Pages • Multi-Mat® Concept • Lamina Multi-Mat® full ... - Tikontools

Pages • Multi-Mat® Concept • Lamina Multi-Mat® full ... - Tikontools

Pages • Multi-Mat® Concept • Lamina Multi-Mat® full ... - Tikontools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

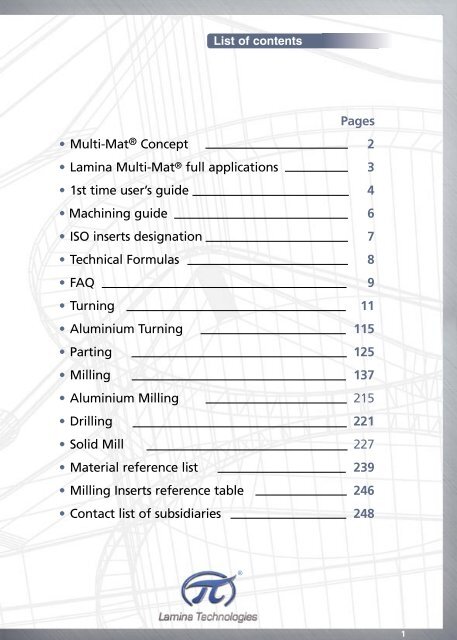

<strong>•</strong> <strong>Multi</strong>-Mat ® <strong>Concept</strong><br />

<strong>•</strong> <strong>Lamina</strong> <strong>Multi</strong>-Mat ® <strong>full</strong> applications<br />

<strong>•</strong> 1st time user’s guide<br />

<strong>•</strong> Machining guide<br />

<strong>•</strong> ISO inserts designation<br />

<strong>•</strong> Technical Formulas<br />

<strong>•</strong> FAQ<br />

<strong>•</strong> Turning<br />

<strong>•</strong> Aluminium Turning<br />

<strong>•</strong> Parting<br />

<strong>•</strong> Milling<br />

<strong>•</strong> Aluminium Milling<br />

<strong>•</strong> Drilling<br />

<strong>•</strong> Solid Mill<br />

<strong>•</strong> Material reference list<br />

<strong>•</strong> Milling Inserts reference table<br />

<strong>•</strong> Contact list of subsidiaries<br />

List of contents<br />

®<br />

<strong>Pages</strong><br />

2<br />

3<br />

4<br />

6<br />

7<br />

8<br />

9<br />

5<br />

25<br />

37<br />

215<br />

22<br />

227<br />

239<br />

246<br />

248

The <strong>Lamina</strong> <strong>Multi</strong>-Mat ® <strong>Concept</strong><br />

<strong>Lamina</strong> Technologies invented an ALTERNATIVE<br />

to the cutting tools world...<br />

THE MULTI-MATERIAL ALTERNATIVE<br />

2<br />

Steel Stainless Steel Cast Iron Exotic Non-Ferrous<br />

Is it really necessary to have so<br />

many chip breakers ?<br />

NO, IT IS NOT!<br />

Is it really possible to machine<br />

efficiently all materials with<br />

just one grade ?<br />

YES, IT IS!<br />

Is the total cost of<br />

production minimized when<br />

machine operation is<br />

optimized?<br />

NOT REALLY!<br />

Because the biggest reductions<br />

in the total cost of production<br />

are achieved by reducing<br />

MACHINE IDLE TIME !<br />

Swiss<br />

Made<br />

What is the <strong>Lamina</strong><br />

<strong>Multi</strong>-Mat ® <strong>Concept</strong>?<br />

<strong>•</strong> Focused range of <strong>Multi</strong><br />

Material inserts.<br />

<strong>•</strong> Each insert performs on<br />

all material as good as,<br />

or better than the<br />

dedicated insert of the<br />

competition.<br />

<strong>•</strong> Top Swiss quality.<br />

<strong>•</strong> Reasonable price.<br />

<strong>Lamina</strong> grades<br />

<strong>•</strong> LT-10 Turning grade.<br />

<strong>•</strong> LT-30 Milling grade.<br />

<strong>•</strong> LT-05 Milling & Turning<br />

Aluminium grade.<br />

<strong>•</strong> LT-40 Solid Carbide<br />

End mills grade.<br />

... AND IT WORKS!<br />

The <strong>Lamina</strong> <strong>Multi</strong>-Mat ® <strong>Concept</strong> in more applications<br />

The <strong>Lamina</strong> <strong>Multi</strong> Mat ® <strong>Concept</strong><br />

is getting wider...<br />

The <strong>Lamina</strong> <strong>Multi</strong>-Mat ® <strong>full</strong> applications<br />

New Inserts <strong>•</strong> More Geometries<br />

Milling<br />

Turning<br />

Parting<br />

Aluminium<br />

End Mills<br />

Drilling<br />

Our top quality Milling inserts from<br />

<strong>Lamina</strong> <strong>Multi</strong>-Mat ® LT-30 Grade and<br />

tight tolerance Milling bodies.<br />

Our top quality Turning inserts<br />

from <strong>Lamina</strong> <strong>Multi</strong>-Mat ® LT-10<br />

grade and our new LT-10CR (Crypto)<br />

for extreme applications.<br />

Our new and revolutionary<br />

Parting line is available<br />

for ordering.<br />

Our new Aluminium line for<br />

Milling and Turning applications<br />

with LT-05 Grade.<br />

The high performance <strong>Multi</strong>-Mat ®<br />

Solid Carbide End Mills<br />

with <strong>Lamina</strong> LT-40 Grade.<br />

Our Drilling line of inserts<br />

with <strong>Lamina</strong> <strong>Multi</strong>-Mat ®<br />

LT-30 Grade.<br />

MULTI-MAT ® , LAMINA ALTERNATIVE <strong>•</strong> TODAY, TOMORROW, ALWAYS!<br />

3

Material Group<br />

Nickel Based Alloys<br />

Titanium Based<br />

Alloys<br />

Group hardness<br />

Material Examples<br />

No<br />

HB Coolant<br />

feed per tooth<br />

o o<br />

45 90<br />

Initial<br />

Vc(m/min)<br />

150 300<br />

XC 12<br />

Low Carbon Steel 1 180 No 0.30 0.22 270<br />

S 250 Pb<br />

210 230<br />

Alloy Steel 2<br />

High Alloy Steel 3<br />

Austenitic<br />

Stainless Steel<br />

4<br />

42 CrMo 4<br />

100 Cr 6<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

X210 CrW 12<br />

X90 CrMoV 8<br />

303 / 304<br />

304 L<br />

180 230<br />

230<br />

190<br />

No 0.25 0.18<br />

280 170<br />

320 150<br />

220<br />

280<br />

320<br />

Yes<br />

Yes<br />

no<br />

0.22 0.15<br />

150<br />

110<br />

100<br />

350 70<br />

Annealed<br />

5 316 / 316 L Annealed<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

No<br />

0.27 0.18 230<br />

0.25 0.15 210<br />

0.23 0.12 90<br />

Ferritic Stainless<br />

Steel<br />

7 430 / 439 / 444 Annealed No 0.25 0.15 210<br />

Martensitic<br />

Stainless Steel<br />

8 410 / 420<br />

Annealed<br />

Treated<br />

No 0.25 0.15<br />

210<br />

130<br />

Grey Cast Iron 9<br />

EN-GJL 200<br />

EN-GJL 250<br />

EN-GJL 300<br />

140<br />

to 250<br />

Yes 0.30 0.18<br />

250<br />

230<br />

190<br />

EN-GJL 400 210<br />

190<br />

Nodular Cast Iron 10 EN-GJL 600 260 Yes 0.25 0.15 150<br />

Aluminium<br />

Basic cutting conditions for first time user - Milling<br />

EN-GJL 800 310 130<br />

Inconel 625 32<br />

11 Inconel 718 -------- Yes 0.23 0.15 32<br />

12<br />

13<br />

Aluminium 14<br />

4<br />

First time <strong>Lamina</strong> user Machining guide<br />

As a new user of the revolutionary <strong>Lamina</strong> <strong>Multi</strong>-Mat ® (<strong>Multi</strong> Material) inserts,<br />

we would like to present to you a short machining guide to insure your<br />

satisfaction from our product.<br />

The cutting data specified in this guide should be considered as a good starting<br />

point. Each insert is able to perform in a wider range of cutting conditions.<br />

For complete cutting data please see our catalog or our online catalog at our web<br />

site www.lamina-tech.ch<br />

Milling<br />

. Select the material group to be machined. In case of doubt, refer to material reference pages in the catalog.<br />

2. Check machining recommendations with or without coolant.<br />

3. Select feed as a function of the tool cutting angle.<br />

4. The cutting speed is indicated in the right-hand column.<br />

Yes / No<br />

Yes<br />

Hastelloy C 55<br />

TiAl 6 V4<br />

48<br />

-------- Yes 0.23 0.15<br />

T40 38<br />

Si < 4%<br />

4% < Si < 8%<br />

Si > 8%<br />

Annealed<br />

----<br />

----<br />

Yes<br />

0.25 0.15<br />

0.18<br />

0.12<br />

800<br />

450<br />

For Alu group 13, please use our Alu line grade LT-05<br />

---- Yes 0.25 0.15 250<br />

For Alu group 14, please use inserts grade LT-10<br />

Milling tips<br />

<strong>•</strong> The cutting conditions mentioned are<br />

just initial recommendations. Inserts<br />

are able to work in a wider range of<br />

cutting conditions. For detailed cutting<br />

conditions, please see catalog.<br />

<strong>•</strong> Please verify working according to<br />

recommended cutting conditions.<br />

<strong>•</strong> For stainless steel, verify that you are<br />

machining well over the minimum<br />

speed. Machining Stainless steel at low<br />

speeds causes sticking - to be avoided.<br />

<strong>•</strong> For material groups 1 / 2 / 4 / 7 / 8, it is<br />

recommended not to use coolant.<br />

<strong>•</strong> For material groups 6 and 12, it is<br />

recommended to use coolant.<br />

<strong>•</strong> For other material groups both, with<br />

or without coolant options should be<br />

checked.<br />

<strong>•</strong> Always recommended to machine in<br />

"climb" milling.<br />

<strong>•</strong> If chips are turning with cutter, increase<br />

cutting speed, feed or both.<br />

<strong>•</strong> If work piece warms up, feed is too low<br />

or cutting speed is too high.<br />

<strong>•</strong> Shank should be as short as possible and<br />

shank diameter as big as possible.<br />

<strong>•</strong> Verify clamping stability.<br />

<strong>•</strong> If coolant is not efficient enough, it is<br />

recommended not to use coolant.<br />

<strong>•</strong> In case of vibrations, reduce cutting<br />

speed and/or increase feed.<br />

The above values are indicated as functions of<br />

the cutting edge angle, i.e. kappa 45° or 90°. The<br />

high feed relates to cutting inserts for surfacing,<br />

attack angles 45° and 75°. The low feed relates<br />

to cutting inserts for surfacing, trimming angle<br />

90°. The above-mentioned cutting conditions<br />

are indicated for each material group and the<br />

respective hardness.<br />

Turning<br />

. Select the material group to be machined. In case of<br />

doubt, consult material reference pages in the catalog.<br />

2. Select the radius of the cutting insert.<br />

3. Select cutting depth and feed according to radius.<br />

4. The cutting speed is indicated in the right-hand column.<br />

Turning tips<br />

<strong>•</strong> The cutting conditions mentioned are just initial<br />

recommendations. Inserts are able to work in a wider range of<br />

cutting conditions. For detailed cutting conditions, please see<br />

catalog.<br />

<strong>•</strong> Please verify working according to recommended cutting<br />

conditions.<br />

<strong>•</strong> If you are working according to the cutting conditions in the<br />

catalog, Amax must be respected.<br />

<strong>•</strong> For stainless Steel, verify that you are machining well over the<br />

minimum speed. Machining Stainless steel at low speeds causes<br />

sticking – to be avoided.<br />

Titanium Based<br />

Alloys<br />

<strong>•</strong> For stainless Steel and Exotic materials, without interrupted cut,<br />

P insert is preferable (CNMP, WNMP).<br />

<strong>•</strong> For all material groups, it is recommended to use coolant.<br />

<strong>•</strong> Verify that the tool holder and shim are not damaged.<br />

<strong>•</strong> If chips are too long, please increase feed.<br />

<strong>•</strong> If chips are not controlled, increase feed and reduce depth of<br />

cut.<br />

<strong>•</strong> For internal boring, tool holder should be as short as possible.<br />

<strong>•</strong> For internal boring, tool holder shank should be as big as<br />

possible.<br />

<strong>•</strong> For internal boring, in case of vibrations, reduce cutting speed,<br />

increase feed.<br />

<strong>•</strong> If coolant is not efficient enough, it is recommended not to<br />

use coolant.<br />

<strong>•</strong> In case of strong interrupted cut, feed should be reduced.<br />

Material Group<br />

Group<br />

Material Examples<br />

No<br />

hardness<br />

HB<br />

Nose radius 04<br />

(04)<br />

d.o.c f<br />

Nose radius 08<br />

(08)<br />

d.o.c f<br />

Nose radius 12<br />

(12)<br />

d.o.c f<br />

Initial<br />

Vc(m/min)<br />

Low Carbon Steel 1<br />

XC 12<br />

S 250 Pb<br />

150<br />

180<br />

210<br />

0.50<br />

to<br />

1.50<br />

0.10<br />

to<br />

0.15<br />

1.00<br />

to<br />

3.00<br />

0.22<br />

to<br />

0.28<br />

1.50<br />

to<br />

5.0<br />

0.35<br />

to<br />

0.50<br />

350<br />

280<br />

250<br />

Alloy Steel 2<br />

High Alloy Steel 3<br />

Austenitic<br />

Stainless Steel<br />

Ferritic Stainless<br />

Steel<br />

Martensitic<br />

Stainless Steel<br />

4<br />

303 / 304<br />

304 L<br />

180 270<br />

230<br />

280<br />

0.50<br />

to<br />

1.50<br />

0.10<br />

to<br />

0.12<br />

1.00<br />

to<br />

3.00<br />

0.22<br />

to<br />

0.28<br />

1.50<br />

to<br />

4.0<br />

0.32<br />

to<br />

0.45<br />

230<br />

190<br />

320 170<br />

220<br />

280<br />

320<br />

0.50<br />

to<br />

1.50<br />

0.10<br />

1.00<br />

to<br />

3.00<br />

0.20<br />

to<br />

0.25<br />

1.50<br />

to<br />

3.0<br />

0.30<br />

to<br />

0.42<br />

170<br />

130<br />

110<br />

350 90<br />

0.50 to 0.10 to 1.00 to 0.18 to 1.50 to 0.32 to<br />

5 316 / 316 L Annealed<br />

190<br />

1.50 0.12 3.00 0.25 4.0 0.48<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

7 430 / 439 / 444 Annealed 0.50 to 0.12 to 1.00 to 0.22 to 1.50 to 0.32 to<br />

190<br />

1.50 0.15 3.00 0.28 4.0 0.48<br />

8 410 / 420<br />

Grey Cast Iron 9<br />

EN-GJL 200<br />

EN-GJL 250<br />

EN-GJL 300<br />

140<br />

to 250<br />

0.20<br />

to<br />

1.50<br />

0.08<br />

to<br />

0.15<br />

1.00<br />

to<br />

4.00<br />

0.18<br />

to<br />

0.35<br />

1.00<br />

to<br />

5.00<br />

0.32<br />

to<br />

0.60<br />

270<br />

230<br />

210<br />

EN-GJL 400<br />

210 0.20 0.10 1.00 0.18 1.00 0.30 210<br />

Nodular Cast Iron 10 EN-GJL 600<br />

260 to to to to to to 170<br />

EN-GJL 800<br />

310 1.50 0.12 3.00 0.30 5.00 0.50<br />

150<br />

Inconel 625<br />

0.20 0.10 1.00 0.18 1.00 0.30 35<br />

Nickel Based Alloys 11 Inconel 718 -------- to to to to to to 38<br />

Hastelloy C 1.20 0.12 3.00 0.28 3.00 0.42 65<br />

Aluminium<br />

Basic cutting conditions for first time user - Turning<br />

12<br />

13<br />

Aluminium 14<br />

42 CrMo 4<br />

100 Cr 6<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

X210 CrW 12<br />

X90 CrMoV 8<br />

0.50 to<br />

1.50<br />

0.50 to<br />

1.20<br />

0.12 to<br />

0.15<br />

0.11<br />

TiAl 6 V4<br />

0.20 to 0.10 to 1.00 to 0.18 to 1.00 to 0.32 to 55<br />

--------<br />

T40 1.20 0.14 3.00 0.32 4.00 0.45 42<br />

Si < 4%<br />

4% < Si < 8%<br />

Si > 8%<br />

Annealed<br />

Annealed<br />

Annealed<br />

Treated<br />

----<br />

----<br />

----<br />

0.50 to<br />

1.50<br />

0.20 to<br />

5.00<br />

0.12 to<br />

0.15<br />

0.12 to<br />

0.25<br />

1.00 to<br />

3.00<br />

1.00 to<br />

2.50<br />

1.00 to<br />

3.00<br />

0.20 to<br />

5.00<br />

0.18 to<br />

0.32<br />

0.18 to<br />

0.23<br />

0.22 to<br />

0.28<br />

0.15 to<br />

0.50<br />

For Alu group 13, please use our Alu line grade LT-05<br />

1.50 to<br />

5.0<br />

1.50 to<br />

3.0<br />

1.50 to<br />

4.0<br />

0.35 to<br />

0.52<br />

0.30 to<br />

0.45<br />

0.32 to<br />

0.48<br />

0.50-5.00 0.12-0.20 0.50-5.00 0.15-0.40 0.50-5.00 0.20-0.60<br />

For Alu group 14, please use inserts grade LT-10<br />

230<br />

110<br />

190<br />

150<br />

800<br />

450<br />

250<br />

5

Machining Recommendation Guide<br />

In order to assist you, our customer, to obtain the best productivity using our cutting<br />

tools, we enclose some relevant comments and tips. Each comment is symbolized by<br />

an icon and the relevant icons appear for each insert.<br />

We hope that you find these comments and tips helpful.<br />

6<br />

In machining Stainless Steel, please verify and respect the cutting<br />

speed recommended for the insert, as there is a tendency<br />

to machine at speeds that are too low.<br />

In machining Stainless Steel or Exotic materials, P geometry<br />

inserts (CNMP, TNMP, WNMP), are recommended as first<br />

choice.<br />

In machining Exotic materials, it is important to verify cutting<br />

conditions of the specific insert.<br />

P geometry inserts (CNMP, TNMP, WNMP) are not recommended<br />

when machining with interrupted cut.<br />

It is important to verify and respect Amax (see column 9 in the<br />

cutting data tables), which is the maximum chip section .<br />

Feed x d.o.c must be lower than the number noted as Amax.<br />

Wiper inserts will give better surface quality at higher feeds,<br />

only when used on a stable machine with rigid clamping (no<br />

vibrations).<br />

To increase machining productivity, it is recommended to<br />

increase speed (Vc) while respecting chip size calculation<br />

(Amax).<br />

Appropriate for boring operation.<br />

To increase productivity it is recommended to increase feed (f)<br />

and respect cutting speed.<br />

When machining materials from groups 1, 2, 4 it is<br />

recommended not to use coolant. When machining material<br />

from groups 3, 5 – using coolant or not, depends on the<br />

application. When machining material from groups 6, 7, 8, 9,<br />

10, 11, 12 it is recommended to use coolant.<br />

C 01<br />

N 02<br />

01<br />

02<br />

M 03<br />

G 04<br />

12<br />

A B C D<br />

E<br />

3° 5° 7° 15°<br />

20°<br />

F<br />

A<br />

R<br />

85°<br />

82°<br />

80°<br />

55°<br />

A B C D<br />

75°<br />

E<br />

86°<br />

M<br />

H K L<br />

O P R<br />

S T V W<br />

25° G<br />

30° N 0° P<br />

11°<br />

D M S<br />

A ± 0.025 ± 0.005 ± 0.025<br />

C ± 0.025 ± 0.013 ± 0.025<br />

E ± 0.025 ± 0.025 ± 0.025<br />

F ± 0.013 ± 0.005 ± 0.025<br />

G ± 0.025 ± 0.025 ± 0.013<br />

H ± 0.013 ± 0.013 ± 0.025<br />

B<br />

T<br />

m<br />

03<br />

55°<br />

35°<br />

m<br />

d d s<br />

U<br />

04<br />

H J M N<br />

C<br />

®<br />

J<br />

K<br />

L<br />

M<br />

N<br />

U<br />

F<br />

80°<br />

D M S<br />

G<br />

Q<br />

W X Special<br />

05<br />

± 0.05<br />

a ± 0.15 ± 0.005 ± 0.025<br />

± 0.05<br />

a ± 0.15 ± 0.013 ± 0.025<br />

± 0.05<br />

a ± 0.15 ± 0.025 ± 0.025<br />

± 0.05<br />

a ± 0.15<br />

± 0.08<br />

a ± 0.20 ± 0.130<br />

± 0.05<br />

a ± 0.15<br />

± 0.08<br />

a ± 0.20 ± 0.025<br />

± 0.08<br />

a ± 0.25<br />

± 0.13<br />

a ± 0.38 ± 0.130<br />

ISO insert designation<br />

ISO-Insert designation<br />

04 08<br />

06<br />

07<br />

- E 08<br />

l<br />

05<br />

N 09<br />

l l l l<br />

l l d<br />

06<br />

s s<br />

01 1,59 04<br />

T1 1,98 06<br />

02 2,38 07<br />

03 3,18 08<br />

T3 3,97 09<br />

A F<br />

45° A A<br />

60° D B<br />

75° E C<br />

85° F D<br />

90° P E<br />

Other angle Z F<br />

G<br />

N<br />

P<br />

Z<br />

07<br />

04<br />

4,76<br />

6,35<br />

7,94<br />

8,00<br />

9,52<br />

3° 02 0,2<br />

5° 04 0,4<br />

7° 08 0,8<br />

15° 12 1,2<br />

20° 16 1,6<br />

25° 20 2,0<br />

30° 24 2,4<br />

0° 32 3,2<br />

11°<br />

Other angle<br />

08<br />

F E T S<br />

09<br />

R L N<br />

s<br />

r<br />

s<br />

7

Turning Milling<br />

Cutting<br />

speed<br />

m/min<br />

Rotation<br />

Rev/min<br />

Chip Removal<br />

Rate<br />

3<br />

cm /min<br />

Cutting<br />

time<br />

in min<br />

Surface<br />

roughness<br />

um<br />

Symbol Designation Unit<br />

Dm<br />

f<br />

lm<br />

n<br />

Q<br />

Amax<br />

r<br />

Tc<br />

3<br />

Machining diameter<br />

Feed<br />

Machining length<br />

Rotation<br />

Chip Removal Rate<br />

d.o.c x feed<br />

Nose radius<br />

Cutting time<br />

Vc =<br />

n =<br />

D m x J x n<br />

1000<br />

V c x 1000<br />

Dm x J<br />

Q = Vc x ap x f<br />

Tc =<br />

Rmax =<br />

lm<br />

f x n<br />

f 2x<br />

n<br />

x 125<br />

r<br />

3<br />

mm<br />

mm<br />

mm<br />

rev/min<br />

3<br />

cm /min<br />

mm<br />

mm<br />

min<br />

2<br />

Technical Formulas<br />

Cutting<br />

speed<br />

m/min<br />

Rotation<br />

Rev/min<br />

Table feed<br />

mm/min<br />

Cutting<br />

output<br />

3 cm / min<br />

Feed<br />

per<br />

rotation<br />

Symbol Designation Unit<br />

Vc<br />

ap<br />

ae<br />

D<br />

fz<br />

K<br />

Vf<br />

Z<br />

Cutting speed<br />

Depth of cut<br />

Radial depth of cut<br />

Cutter diameter<br />

Feed per tooth<br />

Feed rate<br />

Number of teeth<br />

®<br />

Vc =<br />

n =<br />

n x J x D<br />

1000<br />

V c x 1000<br />

J x D<br />

Vf = n x z x fz<br />

Vf = n x K x fz<br />

Q =<br />

f = Z x fz<br />

f = K x fz<br />

ae x ap x Vf<br />

1000<br />

m/min<br />

mm<br />

mm<br />

mm<br />

mm/tooth<br />

Actual number of teeth for calculation<br />

feed rate of feed per revolution.<br />

mm/min<br />

No.<br />

Frequently Asked Questions<br />

Is it true that <strong>Lamina</strong> inserts can really be run in<br />

any type of work-piece material?<br />

<strong>Lamina</strong> inserts have been run on thousands of jobs<br />

the world over and will work practically any type of<br />

turning or milling metal cutting operation. Please<br />

note that, while <strong>Lamina</strong> inserts will work in Aluminium<br />

– often production jobs in Aluminium will require<br />

inserts with a geometry designed specifically for the<br />

chip control needed with Aluminium. Please see<br />

<strong>Lamina</strong> Alu-Line.<br />

What speeds and feeds should <strong>Lamina</strong> inserts be<br />

run at?<br />

Adjacent to each insert ordering info page in this<br />

catalogue, are specific data recommendations for<br />

each individual insert showing the speeds and feeds<br />

for almost every material group. In order to get the<br />

maximum benefit from <strong>Lamina</strong>’s grade technology it<br />

is important to always run the inserts at the<br />

recommended cutting data. In general – the best<br />

results are normally found at the higher end of cutting<br />

speeds shown.<br />

Will <strong>Lamina</strong> grades actually run better than the<br />

hundreds of specialized “dedicated” grades<br />

available from other suppliers?<br />

<strong>Lamina</strong> has extensive know-how in sub-micron<br />

powder technology as well as in sophisticated PVD<br />

coatings. This know-how combines with chip breaker<br />

geometry and application knowledge in order to<br />

perfect our world class offering. Customers that<br />

machine at the high performance speeds and feeds<br />

we recommend – and use sound machining<br />

techniques – continually reports superior results, in<br />

virtually all materials, and are able to replace the<br />

hundreds of confusing insert choices they previously<br />

used.<br />

Even in the applications where a <strong>Lamina</strong> insert runs<br />

“about the same” as the existing insert – the <strong>Lamina</strong><br />

solution is still a better choice – because the same<br />

<strong>Lamina</strong> insert can be used on the next job and the job<br />

after that, and so forth. That’s the <strong>Lamina</strong> <strong>Multi</strong>-Mat<br />

technology advantage.<br />

What can we expect regarding the quality and<br />

consistency of <strong>Lamina</strong> inserts?<br />

Due to <strong>Lamina</strong>’s unique production methods and<br />

Quality Control processes, you should expect inserts<br />

with much higher accuracy than you are used to. You<br />

can also expect inserts with maximum consistency<br />

from edge to edge, insert to insert, box to box and<br />

batch to batch – which offers you the ability to<br />

maximize unattended operation of your machines.<br />

What percentage of my indexable tooling<br />

requirements can <strong>Lamina</strong> supply?<br />

For most typical shops, <strong>Lamina</strong>’s insert program should<br />

cover about 80% of all inserts needed for CNC<br />

machines from 20 Hp and down. The insert program<br />

covers a <strong>full</strong> range of standard turning and milling<br />

operations from finishing up to and including medium<br />

roughing.<br />

In shops that run <strong>Lamina</strong> inserts now – what do<br />

they find are the biggest benefit<br />

- Ability to always have the right insert available<br />

immediately when they need it.<br />

- Tremendous savings in the cost of specifying inserts,<br />

ordering processes, and stocking procedures.<br />

- Simplicity and efficiency of being able to attack the<br />

job knowing that there is no longer a need to worry<br />

about having the right grade of insert.<br />

- Machinists become very familiar with the grade<br />

performance and application and are able to use the<br />

inserts to their maximum usable life.<br />

Are <strong>Lamina</strong> inserts coated the same as other PVD<br />

inserts?<br />

<strong>Lamina</strong>’s unique PVD coating has significant<br />

differences compared to normal PVD coating used on<br />

other inserts. The <strong>Lamina</strong> coating process impacts a<br />

much stronger coating – with far better adhesion –<br />

which results in the ability to machine at higher<br />

speeds, with longer tool life, and in the widest variety<br />

of materials.<br />

What about turning tool holders and boring<br />

bars?<br />

<strong>Lamina</strong>’s ANSI / ISO standard turning inserts are<br />

designed to fit all industry standard turning tools<br />

and boring bars – so you can keep on using the<br />

holders you have already invested in.<br />

In turning – when should I use the _NMP style<br />

inserts compared to the _NMG style inserts?<br />

Most customers find that high-Positive _NMP style<br />

inserts (CNMP, TNMP and WNMP) deliver the best<br />

result in materials with high heat and corrosion<br />

resistant properties. Typical materials in these<br />

categories are 300 Series Stainless steels, Inconels,<br />

and Titanium. The free cutting action of _NMP<br />

inserts offers lower cutting forces and reduces the<br />

work hardening effect.<br />

8 9

Frequently Asked Questions<br />

Are there application ranges or materials in which<br />

<strong>Lamina</strong> grades don’t perform?<br />

Our leading grades, LT-10 for Turning and LT-30 for<br />

Milling cover all materials (apart from Aluminum) in<br />

the complete application ranges of Semi-Roughing<br />

to Super-Finishing. In isolated turning applications, in<br />

extreme cutting conditions (either at very high<br />

speeds or low speeds), specially in sticky materials<br />

like Low Carbon Steel or soft Stainless Steel, LT-10<br />

does not perform as well as some of the top level<br />

dedicated grades of the competition. For this reason<br />

we have developed LT-10CR which we call Crypto. In<br />

milling our customers do not encounter applications<br />

where LT-30 does not perform at least as good as or<br />

better than any of our competitors.<br />

So, what is this magic grade – the Turning LT-10CR<br />

Crypto?<br />

LT-10CR Crypto is a new grade developed by <strong>Lamina</strong><br />

to handle several areas of turning in extreme cutting<br />

conditions. Crypto (if you are reminded of Superman,<br />

it is not a coincidence) grade is complimentary to<br />

LT-10 and should be used in those applications where<br />

LT-10 does not give the best results. For example, if<br />

the material is Low Carbon Steel or Grey Cast Iron,<br />

machining at high speeds 400 m/min and more, with<br />

high feed and Depth of cut, Crypto should be used. If<br />

the material is soft Stainless Steel, machining at low<br />

speeds of 120 m/min and under, with high feed and<br />

Depth of cut, Crypto should be used.<br />

Is LT-10CR Crypto replacing LT-10?<br />

No, LT-10CR Crypto is complementary to LT-10 and<br />

should only be used in applications where extreme<br />

cutting conditions are used.<br />

Alu-line turning inserts, with 4 cutting edges, are<br />

very impressive, but do they perform in Low<br />

Silicon Aluminium?<br />

Yes, absolutely. The insert geometry is specially<br />

designed for Aluminium with under 2% Silicon and<br />

insures chips that break instead of curling like<br />

spaghetti and damaging the work piece material. The<br />

inserts are also coated and treated to reduce friction<br />

so you get excellent chip control and un-beatable<br />

tool life.<br />

0<br />

Swiss<br />

Made<br />

What is special about your Solid-Mill line?<br />

<strong>Lamina</strong> originated from the field of indexable inserts<br />

and came into the domain of solid carbide end mills in<br />

the beginning of 2005. What we have done is applied<br />

our know-how of indexable insert to the production<br />

technology and design of our Solid Mill line. We found<br />

ways to reduce the total heat generated while cutting<br />

so you get better cut and longer tool life.<br />

When should I use Star line?<br />

Star line inserts should be used whenever you want to<br />

save money in turning with positive inserts. If you are<br />

using VBMT, CCMT, DCMT, TCMT inserts with two<br />

cutting edges per each insert, you could use the Star<br />

inserts and get 3 cutting edges instead of one plus the<br />

additional bonus that all the inserts can be mounted<br />

on the same tool holder.<br />

Parting – is your new line for Parting-Off. What is<br />

special about the line?<br />

If you take one look at the insert you will see<br />

immediately the incredible revolution that this line<br />

brings to the market of cutting tools. This line will be<br />

launched in two phases; the first one will be on last<br />

quarter of 2008. This line of inserts and tool holders<br />

are a unique conception that we think is going to<br />

change the field of Parting-Off.<br />

®<br />

Turning<br />

LT- 0<br />

LT- 0 CR<br />

LT-05<br />

<strong>Multi</strong> Mat ® Turning<br />

<strong>Multi</strong> Mat ® Extreme Applications Turning<br />

Aluminium<br />

<strong>Multi</strong>-Mat ®<br />

Turning Inserts<br />

<strong>Pages</strong> 12 to 136<br />

2- 8 CCMT<br />

9-20<br />

2 -27<br />

28-30<br />

3 -33<br />

34-37<br />

38-49<br />

50-5<br />

52-56<br />

60-62<br />

63-67<br />

68-76<br />

77-78<br />

79-8<br />

82-84<br />

85-88<br />

89-9<br />

92-94<br />

95- 04<br />

05- 08<br />

09- 4<br />

5- 23<br />

CNMA<br />

CNMG<br />

CNMM<br />

CNMP<br />

DCMT<br />

DNMG<br />

KNUX<br />

RCMT<br />

57-59 SCMT<br />

25- 36<br />

SNMG<br />

TCMT<br />

TNMG<br />

TNMP<br />

TNUX<br />

TPMR<br />

VBMT<br />

VCMT<br />

VNMG<br />

WNMG<br />

WNMP<br />

STAR<br />

Alu-Line<br />

Parting

CCMT Shape<br />

Turning<br />

Clearance Angle<br />

Tolerance<br />

Insert Type<br />

Insert Designation Grade l s r Catalog Nr. Page*<br />

CCMT 060204 NN<br />

CCMT 09T304 NN<br />

CCMT 09T308 NN<br />

* CCMT 09T308 WM<br />

CCMT 20404 NN<br />

CCMT 20408 NN<br />

Application Guide<br />

Insert designation<br />

CCMT 060204 NN<br />

CCMT 09T304 NN<br />

CCMT 09T308 NN<br />

CCMT 09T308 WM<br />

CCMT 20404 NN<br />

CCMT 20408 NN<br />

LT 10<br />

LT 10<br />

LT 10<br />

LT 10<br />

LT 10<br />

LT 10<br />

C<br />

C<br />

M<br />

T<br />

* To be phaseed out Q1/2009.<br />

Not recommended<br />

2 Acceptable<br />

3 Recommended<br />

4 Excellent<br />

2<br />

80° Diamond<br />

7° Positive rake<br />

d ± 0.05 m ± 0.08<br />

s ± 0.13<br />

Screw Down Clamping<br />

Single Sided<br />

6 2,38 0,4<br />

9 3,97 0,4<br />

9 3,97 0,8<br />

9 3,97 0,8<br />

12 4,76 0,4<br />

T0000055<br />

T0000056<br />

T0000117<br />

T0000057<br />

T0001456<br />

12 4,76 0,8 T0001457 8<br />

NN: All purpose chip breaker. * For Cutting data see<br />

WM:Wiper Medium chip breaker. relevant page<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

Swiss<br />

Made Machining Recommendations Guide - please see page 6<br />

3<br />

4<br />

5<br />

6<br />

7<br />

CCMT 060204 NN<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

®<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 2.0 0.20 0.36 350<br />

180 0.10 2.0 0.08 0.18 0.29 180 280 0.2 to 1 0.18<br />

210 2.0 0.16 0.29 250<br />

180 2.0 0.18 0.29 280<br />

0.08<br />

230<br />

2.0 0.18 0.24<br />

250<br />

0.10<br />

120<br />

280 1.5 0.16 0.24 210<br />

0.09<br />

320 1.5 0.14 0.19 180<br />

220 2.0 0.16 0.24 190<br />

280<br />

1.5 0.14 0.24<br />

150<br />

0.10<br />

0.08<br />

70<br />

320 1.5 0.13 0.17 130<br />

350 1.5 0.13 0.14 100<br />

0.10 1.8<br />

--------- 1.5<br />

7 430 / 439 / 444 Annealed 0.10 2.0<br />

0.2 to 1 0.15<br />

0.2 to 1 0.12<br />

2.0 0.08 0.16 0.22 170 270 0.2 to 1 0.15<br />

0.08<br />

0.08<br />

0.14 0.17 120 210 0.2 to 1 0.12<br />

0.13 0.14 70 120 0.2 to 1 0.12<br />

0.16 0.20 170 250 0.2 to 1 0.15<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420 0.10 2.0 0.08 0.16 0.20<br />

Stainless Steel Treated 120 210<br />

0.08<br />

0.2 to 1 0.15<br />

EN - GJL 200<br />

0.38 280<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.10 2.0 0.06 0.18 0.36 170 250 0.2 to 1 0.18<br />

to 230<br />

EN - GJL 300 0.36 230<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 0.29 230<br />

10 EN - GJS 600 260 0.10 2.0<br />

0.16 0.24 120 190 0.2 to 1 0.15<br />

EN - GJS 800 310 0.24 150<br />

Inconel 625 0.14 25 35<br />

11 Inconel 718 -------- 0.10 1.5 0.08 0.14 0.14<br />

12<br />

Insert designation<br />

CCMT 060204 NN<br />

Hastello y C 0.17 40 65<br />

0.06<br />

40 0.2 to 1 0.12<br />

TiAl 6 V4<br />

0.14 0.17 35 60 0.2 to 1 0.14<br />

-------- 0.10 1.5 0.08<br />

T40 0.13 0.14 28 40 0.2 to 1 0.12<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

28<br />

3<br />

CCMT

CCMT 09T304 NN<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 3.0 0.23 0.60 350<br />

180 0.20 2.5 0.11 0.20 0.48 180 280 0.5 to 2 0.18<br />

210 2.5 0.18 0.48 250<br />

180 2.5 0.20 0.48 280<br />

0.11<br />

230<br />

2.5 0.20 0.40<br />

250<br />

0.20<br />

120<br />

280 2.0 0.18 0.40 210<br />

0.09<br />

320 2.0 0.16 0.32 180<br />

220 2.5 0.18 0.40 190<br />

280<br />

2.5 0.16 0.40<br />

150<br />

0.20<br />

0.09<br />

70<br />

320 2.0 0.14 0.28 130<br />

350 2.0 0.14 0.24 100<br />

0.20 2.0<br />

--------- 2.0<br />

7 430 / 439 / 444 Annealed 0.20 2.0<br />

®<br />

0.5 to 1.5 0.15<br />

0.5 to 1.5 0.12<br />

2.5 0.10 0.18 0.32 170 270 0.5 to 2 0.15<br />

0.09<br />

0.09<br />

0.16 0.24 120 210 0.5 to 1.5 0.12<br />

0.14 0.20 70 120 0.5 to 1.5 0.12<br />

0.18 0.28 170 250 0.5 to 1.5 0.15<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420 0.20 2.0 0.11 0.18 0.28<br />

Stainless Steel Treated 120 210<br />

0.11<br />

0.5 to 1.5 0.15<br />

EN - GJL 200<br />

0.64 280<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.20 3.0 0.08 0.20 0.60 170 250 0.5 to 2 0.18<br />

to 230<br />

EN - GJL 300 0.60 230<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 0.48 230<br />

10 EN - GJS 600 260 0.20 2.5<br />

0.18 0.40 120 190 0.5 to 1.5 0.15<br />

EN - GJS 800 310 0.40 150<br />

Inconel 625 0.24 25 35<br />

11 Inconel 718 -------- 0.20 2.0 0.10 0.16 0.24<br />

12<br />

Insert designation<br />

CCMT 09T304 NN<br />

4<br />

Hastello y C 0.28 40 65<br />

0.08<br />

40 0.5 to 1.5 0.12<br />

TiAl 6 V4<br />

0.16 0.28 35 60 0.5 to 1.5 0.14<br />

-------- 0.20 2.0 0.09<br />

T40 0.14 0.24 28 40 0.5 to 1.5 0.12<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

28<br />

CCMT 09T308 NN<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

®<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 5.0 0.45 1.5 350<br />

180 0.50 4.0 0.21 0.40 1.2 180 280 1 to 2.5 0.32<br />

210 4.0 0.35 1.0 250<br />

180 4.0 0.40 1.2 280<br />

0.21<br />

230<br />

4.0 0.40 1.0<br />

250<br />

0.50<br />

120<br />

280 3.0 0.35 0.8 210<br />

0.18<br />

320 3.0 0.32 0.6 180<br />

220 4.0 0.35 1.0 190<br />

280<br />

4.0 0.32 0.8<br />

150<br />

0.50<br />

0.18<br />

70<br />

320 3.0 0.28 0.6 130<br />

350 3.0 0.28 0.5 100<br />

0.50 3.0<br />

--------- 3.0<br />

7 430 / 439 / 444 Annealed 0.50 3.0<br />

1 to 2.5 0.30<br />

1 to 2.5 0.28<br />

4.0 0.20 0.35 0.8 170 270 1 to 2.5 0.28<br />

0.18<br />

0.18<br />

0.32 0.6 120 210 1 to 2.5 0.28<br />

0.28 0.5 70 120 1 to 2.5 0.28<br />

0.35 0.7 170 250 1 to 2.5 0.28<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420 0.50 3.0 0.22 0.35 0.7<br />

Stainless Steel Treated 120 210<br />

0.22<br />

1 to 2.5 0.28<br />

EN - GJL 200<br />

1.6 280<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.50 5.0 0.15 0.40 1.4 170 250 1 to 3 0.32<br />

to 230<br />

EN - GJL 300 1.2 230<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 1.2 230<br />

10 EN - GJS 600 260 0.50 4.0<br />

0.35 1.1 120 190 1 to 2.5 0.28<br />

EN - GJS 800 310 1.0 150<br />

Inconel 625 0.6 25 35<br />

11 Inconel 718 -------- 0.50 3.0 0.20 0.32 0.6<br />

12<br />

Insert designation<br />

CCMT 09T308 NN<br />

Hastello y C 0.7 40 65<br />

0.15<br />

40 1 to 2.5 0.25<br />

TiAl 6 V4<br />

0.32 0.7 35 60 1 to 2.5 0.25<br />

-------- 0.50 3.0 0.18<br />

T40 0.28 0.6 28 40 1 to 2.5 0.22<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

28<br />

5<br />

CCMT

CCMT 09T308 WM<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 3.0 0.35 0.30 330<br />

180 0.20 3.0 0.12 0.35 0.30 180 280 0.5 to 1.5 0.18<br />

210 3.0 0.35 0.30 250<br />

180 3.0 0.35 0.30 280<br />

0.11<br />

230<br />

3.0 0.35 0.30<br />

250<br />

0.20<br />

120<br />

280 3.0 0.35 0.30 210<br />

0.11<br />

320 3.0 0.35 0.30 180<br />

220 3.0 0.32 0.30 190<br />

280<br />

3.0 0.32 0.30<br />

150<br />

0.20<br />

0.09<br />

70<br />

320 2.5 0.32 0.30 130<br />

350 2.5 0.32 0.30 100<br />

---------<br />

7 430 / 439 / 444 Annealed<br />

Wiper inserts are not recommended for austenitic stainless<br />

®<br />

0.5 to 1.5 0.15<br />

0.5 to 1.5 0.12<br />

Martensitic<br />

Stainless Steel<br />

8 410 / 420<br />

Annealed<br />

Treated<br />

0.5 3.0 0.11 0.35 0.30<br />

170<br />

120<br />

190<br />

250<br />

0.5 to 1.5 0.15<br />

Grey Cast Iron 9<br />

EN - GJL 200<br />

EN - GJL 250<br />

EN - GJL 300<br />

140<br />

to 230<br />

0.20 5.0 0.15 0.35<br />

0.35<br />

0.35<br />

0.35<br />

170<br />

250<br />

230<br />

210<br />

0.5 to 1.5 0.18<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

0.5 3.0<br />

EN - GJS 400 210 0.30 230<br />

10 EN - GJS 600 260 0.20 4.0<br />

0.5 to 1.5 0.15<br />

0.30 0.30 120 190 0.5 to 1.5 0.15<br />

EN - GJS 800 310 0.30 150<br />

Inconel 625<br />

11 Inconel 718 --------<br />

12<br />

Insert designation<br />

CCMT 09T308 WM<br />

Hastello y C<br />

TiAl 6 V4<br />

T40<br />

--------<br />

0.11 0.35<br />

0.15<br />

0.30<br />

170 250<br />

Wiper inserts are not recommended for exotic materials<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

CCMT 120404 NN<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

®<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 3.0 0.23 0.60 400<br />

180 0.20 2.5 0.11 0.20 0.48 180 350 0.5 to 2.0 0.18<br />

210 2.5 0.18 0.48 200<br />

180 2.5 0.20 0.48 300<br />

0.11<br />

230<br />

2.5 0.20 0.40<br />

250<br />

0.20<br />

120<br />

280 2.0 0.18 0.40 210<br />

0.09<br />

320 2.0 0.16 0.32 180<br />

220 2.5 0.18 0.40 190<br />

280<br />

2.5 0.16 0.40<br />

150<br />

0.20<br />

0.09<br />

70<br />

320 2.0 0.14 0.28 130<br />

350 2.0 0.14 0.24 100<br />

0.20<br />

--------- 0.25 2.0<br />

0.5 to 1.0 0.15<br />

0.5 to 1.5 0.12<br />

2.5 0.10 0.18 0.32 170 270 0.5 to 2.0 0.15<br />

2.0<br />

7 430 / 439 / 444 Annealed 0.25 2.0<br />

0.09<br />

0.09<br />

0.16 0.24 120 210 0.5 to 1.5 0.12<br />

0.14 0.20 70 120 0.5 to 1.5 0.12<br />

0.18 0.28 170 250 0.5 to 1.5 0.15<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420 0.25 2.0 0.11 0.18 0.28<br />

Stainless Steel Treated 120 210<br />

0.11<br />

0.5 to 1.5 0.15<br />

EN - GJL 200<br />

0.64 280<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.20 3.0 0.08 0.20 0.60 170 250 0.5 to 1.5 0.18<br />

to 230<br />

EN - GJL 300 0.60 230<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 0.48 230<br />

10 EN - GJS 600 260 0.20 2.5<br />

0.18 0.40 120 190 0.5 to 2.0 0.15<br />

EN - GJS 800 310 0.40 150<br />

Inconel 625 0.24 25 35<br />

11 Inconel 718 -------- 0.25 2.0 0.10 0.16 0.24<br />

12<br />

Insert designation<br />

CCMT 20404 NN<br />

Hastello y C 0.28 40 65<br />

0.08<br />

40 0.5 to 1.5 0.12<br />

TiAl 6 V4<br />

0.16 0.28 35 60 0.5 to 1.5 0.14<br />

-------- 0.25 2.0 0.09<br />

T40 0.14 0.24 28 40 0.5 to 1.5 0.12<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

6 7<br />

28<br />

CCMT

CCMT 120408 NN<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 3.0 0.23 0.60 400<br />

180 0.20 2.5 0.11 0.20 0.48 180 350 0.5 to 2.0 0.18<br />

210 2.5 0.18 0.48 200<br />

180 2.5 0.20 0.48 300<br />

0.11<br />

230<br />

2.5 0.20 0.40<br />

250<br />

0.20<br />

120<br />

280 2.0 0.18 0.40 210<br />

0.09<br />

320 2.0 0.16 0.32 180<br />

220 2.5 0.18 0.40 190<br />

280<br />

2.5 0.16 0.40<br />

150<br />

0.20<br />

0.09<br />

70<br />

320 2.0 0.14 0.28 130<br />

350 2.0 0.14 0.24 100<br />

0.20<br />

--------- 0.20 2.0<br />

®<br />

0.5 to 1.0 0.15<br />

0.5 to 1.5 0.12<br />

2.5 0.10 0.18 0.32 170 270 0.5 to 2.0 0.15<br />

2.0<br />

7 430 / 439 / 444 Annealed 0.20 2.0<br />

0.09<br />

0.09<br />

0.16 0.24 120 210 0.5 to 1.5 0.12<br />

0.14 0.20 70 120 0.5 to 1.5 0.12<br />

0.18 0.28 170 250 0.5 to 1.5 0.15<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420 0.20 2.0 0.11 0.18 0.28<br />

Stainless Steel Treated 120 210<br />

0.11<br />

0.5 to 1.5 0.15<br />

EN - GJL 200<br />

0.64 280<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.20 3.0 0.08 0.20 0.60 170 250 0.5 to 1.5 0.18<br />

to 230<br />

EN - GJL 300 0.60 230<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 0.48 230<br />

10 EN - GJS 600 260 0.20 2.5<br />

0.18 0.40 120 190 0.5 to 2.0 0.15<br />

EN - GJS 800 310 0.40 150<br />

Inconel 625 0.24 25 35<br />

11 Inconel 718 -------- 0.25 2.0 0.10 0.16 0.24<br />

12<br />

Insert designation<br />

CCMT 20408 NN<br />

Hastello y C 0.28 40 65<br />

0.08<br />

40 0.5 to 1.5 0.12<br />

TiAl 6 V4<br />

0.16 0.28 35 60 0.5 to 1.5 0.14<br />

-------- 0.25 2.0 0.09<br />

T40 0.14 0.24 28 40 0.5 to 1.5 0.12<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

28<br />

CNMA Shape<br />

Turning<br />

C<br />

Clearance Angle<br />

N<br />

Tolerance<br />

M<br />

Insert Type<br />

A<br />

80° Diamond<br />

0° No rake<br />

l ± 0.05 m ± 0.08<br />

s ± 0.13<br />

Pin / Top clamp<br />

Double sided<br />

Insert Designation Grade l s r Catalog Nr. Page*<br />

CNMA 204 6 NN LT 10 12 4,76 1,6 T0000612 20<br />

NN: All purpose chip breaker.<br />

Application Guide<br />

Insert designation<br />

CNMA 204 6 NN<br />

Not recommended<br />

2 Acceptable<br />

3 Recommended<br />

4 Excellent<br />

* For Cutting data see<br />

relevant page<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

Swiss<br />

Made Machining Recommendations Guide - please see page 6<br />

8 9<br />

CNMA

CNMA 120416 NN<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

*For all material types and standards, see pages 240 to 245.<br />

150<br />

180<br />

210<br />

180<br />

230<br />

280<br />

320<br />

220<br />

280<br />

320<br />

350<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

---------<br />

7 430 / 439 / 444 Annealed<br />

Martensitic<br />

Annealed<br />

8 410 / 420<br />

Stainless Steel Treated<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

EN - GJL 200<br />

3.3 250<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.50 5.0 0.25 1.20 3.0 170 230 2 to 5 0.70<br />

to 230<br />

EN - GJL 300 2.8 210<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 2.5 230<br />

10 EN - GJS 600 260 0.50 5.0<br />

0.90 2.2 120 190 2 to 5 0.70<br />

EN - GJS 800 310 2.0 150<br />

Inconel 625<br />

11 Inconel 718 --------<br />

12<br />

Insert designation<br />

CNMA 204 6 NN<br />

Hastello y C<br />

TiAl 6 V4<br />

T40<br />

--------<br />

CNMA 120416 NN is not recommended for Low Carbon Steel.<br />

CNMA 120416 NN is not recommended for Alloy Steel.<br />

CNMA 120416 NN is not recommended for High Alloy Steel.<br />

CNMA 120416 NN is not recommended for Austenitic Stainless Steel.<br />

CNMA 120416 NN is not recommended for Ferritic Stainless Steel.<br />

CNMA 120416 NN is not recommended for Martensitic Stainless Steel.<br />

0.25<br />

CNMA 120416 NN is not recommended for Nickel Based Alloys.<br />

CNMA 120416 NN is not recommended for Titanium Based Alloys.<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

®<br />

CNMG Shape<br />

Turning<br />

Application Guide<br />

Not recommended<br />

2 Acceptable<br />

3 Recommended<br />

4 Excellent<br />

Clearance Angle<br />

Tolerance<br />

Insert Type<br />

Insert Designation Grade l s r Catalog Nr. Page*<br />

CNMG 20404 NN<br />

CNMG 20408 NN<br />

CNMG 20408 NN<br />

CNMG 20408 WM<br />

CNMG 204 2 NN<br />

CNMG 204 2 NN<br />

LT 10<br />

LT 10<br />

LT 10 CR<br />

LT 10<br />

LT 10<br />

LT 10 CR<br />

C<br />

N<br />

M<br />

G<br />

80° Diamond<br />

0° No rake<br />

l ± 0.05 m ± 0.08<br />

s ± 0.13<br />

Pin / Top clamp<br />

Double sided<br />

12 4,76 0,4<br />

12 4,76 0,8<br />

12 4,76 0,8<br />

12 4,76 0,8<br />

12 4,76 1,2<br />

12 4,76 1,2<br />

NN: All purpose chip breaker. WM: Wiper Medium chip breaker.<br />

T0000491<br />

T0000059<br />

T0001176<br />

T0000060<br />

T0000061<br />

T0001177<br />

* For Cutting data see<br />

relevant page<br />

Insert designation Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

CNMG 20404 NN<br />

CNMG 20408 NN<br />

CNMG 20408 NN LT- 0 CR<br />

CNMG 20408 WM<br />

CNMG 204 2 NN<br />

CNMG 204 2 NN LT- 0 CR<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

Swiss<br />

Made Machining Recommendations Guide - please see page 6<br />

20 2<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

CNMG

CNMG 120404 NN<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 3.0 0.23 0.54 330<br />

180 0.20 3.0 0.11 0.23 0.54 180 280 0.5 to 1.5 0.18<br />

210 3.0 0.20 0.45 250<br />

180 3.0 0.20 0.45 280<br />

0.11<br />

230<br />

3.0 0.20 0.36<br />

250<br />

0.20<br />

120<br />

280 3.0 0.18 0.36 210<br />

0.09<br />

320 3.0 0.18 0.30 180<br />

220 3.0 0.20 0.36 190<br />

280<br />

3.0 0.20 0.36<br />

150<br />

0.20<br />

0.09<br />

70<br />

320 2.5 0.18 0.24 130<br />

350 2.5 0.18 0.24 100<br />

0.20<br />

--------- 0.25 2.5<br />

®<br />

0.5 to 1.5 0.15<br />

0.5 to 1.5 0.12<br />

3.0 0.10 0.20 0.30 170 270 0.5 to 1.5 0.15<br />

2.5<br />

7 430 / 439 / 444 Annealed 0.25 3.0<br />

0.09<br />

0.09<br />

0.18 0.24 160 210 0.5 to 1.5 0.15<br />

0.18 0.18 70 150 0.5 to 1.5 0.12<br />

0.18 0.27 170 250 0.5 to 1.5 0.15<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420 0.25 3.0 0.11 0.18 0.27<br />

Stainless Steel Treated 120 190<br />

0.11<br />

0.5 to 1.5 0.15<br />

EN - GJL 200<br />

0.60 250<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.20 3.0 0.08 0.30 0.54 170 230 0.5 to 1.5 0.18<br />

to 230<br />

EN - GJL 300 0.54 210<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 0.45 230<br />

10 EN - GJS 600 260 0.20 3.0<br />

0.25 0.39 120 190 0.5 to 1.5 0.15<br />

EN - GJS 800 310 0.36 150<br />

Inconel 625 0.21 25 35<br />

11 Inconel 718 -------- 0.25 2.0 0.10 0.18 0.21<br />

12<br />

Insert designation<br />

CNMG 20404 NN<br />

Hastello y C 0.24 40 65<br />

0.08<br />

40 0.5 to 1.5 0.12<br />

TiAl 6 V4<br />

0.18 0.24 35 60 0.5 to 1.5 0.15<br />

-------- 0.25 2.0 0.09<br />

T40 0.15 0.18 28 40 0.5 to 1.5 0.12<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

28<br />

CNMG 120408 NN<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

*For all material types and standards, see pages 240 to 245.<br />

®<br />

Machining Conditions<br />

Material Group conditions<br />

Group Material d.o.c [mm] feed [mm/rev] A max Vc [m/min]<br />

Optimal cutting<br />

No. Examples*<br />

[mm<br />

min max min max<br />

2 Brinell<br />

hardness<br />

]<br />

HB<br />

min max d.o.c feed<br />

Low Carbon<br />

Steel<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

150 5.00 0.45 1.80 400<br />

180 0.50 5.00 0.21 0.45 1.80 180 350 1.5 to 3 0.35<br />

210 4.00 0.40 1.50 200<br />

180 5.00<br />

0.40 1.20 300<br />

0.21<br />

230<br />

4.00 0.40 1.20<br />

250<br />

0.50<br />

120<br />

280 4.00<br />

0.35 1.20 210<br />

0.18<br />

320 3.50 0.35 1.00 180<br />

220 4.00 0.40 1.20 190<br />

280<br />

4.00<br />

0.40 1.20<br />

150<br />

0.50<br />

0.18<br />

70<br />

320 3.00 0.35 0.80 130<br />

350 3.00 0.35 0.80 100<br />

1.5 to 3 0.30<br />

1.5 to 3 0.28<br />

5.00 0.20 0.40 1.00 170 270 1.5 to 3 0.35<br />

0.50 4.00 0.18 0.35 0.80 170 210 1.5 to 3 0.32<br />

-------- 4.00 0.18 0.35 0.60 80 130 1.5 to 3 0.28<br />

7 430 / 439 / 444 Annealed 0.50 4.00 0.22 0.35 0.90 170 250 1.5 to 3 0.32<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420<br />

0.50 4.00 0.22 0.35 0.90<br />

Stainless Steel Treated 120 210<br />

1.5 to 3 0.32<br />

EN - GJL 200<br />

2.00 280<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.50 5.00 0.15 0.60 1.80 170 250 1.5 to 3 0.35<br />

to 230<br />

EN - GJL 300 1.80 230<br />

Nodular Cast<br />

Iron<br />

EN - GJS 400 210 1.50 230<br />

10 EN - GJS 600 260 0.50 5.00 0.15 0.50 1.30 120 190 1.5 to 3 0.30<br />

EN - GJS 800 310 1.20 150<br />

Inconel 625 0.70 35<br />

11 Inconel 718 -------- 0.50 3.00 0.20 0.35 0.70 25 40 1.5 to 3 0.28<br />

12<br />

Insert designation<br />

CNMG 20408 NN<br />

Hastelloy C 0.80 65<br />

TiAl 6 V4<br />

0.35 0.80 35 60 1.5 to 3 0.30<br />

-------- 0.50 3.00 0.18<br />

T40 0.30 0.60 28 40 1.5 to 3 0.28<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

22 23<br />

CNMG

CNMG 120408 NN LT-10 CR<br />

Material Group Group Material Brinell<br />

No Examples*<br />

hardness<br />

HB<br />

Low Carbon<br />

Steel<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 5.0 0.45 1.8<br />

180 0.50 5.0 0.21 0.45 1.8 120 380 1.5 to 3 0.35<br />

210 4.0 0.40 1.5<br />

180 5.0 0.40 1.5<br />

0.21<br />

230<br />

4.0 0.40 1.2<br />

0.50<br />

280 4.0 0.35 1.2<br />

0.18<br />

320 3.5 0.35 1.0<br />

220 4.0 0.40 1.2<br />

280<br />

4.0 0.40 1.2<br />

0.50<br />

0.18<br />

320 3.0 0.35 0.8<br />

350 3.0 0.35 0.8<br />

0.50 4.0<br />

--------- 4.0<br />

7 430 / 439 / 444 Annealed 0.50 4.0<br />

®<br />

300<br />

100 1.5 to 3 0.30<br />

250<br />

190<br />

70 1.5 to 3 0.28<br />

170<br />

5.0 0.20 0.40 1.0 100 270 1.5 to 3 0.32<br />

Martensitic<br />

Annealed<br />

170<br />

8 410 / 420 0.50 4.0 0.22 0.35 0.9<br />

Stainless Steel Treated 120<br />

0.18<br />

0.18<br />

0.22<br />

0.35 0.8 80 210 1.5 to 3 0.29<br />

0.35 0.6 70 120 1.5 to 3 0.25<br />

0.35 0.9 170 250 1.5 to 3 0.32<br />

1.5 to 3 0.32<br />

EN - GJL 200<br />

2.0<br />

380<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.50 5.0 0.15 0.60 1.8 170 320 1.5 to 3 0.35<br />

to 230<br />

EN - GJL 300 1.8<br />

270<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 1.5<br />

10 EN - GJS 600 260 0.50 5.0<br />

EN - GJS 800 310 1.2<br />

0.50 1.3 120 250 1.5 to 3 0.30<br />

Inconel 625 0.7 25 35<br />

11 Inconel 718 -------- 0.50 3.0 0.20 0.35 0.7<br />

12<br />

Insert designation<br />

CNMG 20408 NN CR<br />

Hastello y C 0.8 40 65<br />

0.15<br />

40 1.5 to 3 0.28<br />

TiAl 6 V4<br />

0.35 0.8 35 60 1.5 to 3 0.30<br />

-------- 0.50 3.0 0.18<br />

T40 0.30 0.6 28 40 1.5 to 3 0.28<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

28<br />

450<br />

250<br />

350<br />

210<br />

230<br />

130<br />

250<br />

210<br />

300<br />

210<br />

CNMG 120408 WM<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

®<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 5.0 0.70 1.2 330<br />

180 0.5 5.0 0.21 0.45(0.70) 1.2 180 280 1.5 to 3 0.35<br />

210 4.0 0.40(0.60) 1.2 250<br />

180 5.0 0.65 1.0 280<br />

0.21<br />

230<br />

4.0 0.40(0.60) 1.0<br />

250<br />

0.5<br />

120<br />

280 4.0 0.35(0.60) 1.0 210<br />

0.18<br />

320 3.5 0.35(0.50) 1.0 180<br />

220 4.0 0.60 0.8 190<br />

280<br />

4.0 0.40(0.60) 0.8<br />

150<br />

0.5<br />

0.18<br />

70<br />

320 3.0 0.35(0.60) 0.8 130<br />

350 3.0 0.35(0.50) 0.8 100<br />

---------<br />

1.5 to 3 0.30<br />

1.5 to 3 0.28<br />

7 430 / 439 / 444 Annealed 0.5 4.0 0.22 0.50 0.8 170 250 1.5 to 3 0.32<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420 0.5 4.0 0.22 0.50 0.8<br />

Stainless Steel Treated 120 190<br />

1.5 to 3 0.32<br />

EN - GJL 200<br />

1.2 250<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.5 5.0 0.15 0.70 1.2 170 230 1.5 to 3 0.35<br />

to 230<br />

EN - GJL 300 1.2 210<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 1.0 230<br />

10 EN - GJS 600 260 0.5 5.0<br />

0.60 1.0 120 190 1.5 to 3 0.30<br />

EN - GJS 800 310 1.0 150<br />

Inconel 625<br />

11 Inconel 718 --------<br />

12<br />

Insert designation<br />

Hastello y C<br />

TiAl 6 V4<br />

T40<br />

CNMG 20408 WM<br />

--------<br />

Wiper inserts are not recommended for austenitic stainless<br />

0.15<br />

Wiper inserts are not recommended for exotic materials<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

24 25<br />

CNMG

CNMG 120412 NN<br />

Material Group<br />

Low Carbon<br />

Steel<br />

Group Material Brinell<br />

No Examples*<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

hardness<br />

HB<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />

230<br />

5 316 / 316 L<br />

Stainless Steel to 270<br />

Ferritic<br />

Stainless Steel<br />

6<br />

316 Ti<br />

630 (F16PH)<br />

*For all material types and standards, see pages 240 to 245.<br />

Machining Conditions<br />

d.o.c [mm] feed [mm/rev] A max Vc [m/min] Optimal cutting<br />

[mm<br />

min max min max<br />

2 conditions<br />

]<br />

min max d.o.c feed<br />

150 5.0 0.68 3.1 330<br />

180 0.50 5.0 0.27 0.68 3.1 180 280 2 to 5 0.50<br />

210 5.0 0.60 2.6 250<br />

180 5.0 0.60 2.6 280<br />

0.27<br />

230<br />

5.0 0.60 2.0<br />

250<br />

0.50<br />

120<br />

280 5.0 0.53 2.0 210<br />

0.23<br />

320 4.0 0.53 1.7 180<br />

220 5.0 0.60 2.0 190<br />

280<br />

5.0 0.60 2.0<br />

150<br />

0.50<br />

0.23<br />

70<br />

320 4.0 0.53 1.4 130<br />

350 4.0 0.53 1.4 100<br />

0.50 5.0<br />

--------- 5.0<br />

7 430 / 439 / 444 Annealed 0.50 5.0<br />

®<br />

2 to 5 0.45<br />

2 to 5 0.40<br />

5.0 0.26 0.52 1.7 170 270 2 to 5 0.40<br />

0.23<br />

0.23<br />

0.46 1.4 160 210 2 to 5 0.36<br />

0.46 1.0 70 150 2 to 5 0.32<br />

0.46 1.5 170 250 2 to 5 0.35<br />

Martensitic<br />

Annealed<br />

170 250<br />

8 410 / 420 0.50 5.0 0.29 0.46 1.5<br />

Stainless Steel Treated 120 190<br />

0.29<br />

2 to 5 0.35<br />

EN - GJL 200<br />

3.0 250<br />

140<br />

Grey Cast Iron 9 EN - GJL 250<br />

0.50 5.0 0.20 0.90 2.7 170 230 2 to 5 0.60<br />

to 230<br />

EN - GJL 300 2.7 210<br />

Nodular Cast<br />

Iron<br />

Nickel Based<br />

Alloys<br />

Titanium Based<br />

Alloys<br />

EN - GJS 400 210 2.3 230<br />

10 EN - GJS 600 260 0.50 5.0<br />

0.70 2.0 120 190 2 to 5 0.50<br />

EN - GJS 800 310 1.8 150<br />

Inconel 625 1.4 25 35<br />

11 Inconel 718 -------- 0.50 5.0 0.26 0.46 1.4<br />

12<br />

Insert designation<br />

CNMG 204 2 NN<br />

Hastello y C 1.6 40 65<br />

0.20<br />

40 2 to 5 0.38<br />

TiAl 6 V4<br />

0.46 1.6 35 60 2 to 5 0.38<br />

-------- 0.50 5.0 0.23<br />

T40 0.39 1.2 28 40 2 to 5 0.32<br />

Super Finishing Finishing Semi Finishing Roughing Interrupted Cut<br />

2 3 4 2 3 4 2 3 4 2 3 4 2 3 4<br />

28<br />

CNMG 120412 NN LT-10 CR<br />

Material Group Group Material Brinell<br />

No Examples*<br />

hardness<br />

HB<br />

Low Carbon<br />

Steel<br />

1<br />

Ck 15<br />

9SMnPb28<br />

42 CrMo 4<br />

Alloy Steel 2 100 Cr 6<br />

High Alloy<br />

Steel<br />

32 NiCrMo 14.5<br />

X38 CrMoV 5<br />

3 X210 CrW 12<br />

4<br />

X90 CrMoV 8<br />

303 / 304 210<br />

304 L to 250<br />

Austenitic<br />