and therefore CO2-emissions<br />

by between 10 to 20% were achieved.<br />

Another advantage <strong>of</strong> hybrid technology is<br />

that <strong>com</strong>ponents susceptible to wear, such<br />

as brake linings and the clutch plate, will<br />

have a longer service life because braking<br />

occurs on the electric engine.<br />

Operational lease<br />

DAF is starting to supply the LF Hybrid in<br />

the UK, the Netherlands, Germany and<br />

Belgium; countries in which market research<br />

has shown that the interest in hybrid vehicles<br />

is highest. Depending on the success <strong>of</strong><br />

the LF Hybrid in these markets, DAF will<br />

decide whether to include the vehicle in the<br />

standard product range in other countries.<br />

It is anticipated that hybrid technology will<br />

develop further in the years to <strong>com</strong>e,<br />

particularly in the area <strong>of</strong> batteries. For<br />

this reason the DAF LF Hybrid is <strong>of</strong>fered as<br />

standard via PACCAR Financial with a full<br />

operational lease contract, so that the DAF<br />

dealer can implement any potential updates<br />

during the contract term. In this way, the<br />

customer is guaranteed to always have the<br />

most environmentally friendly vehicle for a<br />

fixed amount per month.<br />

‘Significant environmental impact’<br />

The LF Hybrid is fitted with the 4.5 litre PACCAR FR<br />

diesel engine, which <strong>com</strong>plies with the ultra-low<br />

EEV emission requirements as standard, without a<br />

soot filter. The 118 kW/160 hp engine is linked to<br />

an automated Eaton six-speed gearbox.<br />

The DAF LF Hybrid <strong>of</strong>fers fuel efficiency gains and corresponding drop in CO2 emissions <strong>of</strong> 10 to 20%,<br />

depending on the application. There are applications where even larger enhancements can be achieved,<br />

as is illustrated by the trials by Kingston upon Hull City Council <strong>of</strong> the LF45 hybrid. Garry Middleton, Head<br />

<strong>of</strong> Fleet Management, said that he was impressed by the results.<br />

“Because the vehicle was used in a recycling role this added emphasis to the need for it to have the least<br />

possible environmental impact,” he said. “Its daily work involved numerous short journeys, which can<br />

negatively impact on fuel efficiency, so<br />

achieving fuel savings <strong>of</strong> 22% was an<br />

excellent out<strong>com</strong>e.”<br />

“Like all public bodies we are under<br />

constant pressure to get the best value<br />

for taxpayers’ money. With over 80 <strong>of</strong> our<br />

vehicles operating at this weight, many <strong>of</strong><br />

them on this type <strong>of</strong> duty cycle, we see<br />

hybrids <strong>of</strong>fering the potential for major<br />

cost savings and making a significant<br />

contribution towards reducing our carbon<br />

footprint.”<br />

11 DAF IN ACTION

Harrie Schippers, President <strong>of</strong> DAF Trucks N.V.:<br />

“Being close to the customer<br />

Less than eight years ago, DAF was the smallest <strong>of</strong> all the truck manufacturers<br />

in Europe in terms <strong>of</strong> market share. Today the <strong>com</strong>pany occupies a strong<br />

second place in the heavy segment and DAF is even the market leader in the<br />

tractor segment. “You have no influence on the size <strong>of</strong> the market”, states<br />

President Harrie Schippers. “But you can influence how you perform within<br />

that market.” Read on for an interview about the success <strong>of</strong> DAF, its ambitions,<br />

Euro 6 and the importance <strong>of</strong> a network <strong>of</strong> independent dealers<br />

Harrie Schippers has been at the helm <strong>of</strong><br />

DAF Trucks N.V. since the 1st <strong>of</strong> April <strong>of</strong><br />

this year. He started working there in 1987<br />

and has held a variety <strong>of</strong> financial roles,<br />

most recently as Director <strong>of</strong> Finance, in<br />

which capacity he has had a place on the<br />

Board <strong>of</strong> Management since 2003. He<br />

has therefore been closely involved in the<br />

measures DAF has taken since the end <strong>of</strong><br />

2008 to weather the economic storm that<br />

has tested the transport world and the<br />

truck industry. “Our expectation is that<br />

– as long as there are no unanticipated<br />

financial setbacks – a structural recovery<br />

will <strong>com</strong>mence in the truck market in the<br />

fourth quarter <strong>of</strong> this year”, says Schippers,<br />

who also adds that there are already<br />

numerous signs that the market situation<br />

is improving. “The Economist Intelligence<br />

DAF IN ACTION 12<br />

Unit expects the Gross National Product in<br />

the EU to grow slightly by 0.7% this year.<br />

There is a worldwide shortage <strong>of</strong> 2 million<br />

sea containers, which shows that world<br />

trade is picking up again. The number <strong>of</strong><br />

kilometres liable for the Maut road toll tariffs<br />

covered by foreign-registered transport<br />

<strong>com</strong>panies in Germany was 10% higher in<br />

June than in the previous year. These are<br />

all signs that the sector is on the up again,<br />

particularly in international transport and<br />

especially in North West Europe.”<br />

Growth in rigids<br />

In August, DAF increased its production <strong>of</strong><br />

medium and heavy trucks and has already<br />

announced further increases. “Dealer stocks<br />

are now back to normal levels, meaning<br />

that orders from the market once again<br />

Photo right: There are numerous signs that the<br />

sector is on the up again, particularly in international<br />

transport and especially in North West<br />

Europe. For instance, the number <strong>of</strong> kilometres<br />

liable for the Maut road toll tariffs covered by<br />

foreign-registered transport <strong>com</strong>panies in Germany<br />

was 10% higher in June than in the previous year.<br />

mean orders for production”, explains<br />

Schippers. “What is certainly important is<br />

that our market share continues to increase.<br />

Eight years ago DAF was the smallest<br />

player in the European truck market in<br />

terms <strong>of</strong> market share; we now occupy<br />

a solid second place with a market share<br />

<strong>of</strong> 16.3% (first half <strong>of</strong> 2010) in the over<br />

15 ton class in the EU. We are even the<br />

EU market leader in tractors, with a market<br />

share <strong>of</strong> 21.3%. Naturally we want to<br />

further reinforce this position, however<br />

we will need to achieve further growth<br />

particularly in the rigid segment. The task<br />

for us is to further emphasise the message<br />

that we are also the best partner in the<br />

rigid sector.”<br />

The keys to success<br />

Naturally the LF, CF and XF105 are an<br />

important key to DAF's success, as are<br />

the <strong>com</strong>plete package <strong>of</strong> services to<br />

support the products. And let's not forget<br />

the pr<strong>of</strong>essional network <strong>of</strong> over one<br />

thousand independent dealers, who are in<br />

close contact with the customer. “That is<br />

DAF's main strength”, explains Schippers.<br />

“We have made a very conscious choice to<br />

work with independent dealers. They represent<br />

their <strong>com</strong>pany and go the extra mile,<br />

because they know better than anyone<br />

that maximum customer satisfaction<br />

determines the future <strong>of</strong> their business.<br />

Stay close to customers and know what<br />

motivates them. Work with them. Come<br />

up with solutions. It's not really rocket<br />

science, but it is DAF's strength.”<br />

Unique in the automotive industry<br />

Despite the challenging economic climate,<br />

DAF's parent <strong>com</strong>pany PACCAR managed<br />

to stay in the black – even during the<br />

challenging year <strong>of</strong> 2009 – and to report a<br />

pr<strong>of</strong>it for the 71st year in a row. This made<br />

the <strong>com</strong>pany unique in the automotive<br />

industry. “Positive results are essential<br />

to enable continued investment in both

is our greatest strength”<br />

Harrie Schippers, President <strong>of</strong> DAF Trucks N.V.:<br />

“Stay close to customers and know what motivates<br />

them. Work with them. Come up with solutions. It's<br />

not really rocket science, but it is DAF's strength.”<br />

product development and production<br />

facilities”, explains Schippers. “In Columbus,<br />

Mississippi, the state-<strong>of</strong>-the-art engine<br />

factory is nearing <strong>com</strong>pletion and with it,<br />

PACCAR has created a <strong>com</strong>pletely new<br />

production facility in very challenging<br />

market conditions. In the United States our<br />

sister brands Peterbilt and Kenworth are<br />

leading the way in hybrid technology. A<br />

significant reduction in fuel consumption<br />

and emissions can be achieved, particularly<br />

in distribution transport, on the way to even<br />

cleaner road transport. At the end <strong>of</strong> this<br />

year DAF will also put hybrid technology<br />

into mass production.”<br />

Euro 6<br />

In terms <strong>of</strong> emissions: DAF is the first truck<br />

manufacturer to already <strong>of</strong>fer all its engine<br />

variants in ultra-clean EEV versions. How<br />

far along is DAF with the development <strong>of</strong><br />

Euro 6? “First <strong>of</strong> all it's good to reflect upon<br />

the tremendous achievements the industry<br />

is making in the field <strong>of</strong> emissions”, says<br />

Schippers. “Euro 6 diesel engines produce<br />

around 97% fewer soot particles and 95%<br />

less NOx than the trucks <strong>of</strong> fifteen years<br />

ago. We are now almost at the level <strong>of</strong> ‘zero<br />

emissions’ with diesel engines. It is still too<br />

early to make any statements about which<br />

technologies DAF is going to use for this.<br />

The fact is that the 12.9 litre PACCAR MXengines<br />

that will be supplied in the United<br />

States in the Kenworth and Peterbilt trucks<br />

as <strong>of</strong> this summer, feature SCR technology,<br />

exhaust gas recirculation and a soot filter in<br />

order to <strong>com</strong>ply with the EPA10 emissions<br />

directive. For Euro 6 we have already<br />

evaluated our experiences and on that basis<br />

we will make the best choice for maximum<br />

reliability, excellent fuel consumption<br />

and great performance. And don't forget<br />

Eight years ago DAF was the smallest<br />

player in the European truck market<br />

in terms <strong>of</strong> market share; the Dutch<br />

truck manufacturer now occupies a<br />

solid second place with a market<br />

share <strong>of</strong> 16.3% (first half <strong>of</strong> 2010) in<br />

the over 15 ton class in the EU. DAF is<br />

even the EU market leader in tractors,<br />

with a market share <strong>of</strong> 21.3%.<br />

In Columbus, Mississippi, the state-<strong>of</strong>-the-art engine<br />

factory is nearing <strong>com</strong>pletion and with it, PACCAR has<br />

created a <strong>com</strong>pletely new production facility in very<br />

challenging market conditions.<br />

that the step from Euro 5 to Euro 6 has a<br />

tremendous impact not only on the engine<br />

but on the entire vehicle. Finally, new<br />

technology must also be integrated into<br />

the vehicle in the smartest way. Everyone in<br />

the industry appears to already be resigned<br />

to the fact that with the arrival <strong>of</strong> Euro 6,<br />

trucks, and therefore transport, will be<strong>com</strong>e<br />

more expensive due to the additional technologies<br />

required.”<br />

Market Share Development EU 27+2 >5t GVW<br />

13 DAF IN ACTION

Alcoa Dura-Bright ® Wheels<br />

GREAT LOOKS<br />

Easy maintenance<br />

www.alcoawheels.<strong>com</strong><br />

Alcoa Wheel Products Europe<br />

Tel. +32 11 458 460<br />

info.wheels@alcoa.<strong>com</strong>

ADVERTORIAL<br />

VDL Containersystemen bv<br />

VDL Containersystemen bv is part <strong>of</strong> the VDL group. The <strong>com</strong>pany develops, manufactures<br />

and sells container handling systems and spreaders, as well as providing After Sales support.<br />

VDL Containersystemen's products find their way into many market sectors, such as waste<br />

collection, transport, the construction and scrap metal industries, agriculture, defence,<br />

local authorities and government. The <strong>com</strong>pany is the market leader in its sector within the<br />

Benelux. Ninety percent <strong>of</strong> the systems are exported via an extensive dealer network within<br />

and beyond Europe. The range <strong>of</strong> container handling systems consists <strong>of</strong> hook arm systems,<br />

portal arm systems and cable installations.<br />

The VDL Groep is an international industrial<br />

<strong>com</strong>pany devoted to the development, production<br />

and sale <strong>of</strong> semi-finished goods and end products.<br />

From the head <strong>of</strong>fice in Eindhoven, the VDL Groep<br />

supervises its operating <strong>com</strong>panies, which<br />

function as independently as possible and are<br />

responsible for their own results. The group<br />

currently includes some 70 operating <strong>com</strong>panies,<br />

with more than 7000 employees.<br />

The cable systems which have recently<br />

been added to the range are supplied<br />

with a standard capacity <strong>of</strong> 15 to 30 tons<br />

and have a standard ride height <strong>of</strong> up to<br />

230 mm. The use <strong>of</strong> high-quality steel<br />

achieves a low individual weight, which<br />

ensures a high load capacity. Thanks to<br />

the newly developed differential drive with<br />

integral interlocking and a sophisticated<br />

freewheel function, straight hoisting can<br />

be carried out even under difficult conditions.<br />

Durable due to the use <strong>of</strong> high-quality<br />

materials and practical due to a lowmainte<br />

nance hydraulic steering system.<br />

Hook arm systems<br />

VDL's hook arm systems are available<br />

with a capacity <strong>of</strong> 5 to 40 tons and in<br />

various models. In the 5 ton model,<br />

bending, tipping, lifting and setting down<br />

is carried out by just one cylinder, thus<br />

reducing maintenance costs.<br />

Portal arm systems<br />

VDL's portal arm systems are available<br />

with capacities <strong>of</strong> at least 18 tons and<br />

can be equipped with a rapid and simple<br />

netting system that is able to cover loads<br />

via a small wireless remote control.<br />

Ongoing improvements<br />

VDL Containersystemen continuously<br />

develops and improves its products. The<br />

<strong>com</strong>pany is ISO 9001 14000 accredited<br />

and its Lean Manufacturing method not<br />

only further increases efficiency but also<br />

improves quality as part <strong>of</strong> a continuous<br />

process. In order to guarantee optimum<br />

quality, critical <strong>com</strong>ponents are manufactured<br />

in-house.<br />

To find out more visit:<br />

www.vdlcontainersystemen.<strong>com</strong><br />

15 DAF IN ACTION

Schmitz Cargobull<br />

Thick-skinned creatures<br />

Nowadays, semi-trailers and bodies with the Schmitz Cargobull<br />

elephant in their logo can be seen on the roads throughout Europe.<br />

With its innovative products and excellent service, Schmitz Cargobull<br />

has catapulted itself to the top <strong>of</strong> the trailer industry.<br />

Big, strong and able to carry vast amounts.<br />

This is not only true <strong>of</strong> elephants, but also<br />

<strong>of</strong> Schmitz Cargobull semi-trailers and<br />

bodies. It is therefore no coincidence that<br />

the North German body manufacturer has<br />

included this trunked creature in its logo.<br />

High level <strong>of</strong> quality<br />

What started out as a small blacksmith's<br />

forge in the German city <strong>of</strong> Altenberge in<br />

1892 has developed, more than 100 years<br />

later, into Europe's largest manufacturer <strong>of</strong><br />

trailers and semi-trailers. During its peak<br />

years, Schmitz Cargobull put more than<br />

66,000 trailers and semi-trailers on the<br />

roads, achieving turnover in excess <strong>of</strong> two<br />

billion euro. The <strong>com</strong>pany's consistent<br />

focus on delivering high-quality, standardised<br />

products in the growing semi-trailer market<br />

helped bring it to this point. In the wake <strong>of</strong><br />

the economic crisis, the current mood is<br />

still somewhat subdued. During the next<br />

DAF IN ACTION 16<br />

few years, the <strong>com</strong>pany expects to sell<br />

around 45,000 trailers and semi-trailers in<br />

Europe each year, generating turnover <strong>of</strong><br />

around 1.7 billion euro.<br />

Eight sites<br />

Schmitz Cargobull would not be the<br />

European market leader it is today if it had<br />

limited its production operations purely to<br />

Altenberge. Over the years, the <strong>com</strong>pany<br />

has significantly increased its capacity and<br />

now has eight production sites throughout<br />

Europe. In Germany, Schmitz Cargobull<br />

operates in Altenberge, Vreden, Gotha,<br />

Toddin and Berlin. It also has assembly<br />

facilities in Lithuania, Spain and Great<br />

Britain. In order to facilitate series production,<br />

each factory specialises in a specific<br />

product group. Schmitz Cargobull now<br />

occupies first place in the closed refrigerator<br />

and freezer semi-trailer segment, with a<br />

market share <strong>of</strong> more than 80% in Germany<br />

Schmitz Cargobull has be<strong>com</strong>e Europe's largest<br />

manufacturer <strong>of</strong> trailers and semi-trailers.<br />

and around 40% in the rest <strong>of</strong> Europe. More<br />

than 100,000 <strong>of</strong> the brand's refrigerator<br />

semi-trailers now travel the length and<br />

breadth <strong>of</strong> Europe. The largest markets<br />

include all European countries, including<br />

those in Eastern Europe, as well as the<br />

Near East and Middle East.<br />

The future<br />

Schmitz Cargobull expects further growth<br />

in road transport volumes in the future,<br />

especially in the consumer markets <strong>of</strong><br />

Eastern Europe. The growing demand for<br />

fast food and for fresh products such<br />

as meat, fruit and vegetables, and dairy<br />

products will further increase demand for<br />

refrigerated transport. In order to further<br />

increase its market share in all segments,<br />

the trailer manufacturer pursues a twopronged<br />

approach: It no longer focuses<br />

purely on the production <strong>of</strong> semi-trailers in<br />

large series as was previously the case;

in Europe<br />

Schmitz Cargobull has eight production sites in<br />

Europe. Here is the factory in Altenberge,<br />

Germany.<br />

thanks to a flexible 'construction kit' system,<br />

it now dedicates more time to customerspecific,<br />

individual transport solutions.<br />

Patented<br />

The manufacturer can attribute most <strong>of</strong> its<br />

success to its modular concept, innovative<br />

developments and clever details. Examples<br />

include the specially designed sandwich<br />

panels made from patented 'Ferroplast', a<br />

damp-pro<strong>of</strong> material used to assemble the<br />

refrigerator bodies. The panels consist <strong>of</strong> two<br />

galvanised steel plates with an extremely<br />

<strong>com</strong>pact polyurethane core incorporated<br />

between them. Unlike glass fibre-reinforced<br />

plastic, this solution prevents the panels<br />

from absorbing moisture, which can eventually<br />

lead to reduced insulating properties.<br />

The segments are glued together seamlessly<br />

in the factory. This method also facilitates<br />

repairs, as the panels can be dismantled<br />

and replaced individually. This applies not<br />

only to the refrigerator and freezer trailers<br />

but also to the refrigerator bodies, which<br />

are now also being fitted on an increasing<br />

number <strong>of</strong> DAFs.<br />

Platform<br />

Schmitz Cargobull follows a modular platform<br />

strategy for its series production<br />

operations. This strategy makes it possible<br />

to build different types on the same assembly<br />

lines. Just as with trucks, the chassis<br />

are not welded, but riveted, after which they<br />

are galvanised. At the customer's request,<br />

Schmitz Cargobull can fit its semi-trailers<br />

with the 'Rotos' chassis, which the <strong>com</strong>pany<br />

developed itself. This chassis is fitted as<br />

standard with RSP (Roll Stability Program);<br />

LSP (Load Spread Program) is available as<br />

an option. The latter program prevents<br />

excessive weight on the driven axle in the<br />

case <strong>of</strong> partial loads. LSP relieves the third<br />

Schmitz Cargobull follows a modular platform strategy for its<br />

series production operations. This strategy makes it possible to<br />

build different types on the same assembly lines.<br />

trailer axle in a controlled manner. This<br />

allows the trailer's point <strong>of</strong> rotation to shift<br />

from the central axle to the foremost axle,<br />

improving the way the trailer handles and<br />

takes bends.<br />

Service partners<br />

Around 1200 contract partners throughout<br />

Europe ensure that Schmitz Cargobull's<br />

equipment remains in tip-top condition.<br />

Playing an important part in this process<br />

are the 40 or so 'Cargobull Trailer Centers'<br />

(CTC). These centres sell new and used<br />

trailers and carry out maintenance and<br />

repairs. They can also <strong>of</strong>fer advice on<br />

maintenance, service contracts, mobility<br />

guarantees and 24-hour parts supply. All<br />

this keeps the elephant going strong in<br />

Europe.<br />

Schmitz Cargobull expects further growth in road<br />

transport volumes in the future, especially in the<br />

consumer markets <strong>of</strong> Eastern Europe.<br />

17 DAF IN ACTION

200 Years <strong>of</strong> Experience<br />

at your Service.<br />

DuPont has a long history <strong>of</strong> involvement with road<br />

transport vehicles, especially in providing paint technologies<br />

for manufacturing and repair.<br />

DuPont has been the leading player in this sector for<br />

several decades, developing solutions that perfectly<br />

answer industrial demands for high performance and<br />

durability, while still respecting the environment.<br />

Solutions that include patented DuPont technology<br />

for using the same topcoat quality, such as DuPont<br />

Imron ®<br />

, on both metal and plastic cab <strong>com</strong>ponents.<br />

Solutions that the DuPont Imron ®<br />

range also provides<br />

to the aftermarket.<br />

Solutions that allow a perfect match <strong>of</strong> any colour,<br />

any time, anywhere in the world.<br />

DuPont CoatingSolutions benefits from being part<br />

<strong>of</strong> a large <strong>com</strong>pany, with <strong>com</strong>prehensive technical<br />

expertise, extensive R&D resources and a high level<br />

<strong>of</strong> consulting experience on new projects. Our worldwide<br />

service network ensures these benefits are<br />

available wherever they are needed.<br />

Taking advantage <strong>of</strong> these strengths, Paccar relies on<br />

DuPont CoatingSolutions to supply superior coating<br />

solutions for their DAF, Leyland, Kenworth and Peterbilt<br />

vehicles.<br />

Whether you build trucks or repair them, DuPont<br />

CoatingSolutions can make it work for you.<br />

Visit DuPont CoatingSolutions today, and let’s make<br />

the future together:<br />

http://coatingsolutions.dupont.<strong>com</strong><br />

2010 The DuPont oval, The Miracles <strong>of</strong> Science ®<br />

, DuPontTM and Imron ®<br />

Copyright ©<br />

are trademarks or registered trademarks <strong>of</strong> DuPont or its affiliates.

Elst Transport pleased with DAF and Saxas<br />

“I am going to order another two!”<br />

In 2003 father and son team Piet and Danny van Loon founded ‘Elst Transport’,<br />

operating out <strong>of</strong> Roosendaal in the Netherlands. Now – seven years later – they<br />

have a fleet <strong>of</strong> 33 vehicles and employ 35 people. A success story with a solid<br />

basis. “We are a trustworthy partner for our customers.”<br />

Elst Transport mainly focuses on the<br />

transport and distribution <strong>of</strong> hinges and<br />

locks for the construction industry. “We<br />

deliver to construction sites, construction<br />

<strong>com</strong>panies and joinery works”, says<br />

Director Danny van Loon. “Our vehicles<br />

cover 300 to 400 kilometres every day.”<br />

Confidence for tomorrow<br />

The success <strong>of</strong> this family <strong>com</strong>pany can<br />

be summarised in one word: trust. “Our<br />

motto is 'confidence for tomorrow’", says<br />

Saxas, located in Werdau in Germany, was<br />

founded in 2004 by employees <strong>of</strong> the former<br />

Kögel Werdau. In just six years Saxas has be<strong>com</strong>e<br />

one <strong>of</strong> Europe’s major producers <strong>of</strong> bodies and<br />

semi-trailers for distribution vehicles. One <strong>of</strong> the<br />

best known Saxas products is the courier superstructure,<br />

<strong>of</strong> which Deutsche Post has ordered<br />

more than 20,000 models.<br />

Van Loon. “And we exude that to our<br />

customers <strong>of</strong> course through excellent<br />

customer service, but most <strong>of</strong> all by<br />

listening and working with our customers.<br />

We have a constant dialogue with our<br />

customers and that creates trust. That is<br />

one <strong>of</strong> the reasons why we have made it<br />

through the recession largely unscathed.”<br />

DAF LF<br />

Elst Transport's fleet <strong>com</strong>prises 13 delivery<br />

vans and 20 DAF LF distribution trucks.<br />

“When selecting the trucks we looked at all<br />

alternatives. Only the LF met all our needs:<br />

a perfect <strong>com</strong>bination <strong>of</strong> favourable fuel<br />

consumption, driver <strong>com</strong>fort and reliability.<br />

Not to forget their excellent appearance:<br />

they are attractive vehicles that exude<br />

quality. Which was exactly what we were<br />

looking for.”<br />

Saxas superstructure<br />

The LFs all have a body made by Saxas,<br />

the Germany <strong>com</strong>pany, and also a lift. Why<br />

Saxas? “There were various reasons”,<br />

explains Van Loon. “Firstly: quality. It is a<br />

very solid rigid made <strong>of</strong> sturdy materials,<br />

which have an excellent finish but which<br />

at the same time are not too heavy. Just<br />

as when choosing a truck, we looked at<br />

several alternatives but came to the<br />

conclusion that the Saxas superstructure<br />

is really perfect. And it looks great in<br />

<strong>com</strong>bination with the LF, doesn't it? I am<br />

so enthusiastic about these vehicles that I<br />

am going to order another two tomorrow.”<br />

One point <strong>of</strong> contact<br />

Another big advantage <strong>of</strong> choosing the<br />

Saxas body is ease. Van Loon: “The shell<br />

truck goes to the Saxas factory in Germany<br />

and is <strong>com</strong>pletely finished there. The final<br />

product then goes to the dealer, who then<br />

delivers the truck to us. The entire process<br />

is monitored by the dealer and he is our<br />

only contact point. We receive a ready-touse<br />

product that we can simply drive away.”<br />

19 DAF IN ACTION

Goodyear's ‘Mission Impossible’<br />

New trailer tyre saves<br />

Tyres play an important role in reducing fuel consumption. Ever more transport<br />

<strong>com</strong>panies are therefore putting greater effort into choosing the right tyres for<br />

their trucks. However, according to Mike Beckers, Account Manager at Goodyear<br />

Dunlop Europe, trailer tyres also play a key role in determining fuel consumption.<br />

Mike Beckers: “Trailer and semi-trailer tyres<br />

also play an important role when it <strong>com</strong>es to fuel<br />

consumption.”<br />

DAF IN ACTION 20<br />

“For a standard 40-tonne tractor/semitrailer<br />

<strong>com</strong>bination, the trailer tyres are<br />

responsible for about 50% <strong>of</strong> the rolling<br />

resistance”, says Beckers. “Unfortunately,<br />

transport <strong>com</strong>panies <strong>of</strong>ten tend to pay<br />

less attention to these tyres. This means<br />

that potential savings are lost.”<br />

New trailer tyre<br />

The tyre industry has played its part. Tyres<br />

with a low rolling resistance for semi-trailers<br />

and trailers have been on the market for<br />

some time and, just like truck tyres, are<br />

being continuously developed. For example,<br />

Goodyear introduced a new trailer tyre in<br />

June: the Marathon LHT II (Long Haul<br />

Trailer II). This tyre has a much lower rolling<br />

resistance than its predecessor. “The<br />

Marathon LHT already had a low rolling<br />

resistance and it was a huge challenge<br />

for developers to reduce this still further.<br />

This was party because other features<br />

such as kilometre performance, braking<br />

distance on wet road surfaces and noise<br />

In recent decades, the tyre industry has developed<br />

tyres that have been better than their predecessors<br />

in all aspects. New generations deliver shorter<br />

braking distances on wet road surfaces, for<br />

example.<br />

level were equally important aspects for the<br />

tyre development” says Beckers. “Internally<br />

we called it ‘Project Mission Impossible’.<br />

Tyre label<br />

However, the results are there: the<br />

Marathon LHT II already more than meets<br />

the statutory requirements that the EU<br />

will impose on tyres as <strong>of</strong> 2012. “As <strong>of</strong><br />

that date, it will only be possible to sell<br />

truck and trailer tyres that bear a label with<br />

information about the rolling resistance,<br />

braking performance on wet road surfaces<br />

and the noise level”, explains Beckers.<br />

“This tyre label will help customers select<br />

suitable tyres for their needs. It will enable<br />

them to save costs and the environment<br />

will also benefit.”<br />

Silica<br />

The use <strong>of</strong> new materials can significantly<br />

reduce the rolling resistance <strong>of</strong> tyres. For<br />

example, by using silica in the rubber on<br />

the running surface <strong>of</strong> the tyres. But does

fuel<br />

this not affect other properties <strong>of</strong> the tyre?<br />

“Improving the rolling resistance is not only<br />

achieved by using silica” says Beckers. “It<br />

is also achieved by optimising the design<br />

<strong>of</strong> the carcass and by using advanced<br />

steel wire. Rolling resistance is actually<br />

simply heat development in the tyre. Using<br />

advanced <strong>com</strong>puter models we can see<br />

where that heat is produced and with this<br />

knowledge we can design a tyre that<br />

minimises heat development, therefore<br />

reducing the rolling resistance. At the<br />

same time, we can use this technology to<br />

ensure not only that the other properties<br />

do not suffer, but rather that they are<br />

enhanced.”<br />

Development<br />

Over recent decades the tyre industry<br />

has developed tyres that have been better<br />

than their predecessors in all aspects.<br />

New generations <strong>of</strong> tyres have, for example,<br />

had a lower weight, lower rolling resistance,<br />

shorter braking distance on wet road<br />

surfaces, a lower noise level, higher kilometre<br />

performance and better durability<br />

than their predecessors. Will there ever be<br />

an end to these developments? “Certainly<br />

not”, says Beckers. “We are <strong>of</strong> course<br />

proud <strong>of</strong> the Marathon LHT II. It is a<br />

classic example <strong>of</strong> progress, but this tyre<br />

certainly does not represent the end <strong>of</strong><br />

development work. Ever stricter requirements<br />

are being imposed on tyres by<br />

customers and legislators. This not only<br />

concerns the performance <strong>of</strong> the tyres,<br />

but also, for example, the impact on the<br />

environment. We are naturally striving to<br />

minimise that. This applies to both the<br />

production process and the materials we<br />

use in the tyres. Most certainly, the end <strong>of</strong><br />

our ‘Mission Impossible’ is not yet in sight.”<br />

The Marathon LHT II already more than meets the<br />

statutory requirements that the EU will impose on<br />

tyres as <strong>of</strong> 2012.

Meiller cooperates closely with the truck industry:<br />

‘It starts with listening’<br />

Meiller's logo, a stylized anvil, recalls the origins <strong>of</strong> the <strong>com</strong>pany as a forge<br />

in 1850. With the invention <strong>of</strong> a toothed bar hoist and by mounting a tipper<br />

onto a truck, Lorenz Meiller laid the foundations in 1907 for a <strong>com</strong>pany whose<br />

tippers still have an excellent reputation today. Close cooperation with the<br />

truck industry is <strong>of</strong> essential importance.<br />

Uwe Meißner: “In many areas we have already<br />

achieved a level <strong>of</strong> zero faults”.<br />

DAF IN ACTION 22<br />

Uwe Meißner, responsible for technology<br />

and production at Meiller, understands<br />

what has made the <strong>com</strong>pany so successful<br />

for so long: “We know how to <strong>com</strong>bine the<br />

expertise and skill <strong>of</strong> the truck manufacturer<br />

and the customer's wishes to create robust<br />

and efficient transport solutions. Listening<br />

is therefore very important. Listening to<br />

customers, who build up a great deal <strong>of</strong><br />

knowledge and experience with their<br />

construction or refuse vehicles during the<br />

course <strong>of</strong> their daily operations, but also<br />

listening to the truck manufacturers, with<br />