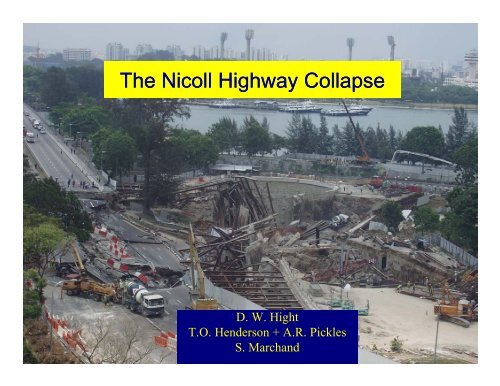

The Nicoll Highway Collapse

The Nicoll Highway Collapse

The Nicoll Highway Collapse

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>The</strong> <strong>Nicoll</strong> <strong>Highway</strong> <strong>Collapse</strong><br />

D W Hi ht<br />

D. W. Hight<br />

T.O. Henderson + A.R. Pickles<br />

S. Marchand

Content<br />

• Background and construction sequence<br />

• Observations up to the point of collapse, including<br />

monitoring<br />

• <strong>The</strong> collapse<br />

• Post-collapse investigations<br />

• Design errors<br />

• Jet grout layers<br />

• Ground conditions and the buried valley<br />

• <strong>The</strong> need for a trigger<br />

• Back analyses of the collapse<br />

• Relative vertical displacement and forced sway<br />

• <strong>The</strong> bored piles<br />

• <strong>Collapse</strong> mechanism and its trigger<br />

• Lessons to be learnt

C825<br />

34m Diameter<br />

Temporary Staging<br />

Area (TSA) Shaft -<br />

35m deep<br />

210m 2-cell cut &<br />

cover tunnels<br />

200m cut 30m & cover - 33m deep<br />

stacked 4-cell<br />

scissors crossover<br />

3-level cut & cover tunnel<br />

Station (NCH) 25m - 30m deep<br />

370m stacked 2-cell<br />

cut & cover tunnel<br />

20m - 25m deep<br />

C824 - 2km of cut and cover construction<br />

mostly in soft clay - up to 35m deep<br />

C824<br />

<strong>Collapse</strong> site<br />

M3 area<br />

Circle Ci Circle l Li Line St Stage 1<br />

800m twin bored<br />

tunnel<br />

3-level cut & cover<br />

Station (BLV)<br />

35m 2-cell cut and<br />

cover tunnel<br />

550m 2-cell cut &<br />

cover tunnel and<br />

siding (BLS)

Plaza Hotel<br />

<strong>The</strong> Concourse<br />

NCH station<br />

Courtesy of Richard Davies<br />

Reclamation dates<br />

Golden Mile<br />

Tower<br />

Cut and Cover<br />

tunnels<br />

Beach Road<br />

1930-1940’s<br />

1930-1940 s<br />

reclamation<br />

GGolden ld Mil Mile<br />

Complex<br />

1970’s<br />

reclamation<br />

<strong>Nicoll</strong> <strong>Highway</strong><br />

TSA<br />

shaft<br />

MMerdeka d k<br />

Bridge<br />

Kallang<br />

Basin

NORRTHING<br />

(m)<br />

ABH27<br />

31700<br />

31650<br />

31600<br />

MC2025<br />

54+812<br />

ABH81<br />

ABH28<br />

M2<br />

MC3007<br />

ABH82<br />

ABH83<br />

ABH29<br />

54+900<br />

ABH30<br />

M3010<br />

ABH32<br />

M3<br />

ABH84<br />

AC-3<br />

ABH31<br />

MC2026<br />

ABH85<br />

AC-2<br />

ABH34<br />

AC-4<br />

AC-1<br />

MC3008<br />

31550 31600 31650 31700 31750 31800<br />

EASTING (m)<br />

ABH33<br />

M2064 M2065<br />

Pre- and post-tender site investigation<br />

ABH35

100<br />

90<br />

80<br />

70<br />

SOUTH NORTH<br />

ABH 31 ABH 32<br />

Fill<br />

Upper estuarine<br />

UUpper<br />

Marine<br />

Clay<br />

Upper F2<br />

M309<br />

M304<br />

Fill<br />

Upper estuarine<br />

Upper<br />

Marine<br />

Clay<br />

Upper F2<br />

Lower<br />

Lower<br />

Marine<br />

Marine<br />

Clay Clay<br />

Base marine clay<br />

Old<br />

Alluvium<br />

Top of OA<br />

Typical section in M3<br />

Lower o e<br />

estuarine<br />

Lower F2<br />

Old<br />

Alluvium

Depth (m)<br />

Cone resistance, qc (MPa)<br />

0 04 0.4 08 0.8 12 1.2 16 1.6 2<br />

0<br />

10<br />

20<br />

AC1<br />

AC2<br />

AC3<br />

AC4<br />

30 30<br />

40 40<br />

Depth (m)<br />

Piezocone data for M3 area<br />

Undrained shear strength (kPa)<br />

0<br />

0<br />

20 40 60 80 100<br />

10<br />

20<br />

AC1<br />

AC2<br />

AC3<br />

AC4<br />

Nkt=12

Construction details and sequence

Formation level<br />

approx 33m bgl<br />

Temporary diaphragm<br />

walls,0.8m<br />

Driven kingpost gp<br />

SOUTH NORTH<br />

Permanent bored piles<br />

supporting<br />

rail boxes Sacrificial JGP<br />

10 levels of steel struts at<br />

3m +3.5m vertical<br />

centres<br />

Permanent JGP<br />

Fill<br />

Upper E<br />

Upper<br />

Marine Clay<br />

Upper F2<br />

Lower<br />

Marine Clay<br />

Lower E<br />

Lower F2<br />

OA SW2 (N=35)<br />

OA SW1 (N (N=72) 72)<br />

OA (CZ)

General Excavation sequence for M3 – up to level for<br />

removal of sacrificial JGP and installation of 10 th level strut

M3<br />

M2<br />

TSA Shaft<br />

Utility crossings<br />

<strong>Nicoll</strong><br />

<strong>Highway</strong><br />

Curved walls<br />

Tidal sea<br />

24/3/04

No waler<br />

C channel stiffener<br />

Walers<br />

M3<br />

Shaft<br />

Jacking point<br />

Non-splayed strut<br />

Splayed strut<br />

Kingpost<br />

Support beam<br />

M2

Two Struts Bearing<br />

Direct on Single panel<br />

Single g Strut with Splays y<br />

Bearing on Waler for Single<br />

panel<br />

Struts on Walers - No Splays<br />

Gaps in Diaphragm Wall for 66kV Crossing

South side 13 March 04

Events Events and and observations observations prior to collapse

Plate stiffener<br />

C channel<br />

stiffener<br />

Replacement of plate stiffeners at strut strut-waler waler connection

C channel<br />

connection<br />

Strut bearing<br />

directly on Dwall

Excavation for the 10th Excavation for the 10 level of struts, including removal of the sacrificial JGP

Observations on the morning of the collapse

M301<br />

333<br />

334<br />

M302<br />

M303<br />

North wall<br />

M304<br />

M305<br />

4 2 3<br />

1<br />

6 7<br />

335 336 337 338 339 340<br />

H H H<br />

KP 181 KP 182<br />

KP 183<br />

1 5 5 5 7 7<br />

M306 M307 M308 M309 M310<br />

1 Order in which distortion to waler noted<br />

Excavation to 10 th complete<br />

Excavation in progress<br />

Location of walers, splays and Dwall gaps

S335 S335-99<br />

Strut 335-9 south wall

Strut 338 338-9 9 north wall<br />

S338 S338-99

Instrumentation and results of monitoring

M2<br />

GWV24<br />

I 65<br />

M2/M3 plan at 9 th level<br />

I 104<br />

M3<br />

All struts at S335<br />

instrumented for load<br />

measurements<br />

TSA Shaft

SG3358 Total Force<br />

SG3359 Total Force<br />

Excavation Front for<br />

10th Level Advancing<br />

from S338<br />

140<br />

15th April<br />

130<br />

120<br />

Excavation Front<br />

Approaches S335 at<br />

the end of Day y Shift on<br />

17th April 2004<br />

Excavation Front<br />

Beyond S335 at the<br />

start of Day Shift on<br />

18th April 2004<br />

5000<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

strut loadd<br />

(kN)<br />

1500<br />

10th Level Between 1000easured<br />

Excavation Front for<br />

110<br />

S336 and S335 M<br />

16th April<br />

100<br />

90<br />

17th April<br />

80<br />

70<br />

60<br />

18th April<br />

Hours before collapse<br />

50<br />

40<br />

19th April<br />

30<br />

20<br />

10<br />

500<br />

20th April<br />

0<br />

0

(kN)<br />

Meeasured<br />

strut<br />

load<br />

5000<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

Change in Measured Load at Strut 335<br />

336(N) & 337(N)<br />

Waler Buckling Observed 335(N)<br />

Support Bracket Waler at 335(S) Buckling Drops Observed Off<br />

Strut Load 335-9<br />

Strut Load 335-8<br />

338(N) & 335(S)<br />

Waler Buckling Observed<br />

0<br />

6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00 16.00<br />

Time on 20April 2004

Load<br />

Observed trends in 8 th and 9 th strut loads<br />

Innstallation<br />

of f 9th<br />

8th<br />

9th<br />

Excavation approaches<br />

+ passes beyond S335<br />

Observed<br />

5 18 20<br />

April 2004<br />

9amm<br />

3.30pm

<strong>The</strong> trends were consistent with there being g<br />

yielding of the 9th level strut-waler connection<br />

when the excavation passed beneath but with<br />

no ffurther th significant i ifi t changes h iin lload d iin either ith<br />

the 9th or 8th level struts until the collapse was<br />

initiated

Deepth<br />

(m)<br />

0<br />

Horizontal displacement (mm)<br />

0 200 400<br />

I 104<br />

10 April<br />

Horizontal displacement (mm)<br />

400 200 0<br />

I 65<br />

10 April<br />

10 10<br />

20<br />

30<br />

Behind South Wall North Wall<br />

40 40<br />

50 50<br />

0<br />

20<br />

Deepth<br />

(m)<br />

30

Deepth<br />

(m)<br />

0<br />

Horizontal displacement (mm)<br />

0 200 400<br />

I 104<br />

10 April<br />

15 April<br />

Horizontal displacement (mm)<br />

400 200 0<br />

I 65<br />

10 April<br />

16 April<br />

10 10<br />

20<br />

30<br />

Behind South Wall North Wall<br />

40 40<br />

50 50<br />

0<br />

20<br />

Deepth<br />

(m)<br />

30

Deepth<br />

(m)<br />

0<br />

Horizontal displacement (mm)<br />

0 200 400<br />

I 104<br />

10 April<br />

15 April<br />

17 April<br />

Horizontal displacement (mm)<br />

400 200 0<br />

I 65<br />

10 April<br />

16 April<br />

17 April<br />

10 10<br />

20<br />

30<br />

Behind South Wall North Wall<br />

40 40<br />

50 50<br />

0<br />

20<br />

Deepth<br />

(m)<br />

30

Deepth<br />

(m)<br />

0<br />

Horizontal displacement (mm)<br />

0 200 400<br />

I 104<br />

10 April<br />

15 April<br />

17 April<br />

20 April<br />

Horizontal displacement (mm)<br />

400 200 0<br />

I 65<br />

10 April<br />

16 April<br />

17 April<br />

20 April<br />

10 10<br />

20<br />

30<br />

Behind South Wall North Wall<br />

40 40<br />

50 50<br />

0<br />

20<br />

Deepth<br />

(m)<br />

30

displacemennt,<br />

mm<br />

Maximum<br />

horizontal<br />

500<br />

400<br />

300<br />

200<br />

100<br />

I104 max<br />

I65 max<br />

South wall<br />

NNorth th wall ll<br />

0<br />

5-Jul 9-Aug 13-Sep 18-Oct 22-Nov 27-Dec 31-Jan 6-Mar 10-Apr<br />

2003<br />

2004<br />

Comparison of inclinometer readings I65 and I104

• S338-9 stood for 8 days under load and was 20m<br />

from excavation front<br />

• S335 S335-9 9 stood for 22.5 5 days under load and was over<br />

8m from excavation front<br />

• BBoth th S335-9S S335 9S & S338 S338-9N 9N bbuckled kl d within ithi 10 minutes i t<br />

• Load in S335-8 and S335-9 was almost constant<br />

bbetween t 18 AApril il and d iinitiation iti ti of f collapse ll<br />

• All C-channel connections failed downwards at both<br />

ends<br />

• <strong>The</strong> south wall was pushing the north wall back<br />

Key observations

<strong>The</strong> collapse

3.33pm

3.33pm

3.34pm

3.34pm

3.34pm

3.41pm

3.46pm

Post-collapse Post collapse investigations<br />

Design errors

Errors<br />

• Misinterpretation of BS5950 with regard to stiff<br />

bbearing i llength h<br />

• Omission of splays<br />

Effects<br />

• Design capacity of strut-waler strut waler connection was 50% of<br />

required design capacity where splays were omitted<br />

Errors in structural design of strut strut-waler waler connection

• Capacity based on BS5950:1990 = 2550 kN<br />

• Average ultimate capacity based on physical<br />

load tests = 4100 kN<br />

• Based on mill tests, 9 95% % of f connections had<br />

capacity of 3800 kN- 4400kN<br />

• Predicted 9th level strut load in 2D analyses<br />

which ignored bored piles was close to<br />

ultimate capacity therefore collapse was<br />

considered by the COI to be inevitable<br />

Inevitability of collapse

• Method A and Method B refer to two alternative ways of<br />

modelling undrained soil behaviour in Plaxis (Pickles,<br />

2002)<br />

• Method A is an effective stress analysis of an undrained<br />

problem bl<br />

• Assumes isotropic elastic behaviour and a Mohr-<br />

CCoulomb ffailure<br />

criterion<br />

• As a result mean effective stress p’ p is constant until yyield<br />

• Method A was being applied to marine clays which were<br />

of low over-consolidation over consolidation or even under-consolidated<br />

under consolidated<br />

because of recent reclamation<br />

• Method B is a total stress analysis<br />

Methods A and B

t<br />

Cu from Method A<br />

Cu from Method B<br />

<strong>The</strong> shortcomings of Method A<br />

p’

RL (m)<br />

Method A Method B<br />

105 105<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60<br />

55<br />

-0.050 0.000 0.050 0.100 0.150 0.200 0.250 0.300<br />

Wall Disp. (m)<br />

Exc to RL 100.9 for S1 Exc to RL 98.1 for S2 Exc to RL 94.6 for S3<br />

Exc to RL 91.1 for S4 Exc to RL 87.6 for S5 Exc to RL 84.6 for S6<br />

Exc to RL 81.6 for S7<br />

Exc to RL 72.3 for S10<br />

Exc to RL 78.3 for S8 Exc to RL 75.3 for S9<br />

RL (m)<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60<br />

55<br />

-0.050 0.000 0.050 0.100 0.150 0.200 0.250 0.300<br />

Wall Disp. (m)<br />

Exc to RL 100.9 for S1 Exc to RL 98.1 for S2 Exc to RL 94.6 for S3<br />

Exc to RL 91.1 for S4 Exc to RL 87.6 for S5 Exc to RL 84.6 for S6<br />

Exc to RL 81.6 for S7<br />

Exc to RL 72.3 for S10<br />

Exc to RL 78.3 for S8 Exc to RL 75.3 for S9<br />

M3 - SSouth th Wall W ll Di Displacement l t<br />

Method A versus Method B

RL (m)<br />

105<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60<br />

55<br />

-3000<br />

-2500<br />

-2000<br />

-1500<br />

-1000<br />

-500<br />

Method A Method B<br />

0<br />

500<br />

1000<br />

1500<br />

Bending Moment (kNm/m)<br />

2000<br />

2500<br />

3000<br />

3500<br />

RL (m)<br />

4000<br />

105<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60<br />

55<br />

-3000<br />

-2500<br />

-2000<br />

-1500<br />

-1000<br />

-500<br />

0<br />

500<br />

1000<br />

1500<br />

Bending Moment (kNm/m)<br />

M3 - South Wall bending moments<br />

Method A versus Method B<br />

2000<br />

2500<br />

3000<br />

3500<br />

4000

Strut Load (kN/m) _<br />

MMethod th dA A<br />

g ( )<br />

3000<br />

2800<br />

2600<br />

2400<br />

2206<br />

2200<br />

S1<br />

2000<br />

S2<br />

1800<br />

S3<br />

1600<br />

S4<br />

1400<br />

1200<br />

S5<br />

1000<br />

S6<br />

800<br />

S7<br />

600 S8<br />

400<br />

S9<br />

200<br />

0<br />

Strut Load (kN/m)<br />

3000<br />

2800<br />

2600<br />

2400<br />

2200<br />

2000<br />

1800<br />

1600<br />

Method B<br />

M3 – strut forces<br />

Method A versus Method B<br />

2383<br />

1400<br />

S3<br />

1200<br />

S4<br />

1000<br />

S5<br />

800<br />

S6<br />

600 S7<br />

400<br />

S8<br />

200<br />

0<br />

S9<br />

S1<br />

S2

• Method A over-estimates the undrained shear<br />

strength of normally and lightly overconsolidated<br />

clays l<br />

• Its use led to a 50% under-estimate of wall<br />

displacements and of bending moments and an<br />

under-estimate of the 9 th level strut force of 10%<br />

• <strong>The</strong> larger than predicted displacements mobilised<br />

the capacity p y of the JGP layers y at an earlier stage g<br />

than predicted<br />

Method A

• St Structural t l design d i errors<br />

• Removal of splays p y at some strut locations<br />

• Introduction of C-channel waler connection detail<br />

• Use of Method A in soil-structure interaction analysis<br />

• C<strong>Collapse</strong> ll was an iinevitable it bl consequence of f th the<br />

design errors which led to the applied loads on the<br />

struts increasing with time and equalling the capacity<br />

of the strut-waler connection<br />

COI view on the principal causes of<br />

the collapse

• St Structural t l design d i errors<br />

• Removal of splays p y at some strut locations<br />

• Introduction of C-channel waler connection detail<br />

• Use of Method A in soil-structure interaction analysis<br />

• C<strong>Collapse</strong> ll was an iinevitable it bl consequence of f th the<br />

design errors which led to the applied loads on the<br />

struts increasing with time and equalling the capacity<br />

of the strut-waler connection<br />

COI view on the principal causes of<br />

the collapse

Post-collapse Post collapse investigations<br />

Jet grout

Excavation of sacrificial JGP in Type H

JGP quality in 100mm cores from borehole M1 in Type K

Shear wave velocity measurements in JGP at Type K

JGP thicckness<br />

(m)<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Shear wave section<br />

Design thickness<br />

Pressuremeter section<br />

0 2 4 6 8<br />

Thicknesses of JGP in Type K

Post-collapse Post collapse investigations<br />

Ground conditions and<br />

soil properties

NORRTHING<br />

(m)<br />

31700<br />

31650<br />

CFVN<br />

CTSN<br />

CPTNa<br />

CPTN<br />

54+812<br />

FN2<br />

FN1<br />

EN2<br />

M2<br />

EN1<br />

FS1<br />

ES1<br />

DN3<br />

DN2E<br />

DN2W<br />

DN1E<br />

DN1W<br />

CL-3g CL 3g<br />

CN3<br />

DS1E<br />

DS1W<br />

CN2<br />

BN3<br />

BN2E<br />

BN2W<br />

P33<br />

P36<br />

P42/P48<br />

P40P41/P47<br />

P45<br />

P52<br />

AN2<br />

54+900<br />

M3<br />

AN1<br />

CN1 BN1W BN1E<br />

BN1Ea<br />

66KVNI<br />

CL-2<br />

CS1<br />

CS2<br />

CL-1a<br />

BS1Ea<br />

BS1Eb<br />

66KVS<br />

SPTSa<br />

BS1W AS1<br />

31600<br />

ES2<br />

DS2E<br />

DS2W<br />

BS3E<br />

AS3<br />

31550 31600<br />

FS2<br />

31650<br />

BS3W<br />

31700 31750 31800<br />

DS3E<br />

CS3<br />

ES3<br />

BS2W<br />

BS2E<br />

DS3W<br />

EASTING (m)<br />

BS4W<br />

BS4E<br />

CS4<br />

BS4Ea<br />

DS4W<br />

DS4E<br />

AS2<br />

P54<br />

TSAN2<br />

TSAS2<br />

TSAS2b<br />

Post Post-collapse collapse ground investigation

Depth D (m)<br />

Cone resistance, qt (MPa)<br />

0<br />

0<br />

0.4 0.8 1.2 1.6 2<br />

10<br />

20<br />

30<br />

BN1W<br />

q t<br />

u2<br />

f s<br />

Cone resistance, qt (MPa)<br />

0<br />

0<br />

0.4 0.8 1.2 1.6 2<br />

BS2W<br />

North 10<br />

South<br />

40<br />

0 0.4 0.81.2 40<br />

Pore pressure, u 0 04 08 12<br />

2 (MPa)<br />

0 0.4 0.8 1.2<br />

Pore pressure, u2 (MPa)<br />

0 0.02 0.04 0.06 0.08<br />

Friction, f s (MPa)<br />

Deepth<br />

(m)<br />

20<br />

30<br />

q t<br />

u2<br />

f s<br />

0 0.02 0.04 0.06 0.08<br />

Friction, f s (MPa)<br />

CPT profiles north and south of collapse area

t (kPPa)<br />

100<br />

50<br />

0<br />

-50<br />

-100<br />

φ=34.2 o<br />

φ=28.5 o<br />

K o =0.5<br />

0 50 100 150 200<br />

s' (kPa)<br />

P-8<br />

P-9<br />

P-24<br />

P-26<br />

φ=35 o<br />

Kisojiban’s CAU tests on<br />

Upper and Lower Marine Clay

NORTHIING<br />

(m)<br />

ABH27<br />

31700<br />

31650<br />

31600<br />

50 55 60 65 70 75 80 85 90 95 100 105<br />

CFVN<br />

CTSN<br />

CPTNa<br />

CPTN<br />

MC2025<br />

DN3<br />

DN2E<br />

CN3<br />

CN2<br />

BN2E<br />

BN2W<br />

54+900<br />

BN3<br />

P33<br />

P45<br />

P36<br />

P40 P41/P47<br />

P52<br />

P42/P48<br />

AN2<br />

P54<br />

TSAN2<br />

Tender SI boreholes<br />

Tender SI CPTs<br />

Detailed design SI<br />

Detailed design SI CPTs<br />

Post collapse SI<br />

Post collapse SI CPTs<br />

Boreholes for bored piles<br />

Magnetic logging boreholes<br />

DN2W<br />

ABH32<br />

AN1<br />

EN2<br />

M3<br />

BN1W<br />

CN1<br />

66KVNI<br />

BN1Ea BN1E WN4 WN2<br />

WN8<br />

WN6<br />

ABH30 WN10<br />

WN3 WN1<br />

FN2<br />

DN1E<br />

WN12 WN7AWN5<br />

WN14<br />

DN1W<br />

WN11<br />

WN9<br />

WN16<br />

WN18 WN13<br />

WN20 WN15<br />

M2<br />

WN22<br />

WN17<br />

WN19<br />

WN24<br />

EN1<br />

MC3007 WN21<br />

WN26 WN23 ABH83<br />

M3010 CL-1a<br />

WN28 WN25<br />

WN30A WN27<br />

AC AC-3 3<br />

FN1 WN32 WN29 CL-3g<br />

CL-2<br />

WN34 WN31<br />

WN33<br />

BS1Ea<br />

ABH84 66KVS SPTSa<br />

BS1Eb WS1<br />

WN37 WN35<br />

ABH31 WS3<br />

WS9 WS7 WS5<br />

WN36<br />

WS13A WS12A WS11A<br />

WN38<br />

WS15WS13C<br />

WS12C WS11C<br />

WS14 WS10 WS8 WS6<br />

DS1E WS17<br />

BS1WWS4A<br />

WS2<br />

WN39<br />

WS13B<br />

WS19<br />

WS13 WS12B WS12 WS11B WS11<br />

WS16<br />

AS1<br />

WS21<br />

WN40<br />

ABH82 WS23 ABH29 WS18<br />

WS25 WS20<br />

WS22<br />

CS1<br />

ABH28<br />

WS27 WS24<br />

WS29<br />

DS1W<br />

WS34<br />

WS26<br />

WS31 WS28<br />

ABH81<br />

WS36 WS30<br />

WS35A<br />

WS32 ES1<br />

WS33<br />

MC2026<br />

WS37<br />

AS2<br />

WS38<br />

BS2E<br />

FS1<br />

CS2<br />

BS2W<br />

ABH34<br />

ABH85<br />

AC-2<br />

AC-4<br />

AC AC-1 1<br />

MC3008<br />

ABH33<br />

TSAS2<br />

TSAS2b<br />

M2064 M2065<br />

54+812<br />

ES2<br />

DS2E<br />

DS2W<br />

FS2<br />

31550 31600 31650 31700 31750 31800<br />

ES3<br />

DS3E<br />

EASTING (m)<br />

BS3E<br />

BS3W<br />

BS4W<br />

BS4E<br />

BS4Ea<br />

DS4E<br />

Evidence for a buried valley in the Old Alluvium<br />

DS3W<br />

DS4W<br />

CS3<br />

CS4<br />

AS3<br />

ABH35

ELEVATION (mRL) (<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

Section along north wall<br />

Bottom of F2 Clay in Marine Clay<br />

Detailed design site investigation<br />

Bottom of F2 Clay in Marine Clay<br />

Post collapse site investigations<br />

Top of OLD ALLUVIUM<br />

Post collapse site investigations

ELEVATION E<br />

(mRRL)<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

Section along south wall

NORTHHING<br />

(m)<br />

ABH27<br />

80.69<br />

31700<br />

31650<br />

31600<br />

CFVN<br />

CTSN 81.97<br />

82.17<br />

MC2025<br />

81.70<br />

54+812<br />

DN3<br />

81.91<br />

DN2E<br />

CN3<br />

82.27<br />

54+900<br />

BN2E<br />

82.61<br />

BN3<br />

77.02<br />

P33<br />

86.39<br />

P45<br />

P36<br />

86.07<br />

P52<br />

85.98<br />

P42/P48<br />

P40 P41/P47<br />

86 86.90 90<br />

86.30 86.84<br />

P54<br />

81.94<br />

M3<br />

ABH32<br />

83.41<br />

AN1<br />

82.91<br />

ABH81<br />

80.13<br />

BN1E 66KVNI<br />

CN1 BN1Ea<br />

81.88<br />

WN1<br />

WN3WN2<br />

81.57 80.68<br />

WN4<br />

WN7A WN6WN5<br />

WN11 WN10WN9WN8<br />

82.3182.16<br />

83.13<br />

81.3881.25<br />

WN13WN12<br />

81.38 81.4281.43<br />

DN1E<br />

WN15 WN14 80.9581.21<br />

81.2581.05<br />

WN16<br />

80.66<br />

81.86<br />

WN17<br />

80.37<br />

WN18<br />

80.72<br />

M304<br />

WN19<br />

79.86<br />

M305<br />

WN20<br />

81.86<br />

WN21<br />

80.81<br />

80.31<br />

WN22 80.88<br />

M2<br />

WN23 80.94<br />

M303<br />

WN24 79.93<br />

WN25 79.91<br />

M3010<br />

WN26 80.65 MC3007 80.15<br />

WN27 80.95 ABH83<br />

82.55<br />

80.36<br />

KP182<br />

KP183<br />

WN29 79.57<br />

M302<br />

CL-3g<br />

WN30A 79.72<br />

83.39 M209<br />

KP181 AC-3<br />

WN31<br />

M210<br />

KP181<br />

WN31<br />

M210<br />

78.34<br />

CL 2<br />

WN32 77.51 80.22<br />

CL-2 M211<br />

WN33 77.71<br />

M301 BS1Ea 81.69<br />

WN34 78.02<br />

78.04<br />

74.60<br />

WN35 80.58<br />

66KVS<br />

WN36 80.53<br />

SPTSa<br />

BS1Eb<br />

WS1<br />

80.66<br />

ABH84 74.72 WS3<br />

WN37<br />

71.09 M307 71.52<br />

81.43<br />

M308 WS7<br />

M309 M310 ABH31<br />

WS10WS9WS8<br />

WS4A WS2<br />

M212 & M306<br />

78.20<br />

76.59<br />

78.35<br />

WN38<br />

WS16WS15<br />

missing82.57<br />

72.2872.7072.6173.84<br />

82.07 76.77 75.20<br />

WN39 80.83<br />

WS18 WS17<br />

WS19 81.39 M213<br />

AS1<br />

81.39<br />

WS21<br />

WS20<br />

75.98<br />

WN40 81.06<br />

WS22<br />

81.2881.45<br />

ABH82 WS23 ABH29 81.38 CS1<br />

WS24<br />

80.84<br />

83.19<br />

WS25<br />

81.48<br />

WS26<br />

79.93<br />

WS27<br />

80.03<br />

79.99 DS1E 82.01<br />

WS28 80.37<br />

81.23<br />

81.59<br />

WS29 79.76<br />

WS34<br />

WS30 78.25<br />

81.09<br />

WS31 78.52<br />

WS35A WS32 79.57<br />

79.23<br />

78.78<br />

79.10<br />

79.69<br />

79.25<br />

WS37<br />

WS38 80.65<br />

81 81.26 26<br />

BS2E<br />

M2064<br />

79.00<br />

DS2E<br />

80.68<br />

86.20<br />

338<br />

86.58<br />

ABH85<br />

81.69<br />

AC-2<br />

81.73<br />

ABH33<br />

80.51<br />

AC-4<br />

79.98<br />

AC-1<br />

80.76<br />

TSAS2b<br />

82.16<br />

Tender SI boreholes<br />

Tender SI CPTs<br />

Detailed design SI boreholes<br />

Detailed design SI CPTs<br />

Post collapse SI boreholes<br />

Post collapse SI CPTs<br />

Boreholes for bored piles<br />

Magnetic logging boreholes<br />

31550 31600 31650 EASTING (m) 31700 31750 31800<br />

-14 -12 -10 -8 -6 -4 -2 0 2 4 6 8 10 12<br />

Distortion to upper F2 layer caused by the collapse<br />

DS4E<br />

79.24<br />

82.28<br />

BS3E<br />

81.29<br />

BS4Ea<br />

80.96<br />

BS4E<br />

80.33<br />

ABH35<br />

81.69

Buried valley in the Old Alluvium

Buried valley in the Old Alluvium

Coincidence between buried valley and<br />

distortion to upper F2 layer

• <strong>The</strong>re was a buried valley crossing the site of the<br />

collapse diagonally from south-west to north-east<br />

• <strong>The</strong> presence and setting of the buried valley explain<br />

the asymmetric conditions and the different collapse<br />

on the north and south sides<br />

• <strong>The</strong> buried valley coincides with the major ground<br />

distortion on the south side and was clearly influential<br />

in the collapse<br />

• Below the Lower Marine Clay the buried valley was<br />

infilled with estuarine organic clays on the south side<br />

and fluvial clays on the north side<br />

• Gas exsolution almost certainly y occurred in the deep p<br />

organic clays as a result of stress relief, reducing<br />

their strength further<br />

<strong>The</strong> buried valley

CN3<br />

DN3<br />

GA<br />

ABH-32<br />

ABH-34<br />

ABH-85<br />

EN2<br />

CN2<br />

AN2<br />

TSAN2<br />

WN1<br />

BN2W<br />

BN1W<br />

DN2W<br />

66KVN<br />

BN2E<br />

I-67<br />

AN1<br />

CN1<br />

DN2E<br />

AS MAIN<br />

94.9<br />

MC3007<br />

MC3008<br />

M3010<br />

ABH 31<br />

ABH-30<br />

AC-2<br />

AC-4<br />

AC-3<br />

AC-1<br />

ABH-83<br />

FN2<br />

EN1<br />

FN1<br />

WN1<br />

WN10<br />

WN20<br />

WN30<br />

WN36<br />

WS1<br />

66KVS<br />

WN26<br />

WN28<br />

WN29<br />

WN33<br />

WN34<br />

WN35<br />

WN24<br />

WN25<br />

WN27<br />

WN31<br />

WN32<br />

DN1W<br />

BN1W<br />

BS1W<br />

I-65<br />

I-102<br />

BN1Ea<br />

BN1E<br />

66KVN<br />

CL-1A<br />

CL-2<br />

CL-3G<br />

KP181<br />

KP182<br />

KP183<br />

I67<br />

DN1E<br />

BS1Ea<br />

BS1Eb<br />

ABH-35<br />

SEA WALL<br />

ABH-33<br />

ABH-31<br />

ABH-28<br />

ABH-27<br />

ABH-29<br />

ABH-81<br />

ABH-82<br />

ABH-84<br />

MC2026<br />

FS1<br />

ES1<br />

DS1E<br />

CS1<br />

TSAS2<br />

WS34<br />

WS30<br />

WS20<br />

WS10<br />

WN40<br />

WS38<br />

66KVS<br />

CPTN<br />

CFVN<br />

CPTNa<br />

SPTSa<br />

WS35<br />

WS36<br />

WS37<br />

WN39<br />

WN38<br />

WN37<br />

TSAS2B<br />

WS32 WS31<br />

WS29<br />

WS28<br />

WS26<br />

WS27<br />

WS33<br />

DS1W<br />

BS1W<br />

AS2<br />

AS1<br />

I-104<br />

I-103<br />

I-66<br />

BS2E<br />

M2064<br />

ABH-26<br />

ABH 27<br />

ABH-80<br />

FS2<br />

ES2<br />

DS2E<br />

CS2<br />

DS3E<br />

CS3<br />

AS3<br />

DS3W<br />

BS2W<br />

DS2W<br />

BS3W<br />

I-64 M2065<br />

BS3E<br />

ES3<br />

BS4E<br />

DS3W<br />

Post-collapse geometry and sequence of excavation<br />

superimposed on buried valley

DN1E<br />

N1W<br />

WN24<br />

5<br />

MC3007<br />

CL CL-3G 3G<br />

ABH-82<br />

WS26<br />

GAS AS MAIN<br />

WN20<br />

ABH-83<br />

WS20<br />

DS1E<br />

DS1W<br />

ABH-29<br />

CN1<br />

ABH-30<br />

CL-2<br />

CS1<br />

LL ABH 29 CS1<br />

M3010<br />

BN1Ea<br />

BN1W<br />

WN10<br />

I-65<br />

KP181<br />

BN1E<br />

66KVN<br />

CL-1A<br />

KP182<br />

66KVS<br />

I-104<br />

ABH ABH-84 84 SPTSa<br />

WS10<br />

66kV Cable<br />

KP183<br />

BS1Ea<br />

BS1Eb<br />

BS1W<br />

AS1<br />

AC-3<br />

WS1<br />

ABH-31<br />

Sequence of excavation in relation to buried valley<br />

WN1<br />

I<br />

AC

• <strong>The</strong> buried valley was crossed without collapse<br />

developing<br />

• Strut forces would have been a maximum in the<br />

buried valley and would have varied across the valley<br />

• <strong>The</strong> collapse was not, therefore, inevitable<br />

• An external influence (trigger) is required to explain<br />

the timing of the collapse and why it occurred after<br />

crossing the buried valley<br />

Significance of crossing the buried valley without<br />

collapse

• S338-9 stood for 8 days under load and was 20m<br />

from excavation front<br />

• S335-9 stood for 2.5 days under load and was over<br />

8m from excavation front<br />

• Both S335-9S & S338-9N buckled within 10 minutes<br />

• Load in S335-8 and S335-9 was almost constant<br />

between 18 April and initiation of collapse<br />

• All C-channel connections failed downwards at both<br />

ends<br />

• <strong>The</strong> south wall was pushing the north wall back<br />

Key observations

• 3D effects cannot explain why the collapse was<br />

initiated at 9am – S338 was 20-24m 20 24m from the<br />

excavation face and had stood for 8 days without<br />

distress, S335 was 8-12m from the excavation face<br />

• Time effects cannot explain why the collapse was<br />

initiated at 9am – there was no evidence of load<br />

increases in the monitoring<br />

Potential triggers

Load<br />

Innstallation<br />

of f 9th<br />

8th<br />

9th<br />

Yielding<br />

of 9th<br />

Excavation approaches<br />

+ passes beyond S335<br />

Observed<br />

Minor additional loading<br />

Post-collapse Post collapse investigations<br />

Back analyses of the collapse

• Analyses by Dr Felix Schroeder and Dr Zeljko<br />

Cabarkapa p using g Imperial p College g Finite Element<br />

Program (ICFEP)<br />

• 2D section through M307 (I104) and M302 (I65)<br />

• Bored piles p are not modelled ( (enhanced JGP) )<br />

• Upper and Lower Marine Clays, F2 and lower Estuarine<br />

Clay modelled using Modified Cam Clay<br />

• Coupled p consolidation<br />

• Fill and OA sand modelled using Mohr Coulomb. OA-CZ<br />

clay/silt modelled as Tresca<br />

Geotechnical analyses

• WWall ll EI reduced d d tto allow ll ffor cracking, ki bbased d on<br />

reinforcement layout<br />

• Bending moment capacities set according to<br />

reinforcement layout and ultimate strengths of steel<br />

and a d co concrete c ete as supp supplied ed<br />

• JGP treated as brittle material<br />

• 9 th level strut capacity set and strut allowed to strain<br />

soften 72 hours after excavation to 10 th level.<br />

Geotechnical analyses

North South<br />

+102.9<br />

+102.9<br />

Fill<br />

Estuarine<br />

+98.58<br />

+96.58<br />

+98.58<br />

+97.07<br />

Fill<br />

Estuarine<br />

Upper Marine Clay Upper Marine Clay<br />

F2<br />

Lower Marine Clay<br />

F2<br />

OA (Sand) - OA-CZ<br />

OA (Clay/Silt) - OA-CZ<br />

+84.58<br />

+81.58<br />

+71.00<br />

+67.00<br />

+63.00<br />

+85.57<br />

+82.07<br />

+63.57<br />

+61.57<br />

+57.57<br />

F2<br />

Lower Marine Clay<br />

OA (Clay/Silt) - OA-SW-1<br />

OA (Sand) - OA-CZ<br />

OA (Clay/Silt) - OA-CZ<br />

Stratigraphy assumed for ICFEP analyses

Elevation<br />

(m RL)<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

North wall 9th South wall<br />

predicted<br />

measured<br />

predicted<br />

measured<br />

65 65<br />

60<br />

Horizontal displacement (mm) Horizontal displacement (mm)<br />

55<br />

50 0 50 100 150 200 250 300 350<br />

55<br />

450 -400 -350 -300 -250 -200 -150 -100 -50 0 50<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

60

Elevation<br />

(m RL)<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60<br />

North wall 10th South wall<br />

predicted<br />

measured<br />

predicted<br />

measured<br />

Horizontal displacement (mm) Horizontal displacement (mm)<br />

55<br />

50 0 50 100 150 200 250 300 350<br />

55<br />

450 -400 -350 -300 -250 -200 -150 -100 -50 0 50<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60

Prop forrce<br />

(kN/mm)<br />

4500<br />

4000<br />

3500<br />

3000<br />

2000<br />

1500<br />

Predicted trends in 7th , 8th and 9th ed cted t e ds ,8 a d 9 strut st ut loads oads<br />

2500 Strut 7<br />

1000<br />

500<br />

0<br />

280.00 281.00 282.00 283.00 284.00 285.00 286.00<br />

( )<br />

9<br />

8<br />

7<br />

Time (days)<br />

6 hours<br />

Strut 8<br />

Strut 9

Load<br />

Observed trends in 8 th and 9 th strut loads<br />

Innstallation<br />

of f 9th<br />

8th<br />

9th<br />

Excavation approaches<br />

+ passes beyond S335<br />

Observed<br />

5 18 20<br />

April 2004<br />

9amm<br />

3.30pm

• <strong>The</strong> analyses matched reasonably well the build up in<br />

horizontal wall movements, and the trends in the forces<br />

in the 7th, 8th and 9th level struts<br />

• To match movements and forces at all stages it was<br />

necessary to model the jet grout as a brittle material<br />

• <strong>The</strong> upper JGP was predicted to pass its peak strength<br />

during excavation to the 6th level and the lower JGP to<br />

pass its peak strength during excavation to the 9th level<br />

• Th <strong>The</strong> 9th 9 h llevel l strut reached h d iits capacity i dduring i excavation i<br />

to the 10th level<br />

Key findings from geotechnical analyses

• <strong>The</strong> collapse had to be initiated by allowing the 9th level<br />

strut to strain soften – a ductile failure of the connection<br />

was not associated with a collapse<br />

• <strong>The</strong> bending moment capacity of the south wall was<br />

reached on the first stage of excavation below the 9th<br />

llevel, l bbut t a hi hinge did not t fform in i th the wall ll until til th the<br />

sacrificial JGP layer had been removed<br />

Key findings from geotechnical analyses

Trigger required required to initiate collapse<br />

Relative vertical displacement between<br />

the kingposts and Dwall panels

Vertical V diisplacement<br />

of Dwwall<br />

(mm) )<br />

100<br />

50<br />

Up<br />

Top of southern wall-nolimit<br />

Top of southern wall-OA1<br />

Top p of southern wall-OA2<br />

0<br />

0 5 10 15 20 25 30 35<br />

-50<br />

-100<br />

Down<br />

Excavation depth (m)<br />

Predicted settlement of south wall during excavation<br />

8th<br />

9th<br />

10th

Verrtical<br />

dispplacementts<br />

(mm)<br />

500<br />

400<br />

300<br />

200<br />

100<br />

Run 4apfnolimit<br />

Run 4apfnolimit_OA1<br />

Run 4apfnolimit_OA2<br />

0<br />

-5 0 5 10 15 20 25 30<br />

-100<br />

-200<br />

North Wall<br />

Distance (m)<br />

South Wall<br />

Predicted vertical displacement of lower JGP layer<br />

after excavation to 10 th level

Typical relative<br />

displacements of<br />

strut between<br />

between<br />

walls and kingpost<br />

(mm)<br />

and kingpost<br />

l between wall<br />

Diffference<br />

in leve<br />

20<br />

10<br />

0<br />

-10<br />

-20<br />

-30<br />

North wall<br />

1<br />

7A<br />

2<br />

7B<br />

3<br />

6A<br />

5<br />

Strut 262<br />

no backfill<br />

kinngpost<br />

2<br />

Soutth<br />

wall<br />

4 5<br />

3<br />

6A<br />

4<br />

1<br />

7A<br />

7B

• Calibrated FE analyses predict downward<br />

displacement of Dwall and upward displacement of<br />

kingpost when sacrificial JGP layer excavated<br />

• Survey data supports upward vertical displacement of<br />

centre of strut relative to ends<br />

Relative vertical displacement

9 th level<br />

KP180<br />

Sacrificial JGP<br />

Excavation front<br />

Kingposts in long section<br />

KP181<br />

335<br />

336<br />

Lower JGP<br />

KP182<br />

337<br />

338<br />

KP183<br />

339<br />

340<br />

KP184

Post-collapse Post collapse investigations<br />

Structural steel physical tests<br />

and numerical analyses.<br />

<strong>The</strong> effect of relative vertical<br />

displacement

Axial load (kN) (<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

12mm stiffener<br />

plates<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Axial displacement (mm)<br />

Comparison of tests on connections with plate and C channel<br />

stiffeners

Axial load (kN) (<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

C channel stiffener has similar capacity<br />

to double plate stiffener but becomes<br />

brittle after an initial ductile response<br />

Unforced sway<br />

12mm stiffener<br />

plates<br />

Waler<br />

C channel<br />

stiffener<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Axial displacement (mm)<br />

Comparison of tests on connections with plate and C channel<br />

stiffeners

Axial loaad<br />

(kN)<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

Test result<br />

C channel<br />

stiffener<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Adjusted axial displacement (mm)<br />

Calibration of FE model of strut strut-waler waler connection

Axial loaad<br />

(kN)<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

Test result<br />

FE prediction<br />

C channel<br />

stiffener<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Adjusted axial displacement (mm)<br />

Calibration of FE model of strut strut-waler waler connection

Axial loaad<br />

(kN)<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

Ductile plateau 10-15mm<br />

Yield<br />

Ductile plateau allows failure to<br />

develop at both ends<br />

Test result<br />

FE prediction<br />

C channel<br />

stiffener<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Adjusted axial displacement (mm)<br />

Calibration of FE model of strut strut-waler waler connection

Axial load<br />

(kN)<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

8m strut<br />

C channel<br />

stiffener<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Axial displacement p (mm) ( )<br />

Effect of strut length (bending restraint) on brittleness of<br />

connection

Axiaal<br />

load (kN)<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

Reduced restraint increases brittleness<br />

and d reduces d dductile til plateau l t<br />

8m strut – effective kingpost<br />

18m strut – ineffective kingpost<br />

8m strut<br />

18m strut<br />

C channel<br />

stiffener<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Axial displacement (mm)<br />

Effect of strut length (bending restraint) on brittleness of<br />

connection

Test on C channel stiffened connection by Nishimatsu

Test on C channel stiffened connection by Nishimatsu

Axial load<br />

(kN)<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

axial load only<br />

C channel<br />

stiffener<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Axial displacement p (mm) ( )<br />

Effect of relative vertical displacement

Axial load<br />

(kN)<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

RVD reduces ductile plateau,<br />

increases brittleness, makes<br />

stable situation unstable<br />

Forced sway<br />

axial load only<br />

axial load+RVD<br />

C channel<br />

stiffener<br />

Waler<br />

0<br />

0 10 20 30 40 50<br />

Axial displacement p (mm) ( )<br />

Effect of relative vertical displacement

Force, P<br />

P<br />

DDuctile til<br />

strain

Prop<br />

forcee<br />

(kN/m)<br />

p ( )<br />

Effect of brittleness of strut to waler connection<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

Ductile<br />

Run 4apf2100drop<br />

Run 4apf2100drop4<br />

Run 4apf2100drop3<br />

p p<br />

Run 4apf2100drop2<br />

Run 4apf2100<br />

0<br />

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0<br />

Total axial strain (%)

Prop<br />

forcee<br />

(kN/m)<br />

Effect of brittleness of strut to waler connection<br />

RRun 44apf2100 f2100<br />

Run 4apf2100drop2<br />

Run 4apf2100drop3<br />

Run 4apf2100drop4<br />

Run 4apf2100drop<br />

2500 500<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

6 hours 9 days<br />

Ductile – no collapse<br />

21 days<br />

-15 -10 -5 0 5 10 15 20 25<br />

Time since reaching excavation level of 72.3m RL (days)

Force, P<br />

P<br />

hours to collapse<br />

DDuctile til<br />

No collapse<br />

Several days y<br />

to collapse<br />

strain

• Th <strong>The</strong>re was relative l ti vertical ti l di displacement l t bbetween t th the<br />

diaphragm wall, which settled when the sacrificial<br />

JGP was removed, and the kingpost, gp which rose, i.e.<br />

relative vertical displacement between the ends and<br />

centre of the strut (RVD)<br />

• <strong>The</strong> strut-waler connection was ductile-brittle. <strong>The</strong><br />

ductile plateau p explains p why y both ends could fail<br />

• <strong>The</strong> brittleness of the connection determines the time<br />

taken for the collapse to develop<br />

Trigger required to initiate collapse

• RVD reduces the length of the ductile plateau and<br />

increases the brittleness<br />

• RVD can make k a stable t bl situation it ti unstable t bl<br />

• RVD can shorten the time to collapse<br />

• Why downward failure at both ends?<br />

• Why collapse after crossing the buried valley?<br />

Trigger required to initiate collapse

• Free<br />

• Fixed<br />

• Forced sway<br />

Downward failure at both ends

Trigger Trigger required required to initiate collapse<br />

Post-collapse positions of the Dwall<br />

panels

DN1E<br />

N1W<br />

WN24<br />

5<br />

MC3007<br />

CL CL-3G 3G<br />

ABH-82<br />

WS26<br />

GAS AS MAIN<br />

WN20<br />

ABH-83<br />

WS20<br />

DS1E<br />

DS1W<br />

ABH-29<br />

CN1<br />

ABH-30<br />

CL-2<br />

CS1<br />

LL ABH 29 CS1<br />

M3010<br />

BN1Ea<br />

BN1W<br />

WN10<br />

I-65<br />

KP181<br />

BN1E<br />

66KVN<br />

CL-1A<br />

KP182<br />

66KVS<br />

I-104<br />

ABH ABH-84 84 SPTSa<br />

66kV Cable<br />

KP183<br />

BS1Ea<br />

BS1Eb<br />

BS1W<br />

Post-collapse geometry superimposed on buried valley<br />

WS10<br />

AS1<br />

AC-3<br />

WS1<br />

ABH-31<br />

WN1<br />

I<br />

AC

NORTTHING<br />

(m)<br />

31650<br />

31640<br />

31630<br />

31620<br />

CL-2<br />

WS16<br />

CS1<br />

WS15<br />

WS14<br />

WS13B 13. 7<br />

WS13 16<br />

WS13A 26<br />

WS12B 15. .2<br />

WS12 12<br />

WS12A 199<br />

WS11B 17.5<br />

WS11 19.6 1<br />

WS11A 13.5<br />

WS13C<br />

122.5<br />

WS112C<br />

12.5<br />

S11C<br />

14.7<br />

WS17 WS<br />

WS13E<br />

WS13F<br />

WS12D<br />

WS11D<br />

WS11E<br />

WS12E<br />

WS11F<br />

WS10<br />

66KVS<br />

WS9<br />

SPTSa<br />

WS8<br />

BS1Ea<br />

Post collapse SI boreholes<br />

Magnetic logging boreholes<br />

Unsuccessful magnetic logging boreholes<br />

2005 boreholes<br />

31670 31680 31690 31700<br />

EASTING (m)<br />

TUNNEL<br />

SOUTH WALL<br />

Coincidence between inability to advance boreholes and<br />

missing Dwall panels

WS11E,11F,<br />

12E,13F<br />

WS11-13A-D<br />

Obstruction created by missing Dwall panels

1<br />

M212<br />

1<br />

1<br />

Gap M306<br />

2<br />

1. Panels M306 and M212, each side of the<br />

gap, and panel 213 fail by toe kick-in and<br />

rotate back. back<br />

2. Soil flows through resulting gap between<br />

M306 and M307, rotating panel 307.<br />

33. SSoil il fl flows th through h resulting lti gap bbetween t<br />

M307 and M308, rotating panel 308, etc.<br />

Sequence of south wall panel movements<br />

3

2<br />

301<br />

drag<br />

3<br />

302<br />

dr rag<br />

4<br />

303<br />

drag d<br />

1 2a 3a 4a<br />

306<br />

Sequence of south and north wall panel movements<br />

5<br />

304<br />

305

Differing restraint<br />

imposed by bored<br />

piles at north<br />

and south walls<br />

SOUTH NORTH<br />

Sacrificial JGP<br />

Permanent JGP<br />

Fill<br />

Upper E<br />

Upper<br />

Marine Clay<br />

Upper F2<br />

Lower<br />

Marine Clay<br />

Lower E<br />

Lower F2<br />

OA SW2 (N=35)<br />

OA SW1 (N (N=72) 72)<br />

OA (CZ)

• <strong>The</strong> bored piles had a major influence on the<br />

displacements of the Dwall panels during the<br />

collapse and on their post-collapse positions<br />

• <strong>The</strong> bored piles restricted toe movements on the<br />

south side and prevented failure as the buried valley<br />

was crossed<br />

• Loads carried by the bored piles contributed to the<br />

under under-reading reading of the strain gauges<br />

Significance of the bored piles

M301<br />

333<br />

334<br />

M302<br />

M303<br />

North wall<br />

M304<br />

M305<br />

4 2 3<br />

1<br />

6 7<br />

335 336 337 338 339 340<br />

H H H<br />

KP 181 KP 182<br />

KP 183<br />

1 5 5 5 7 7<br />

M306 M307 M308 M309 M310<br />

1 Order in which distortion to waler noted<br />

Excavation to 10 th complete<br />

Excavation in progress<br />

Location of walers, splays and Dwall gaps

DN1E<br />

N1W<br />

WN24<br />

5<br />

MC3007<br />

CL CL-3G 3G<br />

ABH-82<br />

WS26<br />

GAS AS MAIN<br />

WN20<br />

ABH-83<br />

WS20<br />

DS1E<br />

DS1W<br />

ABH-29<br />

CN1<br />

ABH-30<br />

CL-2<br />

CS1<br />

LL ABH 29 CS1<br />

M3010<br />

BN1Ea<br />

BN1W<br />

WN10<br />

I-65<br />

KP181<br />

BN1E<br />

66KVN<br />

CL-1A<br />

KP182<br />

66KVS<br />

I-104<br />

ABH ABH-84 84 SPTSa<br />

WS10<br />

66kV Cable<br />

KP183<br />

BS1Ea<br />

BS1Eb<br />

BS1W<br />

AS1<br />

AC-3<br />

WS1<br />

ABH-31<br />

Repositioned bored piles at 66kV crossing<br />

WN1<br />

I<br />

AC

• Upward displacement of KP 180 and 181<br />

accentuated by toe displacement of M306 and M212,<br />

where bored piles had been re-positioned and<br />

additional dditi l ttoe movement t was possible ibl<br />

• Resulting RVD fed back into buried valley<br />

Relative vertical displacement

9 th level<br />

KP180<br />

Upper JGP<br />

Excavation front<br />

Kingposts in long section<br />

KP181<br />

335<br />

335<br />

Lower JGP<br />

KP182<br />

KP183<br />

336<br />

336 337<br />

338 339<br />

340<br />

KP184

• C channel stiffened connection undergoes brittle<br />

failure<br />

• Critical length of strut and of load in strut result in<br />

minimal lateral restraint to connection<br />

• Restraint from rising kingpost results in downward<br />

force on connection<br />

• RVD results in reduction in ductility of connection and<br />

increase in brittleness<br />

• RVD makes a stable situation with overstress<br />

unstable bl<br />

• RVD results in downward failure of connection<br />

• RVD was the trigger for the failure<br />

Failure mode of connection and RVD

Overall conclusions<br />

• <strong>The</strong> use of Method A in the numerical analyses to model<br />

near normally consolidated soils is fundamentally<br />

incorrect<br />

• Its use led to under prediction of wall displacements and<br />

• Its use led to under-prediction of wall displacements and<br />

bending moments and so to a reduction in the<br />

redundancy in the system. <strong>The</strong> JGP was strained<br />

beyond its peak and a plastic hinge formed in the wall as<br />

excavation of the sacrificial JGP was underway

Overall conclusions<br />

• <strong>The</strong>re were errors in the design of the strut-waler connection<br />

resulting in a design capacity that was 50% of the required<br />

capacity where splays were omitted<br />

• <strong>The</strong> collapse initiated some time after the excavation crossed<br />

th the bburied i d valley, ll where h fforces on th the under-designed d d i d strut- t t<br />

waler connections would have been a maximum<br />

• An additional perturbation or trigger was necessary to explain<br />

the timing of the collapse, the downward failure of the walers at<br />

both ends and the trends in the monitoring data

Overall conclusions<br />

• <strong>The</strong> permanent bored piles in combination with the JGP<br />

played p y a significant g role in ppreventing g the collapse p as the<br />

valley was crossed<br />

• <strong>The</strong> collapse was triggered when working in the vicinity of<br />

the 66kV cable crossing<br />

• At this location, the permanent bored piles had been<br />

repositioned and the JGP layout had been modified,<br />

allowing g the wall toe to kick-in and cause additional uplift p of<br />

the local kingposts

Overall conclusions<br />

• This additional upward displacement of the kingposts relative to<br />

the wall fed back into the system, introducing forced sway<br />

failure<br />

• Downward movement of the walls has been predicted by<br />

analysis; the potential for relative upward movement of the<br />

kingposts has been confirmed by surveys<br />

• Forced sway s a failure fail re red reduced ced the strain oover er which hich the<br />

connection remained ductile, increased the brittleness of the<br />

connection and allowed a stable situation to become unstable<br />

• Forced sway failure can explain the timing of the collapse, the<br />

form of the observed distortions, the trends in the monitoring<br />

data data, and the speed at which the collapse developed

Overall conclusions<br />

• <strong>The</strong> collapse was not caused by hydraulic base<br />

heave and and was not related to poor workmanship<br />

• Wall rotation, , which had been linked with inadequate q<br />

penetration of the wall into the OA, was not the cause<br />

of the collapse<br />

• Several factors had to act in combination to cause<br />

the collapse

Unforgiving site<br />

• Deepest excavation in marine clay in Singapore –shortcomings<br />

in use of Method A not previously apparent because of depth<br />

dependence<br />

• Ground conditions – buried valley in OA infilled with soft fluvial<br />

and organic clay, rapid variation in depth of marine clay along<br />

and d across th the excavation ti resulting lti iin an asymmetric t i section ti<br />

• Curvature of walls in plan p requiring q g more frequent q use of<br />

walings<br />

• Presence of 66kVA crossing<br />

• Need to adopt sacrificial JGP layer, removal of which caused<br />

p y ,<br />

step increase in 9th level strut load and step increase in wall<br />

settlement

• JGP is a brittle material<br />

Lessons learnt<br />

• <strong>The</strong> mass properties of JGP need to be more carefully<br />

evaluated<br />

• Coring of JGP is not an adequate check<br />

• <strong>The</strong> use of numerical modelling of soils in design should be<br />

carried out by specialists and its incompatibilities with<br />

current codes needs to be removed<br />

• <strong>The</strong> potential for brittle failure of C channel connections<br />

must tb be recognised<br />

i d

Lessons learnt<br />

• Temporary and permanent works should be subject to<br />

independent checks<br />

• <strong>The</strong> effects of relative displacement between kingposts<br />

and walls should be considered in the design g of strutted<br />

excavations<br />

• Forced sway y failure and its consequences q should be<br />

recognised as a potential mechanism in design<br />

• Monitoring did not warn of the impending collapse