ACH Monroe Webcast Auction Lot Catalog - DAY 1 - Hilco Trading

ACH Monroe Webcast Auction Lot Catalog - DAY 1 - Hilco Trading

ACH Monroe Webcast Auction Lot Catalog - DAY 1 - Hilco Trading

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

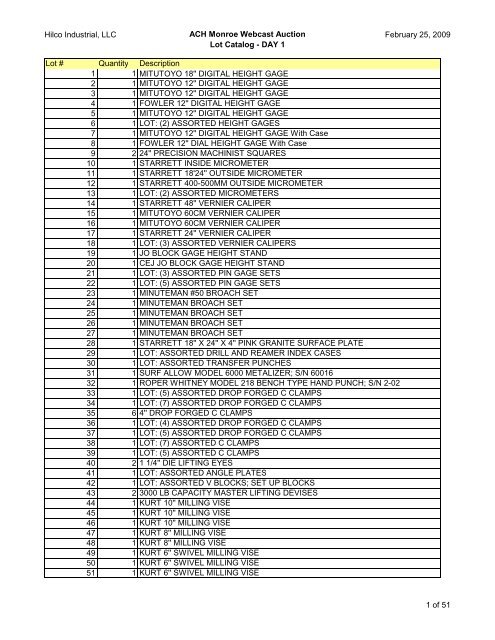

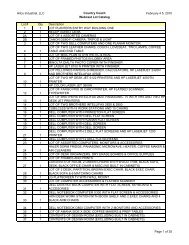

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

<strong>Lot</strong> # Quantity Description<br />

1 1 MITUTOYO 18'' DIGITAL HEIGHT GAGE<br />

2 1 MITUTOYO 12'' DIGITAL HEIGHT GAGE<br />

3 1 MITUTOYO 12'' DIGITAL HEIGHT GAGE<br />

4 1 FOWLER 12'' DIGITAL HEIGHT GAGE<br />

5 1 MITUTOYO 12'' DIGITAL HEIGHT GAGE<br />

6 1 LOT: (2) ASSORTED HEIGHT GAGES<br />

7 1 MITUTOYO 12'' DIGITAL HEIGHT GAGE With Case<br />

8 1 FOWLER 12'' DIAL HEIGHT GAGE With Case<br />

9 2 24'' PRECISION M<strong>ACH</strong>INIST SQUARES<br />

10 1 STARRETT INSIDE MICROMETER<br />

11 1 STARRETT 18'24'' OUTSIDE MICROMETER<br />

12 1 STARRETT 400-500MM OUTSIDE MICROMETER<br />

13 1 LOT: (2) ASSORTED MICROMETERS<br />

14 1 STARRETT 48'' VERNIER CALIPER<br />

15 1 MITUTOYO 60CM VERNIER CALIPER<br />

16 1 MITUTOYO 60CM VERNIER CALIPER<br />

17 1 STARRETT 24'' VERNIER CALIPER<br />

18 1 LOT: (3) ASSORTED VERNIER CALIPERS<br />

19 1 JO BLOCK GAGE HEIGHT STAND<br />

20 1 CEJ JO BLOCK GAGE HEIGHT STAND<br />

21 1 LOT: (3) ASSORTED PIN GAGE SETS<br />

22 1 LOT: (5) ASSORTED PIN GAGE SETS<br />

23 1 MINUTEMAN #50 BRO<strong>ACH</strong> SET<br />

24 1 MINUTEMAN BRO<strong>ACH</strong> SET<br />

25 1 MINUTEMAN BRO<strong>ACH</strong> SET<br />

26 1 MINUTEMAN BRO<strong>ACH</strong> SET<br />

27 1 MINUTEMAN BRO<strong>ACH</strong> SET<br />

28 1 STARRETT 18'' X 24'' X 4'' PINK GRANITE SURFACE PLATE<br />

29 1 LOT: ASSORTED DRILL AND REAMER INDEX CASES<br />

30 1 LOT: ASSORTED TRANSFER PUNCHES<br />

31 1 SURF ALLOW MODEL 6000 METALIZER; S/N 60016<br />

32 1 ROPER WHITNEY MODEL 218 BENCH TYPE HAND PUNCH; S/N 2-02<br />

33 1 LOT: (5) ASSORTED DROP FORGED C CLAMPS<br />

34 1 LOT: (7) ASSORTED DROP FORGED C CLAMPS<br />

35 6 4'' DROP FORGED C CLAMPS<br />

36 1 LOT: (4) ASSORTED DROP FORGED C CLAMPS<br />

37 1 LOT: (5) ASSORTED DROP FORGED C CLAMPS<br />

38 1 LOT: (7) ASSORTED C CLAMPS<br />

39 1 LOT: (5) ASSORTED C CLAMPS<br />

40 2 1 1/4'' DIE LIFTING EYES<br />

41 1 LOT: ASSORTED ANGLE PLATES<br />

42 1 LOT: ASSORTED V BLOCKS; SET UP BLOCKS<br />

43 2 3000 LB CAPACITY MASTER LIFTING DEVISES<br />

44 1 KURT 10'' MILLING VISE<br />

45 1 KURT 10'' MILLING VISE<br />

46 1 KURT 10'' MILLING VISE<br />

47 1 KURT 8'' MILLING VISE<br />

48 1 KURT 8'' MILLING VISE<br />

49 1 KURT 6'' SWIVEL MILLING VISE<br />

50 1 KURT 6'' SWIVEL MILLING VISE<br />

51 1 KURT 6'' SWIVEL MILLING VISE<br />

February 25, 2009<br />

1 of 51

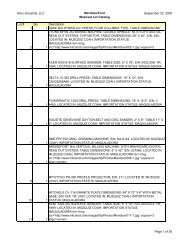

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

<strong>Lot</strong> # Quantity Description<br />

52 1 KURT 6'' SWIVEL MILLING VISE<br />

53 1 KURT 6'' MILLING VISE<br />

54 1 KURT 6'' MILLING VISE<br />

55 1 LOT: (2) ASSORTED M<strong>ACH</strong>INE VISES<br />

56 2 8'' SPEED VISES<br />

57 2 8'' SPEED VISES<br />

58 1 HARTFORD 10'' SUPER SPACER CHUCK<br />

59 1 HARTFORD 10'' SUPER SPACER CHUCK<br />

60 1 CUSHMAN 15'' 3 JAW CHUCK<br />

61 1 CUSHMAN 15'' 3 JAW CHUCK<br />

62 1 CUSHMAN 15'' 3 JAW CHUCK<br />

63 1 CUSHMAN 10'' 3 JAW CHUCK<br />

64 1 WOHLHAUPTER MODEL UPA5 PRECISION BORING HEAD<br />

65 1 NAREX MODEL VHU 2 1/8 PRECISION BORING HEAD<br />

66 1 TREE ADJUSTABLE BORING HEAD<br />

67 1 LOT: (10) ASSORTED DIAMOND GRINDING WHEELS AND STONES<br />

68 1 12'' X 1/2'' X 3'' ARBOR DIAMOND GRINDING WHEEL<br />

69 2 6'' X 6'' MAGNETIC SINE CHUCKS<br />

70 1 8'' DIAMETER PERMANENT MAGNETIC CHUCK<br />

71 1 OWENS OD COLLET FIXTURE<br />

72 1 WHEEL TRUING FIXTURE<br />

73 1 WELDON END MILL SHARPENING FIXTURE<br />

74 1 LOT: (2) ASSORTED DIAMOND WHEEL DRESSERS<br />

75 1 LOT: (2) ASSORTED 5 C COLLET FIXTURES<br />

76 1 46'' X 108'' CAST IRON LAYOUT TABLE<br />

77 1 46'' X 108'' CAST IRON LAYOUT TABLE<br />

78 1 40'' X 95'' STEEL LAYOUT TABLE<br />

79 1 40'' X 95'' STEEL LAYOUT TABLE<br />

80 1 40'' X 95'' STEEL LAYOUT TABLE<br />

81 1 40'' X 95'' STEEL LAYOUT TABLE<br />

82 1 47'' X 108'' CAST IRON LAYOUT TABLE<br />

83 1 47'' X 108'' CAST IRON LAYOUT TABLE<br />

84 1 47'' X 108'' CAST IRON LAYOUT TABLE<br />

85 1 36'' X 68'' STEEL LAYOUT TABLE<br />

86 1 47'' X 108'' CAST IRON LAYOUT TABLE<br />

87 1 47'' X 108'' CAST IRON LAYOUT TABLE<br />

88 1 47'' X 108'' CAST IRON LAYOUT TABLE<br />

89 1 47'' X 102'' STEEL LAYOUT TABLE<br />

90 1 40'' X 97'' STEEL LAYOUT TABLE<br />

91 1 40'' X 96'' STEEL LAYOUT TABLE<br />

92 1 47'' X 108'' CAST IRON LAYOUT TABLE With 4'' Swivel Vise<br />

93 1 47'' X 108'' CAST IRON LAYOUT TABLE With 4'' Swivel Vise<br />

94 1 48'' X 72'' CAST IRON SURFACE PLATE AND STAND<br />

95 1 47'' X 108'' CAST IRON LAYOUT TABLE<br />

96 1 47'' X 108'' CAST IRON LAYOUT TABLE<br />

97 1 40'' X 96'' STEEL LAYOUT TABLE<br />

98 1 40'' X 96'' STEEL LAYOUT TABLE<br />

99 1 40'' X 96'' STEEL LAYOUT TABLE<br />

100 1 40'' X 96'' STEEL LAYOUT TABLE<br />

February 25, 2009<br />

2 of 51

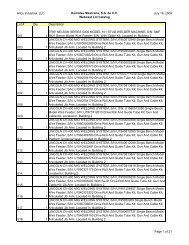

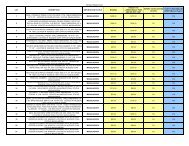

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

OKAMOTO MODEL ACC-124N 12'' X 24'' HYDRAULIC SURFACE GRINDER; S/N<br />

7691; (#GR-017); Electromagnetic Chuck; Overhead Dresser; Extended Vertical<br />

101 1 Column; Coolant; Newall Topaz Readout (Tool room)<br />

OKAMOTO MODEL ACC-124N 12'' X 24'' HYDRAULIC SURFACE GRINDER; S/N<br />

7690; Electromagnetic Chuck; Incremental Downfeed; Coolant Sony 2-Axis<br />

101A 1 Readout (GR016)<br />

OKAMOTO MODEL ACC-124N 12'' X 24'' HYDRAULIC SURFACE GRINDER; S/N<br />

7689; (#GR-015); Electromagnetic Chuck; Overhead Dresser; Coolant; Readout<br />

102 1 (Tool room)<br />

MITSUI HI-TECH MODEL 205MH 6'' X 18'' HAND FEED SURFACE GRINDER;<br />

S/N NA; (#GR-026); Electromagnetic Chuck; Coolant; Newall Topaz Readout (Tool<br />

103 1 room)<br />

LANDIS ABRASIVE 6'' X 18'' HAND FEED SURFACE GRINDER; S/N NA; (#GR-<br />

104 1 032) Permanent Magnetic Chuck (Tool room)<br />

BLANCHARD 48'' VERTICAL SPINDLE ROTARY SURFACE GRINDER; S/N 6622<br />

(Rebuilt 1999); (#GR-009); 48'' Electromagnetic Chuck; 26'' Wheel Diameter; In-<br />

105 1 Base Coolant (Tool room)<br />

CINCINNATI 12'' X 60'' UNIVERSAL ID/OD GRINDER; S/N 3F326X5V-002;<br />

Motorized Workhead; With 12'' 6-Jaw Chuck; Tailstock; Drop-Down Motorized ID<br />

Spindle; SBS Auto Wheel Balancing System; With Model SB-4500 Programmable<br />

Control; Sony 2-Axis Readout; With #FU-052 External Coolant Unit; 6'' Magnetic<br />

106 1 Separator (Tool room)<br />

TRIO TOOL 18'' FACE GRINDER; S/N 956152; (#GR-056); 18'' Wheel Size; 14'' x<br />

22'' Electromagnetic Chuck; Motorized Table Height Adjustment; Self-Contained<br />

107 1 Coolant (Tool room)<br />

MONARCH 20.5'' X 48'' CONVERTED LATHE BASE; S/N 6776; (#GR-031);<br />

Modified to Universal Grinder; Carriage Mounted Motorized Universal ID Grinding<br />

108 1 Spindle; Universal Headstock; Chuck Speeds 17 - 700 RPM (Tool room)<br />

MONARCH MODEL 16''-C 18'' X 54'' CONVERTED LATHE BASE; S/N 6576; (#LA-<br />

006) Modified to Universal Grinder; Carriage Mounted Universal Mounted Universal<br />

Motorized Grinding Spindle; Universal Headstock; Chuck Speeds 17- 700 RPM<br />

109 1 (Tool room)<br />

SENECA FALLS MODEL RO FORM RELIEF OPTICAL TOOL GRINDER; S/N<br />

25RO2020; (#GR-058); Universal Work piece Fixture; 10'' Optical Comparator<br />

110 1 Screen (Tool room)<br />

111 1 SELLERS DRILL GRINDER (GR059)<br />

112 1 12'' BENCH TYPE DISC SANDER With Dust Collector (GR062; FU056)<br />

113 1 BURR KING MODEL 960 4'' BELT GRINDER; S/N NA; (#GR-061) (Tool room)<br />

CINCINNATI BICKFORD SUPER SERVICE 5' ARM X 15'' COLUMN RADIAL<br />

DRILL; S/N 4E-1030; (#DP-019); Spindle Speeds 14 - 1500; Power Clamping; L-<br />

114 1 Base; (1) Universal (1) Plain Box Tables (Tool room)<br />

AMERICAN HOLE WIZARD 4' ARM X 11'' COLUMN RADIAL DRILL; S/N NA; (#DP-<br />

115 1 031); (12) Spindle Speeds 70 - 2100 RPM; Universal Box Table (Tool room)<br />

FOSDICK 20'' SLIDING HEAD FLOOR TYPE DRILL; S/N NA; (#DP-013); Spindle<br />

116 1 Speeds 60 - 1500 RPM Power Down Feed (Tool room)<br />

117 1<br />

SHARP 3-HP PROGRAMMABLE VERTICAL MILLING M<strong>ACH</strong>INE; S/N NA; (#MM-<br />

041); TRAK AGE 2; 3-Axis Programmable Control; 3-Way Power Travel; Table Size<br />

9'' x 50''; Variable Spindle Speeds 60 - 4500 RPM; Power Drawbar (Tool room)<br />

3 of 51

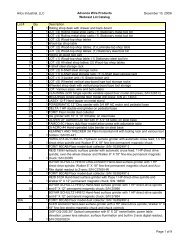

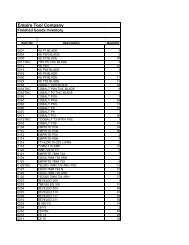

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

SHARP 3-HP PROGRAMMABLE VERTICAL MILLING M<strong>ACH</strong>INE; S/N NA; (#MM-<br />

040); PROTO TRAK SM 3-Axis Programmable Control; 3-Way Power Travel; Table<br />

Size 10'' x 50''; Variable Spindle Speeds 60 - 4500 RPM; Power Drawbar (Tool<br />

118 1 room)<br />

SWI MODEL TRAK K3S 3 HP VARIABLE SPEED VERTICAL MILLING M<strong>ACH</strong>INE;<br />

S/N U32AK12120; 60-4200 RPM; 10'' X 50'' T Slotted 3 Way Power Work Table;<br />

118A 1 Prototrak 3 Axis Programmable Control (M043; Tool room)<br />

BRIDGEPORT SERIES II SPECIAL 2-HP VARIABLE SPEED VERTICAL MILLING<br />

M<strong>ACH</strong>INE; S/N 2414S; (#MM-018); Table Size 11'' x 58''; Spindle Speeds 60 - 4200<br />

119 1 RPM; Power Table Feed (Tool room)<br />

119A 1 BRIDGEPORT SERIES I HEAD<br />

KEARNEY & TRECKER MILWAUKEE MODEL S-15/315 PLAIN VERTICAL<br />

MILLING M<strong>ACH</strong>INE; S/N 16/9923; (#MM-013); Table Size 15'' x 68''; Spindle<br />

120 1 Speeds 25 - 2000 RPM; (Tool room)<br />

CINCINNATI NO.3 PLAIN VERTICAL MILLING M<strong>ACH</strong>INE; S/N 2A3V11-147;<br />

121 1 (#MM-006); Speeds NA; Table Size 15-1/2'' x 62-1/2'' (Tool room)<br />

LUCAS MODEL 548 5'' TABLE TYPE HORIZONTAL BORING MILL; S/N 5480807;<br />

(#MM-011); 5'' Spindle Bar Diameter; Table Size 54'' x 86''; (25) Spindle Speeds 7-<br />

122 1 1/2 - 850 RPM; 48'' Vertical Travel; 72'' Saddle Travel; Morse Taper (Tool room)<br />

LUCAS MODEL 42B 4'' TABLE TYPE HORIZONTAL BORING MILL; S/N 42B-<br />

0713; (#MM-021); 4'' Spindle Bar Diameter; Table Size 40'' x 74''; (27) Spindle<br />

Speeds 9 - 1200 RPM; 42'' Vertical Travel; 72'' Saddle Travel; 4-Way Bed; Morse<br />

123 1 Taper (Tool room)<br />

124 2 30'' X 48'' X 26 1/2'' T SLOTTED ANGLE PLATES<br />

125 1 27 1/2 '' X 39'' X 29'' T SLOTTED ANGLE PLATE<br />

126 1 19 3/4'' X 29'' X 26'' T SLOTTED ANGLE PLATE<br />

127 1 LUCAS 31'' FACING ATT<strong>ACH</strong>MENT<br />

PRATT & WHITNEY MODEL 3B VERTICAL JIG BORE; S/N 198; (#MM-015); 24'' x<br />

128 1 55'' Table; Newall Topaz Readout (Tool room)<br />

MARVEL MODEL 8 UNIVERSAL VERTICAL BAND SAW; S/N NA; (#FM-046) (Tool<br />

129 1 room)<br />

GROB MODEL NS36 36'' VERTICAL BAND SAW; S/N 1062; (#FM-042) Blade<br />

130 1 Welder (Tool room)<br />

SOUTH BEND TURN-NADO 16/22'' X 60'' GAP BED ENGINE LATHE; S/N<br />

318CG166040950; (#LA-040); Spindle Speeds 20 - 2500 RPM; Quick Change<br />

131 1 Threading; Sony Readout (Tool room)<br />

LEBLOND REGAL 22'' X 60'' ENGINE LATHE; S/N 2F587; (#LA-013); (12) Spindle<br />

Speeds 27 - 1080 RPM; Quick Change Threading; Taper Attachment; 2-1/4 Hole-<br />

132 1 Thru Spindle (Tool room)<br />

MONARCH MODEL 2516X48 25'' X 48'' ENGINE LATHE; S/N 47555-K; (#LA-003);<br />

Spindle Speeds 12 - 1500 RPM; Quick Change Threading; 2'' Hole-Thru Spindle<br />

133 1 (Tool room)<br />

MONARCH MODEL 24''-N 27-1/2'' X 60'' ENGINE LATHE; S/N 7308; (#LA-009);<br />

(16) Spindle Speeds 8 - 405 RPM; Quick Change Threading; Taper Attachment; 2-<br />

134 1 1/8'' Hole-Thru Spindle (Tool room)<br />

MONARCH MODEL 16''CK 18'' X 54'' ENGINE LATHE; S/N 17235; (#LA-007); (16)<br />

Spindle Speeds 16 - 650 RPM; Quick Change Threading; 1-1/2'' Hole-Thru Spindle<br />

135 1 (Tool room)<br />

EMCO MODEL MAXIMAT SUPER II 11'' X 24'' GEARED HEAD TOOL ROOM<br />

136 1 LATHE; S/N NA; 55-2200RPM; Threading Pan Bed (LA026)<br />

4 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

MOORE NO.3 JIG GRINDER; S/N G691; (#GR-010); 11'' x 24'' Table; Mill Vision<br />

137 1 Programmable Readout (Tool room)<br />

OKUMA & HOWA MODEL ACT-5L 2-AXIS CNC TURNING CENTER; S/N 19129;<br />

(#LA-015); Approximately 20'' Swing x 48'' Centers; 12-Position Tool Turret;<br />

Programmable Tailstock; 15'' 3-Jaw Chuck; Coolant; Chip Conveyor; Fanuc System<br />

138 1 3T Control (Tool room)<br />

OKUMA & HOWA 2-AXIS CNC TURNING CENTER; S/N 19169; (#LA-005)<br />

Approximately 20'' Swing x 48'' Centers; 12-Position Tool Turret; Programmable<br />

Tailstock; 19-1/2'' 3-Jaw Chuck; Coolant; Chip Conveyor; Fanuc System 10T<br />

139 1 Control (Tool room)<br />

CINCINNATI MILACRON MODEL LANCER ERH 1255 CNC VERTICAL<br />

M<strong>ACH</strong>INING CENTER; S/N 7041-A01-94-0075; (#MM-030); Table Size 24'' x 54'';<br />

CAT 50 Taper; 30-Position Automatic Tool changer; Acramatic 850SX Controls;<br />

140 1 Coolant (Tool room)<br />

CINCINNATI MILACRON MODEL SABRE 1000-ERHA CNC VERTICAL<br />

M<strong>ACH</strong>INING CENTER; S/N 7039-A01-94-0472; (#MM-031); Table Size 20'' x 44'';<br />

CAT 40 Taper; 21-Position Automatic Tool changer; Coolant; Acramatic 850SX<br />

141 1 Control (Tool room)<br />

141A 1 CINCINNATI 12'' 4TH AXIS ROTARY TABLE<br />

141B 1 CINCINNATI 12'' 4TH AXIS ROTARY TABLE<br />

MONARCH MODEL VMC-150B CNC VERTICAL M<strong>ACH</strong>INING CENTER; S/N<br />

94517B; (#MM-029); Table Size 36'' x 84-1/2''; CAT 50 Taper; 30-Position<br />

Automatic Tool changer; Coolant; Chip Conveyor; Fanuc Series 15M Control (Tool<br />

142 1 room)<br />

143A 1 NIKKEN 10'' 4TH AXIS ROTARY TABLE<br />

OKUMA & HOWA MODEL MILLAC 5VA CNC VERTICAL M<strong>ACH</strong>INING CENTER;<br />

S/N A02B-0076-B101; (#MM-019); Table Size 22'' x 60''; CAT 50 Taper; 24-Position<br />

144 1 Automatic Tool changer; Coolant; Fanuc 11M Control (Tool room)<br />

144A 1 MMK MODEL 300 4TH AXIS ROTARY TABLE<br />

OKUMA & HOWA MODEL 5V-NC 3-AXIS CNC VERTICAL MILLING M<strong>ACH</strong>INE;<br />

S/N NA; (#MM-014) 18-1/2'' x 62'' Table; (12) Spindle Speeds 60 - 2500 RPM;<br />

145 1 Standard 50 Taper; Fanuc Control (Tool room)<br />

LEBLOND MAKINO MODEL EDNC-85 CNC RAM TYPE EDM; S/N EHEJ-244;<br />

(#MM-036); Worktable Size 39'' x 27.5''; Work tank Size 47.24'' x 31.5'' x 17.7'';<br />

Travels: 31.5'' X; 19.68'' Y; 13.78'' Z; 2000 Kg. Maximum Work piece Weight;<br />

LeBlond Makino Controls; Dielectric Fluid System; Oil Matic Temperature Regulator<br />

146 1 (Tool room)<br />

MITSUBISHI MODEL DWC-200 CNC WIRE EDM; S/N 5920K233; (#TM-197);<br />

Work tank Size 58'' x 30'' x 20''; Mitsubishi Control; Dielectric Fluid System (Tool<br />

147 1 room)<br />

BRIDGEPORT/JAPAX MODEL LU-3B CNC WIRE EDM; S/N 115-02-684); (#TM-<br />

209); Work tank Size 31'' x 22'' x 18''; Japax JAPT-3F Control; Dielectric Fluid<br />

148 1 System (Tool room)<br />

149 1 FARO MODEL 231 PORTABLE INSPECTION ARM<br />

150 1 LOT: (2) 6-DRAWER VIDMAR CABINETS AND CONTENTS (EDM Tooling)<br />

151 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (EDM Tooling)<br />

152 18 CAT 50 HOLDERS<br />

153 35 CAT 50 HOLDERS<br />

154 17 CAT 50 HOLDERS<br />

155 18 CAT 50 HOLDERS<br />

5 of 51

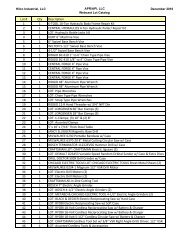

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

<strong>Lot</strong> # Quantity Description<br />

156 16 CAT 40 HOLDERS<br />

157 23 #50 TAPER HOLDERS<br />

February 25, 2009<br />

158 1 VIDMAR 3-DRAWER CABINET AND CONTENTS (CAT 50 Holders and Collets)<br />

159 1 VIDMAR 10-DRAWER CABINET AND CONTENTS (End Mills; Drills; Clamps)<br />

160 1 VIDMAR 10-DRAWER CABINET AND CONTENTS (Square End Mills; Taps)<br />

161 1 VIDMAR 11-DRAWER CABINET AND CONTENTS (Some Office Supplies)<br />

162 1 VIDMAR 7-DRAWER CABINET AND CONTENTS (Layout Fluid)<br />

VIDMAR 12-DRAWER CABINET AND CONTENTS (Drills; End Mills; CAD 50<br />

163 1 Holders)<br />

164 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Reamers; Taps)<br />

165 1 VIDMAR 10-DRAWER CABINET AND CONTENTS (Setup Blocks; End Mills; Pins)<br />

166 1 VIDMAR 4-DRAWER CABINET AND CONTENTS (Machine Bolts; Pins)<br />

167 1 VIDMAR 11-DRAWER CABINET AND CONTENTS (Drills; End Mills)<br />

168 1 VIDMAR 10-DRAWER CABINET AND CONTENTS (End Mills; Drills; Reamers)<br />

169 1 VIDMAR 3-DRAWER CABINET AND CONTENTS (Clamps; Machine Bolts)<br />

170 1 VIDMAR 10-DRAWER CABINET AND CONTENTS (Setup Blocks; Reamers; Drills)<br />

171 1 VIDMAR 3-DRAWER CABINET AND CONTENTS (CAD 50 Holders; Bolts)<br />

172 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Electrodes; Manuals)<br />

173 1 VIDMAR 7-DRAWER CABINET AND CONTENTS (Allen Wrenches; Machine Bolts)<br />

174 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Studs; Nuts)<br />

175 1 VIDMAR 4-DRAWER CABINET AND CONTENTS (Electcord; Filters)<br />

176 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Fixtures; Blocks)<br />

VIDMAR 9-DRAWER CABINET AND CONTENTS (End Mill Boring Bars; Jaw<br />

177 1 Chucks)<br />

178 1 VIDMAR 10-DRAWER CABINET AND CONTENTS (Inserts; Reamers)<br />

179 1 VIDMAR 7-DRAWER CABINET AND CONTENTS (Allen Wrenches; Chuck Jaws)<br />

VIDMAR 10-DRAWER CABINET AND CONTENTS (Small Carbide; Large<br />

180 1 Roughers)<br />

VIDMAR 6-DRAWER CABINET AND CONTENTS (Machine Bolts; Inserts;<br />

181 1 Grinders)<br />

182 1 VIDMAR 6-DRAWER CABINET AND CONTENTS (Machine Bolts; Large Drills)<br />

183 1 VIDMAR 6-DRAWER CABINET AND CONTENTS (Pins)<br />

184 1 VIDMAR 6-DRAWER CABINET AND CONTENTS (Machine Bolts; Hold Downs)<br />

185 1 VIDMAR 6-DRAWER CABINET AND CONTENTS (Inserts; End Mills)<br />

186 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (End Mills; Threaders)<br />

187 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Threaders; Drills)<br />

188 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Bushings; Gage Details)<br />

189 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Shoulder Screws)<br />

190 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Shoulder Screws)<br />

191 1 VIDMAR 2-DRAWER CABINET AND CONTENTS (Shoulder Screws)<br />

192 1 VIDMAR 8-DRAWER CABINET AND CONTENTS (Shoulder Screws)<br />

193 1 VIDMAR 6-DRAWER CABINET AND CONTENTS (Eye Bolts; Screws; Washers)<br />

6 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

<strong>Lot</strong> # Quantity Description<br />

204 1 VIDMAR 4-DRAWER CABINET AND CONTENTS (Threaders; Emery Paper)<br />

205 1 VIDMAR 7-DRAWER CABINET AND CONTENTS (Threaders; Emery Paper)<br />

206 1 VIDMAR 6-DRAWER CABINET AND CONTENTS (Drills; Reamers; Holders)<br />

207 1 VIDMAR 6-DRAWER CABINET AND CONTENTS (Threaders; Large Drills)<br />

February 25, 2009<br />

208 1 VIDMAR 7-DRAWER CABINET AND CONTENTS (Hammer Stamps; Key Stock)<br />

209 1 VIDMAR 6-DRAWER CABINET AND CONTENTS (Reamers; Finger Clamps)<br />

210 1 VIDMAR 12-DRAWER CABINET AND CONTENTS (Drills; Threaders; Sand Paper)<br />

211 1 VIDMAR 10-DRAWER CABINET AND CONTENTS (Air Tool Parts)<br />

212 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Rim Line Spacers; Punches)<br />

213 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Guide Pins; Eye Bolts)<br />

214 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Dowels; Shoulder Bolts)<br />

215 1 VIDMAR 8-DRAWER CABINET AND CONTENTS (Bench Aids)<br />

216 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Bolts)<br />

217 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Friction Bonder Buttons)<br />

218 1 VIDMAR 4-DRAWER CABINET AND CONTENTS (Friction Bonder Buttons)<br />

219 1 VIDMAR 4-DRAWER CABINET AND CONTENTS (Grinding Wheels)<br />

220 1 VIDMAR 4-DRAWER CABINET AND CONTENTS (Grinding Wheels)<br />

221<br />

VIDMAR 5-DRAWER CABINET AND CONTENTS (Shoulder Bolts; Grinding<br />

1 Wheels)<br />

222 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Pins; Machine Parts)<br />

223 1 VIDMAR 4-DRAWER CABINET AND CONTENTS (Grinding Wheels; Pins)<br />

224 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Machine Bolts)<br />

225 1 VIDMAR 5-DRAWER CABINET AND CONTENTS (Tool Holders; Large Drills)<br />

226<br />

VIDMAR 5-DRAWER CABINET AND CONTENTS (End Mills; Machine Nuts; Knee<br />

1 Blocks)<br />

227 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Taps; Drills)<br />

228 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Mills; Tool Holders)<br />

229 1 VIDMAR 9-DRAWER CABINET AND CONTENTS (Drills; Reamers; Bearings)<br />

229A 1 LOT: BUSHINGS AND SHIM STOCK (On 2 Skids)<br />

229B 1 LOT: ASSORTED ALUMINUM (On 2 Skids)<br />

229C 1 LOT: ASSORTED TOOL STEEL (In 2 Shelves And Cabinet)<br />

229D 1 LOT: ASSORTED TOOL STEEL (On 3 Tables - NO Tables)<br />

230 1 DEREX DRILL SHARPENER/GRINDER On Stand; 110V<br />

231 1 BALDOR DOUBLE END GRINDER; 1/2 HP; 3 Ph With Stand<br />

WESTHOFF HORIZONTAL PRECISION DRILL; S/N WM100-1-92308; (#DP-037)<br />

232 1 (Tool room)<br />

ZOELLER MAGNUM COMPUTER CONTROLLED TOOL PRE-SETTER; S/N NA;<br />

233 1 (#TM-524) (Tool room)<br />

234 6 STEEL WORK BENCHES; Approximately 42'' X 26''; Marked With Yellow Paint<br />

236 1 STEEL WORK BENCH; Approximately 42'' X 96''<br />

237 1 STEEL WORK BENCH; Approximately 42'' X 96''<br />

238 1 STEEL WORK BENCH; Approximately 48'' X 72''<br />

239 2 STEEL SURFACE PLATES; 24'' X 36''<br />

240 1 STEEL WORK BENCH; 40'' X 96''<br />

241 1 24'' DEMAGNETIZER<br />

242 1 STRONGHOLD CABINET; 36'' X 72''<br />

243 1 STEEL SURFACE PLATE; 24'' X 36'' With Balancer<br />

7 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

244 1 LOT: TUB With Various Sizes Lifting Chains<br />

245 1 CANTILEVER RACK; 32'' X 74'' X 54''<br />

ALL CABINETS ALONG WALL; Right Side Of Room; Approximately (18); Marked<br />

246 1 With Yellow Marker<br />

ALL CABINETS ALONG WALL; Left Side Of Room; Approximately (14); File<br />

247 1 Cabinets; Racks; Shipping Cabinets<br />

248 1 STEEL WORK BENCH/CABINET; 32'' X 84''<br />

249 1 STEEL WORK BENCH With VISE And Fumehood; 40'' X 68''<br />

250 1 STEEL WORK BENCH With VISE And Fumehood; 40'' X 68''<br />

251 1 STEEL WORK BENCH With Yost #208 Vise; 40'' X 64''<br />

252 1 SINGLE TORCH JACKKNIFE ARM<br />

253 1 LOT: ARC WELDING RODS; Various Sizes And Types With Cabinets<br />

253A 1 LOT: (2) CABINETS; WELDING ROD AND SUPPLIES<br />

253B 1 LOT: (2) SECTIONS SHELVING AND CONTENTS; FASTENERS; BOLTS<br />

ENERCO TECH PRODUCTS MODEL 5184500 GAS FIRED OVEN; S/N<br />

254 1 110210195; (#OF-078); 48'' x 42'' x 24'' (Tool room Heat Treat)<br />

LEEDS & NORTHRUP ELECTRIC HOMO-CARB FURNACE; (#520); MODEL &<br />

255 1 S/N NA; Control Panel (Tool room Heat Treat)<br />

LEEDS & NORTHRUP ELECTRIC HOMO-CARB FURNACE SYSTEM; (#OF-<br />

052/OF-051); With (2) 48 KW 1400 Degree Fahrenheit Pit-Mounted Furnaces;<br />

Control Panel; With Honeywell Digital Controls & Chart Recorder (Tool room Heat<br />

256 1 Treat)<br />

HOSKINS 22'' X 22'' X 14'' ELECTRIC BOX FURNACE; S/N NA; (#OF-055) (Tool<br />

258 1 room Heat Treat)<br />

HAYES ELECTRIC FURNACE CO ELECTRIC BOX FURNACE; S/N NA; (#OF-<br />

053); 32'' x 48'' x 20''; Honeywell Digital Controls & Chart Recorder (Tool room Heat<br />

259 1 Treat)<br />

HAYES ELECTRIC FURNACE CO ELECTRIC BOX FURNACE; S/N NA; (#OF-<br />

260 1 054) (Tool room Heat Treat)<br />

KIRKSITE ELECTRIC MELTING FURNACE; MFG'R & S/N NA; (#OF-067); 48''<br />

Diameter; Trunnion Mounted; Tilting; Honeywell Digital Controls; Exhaust Unit (Tool<br />

261 1 room Heat Treat)<br />

QUENCH TANK; (#TF-004); 60'' x 60'' x 36''; 2-Compartment; Air Pump (Tool room<br />

262 1 Heat Treat)<br />

263 1 LOT: (2) STEEL QUENCH TANKS; Approximately 72'' X 72'' X 36''<br />

264 1 BUFFALO MODEL #16 SINGLE SPINDLE FLOOR DRILL<br />

265 1 <strong>DAY</strong>TON MODEL 32917 14'' SINGLE SPINDLE FLOOR DRILL<br />

TANNEWITZ MODEL GHE 36'' VERTICAL BAND SAW; S/N 7560 (PM-004)<br />

266 1 (Carpenter Shop)<br />

267 1 DELTA 28'' RADIAL ARM CUT OFF SAW (FM-065) (Carpenter Shop)<br />

268 1 DELTA 6/12'' COMBINATION BELT/DISC SANDER (GR-030) (Carpenter Shop)<br />

269 1 STATE MODEL B4 SPINDLE SANDER; S/N 458 (Carpenter Shop)<br />

VIDMAR 10-DRAWER STORAGE CABINET AND CONTENTS (Fasteners)<br />

270 1 (Carpenter Shop)<br />

BOTT/KENNEDY 5-DRAWER LAMINATED WOOD TOP WORK BENCH<br />

271 1 (Carpenter Shop)<br />

272 1 LOT: ASSORTED POWER TOOLS (Carpenter Shop)<br />

272A 1 TARGET MASONRY SAW; 12'' With Wisconsin Motor (Mason Shop)<br />

TARGET CONCRETE SAW; Approx 16'' With Gas Motor; Electric Start (Mason<br />

272B 1 Shop)<br />

272C 1 CONCRETE SAW; Walk Behind; 1-HP; Approx 14'' (Mason Shop)<br />

8 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

272D 1 CONCRETE FINISHER; 5-HP; HONDA; With Trailer/Cart (Mason Shop)<br />

272E 1 WACKER COMPACTOR WITH HONDA MOTOR (Mason Shop)<br />

HILTI MODEL DD-250E PORTABLE ELECTRIC DRILL; 120V With 6'' Hole Drill<br />

272F 1 and Trailer (Mason Shop)<br />

272G 1 WACKER PUMP WITH GAS MOTOR; 1-1/2'' (Mason Shop)<br />

272H 1 3'' GAS PUMP; PORTABLE WITH 8-HP HONDA (Mason Shop)<br />

272I 1 CEMENT MIXER WITH WISCONSIN MOTOR (Mason Shop)<br />

HOBART GENERATOR/ARC WELDER; 3-PH; 480V; 400-AMP; 25-HP (Mason<br />

272J 1 Shop)<br />

272K 1 THERMAL CERAMICS MODEL PYRO-BLOC STUD GUN (Mason Shop)<br />

PNEUMATIC JACK HAMMERS IN CABINET WITH MISC. CONTENTS (Mason<br />

272L 1 Shop)<br />

PNEUMATIC JACK HAMMER AND OTHER PNEUMATIC TOOLS IN CABINET<br />

272M 1 (Mason Shop)<br />

LOT: (3) SHOP VACUUMS AND (1) GAS POWERED WEED EDGER (Mason<br />

272N 1 Shop)<br />

LOT: STORAGE RACK WITH CONTENTS; BAGS OF GROUT; RAGS; WIRE;<br />

PALLET OF PORTLAND TYPE 1 CEMENT; CEMENT FINISHING TOOLS;<br />

BUCKETS; LADDERS; OTHER CABINETS WITH CONTENTS; SHOVELS;<br />

272O 1 BROOMS; FANS; CHAIRS; ETC. (Mason Shop)<br />

273 1 WELDED STEEL RACK AND CONTENTS (Lumber) (Carpenter Shop)<br />

274 1 LOT: TABLES AND CABINETS (Carpenter Shop)<br />

275 1 MARVEL MODEL #8 UNIVERSAL VERTICAL BAND SAW; S/N 84307LC (FM-047)<br />

ACER MODEL ULTIMA-4VK 3-HP VARIABLE SPEED VERTICAL MILLING<br />

M<strong>ACH</strong>INE; S/N 98080953 (1999); (#MM-039); Spindle Speeds 70 - 3600 RPM;<br />

Table Size 9'' x 42''; Alin AL4000 Variable Power Table Feed; Kurt Power Drawbar;<br />

276 1 Newall Topaz 2-Axis Readout (Die Repair; E-16)<br />

ACER MODEL AGS-1020AHD 10'' X 20'' HYDRAULIC SURFACE GRINDER; S/N<br />

9302021; (#GR-970); Electromagnetic Chuck; Manual Overhead Dresser; Coolant<br />

277 1 (Die Repair; E-17)<br />

THOMPSON 8'' X 24'' HYDRAULIC SURFACE GRINDER; S/N 2F652649; (#GR-<br />

278 1 035); Electromagnetic Chuck; Coolant (Die Repair; E-17)<br />

MASTER MODEL 08 VERTICAL OSCILLATING SPINDLE DIE GRINDER; S/N 240<br />

279 1 (Die Repair; E-16)<br />

BOYAR SCHULTZ NO. 2 PROFILE GRINDER; S/N 6-1017; Overarm Spindle (Die<br />

280 1 Repair; E-17)<br />

281 1 BALDOR 12'' BENCH TYPE DISC SANDER (GR-082) (Die Repair)<br />

282 1 PEXTO BENCH TYPE HAND PUNCH & 40'' X 108'' STEEL LAYOUT TABLE<br />

283 1 WILTON 5'' SWIVEL VISE AND 40'' X 108'' STEEL LAYOUT TABLE<br />

284 1 WILTON 5'' SWIVEL VISE AND 36'' X 36'' CAST IRON SURFACE PLATE<br />

285 1 VIDMAR 9-DRAWER STORAGE CABINET AND CONTENTS (Drills)<br />

286 1 VIDMAR 7-DRAWER STORAGE CABINET AND CONTENTS (Die Springs)<br />

VIDMAR 7-DRAWER STORAGE CABINET AND CONTENTS (Grinding Wheels<br />

287 1 And Accessories)<br />

288 1 VIDMAR 7-DRAWER STORAGE CABINET<br />

289 1 VIDMAR SINGLE DOOR STORAGE CABINET<br />

290 1 VIDMAR SINGLE DOOR STORAGE CABINET<br />

291 1 VIDMAR 9-DRAWER STORAGE CABINET AND CONTENTS (Fasteners)<br />

292 1 VIDMAR 6-DRAWER STORAGE CABINET AND CONTENTS (Cylinders)<br />

9 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

<strong>Lot</strong> # Quantity Description<br />

VIDMAR 4-DRAWER STORAGE CABINET AND CONTENTS (Drills;<br />

293 1 Counterbores)<br />

294 1 STEEL STORAGE CABINET AND CONTENTS (Brass; Supplies)<br />

295 1 24'' X 24'' CAST IRON SURFACE PLATE AND TABLE<br />

296 1 BALDOR 12'' 3 HP DOUBLE END PEDESTAL GRINDER (GR-068) (D-14)<br />

297 1<br />

298 1<br />

February 25, 2009<br />

MESSER MODEL SM-1006 CNC PLASMA CUTTING TABLE; S/N SM1006P-01-<br />

4027 (2001); (#FM-093); Single Torch; 80'' x 128'' Dry Type Cutting Table; With<br />

Downdraft Exhaust System; Messer Pilot Model M282-0010 CNC Control; S/N 0800-<br />

00-1385; With Hypertherm MAX 100D 100 Amp Plasma Cutting Power Supply; S/N<br />

71-001242 (Maintenance/Metal Fab)<br />

BETENBENDER MODEL 10-1/4 10' X 1/4'' CAPACITY HYDRAULIC POWER<br />

SQUARING SHEAR; S/N 149598; (#FM-141); Front Operated Power Back Gauge;<br />

(2) 48'' Squaring Arms; (2) 34'' Stock Support Arms (Maintenance/Metal Fab)<br />

BETENBENDER 160-TON X 12' HYDRAULIC PRESS BRAKE; S/N NA; (#FM-058);<br />

299 1 Manual Back gauge; 132'' Between Housings; 8'' Throat (Maintenance/Metal Fab)<br />

DREIS & KRUMP CHICAGO MODEL 184-P.B. 8' POWER APRON BRAKE; S/N<br />

300 1 111222 (Maintenance/Metal Fab<br />

DREIS & KRUMP CHICAGO MODEL 50816; 8' X 16 GAUGE HAND BENDING<br />

301 1 BRAKE; S/N 322091M; (#FM-008) (Maintenance/Metal Fab)<br />

TENNSMITH MODEL HBU-4812 48'' X 12 GAUGE FINGER TYPE HAND<br />

302 1 BENDING BRAKE; S/N 18918; (#FM-007)<br />

HENDLEY & WHITTEMORE 6' INITIAL TYPE POWER BENDING ROLLS; S/N<br />

303 1 15248; (#FM-019) (Metal Fab)<br />

PEXTO MODEL 4-16B 4' X 16 GAUGE INITIAL PINCH TYPE HAND SLIP<br />

304 1 FORMING ROLLS; S/N NA; (#FM-022) (Maintenance/Metal Fab)<br />

BAKER TRU-EDGE CIRCLE SHEAR/NIBBER; S/N NA; (#FM-011); 48'' Throat<br />

305 1 (Maintenance/Metal Fab)<br />

DAKE-JOHNSON MODEL V-40 40'' VERTICAL BAND SAW; S/N 191724; (#FM-<br />

306 1 056); Variable Blade Speeds 0 - 500 FPM (Maintenance/Metal Fab)<br />

307 1 STEEL BENCH With (2) Hand Benders And Vise<br />

SHEET METAL WORKING BENCH; With Pexto Model 0617 18 Gauge Hand Cleat<br />

Roller; S/N 10-97; Pexto Model 544A Hand Bead Roller; S/N 50; Morlin Model 1300<br />

Handy Flanger; Niagara Hand Flanger; 26'' x 44'' Steel Bench; (Maintenance/Metal<br />

308 1 Fab)<br />

HYDRAULIC ANGLE IRON CUTTING STATION; (#FM-020); With 6'' Corner<br />

Notcher; 4'' Angle Shear; Portable Stand Mounted; External Hydraulic Unit<br />

309 1 (Maintenance/Metal Fab)<br />

BUFFALO No. 16; 16'' FLOOR TYPE DRILL PRESS; S/N NA; (#DP-003);<br />

310 1 (Maintenance/Metal Fab)<br />

BALDOR NO. 1215W 12'' 3-HP DOUBLE END GRINDER; S/N P4-91; (#GR-053);<br />

311 1 X0404237009; (#GR-096); P10-91; (#GR-097) (Maintenance/Metal Fab)<br />

312 1 SPECIAL PURPOSE ASSEMBLY M<strong>ACH</strong>INE<br />

313 1 THERMAL DYNAMICS MODEL PM6040 PLASMA CUTTER; S/N NA (Metal Fab)<br />

MILLER DELTAWELD 451 CV DC WELDING POWER SUPPLY; S/N KD416113;<br />

314 1 D54A; (METAL FAB)<br />

MILLER 330A/BP CONSTANT CURRENT AC/DC WELDING POWER SUPPLY;<br />

315 1 S/N JE739854; With Radiator 1 Water Cooling System (Metal Fab)<br />

10 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

MILLER MAXTRON 450 CC/CV DC INVERTER WELDING POWER SUPPLY; S/N<br />

316 1 KF861692; NA; (METAL FAB)<br />

MILLER DIMENSION 400 CC/CV DC WELDING POWER SUPPLY; S/N JK538876;<br />

317 1 (METAL FAB)<br />

318 1 40'' X 108'' CAST IRON LAYOUT TABLE<br />

319 1 40'' X 108'' CAST IRON LAYOUT TABLE<br />

320 1 40'' X 96'' STEEL WELDING TABLE AND VISE<br />

321 1 40'' X 120'' STEEL WELDING TABLE<br />

322 1 STEEL RACK AND CONTENTS (Sheet Stock)<br />

<strong>DAY</strong>TON MODEL 3Z866 6'' BELT/12'' DISC COMBINATION GRINDER; S/N<br />

323 1 310060; (Metal Fab)<br />

LOCKFORMER 18 GAUGE POWER SHEET METAL EDGE CLEAT FORMER; S/N<br />

324 1 2895; (Maintenance/Metal Fab)<br />

325 1 VIDMAR 7-DRAWER STORAGE CABINET<br />

326 1 LOT: ASSORTED STEEL CABINETS<br />

MILLER DIMENSION 650 CC/CV DC WELDING POWER SUPPLY; S/N<br />

327 1 KD457145; Arc Welding Leads (Hot Form Maintenance/Metal Fab)<br />

328 1 BUFFALO BENCH TYPE DRILL<br />

329 1 BALDOR 10'' BENCH TYPE HOSE CUT OFF M<strong>ACH</strong>INE<br />

330 1 OLSEN MODEL DRF FLARING M<strong>ACH</strong>INING (Hose Repair)<br />

331 1 BALDOR 12'' 3 HP DOUBLE END GRINDER (GR-052) (Hose Repair)<br />

MG INDUSTRIES OXY/FUEL BURNING TABLE; S/N AP4X490P-PC/NC-90-2243;<br />

Single Torch; 4' x 12' Burning Table; 4' x 12' Tracer Table; MG System 70<br />

332 1 Programmable Tracer Eye (Hot Form Maintenance; C-7)<br />

SCOTCHMAN MODEL 6509 HYDRAULIC IRONWORKER; S/N 2411R186 (Hot<br />

333 1 Form Maintenance; C-7)<br />

WILTON MODEL VTF-8-4 TILT FRAME UNIVERSAL VERTICAL BAND SAW; S/N<br />

00-75027 (2000); Power Head Infeed; Power Clamping; Power Tilt; Coolant<br />

334 1 (Maintenance/Metal Fab)<br />

ERCOLE MODEL 280 8'' X 10'' POWER HACK SAW; S/N NA (Maintenance/Metal<br />

335 1 Fab)<br />

MILWAUKEE 12'' ABRASIVE CUT-OFF SAW; S/N NA; With 20' Heavy-Duty Roller<br />

336 1 Conveyor Table (Maintenance/Metal Fab)<br />

336A 1 KALAMAZOO 15'' ABRASIVE CUT OFF SAW (Heat Treat) (D17)<br />

H-FRAME HYDRAULIC SHOP PRESS; MFG'R & S/N NA; 60'' x 23'' Bed; Top-<br />

Mounted Electric Powered Hydraulics; With Enerpac 100-Ton Dual-Action Ram<br />

337 1 (Maintenance/Metal Fab)<br />

MFG'R NA 20'' DISC 3-HP DISC GRINDER; S/N NA (#GR-105)<br />

338 1 (Maintenance/Metal Fab)<br />

339 1 BALDOR 12'' 3 HP DOUBLE END PEDESTAL GRINDER (GR-096)<br />

340 1 BALDOR 12'' 3 HP DOUBLE END PEDESTAL GRINDER (GR-097)<br />

CINCINNATI BICKFORD SUPER SERVICE 24'' SLIDING HEAD BOX COLUMN<br />

DRILL; S/N 2L2684; (#DP-004); (8) Spindle Speeds 90 - 1500 RPM; Power Down<br />

341 1 Feed (Maintenance/Metal Fab)<br />

FOSDICK 20'' SLIDING HEAD DRILL PRESS; S/N NA; (#DP-034); (8) Spindle<br />

342 1 Speeds 60 - 1500 RPM; Power Down Feed (Maintenance/Metal Fab)<br />

ESAB MODEL ESP200 200 AMP PLASMA CUTTING POWER SUPPLY; S/N PL-<br />

343 1 J120152; (Hot Form Maintenance; C-10)<br />

THERMAL ARC MODEL PAK 5XR 20 AMP PLASMA CUTTING POWER<br />

344 1 SUPPLY; S/N B70292A183203B (Metal Fab)<br />

344A 1 THERMAL DYNAMICS MODEL PAK 5XR PLASMA CUTTING SYSTEM<br />

11 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

344B 1 THERMAL DYNAMICS MODEL PAK 5XR PLASMA CUTTING SYSTEM<br />

MILLER DELTAWELD 451 CV DC WELDING POWER SUPPLY; S/N KA800415;<br />

345 1 S54A; (D-7)<br />

MILLER DELTAWELD 451 CV DC WELDING POWER SUPPLY; S/N KE584427;<br />

346 1 60M; (C-10) (METAL FAB)<br />

MILLER MODEL DIMENSION 650 CC/DC WELDING POWER SUPPLY; S/N<br />

347 1 KD457146 (C10)<br />

MILLER DELTAWELD 451 CV DC WELDING POWER SUPPLY; S/N KF792263;<br />

348 1 S54A; (METAL FAB)<br />

349 1 MILLER MODEL MILLERMATIC S-54A WIRE FEED; S/N JF897655 (C10)<br />

350 1 HOBART 300 AMP PORTABLE ARC WELDER; S/N 120-7097 (C10)<br />

351 1 48'' X 120'' STEEL TABLE AND VISE<br />

352 1 47'' X 108'' CAST IRON LAYOUT TABLE AND VISE<br />

353 1 26'' X 70'' STEEL TABLE AND VISE<br />

354 1 48'' X 97'' STEEL TABLE<br />

355 2 TORCH CARTS<br />

356 1 12'' DIAMETER BENCH TYPE DISC SANDER (Hot Form)<br />

SERVISE DIAMOND MODEL H14-6 BRINELL HARDNESS TESTER; S/N 2003<br />

357 1 (Hot Form)<br />

357A 1 AIR GAGE CO TEST BENCH (C10)<br />

358 1 48'' X 108'' CAST IRON LAYOUT TABLE AND VISE<br />

359 1 40'' X 96'' STEEL TABLE<br />

360 1 40'' X 96'' STEEL TABLE<br />

361 1 36'' X 96'' CAST IRON LAYOUT TABLE<br />

AMERICAN HOLE WIZARD 6' ARM X 17'' COLUMN RADIAL DRILL; S/N NA;<br />

Spindle Speeds 20 - 1600 RPM; Power Clamping; Plain Box Table (Maintenance<br />

362 1 Dept) (L-27)<br />

BRIDGEPORT/ROMI MODEL TORMAX 16-8; 16'' X 48'' ENGINE LATHE; S/N NA;<br />

(#LA-023); (20) Spindle Speeds 45 - 2240 RPM; Quick Change Threading; 2'' Hole-<br />

363 1 Thru Spindle (Press Bay Maintenance; G-15/G-17)<br />

MICROCUT MODEL 500VS 5-HP VARIABLE SPEED VERTICAL MILLING<br />

M<strong>ACH</strong>INE; S/N 49080711; (#MM-032); Table Size 11-3/4'' x 59-1/2''; Power<br />

Table/Saddle/Knee Travels; Spindle Speeds 60 - 3600 RPM; Kurt Power Drawbar;<br />

364 1 Newall Topaz 2-Axis Readout (Press Bay Maintenance; G-15/G-17)<br />

BRIDGEPORT SERIES I; 2-HP VARIABLE SPEED VERTICAL MILLING<br />

M<strong>ACH</strong>INE; S/N 12BR-206894; (#MM-033); 9'' x 42'' Table; With Power Feed; 60 -<br />

365 1 4200 RPM; Acu-Rite III Readout (Press Bay Maintenance; G-15/G-17)<br />

MARVEL MODEL 8 UNIVERSAL VERTICAL BAND SAW; S/N NA; (#FM-017);<br />

366 1 (Press Bay Maintenance; G-15/G-17)<br />

WILTON MODEL 2025 20'' FLOOR TYPE DRILL PRESS; S/N NA; (#DR-<br />

367 1 009)Spindle Speeds 80 - 1200 RPM (Press Bay Maintenance; G-15/G-17)<br />

FOSDICK 24'' SLIDING HEAD BOX COLUMN DRILL; S/N NA; (#DP-005); (12)<br />

368 1 Speeds 60 - 1500 RPM; 18'' x 36'' Table (Press Bay Maintenance; G-15/G-17)<br />

MILLER MAXTRON 450 CC/CV DC INVERTER WELDING POWER SUPPLY; S/N<br />

369 1 KF880331; 60M; (G-15)<br />

MILLER DELTAWELD 452 CC/CV DC WELDING POWER SUPPLY; S/N<br />

370 1 LA159506; 60M; (G-15)<br />

ENERPAC 30-TON H-FRAME HYDRAULIC SHOP PRESS; (#AP-016) Top-<br />

Mounted Electric Hydraulics; 29'' Between Uprights; Adjustable Rail; With Hydra-Lift<br />

371 1 (Press Bay Maintenance; G-15/G-17)<br />

372 1 POWERMATIC 20'' DISC SANDER; S/N 406160827 (H17) (GR-106)<br />

12 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

373 1 WILTON 12'' DISC SANDER (GR-003) (GG15)<br />

374 1 <strong>DAY</strong>TON DOUBLE ENDED PEDESTAL GRINDER (GR-002) (GG15)<br />

375 1 LOT: BALDOR 10'' BENCH TYPE CUT OFF SAW WITH BENCH AND VISE<br />

TRINCO 40'' X 40'' SL/BP 2 HOLE SHOT BLAST CABINET; S/N 57460-2 (SM-023)<br />

376 1 (GG16)<br />

377 1 DAKE PEDESTAL TYPE ARBOR PRESS (AP-109) (GG16)<br />

378 1 47'' X 120'' STEEL WORK TABLE AND 5'' SWIVEL VISE (GG16)<br />

379 1 47'' X 120'' STEEL WORK TABLE AND 6'' SWIVEL VISE (GG15)<br />

380 1 48'' X 97'' STEEL WORK TABLE AND 6'' SWIVEL VISE) (GG15)<br />

381 1 47'' X 108'' CAST IRON LAYOUT TABLE AND 4'' SWIVEL VISE (GG15)<br />

382 1 HARTFORD 10'' SUPER SPACER CHUCK (GG15)<br />

383 2 8'' QUICK ACTION VISES (GG15)<br />

384 2 KURT 6'' MILLING VISES (GG15)<br />

LAGUN 8-SPEED STEP PULLEY VERTICAL MILLING M<strong>ACH</strong>INE; S/N NA; (#MM-<br />

042); 2-HP; (8) Spindle Speeds 55 - 2940 RPM; 9'' x 42'' Table; With Servo 140<br />

385 1 Power Feed; Newall Topaz 2-Axis Readout (Danly Press Bay)<br />

STARTRITE MODEL V500F 20'' VERTICAL BAND SAW; S/N NA; (#FM-050);<br />

386 1 Blade Welder/Grinder (Danly Press Bay)<br />

THOMPSON 8'' X 24'' HYDRAULIC SURFACE GRINDER; S/N 2F652647; (#GR-<br />

387 1 045); Electromagnetic Chuck; Coolant (Danly Press Bay)<br />

THOMPSON 8'' X 24'' HYDRAULIC SURFACE GRINDER; S/N 2F652648; (#GR-<br />

388 1 037); Electromagnetic Chuck; Coolant (Danly Press Bay)<br />

THOMPSON 8'' X 24'' HYDRAULIC SURFACE GRINDER; S/N 2F652650; (#GR-<br />

389 1 039); Electromagnetic Chuck; Coolant (Danly Press Bay)<br />

390<br />

K.O. LEE MODEL S709NFP2P 6'' X 18'' HAND FEED SURFACE GRINDER; S/N<br />

1 NA; (#GR-050); Electromagnetic Chuck; With Variable Control (Danly Press Bay)<br />

WILTON MODEL 2025 20'' FLOOR TYPE DRILL PRESS; S/N 152718; (#DP-033);<br />

391 1 Spindle Speed Range 80 - 1200 RPM (Danly Press Bay)<br />

392 1 12'' DOUBLE END PEDESTAL GRINDER (GR036)<br />

393 1 BALDOR 8'' DOUBLE END PEDESTAL GRINDER (Press Maintenance)<br />

394 1 KALAMAZOO 10'' ABRASIVE CUT OFF SAW (FM-064) (Press Maintenance)<br />

LOT: 12'' BENCH TYPE DISC SANDER AND DEMAGNETIZER (Press<br />

395 1 Maintenance)<br />

396 1 47'' X 108'' CAST IRON LAYOUT TABLE AND (2) BENCH VISES<br />

LOT: 40'' X 97'' STEEL WORK TABLE WITH WHITNEYHAND PUNCH AND 6''<br />

397 1 HAND SHEAR (Press Maintenance)<br />

LOT: TRACEAPUNCH BENCH TYPE PUNCH AND 48'' X 72'' STEEL TABLE<br />

398 1 (Press Maintenance)<br />

399<br />

BROWN AND SHARPE MODEL MICROXCEL COORDINATE MEASURING<br />

1 M<strong>ACH</strong>INE; S/N NA; X-32''; 2'' X 14''; With Renishaw (Y18) (Press Maintenance)<br />

399B 1 BROWN AND SHARPE MICROHEIGHT GAGE (By CMM2)<br />

LOT: FOWLER 36'' VERNIER HEIGHT GAGE AND 36'' VERNIER CALIPER (By<br />

399C 1 CMM2)<br />

399D 2 GRANITE BENCH PLATES (By CMM2)<br />

399E 1 ELECTRO-ETCH ETCHER (By CMM2)<br />

399F 1 RENISAW PH8 PROBE (By CMM2)<br />

399G 1 COMPUTORQ DIGITAL TORQUE WRENCH (By CMM2)<br />

399H 2 TAYLOR-HOBSON MODEL SURFTRONIC SURFACE INDICATORS (By CMM2)<br />

13 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

399I 8 MAGNETIC INDICATOR STANDS (By CMM2)<br />

399J 1 LOT: (2) ASSORTED DIGITAL SCALES (By CMM2)<br />

399K 1 LOT: ASSORTED OETIKER FORCE CALIBRATORS (By CMM2)<br />

399L 1 LOT: (3) ASSORTED DIGITAL THERMOMETERS (By CMM2)<br />

399M 1 LOT: TESK EQUIPMENT (By CMM2)<br />

ROCKLINIZER MODEL 600 CARBIDE METAL IMPREGNATOR (Press<br />

400 1 Maintenance)<br />

GREENLEE MODEL SMART QUAD 855 POWER CONDUIT BENDER; S/N NA;<br />

(#BF-138); Portable; Hand Pendant Control (Pipe Fitter/Electrician Maintenance; M-<br />

401 1 19)<br />

KALAMAZOO MODEL VT-18 TILT FRAME VERTICAL BAND SAW; S/N 10670;<br />

(#FM-034); Power Head Infeed; Variable Blade Speed (Pipe Fitter/Electrician<br />

402 1 Maintenance; M-19)<br />

JET MODEL HUBS463 7'' CAPACITY HORIZONTAL/VERTICAL METAL CUTTING<br />

403 1 BAND SAW; S/N 8056921 (Pipe Shop)<br />

AMT MODEL 5175 1-HP FLOOR TYPE RADIAL DRILL PRESS; S/N NA (#DP-016)<br />

404 1 (Pipe Fitter/Electrician Maintenance; M-19)<br />

405 1 BALDOR 12'' 3 HP DOUBLE END PEDESTAL GRINDER (GR076) (Pipe Shop)<br />

RIDGIT MODEL 535 PORTABLE PIPE THREADER; S/N 404364; With Reamer;<br />

406 1 Cut Off (Pipe Shop)<br />

406C 1 RIDGID MODEL 535 PORTABLE ELECTRIC PIPE THREADER (Pipe Shop)<br />

407 1 48'' X 97'' STEEL TABLE WITH PIPE VISE<br />

407A 1 THERMAC ARC MODEL WC100B PLASMA CUTTER; S/N 00225365 (2000) (L-16)<br />

MILLER MODEL XMT 304 CC/CV DC INVERTER ARC WELDER; S/N LF034787<br />

407B 1 (L-16)<br />

MILLER MODEL MAX STAR 175 CC/DC INVERTER WELDER POWER SUPPLY;<br />

407C 1 S/N KD444954 (L-16)<br />

MILLER MODEL INVISION 456P DC INVERTER ARC WELDER; S/N LA216996<br />

407D 1 With Wirefeed (L-16)<br />

MILLER MODEL ACCESS 450 DC ARC WELDER; S/N LG025274; With Wirefeed<br />

407E 1 (L-16)<br />

MILLER MODEL ACCESS 450 DC ARC WELDER; S/N LF257412; With Wirefeed<br />

407F 1 (L-16)<br />

407G 1 MILLER MODEL AUTO INVISION ARC WELDER; S/N LA002159 (L-16)<br />

MILLER MODEL DELTAWELD 452 CV/DC WELDER; S/N LA159501 With<br />

407H 1 Wirefeed (L-16)<br />

MILLER MODEL ACCESS 450 DC ARC WELDER; S/N LG310007U With Wirefeed<br />

407I 1 (L-16)<br />

407J 1 MILLER MODEL ACCESS 450 DC ARC WELDER; S/N LG290080U (L-16)<br />

MILLER MODEL DELTAWELD 451 CV/DC ARC WELDER; S/N KC211502 With<br />

407K 1 Wirefeed (L-16)<br />

MILLER MODEL DELTAWELD 451 CV/DC ARC WELDER; S/N KE669586 With<br />

407L 1 Wirefeed (L-16)<br />

IKEDA MODEL RM1300 5' ARM X 13'' COLUMN RADIAL ARM; S/N 66137; (#DP-<br />

035); Spindle Speed Range 55 - 1440 RPM; Power Clamping; Universal Box Table<br />

408 1 (Hydraulic Maintenance (G-10/H-10)<br />

409 1<br />

SOLBERGA MODEL SE1425 20'' GEARED HEAD BENCH TYPE DRILL PRESS;<br />

S/N 3493; (8) Speeds 120 - 1548 RPM (Hydraulic Maintenance; G-10/H-10)<br />

14 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

FOSDICK 24'' SLIDING HEAD BOX COLUMN DRILL; S/N NA; (8) Geared Spindle<br />

410 1 Speeds 220 - 3600 RPM (Hydraulic Maintenance; G-10/H-10)<br />

ENCO MODEL GL30B BENCH TYPE VERTICAL MILLING M<strong>ACH</strong>INE; S/N 2717; 8<br />

411 1 1/4'' X 29'' T SLOTTED WORK TABLE (H-11)<br />

H-FRAME HYDRAULIC SHOP PRESS; MFG'R NA; 36'' Between Uprights;<br />

Adjustable Rail; Enerpac Electric Hydraulic Pump (Hydraulic Maintenance; G-10/H-<br />

412 1 10)<br />

413 1 STATE 16'' VERTICAL DISC SANDER (GR-093) (H12)<br />

414 1 CINCINNATI 12'' DOUBLE END PEDESTAL GRINDER (GR-094) (H12)<br />

LAKELAND MODEL 832 BENCH TOP HYDRAULIC TUBE BENDER; S/N 1523-<br />

RB98; Cart Mounted; With Bending Dies to 1-1/2'' (No Hydraulic Power Unit)<br />

415 1 (Hydraulic Maintenance; G-10)<br />

MILLER DELTAWELD 451 CV DC WELDING POWER SUPPLY; S/N KF792247;<br />

416 1 NA; (HYD. MAINTENANCE H-11)<br />

417 1 STARRETT 36''-42'' INTERCHANGEABLE ANVIL MICROMETER (H10)<br />

418 1 STARRETT 24''-30'' INTERCHANGEABLE ANVIL MICROMETER (H10)<br />

419 1 LOT: (2) ASSORTED OUTSIDE MICROMETERS (H10)<br />

420 1 LOT: (2) ASSORTED MILLING VISES (H10)<br />

421 1 48'' X 156'' STEEL WORK TABLE AND 5'' BENCH VISE (H10)<br />

422 1 BLACK AND DECKER 3/4'' MAGNETIC BASE DRILL (H10)<br />

423 1 MARVEL UNIVERSAL VERTICAL BAND SAW; S/N NA (Slip Yoke Machining; J-1)<br />

424 1 TRINCO MODEL 36 2-HOLE SHOT BLAST CABINET S/N 52596-0 (H1)<br />

425 1 STARRETT 10'' BENCH TYPE SPECIMEN POLISHER (GR-102) (H1)<br />

WILSON ROCKWELL MODEL SERIES 2000 DIGITAL HARDNESS TESTER (TE-<br />

426 1 006) (H1)<br />

427 1 NEW AGE MODEL MT90 MICROHARDNESS TESTER (TE008) (H1)<br />

428 1 GARTNER BENCH TYPE OPTICAL COMPARATOR With Delta Digital Scale (H1)<br />

WILTON MODEL 5212301 4' ARM X 11'' COLUMN RADIAL DRILL; SN 12724;<br />

429 1 (#DP-030); (12) Spindle Speeds 44 - 1500 RPM; Plain Box Table (Prototype)<br />

POWERMATIC MODEL 1200 20'' VARIABLE SPEED FLOOR TYPE DRILL<br />

430 1 PRESS; S/N 9220V198; (#DP-029); 100 - 2000 RPM (Prototype)<br />

DOALL MODEL 2013-10 20'' VERTICAL BAND SAW; S/N 339-77765; (#FM-028);<br />

431 1 Variable Blade Speeds 50 - 5200 FPM; Blade Welder/Grinder (Prototype)<br />

TANNEWITZ MODEL G1NE 36'' VERTICAL BAND SAW; S/N 96007; (#FM-060);<br />

432 1 (Prototype)<br />

DOALL MODEL 2013-20 20'' VERTICAL BAND SAW; S/N 377-921408 (1992);<br />

433 1 (#FM-055); Variable Blade Speeds 0 - 5000 FPM; Blade Welder/Grinder (Prototype)<br />

W.F. WELLS MODEL L-10 10'' X 12'' CAPACITY HORIZONTAL METAL CUTTING<br />

434 1 BAND SAW; S/N L011226; (#FM-143) (Prototype)<br />

JET MODEL HVBS-7MW 7'' CAPACITY HORIZONTAL/VERTICAL METAL<br />

435 1 CUTTING BAND SAW; S/N 5041736; (#FM-072) (Prototype)<br />

KALAMAZOO COMBINATION 6'' BELT/12'' DISC GRINDER; S/N NA; (#GR-065)<br />

436 1 (Prototype)<br />

437 1 KALAMAZOO 12'' VERTICAL DISC GRINDER; S/N NA ; (#GR-054) (Prototype)<br />

KALAMAZOO MODEL FS350S 350mm COLD SAW; S/N 400; (#FM-061); Miter<br />

438 1 Type; Power Vise; Power Head Raise/Lower (Prototype)<br />

15 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

439 1 ROCKWELL/DELTA 12'' BENCH TYPE DISC SANDER (Prototype) (GR027)<br />

440 1 BLACK AND DECKER 8'' DOUBLE END BENCH TYP0E GRINDER<br />

WELDING CART; With (1) Miller Invision 456P DC Inverter Welding Power Supply;<br />

S/N KH475254; (1) Miller Maxstar 175 CC/DC Inverter Welding Power Supply; S/N<br />

KE739646; (1) S60M Wire Feeder; (1) Snap Start High Frequency Arc Starter<br />

441 1 (Prototype)<br />

WELDING CART; With (1) Miller Invision 456P DC Inverter Welding Power Supply;<br />

S/N KK096607; (1) Miller Maxstar 175 CC/DC Inverter Welding Power Supply; S/N<br />

KC236642; (1) S60M Wire Feeder; (1) Snap Start High Frequency Arc Starter<br />

442 1 (Prototype)<br />

MILLER MAXTRON 450 CC/CV DC INVERTER WELDING POWER SUPPLY; S/N<br />

443 1 KF897053; S-60M; (PROTOTYPE)<br />

LOT: MILLER MAXTRON 450 CC/CV DC INVERTER WELDING POWER<br />

SUPPLY; S/N KF764857; D-60; (PROTOTYPE) AND MAXSTAR 175 CC/DC<br />

INVERTER WELDING POWER SUPPLY; S/N KF862672; With Snap Start High<br />

444 1 Frequency Arc Starter (Prototype)<br />

LOT: MILLER INVISION 456P DC INVERTER WELDING POWER SUPPLY; S/N<br />

KH401851; 60M; (PROTOTYPE) AND MAXSTAR 175 CC/DC INVERTER<br />

WELDING POWER SUPPLY; S/N KD537586; With Snap Start High Frequency Arc<br />

445 1 Starter (Prototype)<br />

MILLER SHOP MASTER CC/CV AC/DC WELDING POWER SUPPLY; S/N<br />

KF949809; With Miller D-60 Dual Wire Feeder; Polarity Reversing Control;<br />

Coolmate 3 Water Cooler; HF-251D-1 High Frequency Arc Starter; Leads<br />

446 1 (Prototype)<br />

WELDING CART; With (1) Miller Invision 456P DC Inverter Welding Power Supply;<br />

S/N KH475253; (1) Miller Maxstar 175 CC/DC Inverter Welding Power Supply; S/N<br />

KC236635; (1) Snap Start High Frequency Arc Starter; (1) 60M Series Wire Feeder<br />

447 1 (Prototype)<br />

WELDING CART; With (1) Miller DeltaWeld 450 CP/DC Welding Power Supply;<br />

S/N JG137125; (1) Miller Maxstar 175 CC/DC Inverter Welding Power Supply; S/N<br />

448 1 KC222236; (1) S-54A Wire Feeder (Prototype)<br />

MILLER MODEL MAXTRON 450 CC/DV DC INVERTER ARC WELDER; S/N<br />

KC283769; MILLER MAXSTAR CC/DC INVERTED WELDING POWER SUPPLY;<br />

449 1 S/N KD374321; 24V Constant Speed Wire Feeder (Prototype)<br />

MILLER MODEL INVISION 456P DC INVERTER ARC WELDER; S/N KH4571439;<br />

MILLER MAXSTAR 175 CC/DC INVERTER POWER SUPPLY; S/N KC 302974<br />

450 1 (Prototype)<br />

MILLER MODEL MAXSTAR 175 CC/DC INVERTER POWER SUPPLY S/N<br />

KC302970; MILLER SNAP START HIGH FREQUENCY SNAP START; 60M<br />

451 1 SERIES WIRE FEED (Prototype)<br />

WELDING CART; With (1) Miller Invision 456P DC Inverter Welding Power Supply;<br />

S/N KH453274; (1) Miller Maxstar 175 CC/DC Inverter Welding Power Supply; S/N<br />

KC244131; (1) Snap Start High Frequency Arc Starter; (1) 60M Series Wire Feeder<br />

452 1 (Prototype)<br />

WELDMATION RESISTANCE TYPE ROTARY SEAM WELDER; S/N NA; 20''<br />

453 1 Throat; Press Type; Robotron Series 110 Control (Prototype) (#WP-134)<br />

ACRO PRESS TYPE SPOT WELDER; S/N 94-1375; (#WP-225); 16'' Throat;<br />

454 1 Robotron Series 50 Control (Prototype)<br />

ACRO PRESS TYPE SPOT WELDER; S/N 94-1336; )#WP-298); 16'' Throat;<br />

455 1 Robotron Series 50 Control (Incomplete) (Prototype)<br />

16 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

MELTON C-FRAME HYDRAULIC PRESS; S/N 7725; (#TM-700); Platen Size 12'' x<br />

456 1 17''; 20'' Daylight; Allen Bradley PLC; With Panel View 1000 (Prototype)<br />

CUSTOM H-FRAME DESIGN HYDRAULIC PRESS; (#AP-009) 2' x 3' Bed; 50-HP<br />

457 1 Hydraulic Unit (Prototype)<br />

ENERPAC 10-TON H-FRAME HYDRAULIC SHOP PRESS; 18'' Between Uprights;<br />

458 1 Adjustable Rail; 10-Ton Ram; Hand Pump Hydraulics (Prototype)<br />

ENERPAC 10-TON H-FRAME HYDRAULIC SHOP PRESS; 18'' Between Uprights;<br />

459 1 Adjustable Rail; 10-Ton Ram; Hand Pump Hydraulics (Prototype)<br />

M & M MODEL TRAKTRONIC TFM HF350TT CNC SPIN FORM LATHE; S/N 3-<br />

4499-01 (2001); (#F1-025) Center Height 25.6''; Distance Between Centers 30.3'';<br />

Variable Speeds 0-2450 RPM; Travels: 13.8'' X; 11.2'' Z; 28 Kw; Tailstock 7.8''<br />

460 1 Ejector Travel CNC Control Console; Enclosure Cage (Prototype)<br />

EAGLE MODEL TC-DC HYDRAULIC TUBE/PIPE CUT-OFF M<strong>ACH</strong>INE; S/N<br />

461 1 553983; Allen Bradley SLC-500 Programmable Control; 15-HP (Prototype)<br />

462 1 LASERVISION MODEL LV INSPECTION TABLE W/N 2242251PC (Prototype)<br />

EAGLE MODEL EPT-75-X PE pA CNC HYDRAULIC TUBE BENDING M<strong>ACH</strong>INE;<br />

S/N 66-4155 (EST. 2001); (#BF-137); 3'' Maximum Tube O.D.; Maximum Wall<br />

Thickness .125'' Carbon Steel/.062'' Stainless; Center Line Radius 1.5'' Min. - 10.0''<br />

Max.; Maximum Tube Length Over Mandrel 118''; Carriage Travel 114''; Xycom<br />

463 1 CNC Control (Prototype)<br />

BEN PEARSON MODEL ''MUFFLER SHOP'' PORTABLE HYDRAULIC TUBE<br />

BENDER; S/N NA; (#BF-134); 1-1/2'' x 3'' Capacity; With Flaring Unit & Bending<br />

464 1 Dies (Prototype)<br />

BEN PEARSON MODEL ''MUFFLER SHOP'' PORTABLE HYDRAULIC TUBE<br />

BENDER; S/N NA; (#BF-136); 1-1/2'' x 3'' Capacity; With Flaring Unit & Bending<br />

465 1 Dies (Prototype)<br />

MCKEE MODEL FM70 ID/OD DUAL SIZER HORIZONTAL HYDRAULIC TUBE<br />

END FORMING M<strong>ACH</strong>INE; S/N 74201; (#TM-477); Allen Bradley SLC-5/03 CPU &<br />

466 1 Panel View 900 PLC; Water Cooled Heat Exchanger (Prototype)<br />

MCKEE-ADDISON MODEL FORMASTER 150RF SINGLE SIZER HORIZONTAL<br />

HYDRAULIC TUBE END FORMING M<strong>ACH</strong>INE; S/N 68624; (#TM-479); Allen<br />

Bradley SLC-5/03 CPU; With Panel View 900 PLC; Water-Cooled Heat Exchanger<br />

467 1 (Prototype)<br />

EAGLE MODEL C-2000 SINGLE HEAD HORIZONTAL HYDRAULIC TUBE END<br />

SIZING/FORMING M<strong>ACH</strong>INE; S/N 553936; (#TM-575) Allen Bradley SLC-500<br />

468 1 Programmable Controller; 15-HP (Prototype)<br />

EAGLE MODEL I/O SINGLE SIZER HORIZONTAL HYDRAULIC TUBE END<br />

FORMING M<strong>ACH</strong>INE; S/N 1017; (#TM-090); Water-Cooled Heat Exchanger<br />

469 1 (Prototype)<br />

EAGLE MODEL F SINGLE HEAD HORIZONTAL HYDRAULIC TUBE END SIZING<br />

470 1 M<strong>ACH</strong>INE; S/N 1141; (#TM-088); (Prototype)<br />

MCKEE-ADDISON MODEL FM-A60 PORTABLE AIR OVER HYDRAULIC SINGLE<br />

471 1 TUBE END SIZER; S/N 79176; (# NA) (Prototype)<br />

472 1 LOT: 2 STRONGHOLD 2-DOOR STORAGE CABINETS AND CONTENTS (Dies)<br />

17 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

LASER LAB PENTACON MODEL P-3015 3-AXIS CNC LASER CUTTING<br />

M<strong>ACH</strong>INE; S/N P-35895 (1994); (#FU-024); Worktable Size 68-1/2'' x 132-1/2'';<br />

ANCA Model System 32 CNC Control; S/N 321941 (1994); Stationary Bridge;<br />

Traveling Table; 74'' Between Columns; Arrow Ultimate Industrial 1800 Watt Co2<br />

Laser; S/N 04/995; With GE Fanuc Series 90-30 PLC; Automatic Pallet Table<br />

Transfer System; With (2) 68-1/2'' x 132-1/2'' Spare Pallet Tables; GMT Coordinate<br />

Measuring Gantry; With Faro Arm Model S08/REV-O Inspection Arm; S/N<br />

S08019500189; Model SOS-REV-O Controller; Dell PC; Allen Bradley Panel View<br />

550 PLC Terminal; With (1) (#CW-015); Koolant Koolers Model HCV-7500-PR-NF-<br />

473 1 FILT Chiller; S/N 8782; 7-1/2-HP Compressor<br />

Q.B. & ASSOCIATES LEAK TESTER; (#TM-488); 96'' x 34'' x 18'' Stainless Steel<br />

Submersing Tank; (2) Allen Bradley SLC-5/04 CPU PlC's & (1) Panel View 1000<br />

474 1 PLC Terminal (Prototype)<br />

475 1 Q.B. & ASSOCIATES LEAK TESTER; (#TM-420); 36'' x 60'' Worktable (Prototype)<br />

476 1 WESTWARD 1 TON HYDRAULIC ENGINE CRANE S/N SPC9924152(Prototype)<br />

JET MODEL JDP20E 20'' ELECTRONIC VARIABLE SPEED SINGLE SPINDLE<br />

477 1 DRILL S/N 6080327 (Prototype)<br />

STARRETT 48'' X 96'' X 16'' PINK GRANITE SURFACE PLATE AND STAND<br />

478 1 (Prototype)<br />

479 1 LOT: BENCHES AND VISE (In This Room)<br />

480 1 40'' X 72'' STEEL WELDING TABLE AND VISE (Prototype)<br />

481 1 20'' X 50'' STEEL WELDING TABLE AND VISE (Prototype)<br />

482 1 40'' X 60'' STEEL WELDING TABLE AND VISE (Prototype)<br />

483 1 40'' X 96'' STEEL WELDING TABLE (Prototype)<br />

484 1 41'' X 96'' STEEL WELDING TABLE AND VISE (Prototype)<br />

485 1 41'' X 60'' STEEL WELDING TABLE AND VISE (Prototype)<br />

486 1 41'' X 96'' STEEL WELDING TABLE AND VISE (Prototype)<br />

487 1 41'' X 96'' STEEL WELDING TABLE AND VISE (Prototype)<br />

488 1 41'' X 96'' STEEL WELDING TABLE AND VISE (Prototype)<br />

489 1 41'' X 96'' STEEL WELDING TABLE AND VISE (Prototype)<br />

490 1 41'' X 96'' STEEL WELDING TABLE AND VISE (Prototype)<br />

491 1 41'' X 96'' STEEL WELDING TABLE AND VISE (Prototype)<br />

492 1 LOT: CIM MODEL 1700A EMBOSSER; OHAUS SCALE AND TABLE (Prototype)<br />

493 7 25'' X 50'' STEEL WORK TABLES (Prototype)<br />

494 1 EXHAUST BLOWER AND FUME COLLECTOR (Prototype)<br />

495<br />

NEDERMAN FILTER MAX DUST COLLECTOR; MODEL & S/N NA (Prototype;<br />

Outside Ramp Area) With CEILING MOUNTED WELDING FUME EXHAUST UNIT;<br />

1 MODEL & S/N NA (Prototype)<br />

496 14 PORTABLE SHOP CARTS (Prototype)<br />

497 10 3-TIER PORTABLE CARTS (Prototype)<br />

498 1 LOT: BENCH AND CABINETS (Prototype)<br />

499 3 2-DOOR STORAGE CABINETS (Prototype)<br />

500 2 LYON STORAGE CABINETS (Prototype)<br />

501 1 LOT: (2) CABINETS AND BANDING CART; TORCH CART (Prototype)<br />

502 1 LOT: ASSORTED SHOP CARTS (Prototype)<br />

503 1 LOT: TABLE AND BASKET (Prototype)<br />

504 1 MINUTEMAN MODEL 2800 FLOOR POLISHER (Prototype)<br />

505 1 LOT: ASSORTED CARTS; FANS (Prototype)<br />

18 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

<strong>Lot</strong> # Quantity Description<br />

506 1<br />

February 25, 2009<br />

TORIT DOWNFLO MODEL DFT2-12 DUST COLLECTOR; S/N IG050805; (#FU-<br />

033); 20-HP; (6) 16'' Replaceable Cartridge Filters; Pneumatic Pulse Jet (Prototype)<br />

507 1 LOT: BENCH; ARBOR PRESS; (2) HAND PUNCHES; HAND BENDER (Prototype)<br />

508 1 LOT: ASSORTED STEEL SHELVING AND PARTS PANS (Prototype)<br />

MILLER MODEL DELTAWELD 451 CV/DC WELDING POWER SOURCE; S/N<br />

509 1 KA800424 (Prototype)<br />

510 1 TORIT MODEL P11000 PORTABLE FUME COLLECTOR (Prototype)<br />

511 1 B/T 5000 LB HYDRAULIC PALLET JACK (Prototype)<br />

TANNEWITZ MODEL G1NE 36'' VERTICAL BAND SAW; S/N 22007; (#FM-095);<br />

Hydraulic Power Blade Tension Adjustment; Hydraulic Power Guide Post<br />

512 1 Adjustment (E-4)<br />

TANNEWITZ MODEL G1NE 36'' VERTICAL BAND SAW; S/N 93011; (#FM-054) (E-<br />

513 1 4)<br />

TORIT DOWNFLO MODEL 2DF4 DUST COLLECTOR; S/N IG436678-001;<br />

(#FU081); 5-HP; Pneumatic Pulse Jet Cleaning; (4) 16'' Replaceable Cartridge<br />

514 1 Filters; Stand Mounted; (Used; With Messer CNC Plasma Cutting Table) (OB-11)<br />

515 1 POWERMATIC MODEL 4421 20'' DISC SANDER; S/N 200406 (GR108; K-27)<br />

515A 1 POWERMATIC MODEL DS-20-3 20'' VERTICAL DISC SANDER (GR106; M14)<br />

515B 1 POWERMATIC MODEL DS-20 20'' VERTICAL DISC SANDER (GR107; K11)<br />

516 1 BALDOR 12'' 3 HP DOUBLE END PEDESTAL GRINDER (GR084; K-27)<br />

TANNEWITZ MODEL G1NE 36'' VERTICAL BAND SAW; S/N 77026; (#FM-003);<br />

517 1 (GG-27)<br />

CLEARR H-FRAME HYDRAULIC PRESS; S/N NA; (#AP-003) Approximately 150-<br />

518 1 Ton; 48'' Between Uprights; Fixed Rail; 4-1/2'' Ram (GG-27)<br />

519 1 PACKAGE PRESS LINE 10 CONSISTING OF LOTS 520-524<br />

DANLY MODEL S4-700-108-60 700-TON 4-POINT STRAIGHT SIDE PRESS; S/N<br />

71301401 (Press #10); (#PM-065); Bed Size 108''LR x 60''FB; Stroke 12''; Shut<br />

Height 42''; Adjustment 12''; Speeds Variable 20-60 SPM Continuous/15-45 SPM<br />

Single Stroking; 42'' Windows; Xycom Automation Microprocessor PLC Control;<br />

Press Watch 4-Channel Digital Production Monitor; T-Slotted Bolster & Ram; Air<br />

520 1 Clutch; Air Counterbalance; Floor Standing<br />

AMERICAN STEEL LINE MODEL 1000 20;000 LB X 36'' POWER UNCOILER; S/N<br />

521 1 7547<br />

AMERICAN STEEL LINE MODEL 1000 36'' 7-ROLL POWER STRAIGHTENER;<br />

522 1 S/N 7553<br />

AUTOMATIC FEED CO 36'' PRESS MOUNTED MOTORIZED POWER ROLL<br />

523 1 FEEDER<br />

524 1 CONTROL CABINET<br />

525 1 PACKAGE PRESS LINE 12 CONSISTING OF LOTS 526-531<br />

DANLY MODEL S4-700-108-60 700-TON 4-POINT STRAIGHT SIDE PRESS; S/N<br />

NA (Press #12); (#PM-067); Bed Size 108''LR x 60''FB; Stroke 12''; Shut Height 42'';<br />

Adjustment 12''; Speeds Variable 20-60 SPM Continuous/15-45 SPM Single<br />

Stroking; 42'' Windows; Xycom Automation Microprocessor PLC Control; Press<br />

Watch 4-Channel Digital Production Monitor; T-Slotted Bolster & Ram; Air Clutch;<br />

Air Counterbalance; Floor Standing (Press # 12 With Magnetic Scrap Removal<br />

526 1 Conveyor)<br />

19 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

AMERICAN STEEL LINE MODEL 1000 20;000 LB X 36'' POWER UNCOILER; S/N<br />

527 1 7548<br />

AMERICAN STEEL LINE MODEL 1000 36'' 7-ROLL POWER STRAIGHTENER;<br />

528 1 S/N 7554<br />

AUTOMATIC FEED CO MODEL 736 36'' PRESS MOUNTED MOTORIZED FEED;<br />

529 1 S/N 3260<br />

530 1 MAGNETIC SCRAP REMOVAL CONVEYOR<br />

531 1 CONTROL CABINET<br />

532 1 PACKAGE PRESS LINE 14 CONSISTING OF LOTS 533-538<br />

DANLY MODEL S4-700-108-60 700-TON 4-POINT STRAIGHT SIDE PRESS; S/N<br />

71301406 (Press #14) (#PM-069); Bed Size 108''LR x 60''FB; Stroke 12''; Shut<br />

Height 42''; Adjustment 12''; Speeds Variable 20-60 SPM Continuous/15-45 SPM<br />

Single Stroking; 42'' Windows; Xycom Automation Microprocessor PLC Control;<br />

Press Watch 4-Channel Digital Production Monitor; T-Slotted Bolster & Ram; Air<br />

533 1 Clutch; Air Counterbalance; Floor Standing<br />

AMERICAN STEEL LINE MODEL 1000 20;000 LB X 36'' POWER UNCOILER; S/N<br />

534 1 7584<br />

AMERICAN STEEL LINE MODEL 1000 36'' 7-ROLL POWER STRAIGHTENER;<br />

535 1 S/N 7607<br />

536 1 AUTOMATIC FEED CO MODEL 736 PRESS MOUNTED MOTORIZED FEED<br />

537 1 MAGNETIC SCRAP REMOVAL CONVEYOR<br />

538 1 CONTROL CABINET<br />

539 1 PACKAGE PRESS LINE 15 CONSISTING OF LOTS 540-545<br />

DANLY MODEL S4-700-108-60 700-TON 4-POINT STRAIGHT SIDE PRESS; S/N<br />

71301407 (Press #15) (#PM-070); Bed Size 108''LR x 60''FB; Stroke 12''; Shut<br />

Height 42''; Adjustment 12''; Speeds Variable 20-60 SPM Continuous/15-45 SPM<br />

Single Stroking; 42'' Windows; Xycom Automation Microprocessor PLC Control;<br />

Press Watch 4-Channel Digital Production Monitor; T-Slotted Bolster & Ram; Air<br />

Clutch; Air Counterbalance; Floor Standing (Press #15 With Magnetic Scrap<br />

540 1 Removal Conveyor)<br />

541 1 AMERICAN STEEL LINE MODEL 1000 20;000 LB UNCOILER; S/N 8508<br />

542 1 AMERICAN STEEL LINE MODEL 1000 20;000 LB STRAIGHTENER; S/N 8504<br />

AUTOMATIC FEED CO MODEL 736 PRESS MOUNTED MOTORIZED FEED (No<br />

543 1 Motor)<br />

544 1 CONTROL PANEL<br />

NIAGARA MODEL S2-G-225-77-33-1/2 DOUBLE CRANK GAP FRAME PRESS;<br />

S/N 142166; (#PA-038); Bed Size 77''LR x 33-1/2''FB; Stroke 16''; Shut Height 30'';<br />

545 1 Speed 30 SPM; Air Clutch; Air Counterbalance; Twin End Drive (Danly Press Bay)<br />

NIAGARA MODEL S2-G-225-77-32-1/2 225-TON DOUBLE CRANK GAP FRAME<br />

PRESS; S/N 40919; (#PA-026); Bed Size 80-1/2''LR x 32-1/2''FB; 16'' Stroke; 30''<br />

Shut Height; 5'' Adjustment; 30 SPM; Ram Area 72''LR x 30''FB; Air Clutch; Air<br />

546 1 Counterbalance (Die Repair)<br />

NIAGARA MODEL 2G-25-77-32 GAP FRAME PRESS; S/N NA; AIR CLUTCH; 77<br />

546A 1 LR-32 FB T-Slotted Bed (PA-051) (Yard)<br />

NIAGARA MODEL 2G-25-77-32 GAP FRAME PRESS; S/N NA; AIR CLUTCH; 77<br />

546B 1 LR-32 FB T-Slotted Bed (PA-043) (Yard)<br />

546C 1 NIAGARA HORN PRESS; S/N NA; AIR CLUTCH (PA042) (Yard)<br />

20 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />

<strong>Lot</strong> # Quantity Description<br />

Niagara Model HF5-1/2 110-Ton Adjustable Bed Horn Press; S/N NA; Bed Size<br />

40''LR x 30''FB; 8'' Stroke; 10''-24'' Shut Height; 5'' Adjustment; Ram Area 28''LR x<br />

547 1 21''FB; Air Clutch; Air Counterbalance; #PA-121<br />

Niagara Model HF5-1/2 110-Ton Adjustable Bed Horn Press; S/N 46383; Bed Size<br />

40''LR x 30''FB; 8'' Stroke; 10''-24'' Shut Height; 5'' Adjustment; Ram Area 28''LR x<br />

548 1 21''FB; Air Clutch; Air Counterbalance; #PA-036<br />

NIAGARA MODEL HF-5-1/2 110-TON ADJUSTABLE BED HORN PRESS; S/N<br />

45940; #PA-045; Bed Size 40''LR x 30''FB; 8'' Stroke; 10''-24'' Shut Height; 5''<br />

Adjustment; 45 SPM; Ram Area 28''LR x 21''FB; Air Clutch; Air Counterbalance (Die<br />

548A 1 Repair)<br />

556 1 PACKAGE 206 SPIN FORM LINE CONSISTING OF LOTS 557-565<br />

Hess Engineering Double-End Opposed Horizontal Stuffer; S/N WO-5165/641; (#IN-<br />

557 1 006);<br />

559 1<br />

Hess Engineering Model 2440/CNC-H R.H. & L.H. Inlet Spin Form Machine; S/N<br />

WO-5165/631 (2004); (#F1-026); X; Z; W; U-Axis Control; Collet Gripper Chuck;<br />

Tailstock Fixture; Allen Bradley 9/Series Controls; Hydraulic Unit; Auto-Load;<br />

Hess Engineering Model 2440/CNC-H R.H. & L.H. Inlet Spin Form Machine; S/N<br />

WO-5165/621 (2004); (#F1-027); X; Z; W; U-Axis Control; Collet Gripper Chuck;<br />

560 1 Tailstock Fixture; Allen Bradley 9/Series Controls; Hydraulic Unit; Auto-Load;<br />

Motoman Model UP20 6-Axis CNC Transfer Robot; With XRC 2001/XRC-UP20<br />

562 1 Control; S/N NA (#RO-483);<br />

Hess Engineering Model 2440/CNC-H R.H. & L.H. Outlet Spin Form Machine; S/N<br />

WO-5165-611; (#F1-029); X; Z; W. U-Axis Control; Collet Gripper Chuck; Tailstock<br />

Fixture; Allen Bradley 9/Series Controls; Hydraulic Unit; Auto-Unload; With<br />

564 1 Conveyor<br />

566 1 #58 CAT SPIN FORM CELL CONSISTING OF LOTS 567-569 (M12)<br />

Hess Engineering Horizontal Hydraulic Can Swedger; S/N D-1689; Allen Bradley<br />

SLC-5/04 CPU PLC Controls; With Panel View 1000 Data Programming<br />

567 1 Keypad/Screen; Enclosure Fencing; With Light Curtain; F1-010<br />

567A 1 LOT: SWAGGER AND STUFFER (A-17)<br />

Hess Engineering Model 4246/CNC-H CNC Inlet Spinform Machine; S/N D-1693-4<br />

(2000); X&Z Axis Forming Tool Slides; Tailstock Fixture; Allen Bradley 9/Series<br />

568 1 Controls; Reliance AC Inverter Frequency Control; #F1-009<br />

Hess Engineering Model 4246/CNC-H CNC Outlet Spinform Machine; S/N D-1693-<br />

2 (2000); X&Z Axis Forming Tool Slides; Tailstock Fixture; Allen Bradley 9/Series<br />

569 1 Controls; Reliance AC Inverter Frequency Control; #F1-007<br />

570 1 #50 CAT SPIN FORM CELL CONSISTING OF LOTS 571-575 (L12)<br />

571 1<br />

572 1<br />

573 1<br />

Hess Engineering Horizontal Hydraulic Can Swedger/Shrinker; S/N D-1645; (#F1-<br />

005); Allen Bradley SLC-5/04 CPU PLC; With Panel View 1000 Input Terminal;<br />

Hess Engineering R.H. & L.H. Inlet Horizontal Spin Form Machine; S/N D1651-4;<br />

(#F1-003); (2000); X&Z Axis Slides; Collet Chuck; Tailstock Fixture; Hydraulic Unit;<br />

Allen Bradley 9/Series Controls; Reliance AC Frequency Inverter;<br />

Hess Engineering R.H. & L.H. Inlet Horizontal Spin Form Machine; S/N 1651-1;<br />

(#F1-001); (2000); X&Z Axis Slides; Collet Chuck; Tailstock Fixture; Hydraulic Unit;<br />

Allen Bradley 9/Series Controls; Reliance AC Frequency Inverter;<br />

21 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

<strong>Lot</strong> # Quantity Description<br />

February 25, 2009<br />

Hess Engineering R.H. & L.H. Outlet Horizontal Spin Form Machine; S/N 1651-3;<br />

(#F1-004); (2000); X&Z Axis Slides; Collet Chuck; Tailstock Fixture; Hydraulic Unit;<br />

574 1 Allen Bradley 9/Series Controls; Reliance AC Frequency Inverter<br />

Hess Engineering R.H. & L.H. Outlet Horizontal Spin Form Machine; S/N 1651-2;<br />

(#F1-002); (2000); X&Z Axis Slides; Collet Chuck; Tailstock Fixture; Hydraulic Unit;<br />

Allen Bradley 9/Series Controls; Reliance AC Frequency Inverter; (#F1-002 Missing<br />

575 1 Tailstock Fixture)<br />

576 1 CELL 6 COMAU-PICO ROBOTIC CELL (HH24) CONSISTING OF LOTS 577-584<br />

Spectrum Automation Model 20150GHD Automatic Feeder; S/N 5376; Hopper; With<br />

J-Box Dumper; Inclined Unscrambler/Feeder Conveyor; Enclosure; Auto-Regulated<br />

577 1 Parts Feed Track; #AF-004<br />

Spectrum Automation Model 20150GHD Automatic Feeder; S/N 5375; Hopper; With<br />

J-Box Dumper; Inclined Unscrambler/Feeder Conveyor; Enclosure; Auto-Regulated<br />

578 1 Parts Feed Track; #AF-005<br />

Motoman Model UP130 6-Axis CNC Transfer Robot; S/N S2M592-1-2-2 (2002);<br />

579 1 130 Kg. Capacity; XRC-2001 Controls; #RO-120<br />

Motoman Model UP130 6-Axis CNC Transfer Robot; S/N S2K531-1-4 (2003); 130<br />

580 1 Kg. Capacity; XRC-2001 Controls; #RO-121<br />

Addison-McKee Model FM-70 Digiform Vertical Single Tube-End Forming Machine;<br />

S/N J038504; Allen Bradley SLC-5/04 CPU; With Panel View 1000 PLC Terminal;<br />

581 1 Water Cooled Heat Exchanger; Light Curtain; #CM-014<br />

Spot Weld Fixture; With RoMan 30 KVA Transformer; ATEK Tru Temp III Weld<br />

582 1 Control; #W1-010<br />

Comau Pico Main Control Panel; With Allen Bradley SLC-4/04 CPU; (Missing Panel<br />

583 1 View Terminal); #CP106<br />

584 1 Enclosure Fencing; With Interlocked Access Doors<br />

#76 CAT LINE CELLS COMAU-PICO ROBOTIC CELL CONSISTING OF LOTS<br />

585 1 586-593<br />

20150GHD Spectrum Automation Model Automatic Feeder; S/N 5377; Hopper; With<br />

J-Box Dumper; Inclined Unscrambler/Feeder Conveyor; Auto-Regulated Parts Feed<br />

586 1 Track; Enclosure; #AF-001;<br />

20150GHD Spectrum Automation Model Automatic Feeder; S/N 5389; Hopper; With<br />

J-Box Dumper; Inclined Unscrambler/Feeder Conveyor; Auto-Regulated Parts Feed<br />

587 1 Track; Enclosure; #AF-002<br />

Spectrum Automation Model STOR 20 30'' x 10' Portable Flat Belt Conveyor; S/N<br />

588 1 5379; 10'' High Sides;<br />

589 1 Spectrum Automation Model RC-16 Unscrambler/Feeder Conveyor;<br />

Motoman Model UP-130 6-Axis CNC Transfer Robot; With XRC-2001 Control; S/N<br />

590 1 SIM176-1-5 (2001); #RO-119;<br />

Addision-McKee Model FM-70 Digiform Vertical Single Tube-End Sizing Machine;<br />

S/N J038505; Allen Bradley SLC-5/04 CPU; With Panel View 1000 PLC Terminal;<br />

591 1 Water Cooled Heat Exchanger; Light Curtain; #CM-012<br />

Comau Pico Model 490062 Main Control Panel; S/N 490062006CB; Allen Bradley<br />

592 1 SLC 5/04 CPU; With Panel View 1000 PLC Terminal; #CP105<br />

593 1 Enclosure Fencing; Interlocked Access Doors<br />

#8 CAT LINE ALLIANCE AUTOMATION ROBOTIC/ASSEMBLY CELL<br />

594 1 CONSISTING OF LOTS 595-610<br />

Station 10 - Manual Load Station; With Allen Bradley Panel View 1000 PLC<br />

595 1 Terminal;<br />

22 of 51

<strong>Hilco</strong> Industrial, LLC <strong>ACH</strong> <strong>Monroe</strong> <strong>Webcast</strong> <strong>Auction</strong><br />

<strong>Lot</strong> <strong>Catalog</strong> - <strong>DAY</strong> 1<br />

February 25, 2009<br />