BIO DATA OF DR - Indian Institute of Technology Bhubaneswar

BIO DATA OF DR - Indian Institute of Technology Bhubaneswar

BIO DATA OF DR - Indian Institute of Technology Bhubaneswar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

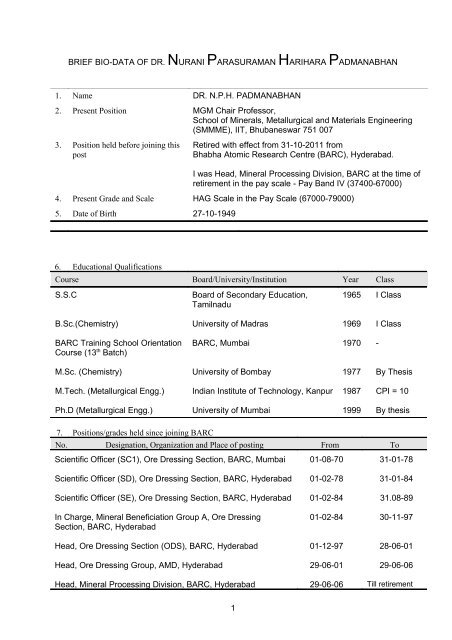

BRIEF <strong>BIO</strong>-<strong>DATA</strong> <strong>OF</strong> <strong>DR</strong>. NURANI PARASURAMAN HARIHARA PADMANABHAN<br />

1. Name <strong>DR</strong>. N.P.H. PADMANABHAN<br />

2. Present Position MGM Chair Pr<strong>of</strong>essor,<br />

School <strong>of</strong> Minerals, Metallurgical and Materials Engineering<br />

(SMMME), IIT, <strong>Bhubaneswar</strong> 751 007<br />

3. Position held before joining this<br />

post<br />

Retired with effect from 31-10-2011 from<br />

Bhabha Atomic Research Centre (BARC), Hyderabad.<br />

I was Head, Mineral Processing Division, BARC at the time <strong>of</strong><br />

retirement in the pay scale - Pay Band IV (37400-67000)<br />

4. Present Grade and Scale HAG Scale in the Pay Scale (67000-79000)<br />

5. Date <strong>of</strong> Birth 27-10-1949<br />

6. Educational Qualifications<br />

Course Board/University/Institution Year Class<br />

S.S.C<br />

B.Sc.(Chemistry)<br />

BARC Training School Orientation<br />

Course (13 th Batch)<br />

M.Sc. (Chemistry)<br />

M.Tech. (Metallurgical Engg.)<br />

Ph.D (Metallurgical Engg.)<br />

7. Positions/grades held since joining BARC<br />

No. Designation, Organization and Place <strong>of</strong> posting From To<br />

Scientific Officer (SC1), Ore Dressing Section, BARC, Mumbai<br />

Scientific Officer (SD), Ore Dressing Section, BARC, Hyderabad<br />

Scientific Officer (SE), Ore Dressing Section, BARC, Hyderabad<br />

In Charge, Mineral Beneficiation Group A, Ore Dressing<br />

Section, BARC, Hyderabad<br />

Head, Ore Dressing Section (ODS), BARC, Hyderabad<br />

Head, Ore Dressing Group, AMD, Hyderabad<br />

Board <strong>of</strong> Secondary Education,<br />

Tamilnadu<br />

University <strong>of</strong> Madras<br />

BARC, Mumbai<br />

University <strong>of</strong> Bombay<br />

Head, Mineral Processing Division, BARC, Hyderabad<br />

<strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Kanpur<br />

University <strong>of</strong> Mumbai<br />

1<br />

01-08-70<br />

01-02-78<br />

01-02-84<br />

01-02-84<br />

01-12-97<br />

29-06-01<br />

29-06-06<br />

1965<br />

1969<br />

1970<br />

1977<br />

1987<br />

1999<br />

I Class<br />

I Class<br />

-<br />

By Thesis<br />

CPI = 10<br />

By thesis<br />

31-01-78<br />

31-01-84<br />

31.08-89<br />

30-11-97<br />

28-06-01<br />

29-06-06<br />

Till retirement

Pr<strong>of</strong>essor, Homi Bhabha National <strong>Institute</strong> (HBNI), Mumbai 23-08-07<br />

8. Pr<strong>of</strong>essional Expertise<br />

on 31-10-11<br />

-<br />

Development <strong>of</strong> mineral processing flow sheets for beneficiation <strong>of</strong> ores <strong>of</strong> atomic and<br />

strategic minerals, including those <strong>of</strong> uranium, zirconium, niobium-tantalum, tin,<br />

tungsten, nickel, cobalt, molybdenum etc.<br />

Development <strong>of</strong> process flow sheets for beneficiation <strong>of</strong> beach sand minerals.<br />

Development <strong>of</strong> process flow sheets involving chemical leaching <strong>of</strong> uranium ores.<br />

Plant audit, material balancing and optimization and trouble shooting <strong>of</strong> operating mineral<br />

beneficiation plants<br />

Mathematical modeling and simulation <strong>of</strong> ore dressing unit operations, such as comminution<br />

and classification, flotation and high gradient magnetic separation.<br />

Liberation analysis, simulation <strong>of</strong> work index determination, locked cycles test-simulation.<br />

Data reconciliation, data adjustment and error minimization, and meaningful interpretation.<br />

Surface and interfacial chemistry related to mineral flotation and selective mineral flocculation.<br />

Development <strong>of</strong> process flow sheet for recovery <strong>of</strong> uranium using hydrometallurgical route<br />

involving acid and alkaline leaching, solid-liquid separation, purification by ion<br />

exchange / solvent extraction and yellow cake precipitation followed by tailings and<br />

effluent processing.<br />

9. Pr<strong>of</strong>essional and Research Experience and Projects handled since joining in 1970<br />

Commissioning <strong>of</strong> by-products recovery plant (BRP) to recover molybdenum, copper and<br />

nickel mineral values from Jaduguda uranium ore for Uranium Corporation <strong>of</strong> India<br />

Limited (UCIL) at Jaduguda.<br />

Recovery <strong>of</strong> uranium mineral values as a by-product from copper plant tailings <strong>of</strong> Singhbhum<br />

by gravity concentration techniques for UCIL.<br />

Improvement <strong>of</strong> uranium recovery from the plant tailings <strong>of</strong> copper concentrator plants <strong>of</strong><br />

Hindustan Copper Limited (HCL) at Singhbhum by fine-gravity separation and high<br />

intensity-high gradient magnetic separation for UCIL.<br />

Development <strong>of</strong> process flow sheet for the recovery <strong>of</strong> molybdenite from Rakha copper<br />

concentrate for Hindustan Copper Limited (HCL).<br />

Studies on optimization <strong>of</strong> copper flotation recovery from Malanjkhand copper ore for HCL.<br />

Design, development, testing and commissioning <strong>of</strong> proto-type superconducting high gradient<br />

magnetic separator (BARC Inter-Divisional Project).<br />

Studies on beneficiation <strong>of</strong> cassiterite from Bastar tin ores for Madhya Pradesh State Mining<br />

Corporation Limited (MPSMC).<br />

Studies on beneficiation <strong>of</strong> tungsten values from Degana vein type ore for Rajasthan State<br />

Tungsten Development Corporation Limited (RSTDC).<br />

Studies on beneficiation <strong>of</strong> wolframite ore from Burugubanda-Tapaskonda graphite-wolframite<br />

ores for National Mineral Development Corporation Limited (NMDC).<br />

Development <strong>of</strong> plant design and simulation s<strong>of</strong>tware package for design <strong>of</strong> beach sand<br />

2

processing plants in collaboration with <strong>Indian</strong> School <strong>of</strong> Mines (ISM), Dhanbad (DAE<br />

Coordinator for a BRNS Project awarded to ISM).<br />

Studies on development <strong>of</strong> a novel process for recovery <strong>of</strong> uranium from Domiasiat uranium<br />

ore (Departmental Project).<br />

Studies on improvement <strong>of</strong> recovery <strong>of</strong> rutile in the mineral separation plants <strong>of</strong> <strong>Indian</strong> Rare<br />

Earths Limited (IREL) at Chavara and Manavalakurichi for IREL and studies on<br />

beneficiation <strong>of</strong> beach sand minerals from the sands <strong>of</strong> Bhimlipatnam for IREL.<br />

Studies on beneficiation <strong>of</strong> beach sand minerals from the sands <strong>of</strong>, Kalingapatnam and<br />

Bhavanapadu for Development <strong>of</strong> Mineral Resources and <strong>Technology</strong> Upgradation<br />

Fund (DMRTDF), Government <strong>of</strong> Andhra Pradesh.<br />

Studies on ultra-purification <strong>of</strong> clays using superconducting high gradient magnetic separator<br />

to improve the brightness and reflective properties for <strong>Indian</strong> Bureau <strong>of</strong> Mines (IBM),<br />

Regional Research Laboratory, Thiruvanathapuram (RRL-T) and several other clay<br />

manufacturers.<br />

IX Plan Capital Project, “Development <strong>of</strong> Novel and Synergistic Beneficiation Processes” as<br />

Project Coordinator to develop synergistic process equipment such as magnetic<br />

hydrocyclone and magnetic spiral for processing low grade and finely disseminated<br />

uranium ores.<br />

Plant-audit and material balance <strong>of</strong> the Jhamarkotra phosphate beneficiation plant <strong>of</strong><br />

Rajasthan State Mines and Minerals Limited (RSMML), Udaipur for process<br />

performance evaluation and optimization and studies on the effect <strong>of</strong> variation in the<br />

mill feed on the flotation behaviour carbonate minerals and its consequence on grade<br />

and recovery <strong>of</strong> phosphate minerals from Jhamarkotra phosphate ore.<br />

Guiding M.Tech. (Mineral Processing) students from PG Centre, Gulbarga University, Sandur<br />

and University <strong>of</strong> Karnataka, Dharwar.<br />

Process development studies on extraction <strong>of</strong> uranium from Tummalapalle (Andhra Pradesh)<br />

ore by alkaline pressure leach technique (an industrial uranium extraction plant is being<br />

set up based on the process developed).<br />

Process development studies on extraction <strong>of</strong> uranium from Gogi (Karnataka) ore by alkaline<br />

pressure leach technique (under serious consideration for setting up a uranium plant).<br />

10. Other Pr<strong>of</strong>essional Involvements<br />

Was a regular Member <strong>of</strong> Materials and Chemical Engineering Group Board, BARC, Mumbai<br />

from 01-12-1997 to 28-06-2001.<br />

Was a Permanent Invitee to the Board Meetings <strong>of</strong> <strong>Indian</strong> Rare Earths Limited, Mumbai from<br />

April 1998 to June 2001.<br />

Was a Member, Board <strong>of</strong> Studies for M.Tech. (Mineral Processing), <strong>of</strong>fered by University <strong>of</strong><br />

Karnataka, Dharwar.<br />

Member, Tummalapalle Work Group, constituted by Department <strong>of</strong> Atomic Energy to go into<br />

the techno economic feasibility <strong>of</strong> recovery <strong>of</strong> uranium values from the Tummalapalle<br />

uranium ore deposit located in Dist. Cuddapah, Andhra Pradesh.<br />

Member, Board <strong>of</strong> Studies for B.Tech. andM.Tech. Courses on Mineral Engineering, <strong>of</strong>fered<br />

by <strong>Indian</strong> School <strong>of</strong> Mines, Dhanbad.<br />

Vice President, <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> Mineral Engineers, Jamshedpur during 2002-04.<br />

Was a Member <strong>of</strong> Nuclear Fuels and Materials Groups Board till retirement on 31-10-2011.<br />

Designed and taught the Course, Mineral Engineering for the BARC Training School-AMD<br />

3

Hyderabad Campus.<br />

11. Membership <strong>of</strong> Pr<strong>of</strong>essional Bodies<br />

Life Memebr, <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> Metals, Kolkata.<br />

Life Member, <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> Mineral Engineers, Jamshedpur.<br />

Life Member, <strong>Indian</strong> Nuclear Society, Mumbai.<br />

12. Major Events Organized<br />

Organized National level one-day Discussion Meeting on ‘Mineral Beneficiation in India:<br />

Present Status and Future Needs (MINBEN-97), in the capacity <strong>of</strong> CONVENER at<br />

Hyderabad on November 24, 1997 under the aegis <strong>of</strong> Bureau <strong>of</strong> Research in Nuclear<br />

Studies (BRNS).<br />

Organized International Seminar on Mineral Processing <strong>Technology</strong> (MPT-2001) in the<br />

capacity <strong>of</strong> CONVENER, with collaboration Ore Dressing Section, BARC and National<br />

Mineral Development Corporation Limited, under the aegis <strong>of</strong> <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> Mineral<br />

Engineers at Hyderabad during February 15-17, 2001.<br />

13. Awards and Other honours<br />

Scored a CPI 10 (out <strong>of</strong> 10) in the M.Tech course at <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Kanpur.<br />

Hargopal Memorial Prize in Metallurgical Engineering for Best Thesis in Ore Dressing in the<br />

Master’s Programme from <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Kanpur in the year 1988.<br />

Khare Award for the Best Paper entitled, “Studies on Flotation <strong>of</strong> Uranium Values from<br />

Domiasiat Ore” by A.K.Singh, N.P.H.Padmanabhan, U.Sridhar and N.K.Rao,<br />

presented in the National Seminar on Research and Process Development in Mineral<br />

Preparation, organized by <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> Mineral Engineers, Jamshedpur, 1992.<br />

Mineral Beneficiation Award for the contribution in the field <strong>of</strong> mineral processing, received<br />

from <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> Mineral Engineers, during the International Seminar on Mineral<br />

Processing <strong>Technology</strong>, MPT-2006, Chennai, 2006.<br />

Group Achievement Award 2008 from Department <strong>of</strong> Atomic Energy, Government <strong>of</strong> India for<br />

process development for the recovery <strong>of</strong> uranium from the Tummalapalle ore,<br />

Cuddappah District, Andhra Pradesh, using an innovative alkaline pressure leaching<br />

process.<br />

14. Publications<br />

Author and co-author <strong>of</strong> 100 technical articles in the categories<br />

(i) Publications in refereed national international journals,<br />

(ii) Presented in various symposia and published in the proceedings and<br />

(iii) Reports <strong>of</strong> investigations, BARC Internal Reports etc.<br />

List <strong>of</strong> selected recent publications is enclosed as Annexure<br />

15. My interests in the last Five years before retirement<br />

During the past 5 years, I have spearheaded the Ore Dressing Section (ODS) under BARC<br />

4

and Ore Dressing Group (ODG) under AMD in very Projects <strong>of</strong> importance and great<br />

relevance to our Department.<br />

Since attempts are being made to open new mines outside Singhbhum area and since these<br />

ore have characteristics much different from the Jaduguda ore, the technology has to<br />

be developed for the extraction <strong>of</strong> uranium from these ores by laboratory studies<br />

follwed by pilot plant studies to demonstrate the process and also to generate scale up<br />

and other process engineering parameters. For this purpose, AMD is setting up a<br />

<strong>Technology</strong> Demonstration Pilot Plant at UCIL Premises, Jaduguda and I am the main<br />

Coordinator for the Project. The Officers <strong>of</strong> ODG are posted at TDPP for three months<br />

on rotational basis. I am frequently visiting TDPP, Jaduguda and closely monitoring the<br />

progress <strong>of</strong> the Project.<br />

The Tummalapalle uranium ore deposit, discovered by AMD in the late eighties but discarded<br />

due to the technological difficulties in the uranium extraction arising due to the<br />

complicated mineralogy <strong>of</strong> the ore and nature <strong>of</strong> uranium mineralization was revisited.<br />

I was guiding and coordinating the laboratory investigations carried out by our Group.<br />

The ore contained nearly 83% carbonate gangue whichmade alkaline leaching<br />

technique mandatory. Although it was difficult to obtain leachabilities higher than 75%<br />

from this ore, experiments by our Group established that it is possible to precipitate<br />

uranium values directly from the leach liquor, without going through ion exchange or<br />

solvent extraction stages. For this, a cross current leach-filter-counter current wash<br />

technique (CCLFCCW) was developed. On the laboratory scale the tests have been<br />

quite encouraging. I have carried out the CCLFCCW initially in the laboratory in locked<br />

cycle manner till the steady state is attained. The experimental results have been<br />

critically analyzed and evaluated before any recommendation was made.<br />

In view <strong>of</strong> the need to improve the resource position <strong>of</strong> the raw material, uranium for our<br />

ongoing power programme, this process is being tested on a large scale at the<br />

<strong>Technology</strong> Demonstration Pilot Plant (TDPP) with the active involvement <strong>of</strong> BARC,<br />

AMD, UCIL and NPCIL. I am a key member from AMD looking after the Project.<br />

This process also envisages complete recirculation and reutilization <strong>of</strong> the reagents making it<br />

a zero liquor waste process, which will make the process environmentally attractive.<br />

I am a Member <strong>of</strong> the Tummalapalle WorkGroup constituted specially for monitoring the<br />

investigations and for evaluating the techno-economic feasibility <strong>of</strong> extraction <strong>of</strong><br />

uranium values from the Tummalapalle ore.<br />

In addition, I have carried out leachability studies on ore samples from Gogi, Lambapur,<br />

Peddagattu etc.<br />

I have also studied the feasibility <strong>of</strong> recovering the heavy And industrial minerals from the<br />

beach sands <strong>of</strong> Kalingapatnam, Bhimlipatnam, Bhavanapadu and Srikoormam- all<br />

located in the eastern coast <strong>of</strong> Andhra Pradesh. I have been always interested in<br />

modeling and simulation <strong>of</strong> the beneficiation process and I have synthesized flow<br />

sheets for pre-concentration, concentrate upgradation and mineral separation using<br />

numerical modling and process simulation. The simulation date has been verified a<br />

number <strong>of</strong> times in the laboratory studies.<br />

I have also been exposed to the recent management concepts during a sponsored executive<br />

program at Jamnalal Bajaj Institue <strong>of</strong> Management, Mumbai to improve the<br />

organizational effectiveness by motivation and leadership.<br />

I was teaching the Mineral Engineering Course at the BARC Training School-AMD Hyderabad<br />

Camus to the Trainee-Officers<br />

16. Recent Publications - Given in Annexure<br />

5