finishes edging - Netlineservices.co.nz

finishes edging - Netlineservices.co.nz

finishes edging - Netlineservices.co.nz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

m a g a z i n e<br />

Joinery, Cabinetmaking & Kitchen Manufacturing Industries<br />

benches<br />

<strong>finishes</strong><br />

and sinks<br />

protect and beautify<br />

<strong>edging</strong><br />

questions, tools and answers<br />

Southland Maple Beech - Novotel Hotel - Auckland Airport<br />

June 2011

Marriage of the Minds<br />

Broken Stone<br />

Polar White<br />

King Sand<br />

Alabaster<br />

Platinum<br />

When the natural look of an Infinity ® solid surface worktop meets<br />

a German handcrafted sink, you have a marriage that lasts<br />

a lifetime.<br />

The range of Blan<strong>co</strong> sink and tapware are a perfect partner with<br />

Infinity ® benchtops. Together they will service you for a lifetime.<br />

Glacier Acrylic benchtops have been around for over 30 years and have been regularly<br />

used in <strong>co</strong>mmercial applications. Now this high quality surface has be<strong>co</strong>me<br />

popular in residential homes.<br />

The most attractive feature of Infinity ® Available August 2011 Sonara<br />

is the ability<br />

Available August 2011 Silver Birch<br />

to join pieces together seamlessly, providing the appearance that<br />

your benchtop is carved from one solid piece. Undermount sinks can be<br />

easily integrated into the benchtop.<br />

Available August 2011 Storm<br />

New Zealand’s only online benchtop calculator at www.hafele.<strong>co</strong>m/<strong>nz</strong> -<br />

– click on the Infinity banner.<br />

Auckland Design Centre 16 Accent Drive, East Tamaki, Auckland Beaumont Design Centre 20 Beaumont Street,<br />

St Mary’s Bay, Auckland Wellington Design Centre The Wool Store Level 1, 262 Thorndon Quay, Wellington<br />

Christchurch Design Centre 5 Wigram Close, Sockburn, Christchurch<br />

Visit www.hafele.<strong>co</strong>m/<strong>nz</strong> or freephone 0800 4 hafele

The latest range of Blan<strong>co</strong> sinks and taps can be seen in The 2011 catalogue BLANCO<br />

From the Sink to the Kitchen Centre. Go to www.hafele.<strong>co</strong>/<strong>nz</strong>, Online Catalogues now.<br />

Highlights are Silgranit taps and sinks. The new satin stone finish with its unique<br />

properties that bring precious stone into your kitchen.<br />

Steelart Claronline, the award winning, elegant stainless steel undermount sink with the low<br />

profile rim for <strong>co</strong>nventional installation.<br />

The 2011 catalogue<br />

BLANCO From the Sink to the Kitchen Centre online now<br />

www.hafele.<strong>co</strong>m/<strong>nz</strong> • 0800 4 hafele • info@hafele.<strong>co</strong>.<strong>nz</strong><br />

JOINERS Magazine June 2011 page 1

There’s a<br />

world of<br />

difference<br />

between<br />

a good<br />

MDF<br />

and the Best.<br />

JOINERS Magazine June 2011 page 2<br />

Explore the subtle strengths of GoldenEdge<br />

and you’ll soon dis<strong>co</strong>ver a strong measure<br />

of independence, maturity and experience.<br />

Combine with a history of technical<br />

innovation, sophisticated production<br />

processes and the extensive knowledge of<br />

staff who have grown with us and you'll<br />

experience a world of difference with<br />

GoldenEdge MDF.<br />

Experience the Best<br />

www.nelsonpine.<strong>co</strong>.<strong>nz</strong><br />

FURNITURE &<br />

FITTINGS<br />

No. 3208038<br />

Nelson Pine Industries Ltd, Nelson, New Zealand<br />

MS 20334 J

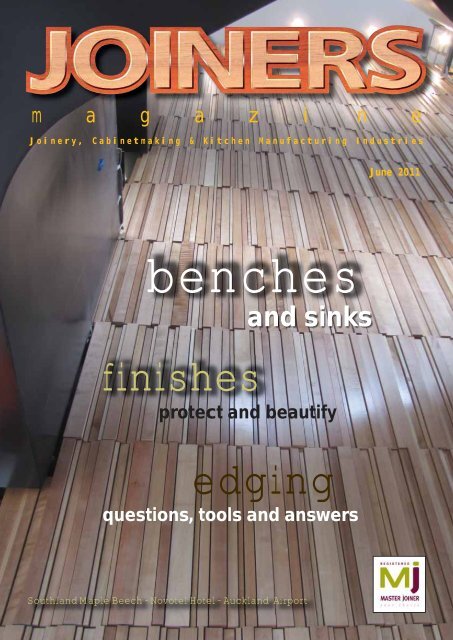

COVER Novotel Hotel Auckland<br />

International Airport. Photograph<br />

<strong>co</strong>urtesy Woodform Design<br />

see story page 63<br />

COLUMNS<br />

Master Joiners 4<br />

Julian Jaques says his goodbyes<br />

Dr Buzz 72<br />

Duncan Such refl ects on<br />

insurance, Christchurch and the<br />

rising dollar<br />

Laminex Update 73<br />

Robert Gibbes on attitudes and<br />

opportunities in a fl at market<br />

A view from both sides 76<br />

Tony DeLore<strong>nz</strong>o talks about<br />

improving health and safety<br />

standards and rewiring his old<br />

villa<br />

Due Process 77<br />

Geoff Hardy looks at ethics in<br />

hard times<br />

Web Directions 78<br />

Matt Woodward enlightens us on<br />

Google voice search<br />

REGULAR<br />

News & Info 4 - 13<br />

JITO news - 75<br />

FITEC news - 74<br />

Trade Directories - 80 - 84<br />

Product Focus - 84<br />

Classifi eds - 87 - 88<br />

Things to watch for ...<br />

m a g a z i n e<br />

interzum 14<br />

sinks & surrounds 16<br />

Often viewed as <strong>co</strong>mmodities there are however huge<br />

discrepancies in prices and types of sink inserts and<br />

benchtops. We look at some from local suppliers.<br />

edgebanding essence 48<br />

A diffi cult part of the manufacturing process which<br />

includes a <strong>co</strong>mbination of different materials, glue and<br />

heat - we talk to some who do it and other who supply<br />

those who do.<br />

fi nishing fl ourish 34<br />

<strong>co</strong>ntents<br />

If expo’s are a barometer of the health of an industrial<br />

sector then things are looking brighter with news of a<br />

very successful interzum in Germany last month.<br />

The fi nish is the thing - we look at what make a<br />

good fi nish in kitchen and bathroom cabinetry. From<br />

clear stains to lacquers to paints and oils.<br />

novotel 63<br />

Auckland latest hotel, adjacent to the International Airport<br />

has some interesting wall panels made from Southland<br />

Maple Beech which look great and help absorb airport noise.<br />

3D Kitchen software giveaway p 7 • Formica <strong>co</strong>mpetition p 8 • Trip to Turkey p 44<br />

JOINERS Magazine June 2011 page 3

from the presidents desk<br />

This is my last <strong>co</strong>lumn to members as I hand over<br />

the Presidency to Rhys Powell at the Rotorua<br />

<strong>co</strong>nference in June. It would be great to be able to<br />

report loads of positive aspects to the past two years, but<br />

in fact it’s been a tough road for us all since 2009, and a<br />

great deal tougher again for our Canterbury members.<br />

The e<strong>co</strong>nomic environment has thrown, and <strong>co</strong>ntinues<br />

to throw, enormous business challenges at us. I take my<br />

hat off to all of you who’ve survived this recession and<br />

I’m <strong>co</strong>nfi dent that we’ll see the building industry begin<br />

to re<strong>co</strong>ver before the year is out.<br />

The MJF has retained a focus over this period on<br />

introducing NZS4211. I fi rmly believe that this will<br />

spur new life into timber joinery for the home. The<br />

Rotorua <strong>co</strong>nference will introduce our plans for rolling<br />

this out and how members can take advantage of this<br />

new standard.<br />

And this is why it’s a great time to leverage the benefi ts<br />

of being a Master Joiner. We give you a solid brand<br />

that customers can rely on. Customers are aware of the<br />

dangers of shoddy building practices, they’re strapped<br />

for cash and every dollar must <strong>co</strong>unt. But they can<br />

research everything on the net and they’re spoilt for<br />

choice. Most will prefer to choose tradesmen that are<br />

backed by a reputable organisation like MJF.<br />

There’s been a pleasing amount of entries for our national<br />

awards and I’m looking forward to viewing these at<br />

<strong>co</strong>nference in Rotorua. And of <strong>co</strong>urse <strong>co</strong>nnecting with<br />

friends and <strong>co</strong>lleagues from around the <strong>co</strong>untry.<br />

It has been a privilege to represent the Master Joiners<br />

Federation these past years. The Executive team all<br />

bring expertise and skills to the table, and I’ve learned<br />

much from their experiences and have enjoyed working<br />

alongside them. It’s good to see some younger joiners<br />

stepping up to accept tomorrow’s challenges and steer<br />

the MJF and its members towards a prosperous future.<br />

Best wishes to you all, and see you in Rotorua.<br />

Julian Jaques<br />

President<br />

Registered Master Joiners<br />

JOINERS Magazine June 2011 page 4<br />

Mayor<br />

in hot<br />

seat<br />

DNZ CEO Paul Duffy,<br />

Auckland Mayor<br />

Len Brown and The<br />

Laminex Group<br />

General Manager<br />

Robert Gibbes.<br />

Auckland Mayor Len Brown was in the hot seat recently<br />

during the offi cial opening of The Laminex Group’s new<br />

head offi ce and distribution centre in Penrose Auckland. The<br />

Mayor tried out for size the J Chair which was designed by US<br />

architect Michael Graves. The chair was one of nine designs<br />

created by world-renowned US architects in 2008. It formed<br />

part of a <strong>co</strong>llection that was recently on display at the Formica<br />

Formations Exhibition at the Aotea Centre.<br />

The Laminex Group General Manager, Robert Gibbes, said the<br />

organisation’s new purpose-built 12,378m 2 distribution centre<br />

had brought together fi ve separate sites into the one purpose-built<br />

facility. The premises which took 12 months to <strong>co</strong>mplete were<br />

built by Fletcher Construction, with the Laminex Group leasing<br />

both buildings from DNZ Property.<br />

“The new offi ce building design in<strong>co</strong>rporates environmentallyfriendly<br />

initiatives including maximising the use of natural<br />

lighting in all offi ce areas, low-energy sensor <strong>co</strong>ntrolled lighting,<br />

some reticulated water and waste recycling,” Robert said. “A<br />

number of new technologies have also been introduced including<br />

the placement of a state-of-the-art Hubtex lifting platform in<br />

the warehouse.”<br />

Manufactured in Germany, it is the fi rst of its kind in use in New<br />

Zealand. It moves along a wire embedded in the <strong>co</strong>ncrete fl oor<br />

and features a lifting platform capable of reaching heights of 7-8<br />

metres, carrying weights of 1.5 tonnes.<br />

<br />

IMPORTERS / EXPORTERS & MERCHANTS<br />

STOCKISTS OF:<br />

BLACK BEAN, BUBINGA, CHERRY, CALOPHYLLUM, CEDAR, JARRAH,<br />

KAURI, OAKS, KWILA, TAWA, RIMU, MATAI, KAHIKATEA, MAHOGANIES,<br />

BLACKWOOD, VITEX, ROSEWOOD, VIC ASH, WALNUT, RADIATA,<br />

BEECH, TEAK, IROKO, EUCALYPTUS, TAS OAK, SALIGNA, SPOTTED GUM,<br />

FASTIGATA, IRONBARK and OTHERS.<br />

TEL 07-575 7685 07-575 7681<br />

FAX 07-575 7689 50 HULL ROAD, MT MAUGANUI<br />

THE MOXON GROUP<br />

New Zealand Australia North America

Exposicam srl<br />

Via G. Carducci, 12<br />

20123 Milano - Italy<br />

Tel: +39 0286995712<br />

Fax: +39 0272095158<br />

info@exposicam.it<br />

JOINERS Magazine June 2011 page 5

From The Publisher<br />

Interzum and FSM<br />

I have had the fortunate opportunity to visit<br />

interzum 2011 in Cologne recently to see<br />

how things have developed particularly<br />

in the architectural hardware scene. The<br />

show was heavily attended indicating<br />

things are not as bad as we might think.<br />

Overseas attendees were up 24% over the<br />

last show in 2009. The general feeling was<br />

one of calculated optimism for the future.<br />

New products abound as you will see in<br />

our next <strong>co</strong>uple of issues.<br />

The reason I went to Germany was in fact<br />

to attend the Annual meeting of members<br />

of the International Woodworking &<br />

Furniture Supplier Magazines’ Association<br />

(FSM) of which JOINERS magazine<br />

is now a member. There are some 27<br />

<strong>co</strong>untries involved in this Association. The<br />

aim is to promote <strong>co</strong>operation between<br />

the various publications with such things<br />

as exchange of articles, joint events and<br />

information about individual markets.<br />

This will lead to a better understanding<br />

of the world scene rather than just a<br />

local market. This should have some<br />

exciting implications down the track for<br />

the magazines involved. More on this as<br />

developments occur.<br />

All this aside, we have some interesting<br />

features in this issue. Edgebanding<br />

machinery and related products are a big<br />

part of the joinery arsenal of technology.<br />

We have some of the latest developments<br />

in this issue. When it <strong>co</strong>mes to fi nishes<br />

in the kitchen and bathroom there are a<br />

lot of options to <strong>co</strong>nsider and issues to<br />

watch out for. We have some insights from<br />

some of the leading suppliers on what to<br />

look out for and what they have to offer.<br />

This <strong>co</strong>vers not only walls, ceilings and<br />

splashbacks but also fi nishes for cabinetry<br />

and internal joinery. Another important<br />

aspect of the kitchen and indeed the<br />

bathroom are sinks and benchtops. Having<br />

a good (and expensive) looking sink and<br />

benchtop is no longer the preserve of just<br />

the well to do. They are now priced for any<br />

size pocket. We show some of the latest<br />

product from leading suppliers.<br />

For Master Joiner members note that you<br />

have <strong>co</strong>ming up soon the Annual Master<br />

Joiners Conference to be held in Rotorua<br />

this year. We will have in depth <strong>co</strong>verage<br />

of this including the winners in the Master<br />

Joiner Awards and Apprentice Awards in<br />

our September issue along with more on<br />

interzum and a look at the international<br />

woodworking machinery show Ligna<br />

2011. Catch you next time.<br />

Bob Nordgren<br />

JOINERS Magazine June 2011 page 6<br />

PMA/WPA<br />

Joint Conference<br />

Nelson 21st & 22nd July 2011<br />

The PMA / WPA Joint <strong>co</strong>nference will involve<br />

one day of papers and a half day bus tour<br />

around Nelson and Richmond to visit four new<br />

timber structural <strong>co</strong>mmercial and industrial<br />

buildings, which were once the preserve of<br />

steel and <strong>co</strong>ncrete! Come along, and hear fi rst<br />

hand some exciting developments in our sector,<br />

including how the industry intends to position<br />

itself, post the Canterbury earthquakes.<br />

www.pine.net.<strong>nz</strong><br />

www.wpa.org.<strong>nz</strong><br />

Master Joiners national<br />

associate membership<br />

Taking into <strong>co</strong>nsideration suggestions received<br />

from suppliers interested in a national associate<br />

membership, Master Joiners have agreed to<br />

provide this facility. We value the support<br />

of suppliers to the joinery industry and<br />

understand the importance of the interaction<br />

and networking value between suppliers and<br />

quality Master Joiners.<br />

Suppliers are wel<strong>co</strong>me to have a representative<br />

attend and participate in all the local Joinery<br />

Manufacturers’ Associations meetings and<br />

social functions throughout New Zealand.<br />

The national associate subscription will be<br />

distributed evenly to each of our current nine<br />

Master Joiners regional associations.<br />

National Associate Member facility is available<br />

to all supplying <strong>co</strong>mpanies and can be<br />

arranged by <strong>co</strong>ntacting the Master Joiners at<br />

info@masterjoiners.<strong>co</strong>.<strong>nz</strong>.<br />

Corinne Moore<br />

Master Joiners EO<br />

For a list of current associates go to page 83.<br />

Smart hardware<br />

solution<br />

The Laminex Group has recently launched the<br />

Samet range of drawer systems and hinges.<br />

Based in Turkey, Samet have been making<br />

quality drawer systems since the early 1970’s.<br />

They are a family owned and run <strong>co</strong>mpany,<br />

who focus on offering great value products<br />

to the furniture and joinery industry around<br />

the world.<br />

SmartBox soft close drawers have a standard<br />

loading capacity of 40kg, and a range of<br />

<strong>co</strong>nfi gurations <strong>co</strong>vering 270mm to 600mm<br />

depths. The SmartBox range offers several<br />

gallery rail and inner draw options, as well as<br />

side panels for that designer look.<br />

Please <strong>co</strong>ntact your Sales representative from<br />

The Laminex Group to obtain a catalogue for<br />

the full Samet range, and to dis<strong>co</strong>ver how you<br />

<strong>co</strong>uld win a trip to Istanbul <strong>co</strong>urtesy of The<br />

Laminex Group in October.

m a g a z i n e<br />

The magazine for the joinery, cabinetmaking<br />

& kitchen manufacturing industries<br />

Offi cial Publication of the New Zealand Joinery Manufacturers Federation<br />

and the Laminate Fabricators Society<br />

EDITOR<br />

Michael Goddard<br />

email: michael@joiners.net.<strong>nz</strong><br />

PUBLISHER<br />

Bob Nordgren<br />

email: bob@joiners.net.<strong>nz</strong><br />

PRINTING<br />

DISTRIBUTION<br />

SUBSCRIPTIONS<br />

Ph 64-9-624 4680<br />

Fax 64-9-624 4681<br />

42 Aldersgate Rd,<br />

PO Box 27 - 513,<br />

Mt. Roskill, Auckland, 1440, New Zealand.<br />

Ph: 64-9-624 4680<br />

Fax: 64-9-624 4681<br />

email: magpub@xtra.<strong>co</strong>.<strong>nz</strong><br />

JOINERS MAGAZINE ONLINE<br />

www.joiners.<strong>co</strong>.<strong>nz</strong><br />

ISSN 1173-6836<br />

JOINERS Magazine is the offi cial publication of the New Zealand Joinery Manufacturers<br />

Federation, and the Laminate Fabricators Society. It is distributed to members of the joinery,<br />

cabinetmaking and kitchen manufacturing industries and is published quarterly in March, June,<br />

September and December. Advertising statements or editorial opinion are not necessarily<br />

those of the publisher, its staff, the New Zealand Joinery Manufacturers Federation Inc., the<br />

Laminate Fabricators Society, or their executives, unless expressly stated. All articles printed<br />

in JOINERS are subject to <strong>co</strong>pyright and cannot be reproduced without the express <strong>co</strong>nsent of<br />

the Publisher or the authors therein. Advertisements and articles are accepted without liability<br />

as to the accuracy or otherwise of the factual matters represented.<br />

FREE<br />

Are you a cabinetmaker<br />

currently not using any design<br />

software? If so you are eligible<br />

to be in the draw to ...<br />

win a full design<br />

and manufacturing<br />

package<br />

3D Kitchen in association with JOINERS<br />

Magazine are inviting all readers who fi t the<br />

above to enter the draw. Entry is open until the<br />

end of October 2011 with winners announced<br />

in the December issue of JOINERS Magazine.<br />

Conditions may apply.<br />

TO ENTER DRAW<br />

Email your name, <strong>co</strong>mpany name<br />

and <strong>co</strong>ntact details to<br />

michael@joiners.net.<strong>nz</strong><br />

Fax: 09 624 4681<br />

m a g a z i n e<br />

JOINERS Magazine June 2011 page 7

Two of the judges in this year’s inaugural<br />

Formica Formations design <strong>co</strong>mpetition<br />

have been announced and include a top local<br />

and international designer. The Laminex Group<br />

Sales and Marketing Manager, Nicky Duggan,<br />

said she was delighted with the line-up of<br />

judges which include leading New Zealand<br />

designer David Trubridge.<br />

“David Trubridge has worked in the design<br />

industry for over 18 years,” Nicky said.<br />

“During that time, he has notched up numerous<br />

ac<strong>co</strong>lades including being named by a French<br />

magazine as one of the top 15 designers in the<br />

world. In 2007, he was given New Zealand’s<br />

highest design award – the John Britten Award<br />

– by the Designer’s Institute of NZ.”<br />

Also included on the judging panel is Formica<br />

US Vice President of Design Renée Hytry<br />

Derrington who was instrumental in initiating<br />

a similar US design event. A third guest judge<br />

is yet to be announced although The Laminex<br />

Group is expecting that person to be an<br />

internationally re<strong>co</strong>gnised architect.<br />

“Having top industry professionals from<br />

both New Zealand and overseas judging the<br />

inaugural <strong>co</strong>mpetition is a great refl ection of<br />

how well supported the <strong>co</strong>mpetition is within<br />

the design <strong>co</strong>mmunity,” Nicky said.<br />

JOINERS Magazine June 2011 page 8<br />

Renée Hytry Derrington and David Trubridge<br />

Judges announced for inaugural design <strong>co</strong>mpetition<br />

“Furthermore, having a leading light like<br />

David Trubridge involved in this event will<br />

ensure that New Zealand entries are judged to<br />

a particularly high international standard.”<br />

David said he was looking forward to judging<br />

the <strong>co</strong>mpetition. “I’m very interested in seeing<br />

what kind of clever designs New Zealand<br />

designers and architects can create,” he said.<br />

“There are a number of very talented and<br />

creative professionals in this <strong>co</strong>untry and a<br />

strong <strong>co</strong>llective of promising young designers.<br />

I’m certain there will be some great entries and<br />

am eager to see the fi nished results.”<br />

The Formica Formations <strong>co</strong>mpetition was<br />

unveiled earlier this month by The Laminex<br />

Group. The <strong>co</strong>mpetition aims to en<strong>co</strong>urage<br />

both experienced and emerging designers<br />

to pit their design talents against 10 of the<br />

world’s best architects. The <strong>co</strong>mpetition came<br />

about following a successful <strong>co</strong>llaboration in<br />

2008 between Formica US and the Centre for<br />

Contemporary Arts in Cincinnati.<br />

“World-renowned architects were invited<br />

to design a limited <strong>co</strong>llection of furniture,<br />

using Formica laminates and solid surface<br />

materials,” Nicky said. “Ten distinctive chairs<br />

– all museum pieces in their own right - were<br />

<strong>co</strong>nstructed using over 420m 2 of Formica.”<br />

Spurred on by the success of that project,<br />

Formica in New Zealand devised its<br />

own <strong>co</strong>mpetition for local architects and<br />

designers.<br />

The 2011 Formica Formations <strong>co</strong>mpetition<br />

requires entrants to submit design drawings<br />

for a piece of sculptural furniture that would<br />

use Formica brand materials. The <strong>co</strong>mpetition<br />

aims to celebrate and showcase the creativity<br />

of architects and designers throughout New<br />

Zealand.<br />

There are two entry categories – professional<br />

architects and designers, and emerging<br />

architects and designers. Individual and group<br />

submissions of up to four team members will<br />

be accepted. The Laminex Group will fabricate<br />

the winning design from each category for<br />

display at an offi cial awards ceremony later<br />

this year.<br />

Entries close on 31 July, with submissions<br />

and further information available at www.<br />

formicaformations.<strong>co</strong>.<strong>nz</strong>.

JOINERS Magazine June 2011 page 9

Winning With Wood<br />

Lockwood and Verda<br />

<strong>co</strong>mbine for showcase<br />

The Lockwood Group is marking its 60th<br />

anniversary by <strong>co</strong>mbining with Verda to stage<br />

a showcase of innovative residential design<br />

and building during Rugby World Cup 2011.<br />

Their showcase site, at the Lockwood village<br />

of show homes in Rotorua, will feature four<br />

different designs of houses, together with<br />

outdoor furniture and features by Verda.<br />

The site will be one of a wide range of<br />

showcase sites around New Zealand under<br />

the Winning With Wood programme, aimed<br />

particularly at showing some of the 85,000<br />

RWC visitors the many innovative uses of<br />

timber in New Zealand. Organised by NZ<br />

Trade & Enterprise, Winning With Wood is<br />

intended to promote exports of New Zealandmade<br />

timber products, as part of the Real<br />

New Zealand Showcase featuring 16 industry<br />

sectors.<br />

Lockwood and Verda’s site will be one<br />

of the largest in Winning With Wood and<br />

will feature an example of the innovative<br />

Lockwood E<strong>co</strong>Smart home, as well as Verda’s<br />

sustainably treated outdoor furniture, decking<br />

and panels.<br />

Lockwood Group marketing manager Melanie<br />

Short said the <strong>co</strong>mpany decided to participate<br />

in Winning With Wood because the group is an<br />

innovative, Kiwi organisation and has a strong<br />

export focus. “Verda and Lockwood have a<br />

strong mutual relationship – our products are<br />

<strong>co</strong>mplementary. We are really excited about<br />

the opportunity to meet with returning Kiwis<br />

and overseas visitors. We plan to ensure that<br />

during the showcase overseas visitors are<br />

greeted, wel<strong>co</strong>med and hosted.”<br />

For Verda, a much newer timber success<br />

story, Winning With Wood is an opportunity<br />

to present a medium-sized <strong>co</strong>mpany, with 60<br />

staff, to visitors from around the world. Verda’s<br />

Mathilde Carles said the <strong>co</strong>mpany, founded in<br />

2002, has been developing Australian and<br />

European export markets over the past two<br />

years and plans to grow its exports, especially<br />

of premium decking, from 25% of turnover to<br />

60-70% in the next four to fi ve years.<br />

“New Zealand is hosting one of the biggest<br />

sporting events, with 85,000 visitors from<br />

everywhere in the world. This is a good<br />

opportunity for a medium-sized <strong>co</strong>mpany,”<br />

she said.<br />

For more information, <strong>co</strong>ntact: Lionel<br />

Crawley, NZTE Bay of Plenty Regional<br />

Manager, Phone +64 7 577 6199, mobile<br />

+64 27 5 498 173.<br />

JOINERS Magazine June 2011 page 10<br />

Kiwi Lumber<br />

<strong>co</strong>mmitted to high standards<br />

Kiwi Lumber is a privately owned New<br />

Zealand <strong>co</strong>mpany that operates three<br />

modern sawmills in Putaruru, Dannevirke<br />

and Masterton. The plants are strategically<br />

situated to take advantage of the close<br />

proximity to the large <strong>co</strong>mmercial plantations<br />

in the Hawkes Bay, Wairarapa and Central<br />

Plateau areas of the North Island.<br />

Kiwi Lumber, which produces a range of<br />

products specifi cally to meet the needs of<br />

manufacturers in the furniture, joinery,<br />

mouldings and building industries have<br />

recently taken possession of three Clark<br />

GEN2 8-tonne forklifts from NZ distributor,<br />

Clark Equipment New Zealand Limited.<br />

“Kiwi Lumber is <strong>co</strong>mmitted to understanding<br />

the needs of its customers, so it was<br />

gratifying to find that Clark Equipment<br />

has a like-minded approach and were<br />

responsive towards finding solutions to<br />

improve our <strong>co</strong>mpetitiveness,” says Kiwi<br />

Lumber’s Putaruru Site Manager, Grant<br />

Williams. “This is extremely important,<br />

as our customers operate in a <strong>co</strong>mpetitive<br />

global market and we also vie with other<br />

international suppliers for their business.”<br />

The three GEN2 forklifts have been supplied<br />

with 1350mm lumber forks and will be used<br />

for loading green and kiln dried timber<br />

products on to T&T units. Also as a yard<br />

fork for unloading dry timber, stacking and<br />

feeding in and out of fi lleting and de-fi lleting<br />

stations. As well, the forklifts will bring<br />

dry semi-processed timber into the planer<br />

operation and take fi nished goods out to the<br />

pre-despatch storage area.<br />

The GEN2 are particularly suited to<br />

yard applications and in particular,<br />

heavy manufacturing, stevedoring and<br />

warehousing. With the <strong>co</strong>mbination of a<br />

100HP engine, fully automatic 3-speed<br />

‘smart shift’ transmission, wet disc brakes<br />

and rugged chassis design, the GEN2 C80<br />

provides the exceptional performance,<br />

manoeuvrability and durability.<br />

The GEN2 provides maximum visibility and<br />

hydraulic cushioning valves to reduce shock<br />

and vibration. The operator <strong>co</strong>mpartment<br />

is state of the art and features among other<br />

things, a fully adjustable suspension seat,<br />

a tilt steering <strong>co</strong>lumn and hood mounted<br />

hydraulic <strong>co</strong>ntrols. A parking brake that<br />

disengages the transmission when applied<br />

is a major safety feature.<br />

Kiwi Lumber process radiata logs that are<br />

milled entirely from renewable plantations,<br />

all of which <strong>co</strong>mply with New Zealand’s<br />

environmental management policies. “Our<br />

logs are purchased from these leading<br />

forestry <strong>co</strong>mpanies, allowing us to secure<br />

grades of logs that are best suited to our<br />

customer’s requirements,” says Grant<br />

Williams. “With the increasing international<br />

awareness of the desirability to harvest and<br />

use a renewable resource, Kiwi Lumber<br />

has expanded its export markets and now<br />

supplies clients in North America, Asia,<br />

Europe, Australia and throughout New<br />

Zealand.”<br />

For further information on the Clark<br />

GEN2 range of forklifts <strong>co</strong>ntact Clark<br />

Equipment on 0800 262 228 or visit the<br />

website www.clarkequipment.<strong>co</strong>.<strong>nz</strong>

educate / inform / win<br />

build<strong>nz</strong> / designex 2011 is your number one opportunity<br />

to sample the very best from the world of building,<br />

<strong>co</strong>nstruction, architecture, interior design, engineering,<br />

textiles, furnishing and all the associated trades - all under<br />

one roof over 3 days from Sunday 26th of June.<br />

PLUS the opportunity to earn CPD points and win a Ford<br />

XLT 2WD Double cab ute.<br />

www.prowood.<strong>co</strong>.<strong>nz</strong><br />

BUY ON LINE<br />

BUY CHEAPER<br />

Prowood has recently developed<br />

online shopping for its customers.<br />

The aim is to bring a wide range of<br />

tooling accessories and machines to<br />

its customers. The goal is to allow<br />

customers to buy products cheaper<br />

and we have priced items very<br />

<strong>co</strong>mpetitively as our overhead structure<br />

is low. We en<strong>co</strong>urage customer to log<br />

on line and register for the news letter<br />

to receive weekly specials, dis<strong>co</strong>unts<br />

and promotions. The goal is to have<br />

all the standard items available that a<br />

workshop buys. If it is not there now<br />

it will be soon. The web site will also<br />

have popular spare parts for machines<br />

our brand or not.<br />

Open 24 hours a day every day.<br />

www.prowood.<strong>co</strong>.<strong>nz</strong><br />

It was worth<br />

waiting for<br />

online<br />

shopping<br />

machinery<br />

“dis<strong>co</strong>unts<br />

& special<br />

offers<br />

- register<br />

now”<br />

buy online<br />

buy cheaper<br />

JOINERS Magazine June 2011 page 11

RUBBISH BINS<br />

<br />

<br />

<br />

<br />

<br />

<br />

CONTOUR CORNER UNIT<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

AUCKLAND<br />

22 Fisher Crescent<br />

Mt. Wellington 1060<br />

Email: auckland@artia.<strong>co</strong>.<strong>nz</strong><br />

JOINERS Magazine June 2011 page 12<br />

KITCHEN ACCESSORIES<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

CHRISTCHURCH<br />

6C Michelle Road,<br />

Sockburn<br />

Email: christchurch@artia.<strong>co</strong>.<strong>nz</strong><br />

Tel: 0800 267 625 Fax: 0800 100 224<br />

www.artia.<strong>co</strong>.<strong>nz</strong><br />

New at Jacks<br />

Jacks are pleased to announce<br />

the appointment of Alexis<br />

Pantelides as Sales Manager -<br />

Panel Processing Division. With<br />

NZ’s e<strong>co</strong>nomy showing signs<br />

of growth, and the <strong>co</strong>ntinued<br />

success of German manufacturing<br />

giant Homag’s products around<br />

the world, Alexis’s appointment<br />

increases Jacks’ capacity to<br />

support medium to large scale<br />

panel-based customers around<br />

the <strong>co</strong>untry.<br />

With Jerry Williams <strong>co</strong>ntinuing<br />

to provide technical expertise,<br />

Alexis will be representing all of<br />

the Homag Group <strong>co</strong>mpanies in<br />

New Zealand, including favourites<br />

Brandt edgebanders, Weeke CNC,<br />

and Holzma beamsaws.<br />

Alexis will be part of Jacks’ sixstrong<br />

team attending LIGNA in<br />

Hannover, Germany, this June.<br />

Managing Director Robin Jack<br />

says: “With three separate groups<br />

of Kiwi customers joining us at<br />

LIGNA this year, we’re seeing<br />

a growing <strong>co</strong>nfidence in the<br />

NZ market. Alexis joins us at a<br />

time when more than ever our<br />

customers rely on us to present<br />

them with efficient, affordable<br />

manufacturing solutions. LIGNA<br />

offers us the opportunity to keep<br />

right-up-to date with the latest<br />

technology from our suppliers,<br />

while also ensuring that our<br />

customers experience European<br />

innovations. No doubt our Panel<br />

customers will be hearing plenty<br />

about what’s new at LIGNA from<br />

Alexis on his return”.<br />

<br />

3D Kitchen sponsor<br />

TAFE Awards<br />

Chris and Rose Adams, owners<br />

of 3D Kitchen, attended the<br />

Holmesglen TAFE annual student<br />

achievement award dinner in<br />

Melbourne on 18th of May. The<br />

Holmesglem Institute of TAFE is<br />

one of Australia’s largest training<br />

institutions training students in<br />

the joinery, furniture and design<br />

trades. 3D Kitchen has been<br />

associated with the TAFE for<br />

many years now and has been the<br />

main award sponsor for the past<br />

fi ve years.<br />

It was a very enjoyable evening<br />

and a unique opportunity to see<br />

the extremely high degree of skill<br />

these students have achieved. 3D<br />

Kitchen provides over $3,000<br />

worth of sponsorship to the TAFE<br />

annually and it is a delight to be<br />

able to provide sponsorship to such<br />

worthy recipients. Congratulations<br />

to all winners and in particular to<br />

Ruben Becker (pictured above) on<br />

winning the 3D Kitchen prize.<br />

3D Kitchen also provides its full<br />

design and production software<br />

to the TAFE for student training<br />

purposes. Because of the very<br />

limited time the TAFE has to<br />

teach its various modules, the<br />

speed at which this software can<br />

be learned is a key reason for<br />

the TAFE choosing 3D Kitchen<br />

as part of its cabinetmaking and<br />

joinery teaching.<br />

Total CNC Solutions<br />

0800 422 669<br />

www.icam.<strong>co</strong>.<strong>nz</strong>

new products to be<br />

shown at Conference<br />

ASSA ABLOY New Zealand wel<strong>co</strong>mes all<br />

Master Joiners to their stand at the Rotorua<br />

Master Joiners Conference, June 23-25. It is our<br />

pleasure to <strong>co</strong>ntinue to offer quality products<br />

and service with the Interlock - Folding and<br />

Sliding range.<br />

The most recent additions to the Interlock<br />

– Folding and Sliding range includes the<br />

Weatherfold Window 20 and Single Run<br />

80. These will be on our stand to check<br />

out, alongside some of our well known and<br />

established folding and sliding products.<br />

Weatherfold Window 20 is an extension<br />

of the proven Window Servery System. Its<br />

self draining, <strong>co</strong>ncealed guide uses modern<br />

technology and provides superior functionality<br />

while allowing it to be in<strong>co</strong>rporated into<br />

traditional timber joinery. Two sash thickness<br />

options are available to suit both single and<br />

double glazed applications.<br />

The Single Run 80 has had a hanger in the<br />

market for some time but a new and <strong>co</strong>st<br />

effi cient 80kg track is now available. This<br />

track, in mill or anodized <strong>finishes</strong>, offers<br />

a smooth look with no seal grooves and is<br />

ideally suited to shutters and lighter door<br />

applications.<br />

The ASSA ABLOY New Zealand Trade Team<br />

can be found on stand 10 at the Master Joiners<br />

Conference and are looking forward to catching<br />

up with as many of you as possible.<br />

ASSA ABLOY New Zealand would like to<br />

acknowledge the tough business <strong>co</strong>nditions the<br />

industry has experienced this year, in particular<br />

the Canterbury Region. As we look ahead to<br />

improving times, ASSA ABLOY is proud to be<br />

supporting the Timber Joinery industry and we<br />

look forward to seeing you in Rotorua.<br />

Coverage in September<br />

Full <strong>co</strong>verage of the Master Joiners Conference including details and photographs of the<br />

Master Joiners Awards and the Apprentice Awards will be <strong>co</strong>ntained in the September issue<br />

of JOINERS Magazine. Following the Awards night on the 25th of June winners details<br />

will be available for viewing on the master Joiners website www.masterjoiners.<strong>co</strong>.<strong>nz</strong><br />

<br />

Come and<br />

visit us at<br />

the Master<br />

Joiners<br />

Conference<br />

23rd-25th June<br />

Novotel Rotorua<br />

Lakeside Hotel<br />

ASSA ABLOY New Zealand Ltd.<br />

PO Box 100407, North Shore<br />

Auckland 0745<br />

6 Armstrong Road, Albany<br />

Auckland 0632<br />

New Zealand<br />

Tel: +64 9 415 8031<br />

Fax: +64 9 415 7222<br />

Website: www.assaabloy.<strong>co</strong>.<strong>nz</strong><br />

JOINERS Magazine June 2011 page 13

52,000 52, 52 52,000 2,000 2 000 00 000 at aat<br />

aat<br />

a<br />

Richard Abela MD Hettich Australia/NZ and<br />

Marc Reichling Head of Corporate Marketing.<br />

Philipp Blum and Blum NZ Managing Director<br />

Michael Hawkins.<br />

Eddie Marsh and Kevin Kyle from Hafele NZ.<br />

Andrew Whisker NZ Manager Rehau.<br />

JOINERS Magazine June 2011 page 14<br />

Sensational was the general <strong>co</strong>nsensus<br />

amongst exhibitors at the end of this year’s<br />

interzum. With 52,400 trade visitors from 147<br />

<strong>co</strong>untries, the leading international trade fair<br />

for the furniture supplier industry was able to<br />

announce growth of 13%. The internationality<br />

of the visitor structure, traditionally always<br />

high anyway, increased signifi cantly this year<br />

with a plus of 24%. “I’m absolutely thrilled.<br />

What’s been happening here over the last<br />

few days is incredible. For four days, the<br />

exhibitors have been showing what I can only<br />

describe as a fi rework display. The industry has<br />

been celebrating itself – with good reason,”<br />

<strong>co</strong>ncludes Frank Haubold, product manager of<br />

interzum and director of the imm <strong>co</strong>logne.<br />

“With this interzum, Koelnmesse has defi nitely<br />

underlined its position as a bea<strong>co</strong>n for the<br />

furniture industry. I don’t believe there is<br />

any other trade fair venue in the world where<br />

three absolute leading events for the respective<br />

sectors take place so successfully, in such<br />

<strong>co</strong>ncentrated form and in such a brief space<br />

of time. We are creating precedents for an<br />

extremely promising future,” says a visibly<br />

satisfi ed Gerald Böse, CEO of Koelnmesse.<br />

This year’s interzum was the international<br />

meeting point for the supplier industry. The<br />

mood was extremely good, exhibitors were<br />

able to make new <strong>co</strong>ntacts and boost business.<br />

And visitors had the opportunity to get a<br />

<strong>co</strong>mprehensive overview of what the sector<br />

has to offer. There were sophisticated newly<br />

developed products on show in all segments.<br />

As in the past, it was mostly decision-makers<br />

who came to interzum, an important aspect<br />

repeatedly applauded by exhibitors. “It was a<br />

very good fair for us. The number of visitors<br />

was much higher than last time, and we’re very<br />

satisfi ed with the quality of the visitors as well.<br />

In our opinion, it was a fi rst-rate interzum,”<br />

<strong>co</strong>ncludes Wolfgang Steib, executive board<br />

member at Hettich.<br />

And it’s not just the exhibitors who are satisfi ed<br />

with the quantity and quality of the visitors.<br />

The visitors were equally enthusiastic about<br />

the <strong>co</strong>mprehensive product spectrum on<br />

show in Cologne. “It was an extraordinary<br />

interzum! Great atmosphere, fantastic fl air,<br />

attractive exhibitors with some very individual<br />

presentations, and some very interesting<br />

proposals for own idea pool,” <strong>co</strong>mmented one<br />

trade visitor from abroad.<br />

The supporting programme for this year’s fair<br />

was more extensive than ever before and went<br />

down extremely well with visitors. In particular,<br />

the se<strong>co</strong>nd edition of “innovation of interior”,<br />

a forum for interior architects, tradesmen,<br />

architects, designers and developers, was a<br />

huge success. Together with Professor Hartmut<br />

A. Raiser and Antonius Quodt, Koelnmesse<br />

created a groundbreaking special exhibition<br />

on materials, fi nishes and lighting.<br />

“In our opinion, the ‘innovation of interior’<br />

<strong>co</strong>ncept is a great success. We were delighted<br />

to wel<strong>co</strong>me so many visitors, principally<br />

architects, but lots of visitors from other target<br />

groups as well, and call their attention to our<br />

innovations. They included lots of new <strong>co</strong>ntacts<br />

for whom our presence in Hall 4.2 was the<br />

starting point before going to our booth in Hall<br />

7 for more in-depth information,” <strong>co</strong>ncludes<br />

Julia Sohler, Marketing Communications<br />

Offi cer at Blum GmbH.<br />

This years “interzum award: material<br />

innovations and design”, presented for the<br />

fi fth time by Koelnmesse in <strong>co</strong>llaboration with<br />

red dot, again honoured some of the industry’s<br />

most outstanding innovations. The top-notch<br />

jury awarded prizes to a total of 43 products,<br />

which were presented in their own special<br />

exhibition on the boulevard for the duration<br />

of the trade fair.<br />

interzum 2013 13 – 16 May 2013

JOINERS Magazine June 2011 page 15

sinks & surrounds<br />

A focal point of the kitchen, the<br />

benchtop and sinkware instantly<br />

create the style of the kitchen. High<br />

functionality and high aesthetics are<br />

a must for most, often tempered by<br />

price where <strong>co</strong>st effective solutions<br />

are required.<br />

And the price can vary <strong>co</strong>nsiderably<br />

across the range of materials<br />

and designs available. We look at<br />

stainless steel, solid timber, laminate<br />

and synthetic options on the market<br />

as well as some of the accessories<br />

available and processes involved in<br />

manufacturing and installing benches<br />

and sinks.<br />

JOINERS Magazine June 2011 page 16<br />

Classic stainless from Burns & Ferrall p. 22<br />

Local product from Mercer p. 21<br />

Fire retardant splashbacks from The Laminex Group p. 19

JOINERS Magazine June 2011 page 17

Benchtops and sinks – a marriage of the minds<br />

With Häfele’s versatile product offering of sinks and benchtops – creating an<br />

attractive kitchen be<strong>co</strong>mes so much easier.<br />

Broken Stone<br />

Polar White<br />

King Sand<br />

Alabaster<br />

Platinum<br />

Glacier<br />

Available August 2011 Sonara<br />

Available August 2011 Silver Birch<br />

Available August 2011 Storm<br />

JOINERS Magazine June 2011 page 18<br />

Infi nity benchtops are produced via e<strong>co</strong>nomies of<br />

scale. They <strong>co</strong>me to us prefabricated as blanks and<br />

only require joining together on site. A signifi cant<br />

<strong>co</strong>ntributor to the high <strong>co</strong>st of acrylic tops is the<br />

labour required to fabricate benchtops from scratch<br />

out of raw sheet. Infi nity avoids this lengthy expensive<br />

fabrication process, which allows us to offer a price<br />

advantage with no <strong>co</strong>mpromise on quality as well as<br />

a short lead time.<br />

Seamless joins<br />

A major plus of Infi nity tops is that the joins are almost<br />

impossible to detect.<br />

Hygienic<br />

Infi nity is non-porous therefore hygienic as bacteria<br />

can not harbour in the material.<br />

Easy to Clean<br />

Cleaning with simple soap and water, or Spray ‘n’<br />

Wipe type products. The surface can also handle mild<br />

abrasives like Jiff (which actually does the surface<br />

good as it will remove any minor abrasions and scuff<br />

marks.) Acrylic surfaces are non-porous therefore<br />

will not stain.<br />

Re<strong>co</strong>verable<br />

Infi nity tops can be brought back to their original fi nish<br />

by a simple sand and polish.<br />

Touch<br />

Smooth as silk and not as <strong>co</strong>ld to the touch as stone<br />

or stone <strong>co</strong>mposites.<br />

Colour Fast<br />

Infi nity tops being 100% acrylic are less likely to<br />

fade when exposed to normal levels of UV. One of<br />

the many benefi ts is, that your Infi nity top can easily<br />

be restored to its original beauty many years later by<br />

simply sanding and buffi ng. Consult any one of our<br />

accredited installers to facilitate this work.<br />

Guaranteed to Last<br />

Häfele offers a 10 year warranty on Infi nity bench<br />

tops.<br />

The latest BLANCO range of sinks and taps include<br />

Silgranit Puradur II sinks which are resistant to dirt<br />

deposits, stains, metal abrasion as well as being scratch<br />

resistant, heat resistant up to 280°C and resistant to<br />

impact. The new satin stone fi nish with its unique<br />

properties helps to repel water, preventing the build-up<br />

of surface deposits, stains and lime scale and is easier<br />

to care for than virtually any other surface.<br />

The seamless nature of Infi nity <strong>co</strong>mbined with the<br />

unique natural look of Blan<strong>co</strong>Silgranit Puradur II<br />

sinks and taps, create an unbeatable duo in design<br />

standards.<br />

To see this Marriage of the Minds visit any of our Häfele<br />

Showrooms nationwide from Mondays to Saturdays.<br />

Visit www.hafele.<strong>co</strong>m/<strong>nz</strong> – choose Catalogues

Laminex Metaline ®<br />

Just launched into the New Zealand market, Laminex Metaline ® is a fi re retardant<br />

<strong>co</strong>mposite panel that has been specifi cally developed for kitchen splashbacks. It offers<br />

the look and feel of <strong>co</strong>loured glass, but allows greater design fl exibility.<br />

Laminex Metaline ® can be cut, machined and formed using standard tools. It can<br />

be formed around <strong>co</strong>rners, and have folded edges for tidy butt joins. It can be cut<br />

after installation to install power points, and has no restrictions on edge distances for<br />

holes and cutouts. Laminex Metaline ® has a wear resistant <strong>co</strong>ating with a high gloss<br />

surface fi nish and is available in 12 stocked <strong>co</strong>lours through The Laminex Group. The<br />

Laminex Metaline ® Splashback system is Codemark certifi ed, and is supported by a<br />

7 year product warranty.<br />

For more info, go to www.metaline.<strong>co</strong>.<strong>nz</strong> or call 0800 303 606<br />

Corian®<br />

…surfaces that are durable,<br />

versatile and hygienic.<br />

Å Long spans that appear virtually seamless<br />

Å Curved designs, integrated sinks and draining grooves<br />

Å Non porous, stain resistant – ideal for food preparation<br />

PLUS<br />

Å Up to a third less waste during fabrication than stone<br />

Å 10 year manufacturer’s residential warranty<br />

Å Proven for more than 30 years<br />

O’Brien Group is an approved fabricator of Corian®<br />

and New Zealand’s leading supplier of benchtops for<br />

domestic and <strong>co</strong>mmercial applications.<br />

Contact us today on 03 384 2139<br />

For more information about Corian® go to www.obrien-group.<strong>co</strong>.<strong>nz</strong><br />

Corian ®<br />

Since its introduction in 1967, Corian has<br />

proven itself to be a remarkably durable,<br />

versatile material that’s easy to live<br />

with in both residential and <strong>co</strong>mmercial<br />

environments. Colour and pattern run all<br />

the way through and cannot wear away.<br />

Corian ® cannot delaminate.<br />

Through its advanced blend of pure acrylic<br />

polymer, long spans can be created that<br />

appear to be virtually seamless. Curved<br />

designs, integrated sinks and draining<br />

grooves are all possible with Corian ® .<br />

Corian ® is non porous and stain resistant<br />

making it a hygienic surface solution ideal<br />

for use in food preparation areas.<br />

The new Corian Organics <strong>co</strong>llection will<br />

be launched in July, bringing the total New<br />

Zealand range to 20 <strong>co</strong>lours.<br />

Corian is available through the nationwide<br />

network of approved Corian ® fabricators<br />

and installers, with a 10 year warranty on<br />

both the Corian ® and the installation.<br />

For the latest brochure<br />

0800 99 99 39<br />

www.thelaminexgroup.<strong>co</strong>.<strong>nz</strong><br />

JOINERS Magazine June 2011 page 19

Mercer Products is proud to remain a<br />

New Zealand manufacturer of Stainless<br />

Steel sinkware and our Christchurch<br />

facility produces a great number of the<br />

excellent items that we sell.<br />

“Cold off the press” might seem strange<br />

at first, but the pressing process is<br />

actually a <strong>co</strong>ld one, done under immense<br />

pressure with utmost care. The annealing<br />

process (pictured in the background<br />

right) is a heat treatment wherein a<br />

material is altered, relieving internal<br />

stresses, refining the structure by making<br />

it homogeneous, and improving <strong>co</strong>ld<br />

working properties.<br />

Our factory also allows us to produce<br />

sinks and sinkware from the durable and<br />

resistant 316 grade stainless steel. Greater<br />

resistance to pitting and <strong>co</strong>rrosion over<br />

regular 304 grade makes 316 the choice<br />

in tough environments, labs and medical<br />

facilities. You will be able to tell the sink<br />

is 316 grade as it<br />

will have this logo<br />

etched on it.<br />

Mercer Products, proudly New Zealand<br />

owned and operated.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

JOINERS Magazine June 2011 page 20<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Phone: 0800 2 637237<br />

Fax: 0800 4 637237<br />

Website: www.mercerproducts.<strong>co</strong>.<strong>nz</strong>

go local call from Mercer<br />

New Zealand’s biggest sink manufacturer is calling on the Government to think local when it <strong>co</strong>ntracts suppliers for the mammoth<br />

housing rebuild in Christchurch. Mercer Products, which manufactures and supplies kitchen sinks, laundry tubs and their “Bisonne”<br />

laminate and “borelli” solid surface benching materials, is currently supporting its trade customers who in turn are tendering for<br />

Department of Building and Housing <strong>co</strong>ntracts.<br />

If they are successful, the Lunns<br />

Rd factory would be able to extend<br />

its 40 hour week, employing more<br />

staff. General manager David<br />

Mayell said allocation of <strong>co</strong>ntracts<br />

to local business would provide<br />

a much-needed stimulus to the<br />

Christchurch e<strong>co</strong>nomy.<br />

“For us, there are opportunities<br />

to assist with both the 10,000<br />

temporary houses that are<br />

earmarked for the city, and also the<br />

thousands of homes that are likely<br />

to be demolished and rebuilt.<br />

The potential for well-positioned<br />

Christchurch manufacturers and<br />

suppliers to be part of the re<strong>co</strong>very<br />

is huge. ”<br />

“It is an excellent opportunity<br />

for policy makers and businesses<br />

to support Christchurch manufacturing<br />

and thus employ people<br />

that make up our Christchurch<br />

<strong>co</strong>mmunity” Mayell says.<br />

The business currently employs<br />

50 staff across the <strong>co</strong>untry,<br />

including 15 at its 3,000 m2 local<br />

factory. The remainder work from<br />

its centralised warehouse and<br />

distribution centre in Hamilton,<br />

which also houses its customer<br />

service centre. Mercer’s products<br />

are warehoused in the both<br />

Hamilton and in Christchurch.<br />

Currently around 70%, domestic<br />

sales still make up the largest<br />

proportion of business with<br />

<strong>co</strong>mmercial sales taking up the<br />

balance. Mercer’s name is part<br />

of the fabric of Christchurch’s<br />

heritage. The manufacturer dates<br />

back nearly 130 years, established<br />

in 1882 by James Mercer in Tuam<br />

St before subsequently shifting to<br />

Moorhouse Ave.<br />

In 2002 Mercer Products built a<br />

new purpose build sink factory,<br />

on the Lunns Rd property shared<br />

with its allied <strong>co</strong>mpany, Mercer<br />

Stainless Ltd which services the<br />

dairy sector.<br />

The move to purpose-built<br />

premises suffered a severe blow<br />

just short of a year later when fi re<br />

damaged the factory’s fi nishing<br />

room and the entire roof, causing<br />

upheaval for the following six<br />

months. Mayell, who’s been<br />

general manager for the past 11<br />

years, has vivid memories of the<br />

work required to keep the factory<br />

onstream.<br />

While Mercer is the biggest sink<br />

manufacturer in New Zealand, it<br />

too has climbed the heady heights<br />

of the building and renovations<br />

boom but suffered falling volumes<br />

during the e<strong>co</strong>nomic downturn.<br />

Despite this, Mercer Products<br />

in New Zealand has remained<br />

profitable – this being due to<br />

its strong market position, its<br />

quality product and ability to meet<br />

customer requirements.<br />

“We’ve been working 40 hours<br />

a week but an automated factory<br />

like ours has potential to greatly<br />

increase production as required<br />

so that we <strong>co</strong>uld <strong>co</strong>nceivably<br />

manufacture around the clock,”<br />

Mayell said. It’s that investment<br />

in sophisticated plant and<br />

equipment, which helps keep<br />

Mercer Products <strong>co</strong>mpetitive in<br />

the face of increasing imports – its<br />

largest rival.<br />

“By manufacturing locally we can<br />

keep our raw materials and fi nished<br />

goods inventory at required market<br />

levels for supply, and keep local<br />

people employed.”<br />

<br />

By manufacturing locally Mercer Products can keep raw materials and fi nished<br />

goods inventory at required market levels for supply, and keep local people<br />

employed.<br />

JOINERS Magazine June 2011 page 21

All leading laminate brands<br />

Silestone • Caesarstone • Roxx •<br />

HiMacs • Corian • Saba Surface<br />

Roller<br />

Shutter<br />

Doors<br />

JOINERS Magazine June 2011 page 22<br />

Graeme Faire Ltd<br />

3/64 Hunua Road, Papakura 2110<br />

Ph: 09 299 6237<br />

Mob: 027 2551467<br />

Fax: 09 298 2809<br />

Email: info@fairebenchtops.<strong>co</strong>.<strong>nz</strong><br />

Web: gfl -benchtops.<strong>co</strong>.<strong>nz</strong><br />

laminate • solid surface • stainless steel<br />

Deal Direct<br />

We are the specialists<br />

Kitchens, Offi ces, Churches, Schools, Bars.<br />

Come to us for all your roller door needs for solid timber,<br />

melamine and aluminium quality products and have the<br />

options of manual lift or electric openers.<br />

Call us for an information pack today<br />

0800 476 552 or 0800 4 rolla door<br />

www.northrolldoors.<strong>co</strong>.<strong>nz</strong><br />

Sinks can be integrated into custom stainless steel benchtops from<br />

Burns & Ferrall. The benchtops are made from 304-grade steel, and<br />

are available in a range of textures, including brushed, satin and<br />

classic fi nishes.<br />

a true trend setter<br />

stainless steel benchtops<br />

Every decade is defi ned by different fashions, but there is<br />

one material that has endured the changing trends in kitchen<br />

design. Stainless steel is in fact even more sought after today<br />

than it was in the 50’s. But it is fair to say today’s kitchen<br />

benchtops and sinks are a far cry from those early models.<br />

The latest designs from Burns & Ferrall refl ect the increasing<br />

high-tech nature of the modern kitchen.<br />

Just as kitchen designs have be<strong>co</strong>me more streamlined in<br />

recent years, so have material palettes be<strong>co</strong>me more refi ned.<br />

And one of the most noticeable trends is the move towards<br />

raw materials that provide a crisp, sleek look. Burns &<br />

Ferrall’s custom stainless steel benching is transforming<br />

modern kitchens. The benchtops, which are made from highgrade<br />

304 stainless steel, once only seen on a sink bench or<br />

in a <strong>co</strong>mmercial kitchen, is now the material of choice for an<br />

increasing number of homeowners.<br />

Burns & Ferrall believe the growing demand for stainless steel<br />

surfaces can be attributed to the sleek, <strong>co</strong>ntemporary aesthetics<br />

and its renowned benefi ts. Stainless steel is a highly durable<br />

and hygienic surface – one that won’t chip or stain. In fact,<br />

many designers say the more it wears, the better it looks.<br />

Burns & Ferrall, a specialist stainless steel benchtop<br />

manufacturer offer new fi nishes and plenty of s<strong>co</strong>pe for<br />

designers. As well as the Classic and Satin fi nishes, a variety<br />

of de<strong>co</strong>rative textured surfaces are available. Custom stainless<br />

steel benchtops also <strong>co</strong>me with a choice of up stand and fascia<br />

profi les, and may in<strong>co</strong>rporate sink bowls.<br />

For details, <strong>co</strong>ntact Burns & Ferrall Ltd. Auckland: 208<br />

Neilson St, Onehunga, phone (09) 633 0900; Wellington:<br />

4 Railway Avenue, Lower Hutt, phone (04) 568 7052;<br />

Christchurch: Units 5/6, 191 Main South Rd, phone (03) 349<br />

5394. Or visit the website: www.burnsferrall.<strong>co</strong>.<strong>nz</strong>.

FRANKE LARGO<br />

The centre of a good kitchen<br />

Proving that big benefits can <strong>co</strong>me in small packages, Franke has developed an<br />

exciting new sink that’s ergonomically designed to maximise every millimetre of<br />

available space. The result is a surprisingly spacious bowl that fits into a smaller<br />

than average cabinet – making it perfect those looking to maximise storage space.<br />

The new Largo LAX 110 45 boasts ultra-modern looks and generous proportions,<br />

yet the bowl squeezes perfectly within a slender 500mm-wide base unit.<br />

Undermounted sinks are essential ingredients for achieving a sleek, streamlined<br />

kitchen design and are particularly stunning when <strong>co</strong>mbined with granite, wood<br />

and other solid surfaces. With their silky stainless steel finish, the five new Largo<br />

models are a great example of the undermounted look working its magic.<br />

Franke. For kitchens without <strong>co</strong>mpromise.<br />

NOW AVAILABLE<br />

Largo LAX110-16 & LAX110-45<br />

Largo LAX160R<br />

For all enquiries <strong>co</strong>ntact 0800 697 465 (0800 MY SINK)<br />

or visit our WEBSITE at www.burnsferrall.<strong>co</strong>.<strong>nz</strong><br />

JOINERS Magazine June 2011 page 23

CDK Stone makes digital measuring simpler!<br />

CDK Stone New Zealand Ltd, based<br />

on Auckland’s North Shore, is owner<br />

operated and is dedicated to bringing “Quality<br />

Diamond Tooling Solutions” to their customers<br />

to help them process stone both effi ciently and<br />

<strong>co</strong>st effectively.<br />

The <strong>co</strong>mpany offers an extensive range of stone<br />

processors’ tools that will get the job done<br />

from start to fi nish including cutting blades,<br />

abrasives, profi ling tools, handling equipment,<br />

adhesives, sealers and cleaners.<br />

Included in their range of products that will<br />

improve and stream-line the stone industry<br />

are the Proliner ® Series Measuring Devices,<br />

the world’s leading digitizer in 2D and 3D<br />

measurements. The Proliner ® Series uses the<br />

Proliner ® Principle which is very simple:<br />

measuring with a wire.<br />

At the end of the length of measuring wire is a<br />

metal measuring pen. By simply marking the<br />

relevant points with the pen, for example the<br />

<strong>co</strong>rners of a kitchen <strong>co</strong>untertop, the points are<br />

directly translated into a digital DXF CAD fi le.<br />

Measurements can be made of even the most<br />

<strong>co</strong>mplex of shapes to an accuracy of 0.5mm in<br />

just se<strong>co</strong>nds saving time and reducing errors.<br />

JOINERS Magazine June 2011 page 24<br />

The digital drawing that is produced can<br />

then be used to operate your CNC machine,<br />

print your plots or be used as a base for your<br />

design. To view a demonstration on using the<br />

Proliner ® go to http://www.youtube.<strong>co</strong>m/user/<br />

ProdimInternational#p/f<br />

The Proliner ® can be used easily by a single<br />

person being <strong>co</strong>mpact and easy to carry. It<br />

reduces time spent on-site taking measurements,<br />

and ensures measurements taken are accurate<br />

and reliable. The Proliner ® is an invaluable<br />

investment that will pay for itself for many<br />

years to <strong>co</strong>me.<br />

By simply marking the<br />

relevant points with the pen,<br />

for example the <strong>co</strong>rners of a<br />

kitchen <strong>co</strong>untertop, the points<br />

are directly translated into a<br />

digital DXF CAD fi le.<br />

CDK Stone customers who have purchased<br />

the Proliner ® to date are more than satisfi ed<br />

with it’s performance. And should the need<br />

ever arise that repairs need to be made as<br />

part of their <strong>co</strong>mmitment to customer service<br />

CDK Stone carry a loan machine for that rare<br />

occasion.<br />

<br />

“the Proliner ® Principle:<br />

measuring with a wire”

CDK cares for your stone<br />

When it <strong>co</strong>mes to caring for stone kitchen<br />

benchtops CDK Stone brings you<br />

Lithofin, a product range that has been<br />

developed in Germany over the past 50 years<br />

and has be<strong>co</strong>me synonymous with quality.<br />

CDK highly re<strong>co</strong>mmends that new natural<br />

stone tops are sealed using a high quality<br />

impregnating sealer to largely prevent liquid<br />

pollutants from penetrating the surface – the<br />

Lithofi n Stain-Stop range has been designed for<br />

this purpose and is available in both water and<br />

solvent based products. The application process<br />

is easy, and with <strong>co</strong>rrect maintenance will help<br />

protect stone for up to 20 years.<br />

As natural and engineered stone in kitchen<br />

benchtops are subjected to heavy wear, they<br />

need maintaining. Regular cleaning with<br />

Lithofi n MN Easy-Clean will not only help<br />

remove grease, oil and general dirt but will<br />

also help enhance the natural <strong>co</strong>lour and lustre<br />

of the stone. MN Easy-Clean <strong>co</strong>mes in a ready<br />

to use spray bottle and has been designed<br />

specifi cally to help support the effectiveness<br />

of the impregnating sealer which in turn will<br />

extend the lifetime of the natural stone top.<br />

To keep stone benchtops looking polished and<br />

brand new, especially marble, Lithofi n MN<br />

Polish Cream <strong>co</strong>mes to the rescue. It produces<br />

a sheen, enhances the natural appearance and<br />

produces a protective layer to help stop any<br />

pollutants from penetrating the stone surface.<br />

Used monthly and after cleaning MN Polish<br />

Cream will also make blemishes and scratches<br />

less visible.<br />

As an ideal gift for new stone benchtop owners,<br />

CDK Stone have available an extensive<br />

Lithofi n Carekit that includes:<br />

• MN Polish Cream White 125mL<br />

• MN Power Clean 500mL<br />

• MN Easy Clean 500mL<br />

• Non-abrasive nylon scrubbing sponges<br />

• Micro fi bre cleaning cloths<br />

• Care Instructions<br />

CDK Stone are the exclusive NZ distributor of<br />

Lithofi n products, and offer a training service<br />

to applicators and resellers.<br />

<br />

As an ideal gift for new stone<br />

benchtop owners, CDK Stone<br />

have available an extensive<br />

Lithofi n Carekit<br />

JOINERS Magazine June 2011 page 25

multifunction ovens<br />

ceramic <strong>co</strong>ok tops<br />

induction hobs<br />

range hoods<br />

sinkware<br />

Totara Marketing 2009 Ltd<br />

49 Sir William Ave,<br />

East Tamaki, Auckland<br />

Telephone 09 274 4393<br />

Facsimile 09 273 0016<br />

www.totaramarketing.<strong>co</strong>.<strong>nz</strong><br />

JOINERS Magazine June 2011 page 26<br />

Appliances<br />

and sinkware<br />

TEKA RANGE<br />

Totara Marketing is pleased to announce the introduction of a select<br />

range of sinks and appliances from our Teka range.<br />

Teka sinks and appliances are available in over 125 <strong>co</strong>untries worldwide,<br />

across fi ve <strong>co</strong>ntinents, and are backed by over 80 years experience.<br />

A household name in Europe, Teka is synonymous with quality and<br />

performance across all sectors that it <strong>co</strong>mpetes in.<br />

SINKS<br />

At the heart of every discerning kitchen is discerning sink wear with Teka<br />

fi tting this bill, however not carrying the price tag you would expect.<br />

Manufactured in 18/10 surgical grade stainless steel for premium quality.<br />

A selection of bowl & drainer and top or under mounted sink options<br />

are available to cater to any requirements.<br />

APPLIANCES<br />

The appliance range includes multifunction ovens in fi ngerprint resistant<br />

stainless steel, ceramic and gas hobs, induction hobs and range hoods<br />

with extremely quiet extraction.<br />

The Teka steam oven has been designed with the reservoir sitting on the<br />

top of the oven, so that the standard width oven lay will fi t inside the<br />

oven. Unique <strong>co</strong>mpared to other European brands where oven width is<br />

often <strong>co</strong>mpromised to fi t the reservoir.<br />

Teka’s attention to design detail ensures that when you look around a<br />

kitchen you’ll notice that the digital displays on <strong>co</strong>ok tops and ovens<br />

match, the luster of the stainless steel used on the gas hob is the same<br />

as the oven and the sink. Often a mismatch of appliances leads to<br />

differing stainless fi nishes throughout the kitchen whereas the Teka<br />

range uniquely avoids this.

PROJECT RANGE<br />

Now Totara Marketing is offering sinkwear and appliance solutions<br />

catering to the developer and home makeover market, where quality<br />

and <strong>co</strong>st effectiveness are factors.<br />

SINKS<br />

All project sinks are .9mm 18/10 304 stainless steel, which is above the<br />

NZ expected standard, making this range not only affordable but reliable<br />

and of the highest quality.<br />

Included in the range is the slim line series, perfect for narrow bench<br />

tops, <strong>co</strong>ming with the option of single, one ¼ & double bowl with<br />

drainer. The 500 series includes all standard sink formats, including a<br />

one ¼ bowl model without drainer, popular for apartments and smaller<br />

kitchens. Our Project range is extensive & can cater and <strong>co</strong>ver the needs<br />

of all requirements.<br />

APPLIANCES<br />

Totara is pleased to introduce the Project range of appliances, which are<br />

affordable <strong>co</strong>ming from leading manufacturers. The range <strong>co</strong>nsists of an<br />

8 function oven, touch <strong>co</strong>ntrol ceramic hob (including a two burner touch<br />

<strong>co</strong>ntrol hob) through to gas hobs and a selection of range hoods.<br />

* SPECIAL<br />

For a limited time, to introduce the range into the market<br />

we are offering a package <strong>co</strong>nsisting of oven, hob (gas or<br />

ceramic) & rangehood for under $1,000. Contact us at<br />

Totara Marketing for more information.<br />

Project sinkware<br />

and appliances<br />

oven, hob & rangehood<br />

for under $1,000*<br />

multifunction ovens<br />

ceramic <strong>co</strong>ok tops<br />

gas hobs<br />

range hoods<br />

sinkware<br />

Totara Marketing 2009 Ltd<br />

49 Sir William Ave,<br />

East Tamaki, Auckland<br />

Telephone 09 274 4393<br />

Facsimile 09 273 0016<br />

www.totaramarketing.<strong>co</strong>.<strong>nz</strong><br />

JOINERS Magazine June 2011 page 27

meeting benchlines with a TN38<br />

One of the better known specialists of custom built benchtops using high pressure de<strong>co</strong>rative laminate are Franklin Laminates Ltd<br />