Brochure - ABA Gas

Brochure - ABA Gas

Brochure - ABA Gas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

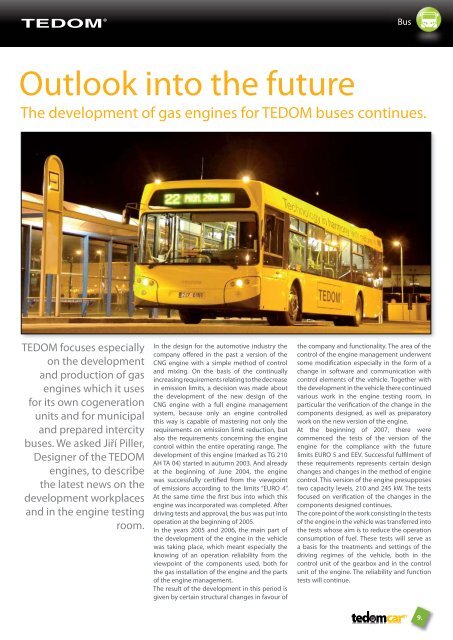

Outlook into the future<br />

The development of gas engines for TEDOM buses continues.<br />

TEDOM focuses especially<br />

on the development<br />

and production of gas<br />

engines which it uses<br />

for its own cogeneration<br />

units and for municipal<br />

and prepared intercity<br />

buses. We asked Jiří Piller,<br />

Designer of the TEDOM<br />

engines, to describe<br />

the latest news on the<br />

development workplaces<br />

and in the engine testing<br />

room.<br />

In the design for the automotive industry the<br />

company offered in the past a version of the<br />

CNG engine with a simple method of control<br />

and mixing. On the basis of the continually<br />

increasing requirements relating to the decrease<br />

in emission limits, a decision was made about<br />

the development of the new design of the<br />

CNG engine with a full engine management<br />

system, because only an engine controlled<br />

this way is capable of mastering not only the<br />

requirements on emission limit reduction, but<br />

also the requirements concerning the engine<br />

control within the entire operating range. The<br />

development of this engine (marked as TG 210<br />

AH TA 04) started in autumn 2003. And already<br />

at the beginning of June 2004, the engine<br />

was successfully certified from the viewpoint<br />

of emissions according to the limits “EURO 4”.<br />

At the same time the first bus into which this<br />

engine was incorporated was completed. After<br />

driving tests and approval, the bus was put into<br />

operation at the beginning of 2005.<br />

In the years 2005 and 2006, the main part of<br />

the development of the engine in the vehicle<br />

was taking place, which meant especially the<br />

knowing of an operation reliability from the<br />

viewpoint of the components used, both for<br />

the gas installation of the engine and the parts<br />

of the engine management.<br />

The result of the development in this period is<br />

given by certain structural changes in favour of<br />

Bus<br />

the company and functionality. The area of the<br />

control of the engine management underwent<br />

some modification especially in the form of a<br />

change in software and communication with<br />

control elements of the vehicle. Together with<br />

the development in the vehicle there continued<br />

various work in the engine testing room, in<br />

particular the verification of the change in the<br />

components designed, as well as preparatory<br />

work on the new version of the engine.<br />

At the beginning of 2007, there were<br />

commenced the tests of the version of the<br />

engine for the compliance with the future<br />

limits EURO 5 and EEV. Successful fulfilment of<br />

these requirements represents certain design<br />

changes and changes in the method of engine<br />

control. This version of the engine presupposes<br />

two capacity levels, 210 and 245 kW. The tests<br />

focused on verification of the changes in the<br />

components designed continues.<br />

The core point of the work consisting in the tests<br />

of the engine in the vehicle was transferred into<br />

the tests whose aim is to reduce the operation<br />

consumption of fuel. These tests will serve as<br />

a basis for the treatments and settings of the<br />

driving regimes of the vehicle, both in the<br />

control unit of the gearbox and in the control<br />

unit of the engine. The reliability and function<br />

tests will continue.<br />

9.