A clean job. - uraca

A clean job. - uraca

A clean job. - uraca

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

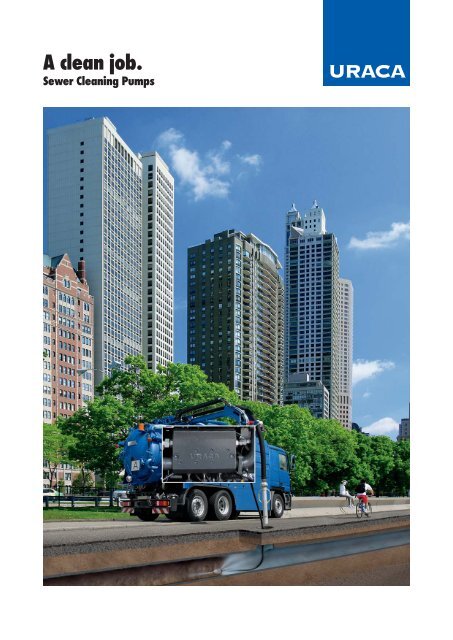

A <strong>clean</strong> <strong>job</strong>.<br />

Sewer Cleaning Pumps

2<br />

We are working on the ideal solution under maximum pressure.<br />

URACA sewer <strong>clean</strong>ing pumps<br />

are well known in the industry.<br />

Our high pressure pumps combine longstanding<br />

competency in development<br />

and construction, innovative technology<br />

and, last but not least, high-quality<br />

manufacturing. It is not without reason<br />

that URACA high-pressure pumps lie<br />

at the core of many pipe and sewer<br />

<strong>clean</strong>ing vehicles. Our plunger pumps<br />

have a compact design and are robust,<br />

powerful and versatile and have proven<br />

themselves to our clients over centuries.<br />

A <strong>clean</strong> <strong>job</strong> also comes from experience,<br />

and therefore, URACA Technology is used<br />

wherever soil and deposit on all kinds of<br />

surfaces have to be removed. Especially<br />

in those places, where many others<br />

fail – but let us listen to our customers’<br />

feedback…<br />

Benefi ts at a glance<br />

■ Cost-effective to operate<br />

■ Performance without competition<br />

■ Robust, long service life and reliable<br />

■ Extremely versatile<br />

■ Reliable and intelligent technology<br />

■ Optimised design for the best balance of<br />

weight and performance<br />

■ Easy to maintain and service<br />

■ Environmental friendly<br />

“Not only the air in Berlin is unique – thanks to URACA sewer <strong>clean</strong>ing pumps the sewers are too.”<br />

“For over 150 years, the Berlin water works supply 3.7 million people<br />

in Berlin and the surrounding areas with drinking water and treat<br />

waste water from 3.9 million people. In order to <strong>clean</strong> the sewer<br />

network of 9,500km, we have been relying on URACA sewer <strong>clean</strong>ing<br />

pumps and high pressure <strong>clean</strong>ing technology for years. Through<br />

that, we ensure the quality of our waste water and preserve our<br />

environment.”<br />

Dipl. Ing. Wolfgan Joezwiak<br />

Maintenance<br />

Director of Fleet Management<br />

Berlin Water Works

“The high reliability of URACA sewer <strong>clean</strong>ing pumps ensures our quality during everyday operations.”<br />

“Our customers have to rely on us. We rely on the URACA high-pressure <strong>clean</strong>ing technology”.<br />

“Kanal Wambach is a family company, which<br />

has been standing for quality in sewer and<br />

industry <strong>clean</strong>ing for over 40 years. For<br />

over two generations, we ensure safety and<br />

operational capability of sewers and pipes<br />

with our technical intuition, expertise and high<br />

performing vehicles. Therefore, we rely on<br />

URACA high-pressure pumps for our sewer<br />

<strong>clean</strong>ing vehicles and high-pressure water jet<br />

technology.”<br />

Bruno Wambach<br />

Management Director<br />

Kanal Wambach GmbH<br />

D-56566 Neuwied-Engers<br />

“The Onyx Rohr- und Kanal-Service GmbH & Co. KG<br />

has over 30 years experience and is the competent<br />

partner for private clients, communities and enterprises.<br />

We rely on the experience of URACA for the<br />

<strong>clean</strong>ing and inspection of pipe and sewer systems.<br />

The high reliability of URACA sewer <strong>clean</strong>ing pumps<br />

ensures our quality during everyday operations.“<br />

Horst-Peter Stachorski<br />

Management<br />

Onyx Rohr- und Kanal-Service<br />

GmbH & Co. KG<br />

Hannover<br />

– A company of<br />

Veolia Umweltservice GmbH –<br />

3

4<br />

The portfolio of the number 1 in sewer <strong>clean</strong>ing pumps in Europe.<br />

You don’t become market leader<br />

by chance.<br />

In our case, we have achieved this by<br />

applying a great degree of precision<br />

and only being satisfi ed with a solution<br />

High-pressure sewer <strong>clean</strong>ing<br />

pumps<br />

The core of sewer <strong>clean</strong>ing<br />

Hoses<br />

For use as a sewer <strong>clean</strong>ing hose or on a<br />

spray gun<br />

which is clear in all respects. Which tasks<br />

does our client have to fulfi l? What are<br />

their daily needs? And which special<br />

challenges do they have to face during<br />

their operations? The sewer <strong>clean</strong>ing<br />

vehicle, for which we don’t have a<br />

tailored solution, has yet to be built. As<br />

a full-service provider for the complete<br />

high-pressure technology for sewer<br />

<strong>clean</strong>ing vehicles, URACA always offers<br />

the fi tting solution – for every kind of<br />

sewer <strong>clean</strong>ing vehicles.<br />

Spray Guns<br />

For the perfect <strong>clean</strong>ing<br />

Therefore, URACA is the market leader<br />

in Europe.<br />

Valves<br />

For the operation of high-pressure<br />

plunger pumps<br />

Nozzles<br />

Suitable for every application

URACA offers you tailored solutions.<br />

Only those who understand the needs<br />

of their customers in every detail and<br />

possess the necessary experience and<br />

technical know-how can provide the right<br />

answers through matured technologies<br />

and sound construction.<br />

Liquid end variations<br />

Different pressure levels<br />

Clear water model<br />

Recycling model<br />

Hot water model<br />

Design Drive Systems<br />

Power end<br />

right<br />

The range of the pump portfolio with<br />

individual constructive solutions, as well<br />

as the extensive accessory portfolio,<br />

ensures fl awless operation and reliability<br />

of the system.<br />

left<br />

horizontal vertical<br />

Suction and pressure connections alternatively left or right<br />

Z model<br />

■ Compressed oil lubrication for<br />

safe operation in all positions<br />

K model<br />

■ with special crosshead sealing<br />

Power end cooling<br />

■ with or without<br />

What requirements do you have for<br />

the sewer <strong>clean</strong>ing technology? We are<br />

confi dent that we are able to fi nd a clear<br />

solution for you as well.<br />

LW model<br />

■ without gear<br />

G model<br />

■ with gear<br />

GS model<br />

■ with 180 degree gear<br />

H models<br />

■ with interlocked crank shaft for<br />

direct connection to hydraulic<br />

drive systems<br />

■ surface mounting with coupling<br />

housing for hydraulic drive systems<br />

ISO 140<br />

Options<br />

ATEX model<br />

Valve-lift<br />

for drainage<br />

5

6<br />

High-pressure pumps for sewer <strong>clean</strong>ing.<br />

Sewer <strong>clean</strong>ing pump P3-08 –<br />

“Made in Bad Urach”<br />

P3-08<br />

Power kW 7 – 30<br />

Pump speed<br />

at shaft<br />

min-1 250 – 1,000<br />

Pressure bar 100 – 200<br />

Flow Rate l/min 20 – 163<br />

Pressure Levels<br />

100 bar<br />

125 bar<br />

160 bar<br />

200 bar<br />

Liquid end variations<br />

■ Clear water<br />

Design<br />

■ horizontal<br />

■ left/right<br />

■ suction and pressure<br />

connections left/right<br />

P3-10 A 1<br />

Power kW 9 – 38<br />

Pump speed<br />

at shaft<br />

min-1 250 – 1,000<br />

Pressure bar 125 – 250<br />

Flow Rate l/min 20 – 163<br />

Pressure Levels<br />

A 1 125 bar<br />

160 bar<br />

200 bar<br />

250 bar<br />

A 2 250 bar<br />

330 bar<br />

415 bar<br />

530 bar<br />

B up to 1,000 bar<br />

Liquid end variations<br />

■ Clear water<br />

■ Recycling<br />

■ Hot water<br />

up to 30 kW<br />

Drive Systems<br />

■ LW Model<br />

■ H Model<br />

Sewer <strong>clean</strong>ing pump P3-10 – For private and<br />

community <strong>clean</strong>ing companies<br />

up to 38 kW<br />

Design<br />

■ horizontal<br />

■ left/right<br />

■ suction and pressure connections<br />

left/right<br />

Power End<br />

■ with and without power end<br />

cooling<br />

Drive Systems<br />

■ LW Model<br />

■ H Model<br />

Power End<br />

■ with and without power end<br />

cooling<br />

Option<br />

■ Valve-lift for drainage<br />

Option<br />

■ Valve-lift for drainage

Sewer <strong>clean</strong>ing pump KD 708 – Versatile for<br />

communal use<br />

KD 708 A 1<br />

Power kW 29 – 75<br />

Pump speed<br />

at shaft<br />

min-1 292 – 731<br />

Pressure bar 135 – 250<br />

Flow Rate l/min 63 – 295<br />

Pressure Levels<br />

A 1 135 bar<br />

160 bar<br />

200 bar<br />

250 bar<br />

A 2 250 bar<br />

400 bar<br />

520 bar<br />

C 1 up to 1,200 bar<br />

D up to 2,800 bar<br />

Liquid end variations<br />

■ Clear water<br />

■ Recycling<br />

■ Hot water<br />

KD 716 / KD 718 A 1<br />

Power kW 20 – 110<br />

Pump speed<br />

at shaft<br />

min-1 257 – 565<br />

Pressure bar 140 – 200<br />

Flow Rate l/min 123 – 391<br />

up to 75 kW<br />

Sewer <strong>clean</strong>ing pump KD 716 / KD 718 – At home<br />

in the city<br />

Pressure Levels<br />

A 1 140 bar<br />

170 bar<br />

200 bar<br />

A 2 270 bar<br />

340 bar<br />

530 bar<br />

A 3 170 bar<br />

200 bar<br />

250 bar<br />

300 bar<br />

380 bar<br />

400 bar<br />

B up to 850 bar<br />

C up to 1,200 bar<br />

D up to 2,800 bar<br />

Design<br />

■ horizontal<br />

■ left/right<br />

■ suction and pressure connections<br />

left/right<br />

up to 110 kW<br />

Liquid end variations<br />

■ Clear water<br />

■ Recycling<br />

■ Hot water<br />

Design<br />

■ horizontal/vertical<br />

■ left/right<br />

■ suction and pressure connections<br />

left/right<br />

Drive Systems<br />

■ LW Model<br />

■ G Model<br />

■ GS Model<br />

Drive Systems<br />

■ LW Model<br />

■ G Model<br />

■ GS Model<br />

■ H Model (Surface mounting)<br />

Power End<br />

■ with and without power end cooling<br />

■ Z Model<br />

■ K Model<br />

Option<br />

■ Valve-lift for drainage<br />

Power End<br />

■ with and without power end cooling<br />

■ Z Model<br />

■ K Model (KD 716)<br />

■ with integrated power end sealing<br />

by default (KD 718)<br />

Option<br />

■ Valve-lift for drainage<br />

7

8<br />

Sewer <strong>clean</strong>ing pump P3-45 – Number 1<br />

within Europe<br />

P3-45<br />

Power kW 72 – 134<br />

Pump speed<br />

at shaft<br />

min-1 30 – 575<br />

Pressure bar 150 – 250<br />

Flow Rate l/min 162 – 473<br />

Pressure Levels<br />

150 bar<br />

175 bar<br />

205 bar<br />

250 bar<br />

P4-45<br />

Power kW 96 – 179<br />

Pump speed<br />

at shaft<br />

min-1 319 – 575<br />

Pressure bar 150 – 250<br />

Flow Rate l/min 216 – 631<br />

up to 130 kW<br />

Liquid end variations<br />

■ Clear water<br />

■ Recycling<br />

■ Hot water Drive Systems<br />

■ G Model<br />

Design<br />

■ horizontal<br />

■ left/right<br />

■ suction and pressure connections<br />

left/right<br />

Sewer <strong>clean</strong>ing pump P4-45 – Victory parade<br />

in the metropolises<br />

Pressure Levels<br />

150 bar<br />

175 bar<br />

205 bar<br />

250 bar<br />

up to 180 kW<br />

Liquid end variations<br />

■ Clear water<br />

■ Recycling<br />

■ Hot water Drive Systems<br />

■ G Model<br />

Design<br />

■ horizontal<br />

■ left/right<br />

■ suction and pressure connections<br />

left/right<br />

Power End<br />

■ with power end cooling<br />

■ Z Model<br />

Power End<br />

■ with power end cooling<br />

■ Z Model<br />

Option<br />

■ Valve-lift for drainage<br />

Option<br />

■ Valve-lift for drainage

Sewer <strong>clean</strong>ing pump KD 724 – Industrial <strong>clean</strong>ing<br />

on a large scale<br />

KD 724 A 1<br />

Power kW 69 – 170<br />

Pump speed<br />

at shaft<br />

min-1 238 – 571<br />

Pressure bar 170 – 275<br />

Flow Rate l/min 138 – 548<br />

Pressure Levels<br />

A 1 170 bar<br />

200 bar<br />

230 bar<br />

275 bar<br />

A 2 170 bar<br />

200 bar<br />

230 bar<br />

275 bar<br />

330 bar<br />

400 bar<br />

B up to 1.000 bar<br />

C up to 1.200 bar<br />

D up to 2.800 bar<br />

UD 200<br />

Power kW 20 – 180<br />

Lift Frequency min -1 20<br />

Pressure bar 70 – 200<br />

Flow Rate l/min 470<br />

up to 170 kW<br />

Liquid end variations<br />

■ Clear water<br />

■ Recycling<br />

■ Hot water<br />

Design<br />

■ horizontal/vertical<br />

■ left/right<br />

■ suction and pressure<br />

connections left/right<br />

Drive Systems<br />

■ LW Model<br />

■ G Model<br />

Pressure converter UD 200 – Well known<br />

all over the world<br />

up to 180 kW<br />

The oil-hydraulic driven pressure<br />

converter UD 200 is suitable for<br />

installation on sewer vehicles and is<br />

an alternative to the plunger pump.<br />

Power End<br />

■ with and without power end<br />

cooling<br />

■ Z Model<br />

■ K Model<br />

Option<br />

■ Valve-lift for drainage<br />

9

10<br />

Valves for high-pressure plunger pumps.<br />

A broad portfolio of highpressure<br />

valves ensures the<br />

reliable and safe operation of<br />

sewer <strong>clean</strong>ing pumps.<br />

Type VS Type HHV Type VSV Type MSSV<br />

Mechanical safety valve<br />

For securing of high-pressure<br />

pumps against pressure overload<br />

Type<br />

The high-pressure valves are used for the<br />

following applications:<br />

Mechanical safety valves Mechanical safety valves Diaphragm-controlled switch/safety<br />

valves<br />

Reliable mechanical safety valve<br />

for different pressure/volume<br />

levels<br />

VS<br />

200/180<br />

HHV<br />

5/800<br />

VSV<br />

10/300<br />

■ Safety Valve<br />

■ Relief Valve<br />

■ Pump unloading Valve<br />

■ On/Off Valve<br />

Robust, reliable and long service<br />

life, especially suitable for<br />

frequent activation<br />

VSV<br />

12/300<br />

MSSV<br />

13/100<br />

MSSV<br />

32/150<br />

Pneumatic activation valve for<br />

soft switching<br />

MSSV<br />

11/250<br />

MSSV<br />

24/250<br />

Safety function ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔<br />

Relief function - - - - - - - - -<br />

Pump Switching function - - - - ✔ ✔ ✔ ✔ ✔<br />

MSSV<br />

16/400<br />

Holding function - - - - ✔ ( ✔ ) ( ✔ ) ( ✔ ) ( ✔ )<br />

Operating pressure (max.) bar 180 800 150 - 300 150 - 300 100 150 250 250 400<br />

Recommended fl ow rate l / min 0 - 200 5 - 550 100 - 500 250 - 650 0 - 100 0 - 1,000 0 - 100 0 - 500 0 - 250<br />

Operation mode mechanical mechanical mechanical mechanical pneumatic pneumatic pneumatic pneumatic pneumatic<br />

✔ Standard<br />

( ✔ ) Option

MSÜV<br />

20/150<br />

Type MSÜV Type HDV Type ZV / VZV Type PZV<br />

Diaphragm-controlled switch/relief/<br />

safety valves<br />

Pneumatic activated valve with<br />

relief function<br />

MSÜV<br />

29/300<br />

MSÜV<br />

29/450<br />

HDV<br />

180<br />

Hydraulic pressure valves<br />

Mechanical Unloader valve –<br />

always there if there’s no power<br />

HDV<br />

262/1<br />

HDV<br />

262/2<br />

HDV<br />

300/1<br />

Mechanical holding valve<br />

Spring-loaded valve with holding<br />

function<br />

HDV<br />

300/2<br />

HDV<br />

300/3<br />

ZV<br />

29/300<br />

Pneumatic holding valve<br />

Pneumatic operating valve<br />

with holding function<br />

VZV<br />

25/400<br />

✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ - - -<br />

✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ - - -<br />

✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ - - -<br />

- - - - - - - - - ✔ ✔ ✔<br />

150 300 450 10 -210 40 - 120 40 - 280 40 - 110 110 - 220 220 - 400 300 400 550<br />

PZV<br />

23/550<br />

0 - 650 0 - 1,000 0 - 1,000 5 - 30 8 - 135 8 - 100 8 - 170 8 - 120 8 - 60 0 - 1,000 0 - 650 0 - 800<br />

pneumatic pneumatic pneumatic mechanical mechanical mechanical mechanical mechanical mechanical mechanical mechanical pneumatic<br />

11

12<br />

Accessories and special equipment –<br />

for perfectly <strong>clean</strong> work.<br />

Whether it’s tools, additional<br />

pumping equipment or just<br />

equipment for your work: We<br />

offer you the full portfolio.<br />

Suction pulsation damper<br />

Pressure gauge<br />

Defl exion Roller<br />

■ Suction pulsation damper<br />

■ Suction pressure monitor and switch<br />

■ Pressure sensors<br />

■ Pressure gauge<br />

■ Temperature switch and sensors<br />

■ High-pressure hoses for sewer<br />

<strong>clean</strong>ing and spray gun operation<br />

■ Defl exion Roller<br />

Suction pressure monitor and switch<br />

Temperature switch and sensors<br />

Tools,<br />

special tools and assembling aids<br />

■ Tools, Special tools and<br />

assembling aids<br />

Pressure sensor<br />

High-pressure hoses for sewer<br />

<strong>clean</strong>ing and spray gun operation

Spray guns – for hand-guided <strong>clean</strong>ing <strong>job</strong>s.<br />

Robust and resilient – you will<br />

enjoy using URACA spray guns<br />

for a long time.<br />

Clear advantages<br />

■ Low weight, easy handling<br />

■ Large volume fl ow, low pressure loss<br />

■ Easy trigger, low retention force<br />

■ Tough, reliable and long-lasting<br />

Type SP 250 SP 250-Vario*<br />

Operating Pressure (max.) bar 250 250<br />

Weight (with spray tube) kg 1,5 1,5<br />

Length standard<br />

spray tube<br />

mm 390 390<br />

Nozzle assembly (standard) Type N N<br />

Connection thread at inlet G 3/4 G 3/4<br />

Hose connection with standard<br />

connecting studs<br />

M24x1,5 DKO-S M24x1,5 DKO-S<br />

*With adjustable fl ow rate<br />

For all hand-guided <strong>clean</strong>ing <strong>job</strong>s on<br />

sewer <strong>clean</strong>ing vehicles, it is the perfect<br />

addition.<br />

Type SP503* SP802<br />

Operating Pressure (max.) bar 500 800<br />

Weight (with spray tube) kg 1,0 1,6<br />

Length standard<br />

spray tube<br />

mm 800 800<br />

Nozzle assembly (standard) Type N P<br />

Connection thread at inlet G 1/2 G 1/2<br />

Hose connection with standard<br />

connecting studs<br />

M24x1,5 DKO-S M24x1,5 DKO-S<br />

*Also suited for use with hot water<br />

■ Extensive range of accessories<br />

■ Integrated safety concept<br />

■ Suitable for all pump brands<br />

The SP 250 Spray Gun –<br />

Pure Power<br />

Cleaning power at an extremely low<br />

weight of only 1.5 kg. The adjustable<br />

fl ow rate enables the user to practically<br />

dose the large volume fl ow of the<br />

Spray Guns –<br />

Modern Design<br />

URACA spray guns maximize user<br />

effi ciency due to their low weight, easy<br />

handling, and minimize retention forces.<br />

SP 250-Vario making the SP 250<br />

extremely versatile. Its attractive price<br />

performance ratio is outstanding.<br />

The technical optimization of these<br />

tools makes them robust, simple to<br />

use, virtually fatigue free and they can<br />

be used with any pump system.<br />

13

14<br />

Pipe and Sewer Cleaning Nozzles – The full portfolio.<br />

Rotating sewer <strong>clean</strong>ing nozzles<br />

with adjustable rotational<br />

speed made by URACA.<br />

DFK 55<br />

The robust nozzle for sewer <strong>clean</strong>ing –<br />

also suited for narrow pipes.<br />

DFK 90<br />

The all-rounder amongst the rotating<br />

sewer <strong>clean</strong>ing nozzles for high fl ow<br />

rate capacity.<br />

Type DFK 55 DFK 61 DFK 90<br />

Allowed Operating Pressure bar 50 - 1,600 1,600 - 3,000 50 - 800<br />

Recommended Flow Rate l/min 25 - 150 10 - 40 30 - 400<br />

Rotational Speed Range min -1 100 - 1,500 500 - 2,000 200 - 1,200<br />

Minimum Diameter<br />

(with smallest slide)<br />

Minimum Diameter<br />

(without slide)<br />

The effective way to <strong>clean</strong> sewers<br />

and pipes.<br />

DFK 61<br />

The leakage-free pipe <strong>clean</strong>ing nozzle<br />

with adjustable rotational speed for<br />

maximum pressure.<br />

mm 67 75 145<br />

mm 55 61 90<br />

All nozzles can be supplied with various<br />

nozzle heads, nozzle extensions as well<br />

as adjustable slides. This allows for<br />

thorough <strong>clean</strong>ing of pipes and sewers<br />

with different diameters.

All-purpose Pipe and Sewer<br />

Cleaning Nozzles as well as extra<br />

All-purpose Pipe and Sewer Cleaning Nozzles<br />

Individually drilled, reversible<br />

Extra and Special Nozzles<br />

Rod Nozzles<br />

Flounder<br />

Bombs and Grenades<br />

Bulldozer<br />

Bulldog Root Cutter, Cutting Chain<br />

Rotation Nozzle<br />

Nozzle Inserts<br />

and special nozzles. The right<br />

equipment for all requirements.<br />

Type R Type E Type L Type N<br />

Individually drilled, reversible<br />

All nozzles are available in various<br />

diameters and for different pressure<br />

levels. Nozzle inserts for various<br />

pressure levels and fl ow rates are also<br />

available.<br />

15

Our experience is limitless.<br />

Wherever you see URACA technology,<br />

you will come across a professional<br />

solution. That’s because we have<br />

been at the forefront of worldwide<br />

development as a leading manufacturer<br />

of high-pressure plunger pumps and<br />

high-pressure water jet technology.<br />

Our products are as versatile as their<br />

application areas. You can fi nd us in<br />

nearly all areas of the industry.<br />

As an independent family-owned company<br />

with over 100 years experience<br />

and approx. 320 employees, URACA<br />

consistently relies on Germany as its<br />

production location. The high degree of<br />

vertical integration in-house ensures the<br />

quality and durability of our products as<br />

required by our clients.<br />

Construction alterations are subject to change. Measurements, weights, illustrations and data are non-binding.<br />

1 bar = 14,5038 psi, 1 l / min = 0,26417 USGPM = 0,22 IPGPM., 1 kW = 1,3410 HP, 1mm = 0,03937 inch<br />

Our engineers develop and construct<br />

challenging systems for manufacturing,<br />

production and <strong>clean</strong>ing processes or<br />

optimise existing solutions with the<br />

latest technological advancements.<br />

You have our word that: Every system<br />

is “Made in Germany”, is thoroughly<br />

tested by URACA and can be operated<br />

shortly after deployment.<br />

Certifi ed according to:<br />

■ DIN EN ISO 9001: 2008 by LRQA<br />

■ VGB KTA 1401<br />

■ AD 2000 – HP 0<br />

■ Further certifi cations on request<br />

URACA Pumpenfabrik GmbH & Co. KG<br />

Sirchinger Str. 15<br />

D-72574 Bad Urach<br />

Telefon: +49 (0)7125 133-0<br />

Telefax: +49 (0)7125 133-202<br />

Email: info@<strong>uraca</strong>.de<br />

www.<strong>uraca</strong>.de<br />

URACA_KS.e 0312 Ra LS