chemistry of 1, 3, 5-trinitroperhydro-1, 3, 5-triazine - Internationale ...

chemistry of 1, 3, 5-trinitroperhydro-1, 3, 5-triazine - Internationale ...

chemistry of 1, 3, 5-trinitroperhydro-1, 3, 5-triazine - Internationale ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CHEMISTRY OF 1, 3, 5-TRINITROPERHYDRO-1, 3, 5-TRIAZINE<br />

ABSTRACT<br />

RDX, an initialism for Research Department Explosive, is an explosive<br />

nitroamine widely used in military and industrial applications. It is also<br />

known less commonly as cyclonite, hexogen (particularly in German and<br />

German-influenced languages) and T4. Its chemical name is<br />

cyclotrimethylenetrinitramine; variants include cyclotrimethylene-<br />

trinitramine and cyclotrimethylene trinitaramine. In its pure, synthesized<br />

state RDX is a white, crystalline solid. As an explosive, it is usually used in<br />

mixtures with other explosives and plasticizers, phlegmatizers or<br />

desensitizers. It is stable in storage and is considered one <strong>of</strong> the most<br />

powerful and brisant <strong>of</strong> the military high explosives.<br />

Keywords: RDX, PBX, Cyclonite, Cyclotol, Hexamine, TNT, Hexogen T4,<br />

HBX, H-6, Torpex, PETN, PBXN.<br />

RDX, abbreviation <strong>of</strong> Research Department eXplosive<br />

or Royal Demolition eXplosive, formally<br />

cyclotrimethylenetrinitramine, also called cyclonite,<br />

hexogen, or T4, powerful explosive, discovered by<br />

Georg Friedrich Henning <strong>of</strong> Germany and patented in<br />

1898 but not used until World War II, when most <strong>of</strong><br />

the warring powers introduced it. Relatively safe and<br />

inexpensive to manufacture, RDX was produced on a<br />

large scale in the United States by a secret process<br />

developed in the United States and Canada. The name<br />

RDX was coined by the British. This name was<br />

accepted in the United States, although the name<br />

cyclonite was also commonly used there. The Germans<br />

called it hexogen, and the Italians called it T4. RDX is a<br />

hard, white crystalline solid, insoluble in water and<br />

Address for correspondence<br />

Pr<strong>of</strong>. Dr. Dhrubo Jyoti Sen<br />

Department <strong>of</strong> Pharmaceutical Chemistry, Shri<br />

Sarvajanik Pharmacy College, Gujarat Technological<br />

University, Arvind Baug, Mehsana-384001, Gujarat,<br />

India.<br />

E-mail: dhrubosen69@yahoo.com<br />

INTERNATIONALE PHARMACEUTICA SCIENCIA<br />

| April-June 2011 | Vol. 1 | Issue 2 |<br />

Available online http://www.ipharmsciencia.com<br />

ISSN 2231-5896<br />

©2011 IPS<br />

only slightly soluble in some other solvents. Sensitive<br />

to percussion, its principal nonmilitary use is in<br />

blasting caps. It is <strong>of</strong>ten mixed with other substances<br />

to decrease its sensitivity (Bachmann et al., 1949). 1<br />

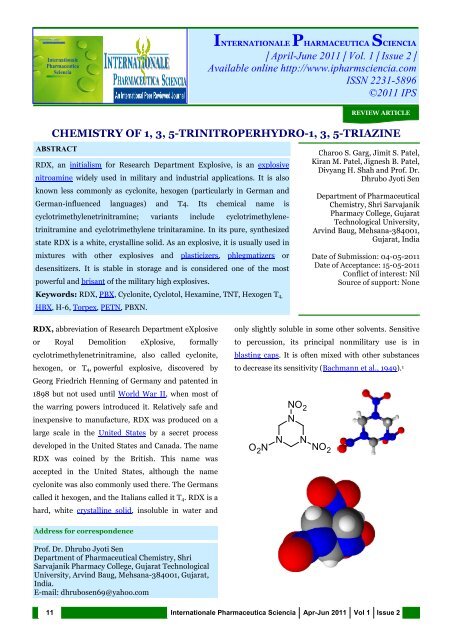

NO 2<br />

N<br />

N N<br />

O2N NO2 REVIEW ARTICLE<br />

Charoo S. Garg, Jimit S. Patel,<br />

Kiran M. Patel, Jignesh B. Patel,<br />

Divyang H. Shah and Pr<strong>of</strong>. Dr.<br />

Dhrubo Jyoti Sen<br />

Department <strong>of</strong> Pharmaceutical<br />

Chemistry, Shri Sarvajanik<br />

Pharmacy College, Gujarat<br />

Technological University,<br />

Arvind Baug, Mehsana-384001,<br />

Gujarat, India<br />

Date <strong>of</strong> Submission: 04-05-2011<br />

Date <strong>of</strong> Acceptance: 15-05-2011<br />

Conflict <strong>of</strong> interest: Nil<br />

Source <strong>of</strong> support: None<br />

11 <strong>Internationale</strong> Pharmaceutica Sciencia Apr-Jun 2011 Vol 1 Issue 2

Chemical name 1,3,5-trinitro-1,3,5-triazinane, 1,3,5-Trinitroperhydro-1,3,5-<strong>triazine</strong>, 1,3,5-Trinitro-1,3,5triazacyclohexane,<br />

1,3,5-Trinitrohexahydro-s-<strong>triazine</strong>, cyclonite, hexogen,<br />

Cyclotrimethylenetrinitramine<br />

Molecular formula C3H6N6O6<br />

Formula Weight 222.11 gm<br />

Molar mass 222.12 g mol −1<br />

Composition C(16.22%) H(2.72%) N(37.84%) O(43.22%)<br />

Molar Refractivity 43.65 ± 0.4 cm 3<br />

Molar Volume 117.0 ± 5.0 cm 3<br />

Parachor 376.0 ± 6.0 cm 3<br />

Index <strong>of</strong> Refraction 1.668 ± 0.03<br />

Surface Tension 106.6 ± 5.0 dyne/cm<br />

Density 1.89 ± 0.1 g/cm 3<br />

Polarizability 17.30 ± 0.5 10 -24 cm 3<br />

Monoisotopic Mass 222.034882 Da<br />

Nominal Mass 222 Da<br />

Average Mass 222.1163 Da<br />

CAS number 121-82-4<br />

PubChem 8490<br />

ChemSpider 8177<br />

UN number 0072, 0391, 0483<br />

Appearance Colorless crystals<br />

Melting point 205.5 °C, 479 K, 402 °F<br />

Boiling point 234 °C, 507 K, 453 °F<br />

Shock sensitivity Low<br />

Friction sensitivity Low<br />

Explosive velocity 8750 m/s<br />

RE factor 1.60<br />

Name<br />

Pr<strong>of</strong>. Dr. Dhrubo Jyoti Sen et al: Chemistry <strong>of</strong> 1, 3, 5-Trinitroperhydro-1, 3, 5-Triazine<br />

RDX is also known, but less commonly, as cyclonite,<br />

hexogen (particularly in German and German-<br />

influenced languages), T4 and chemically as<br />

cyclotrimethylenetrinitramine. Tenney L Davis,<br />

writing in the USA in 1943, stated it was generally<br />

known in the USA as cyclonite; the Germans called it<br />

Hexogen, the Italians T4. In the 1930s, the Royal<br />

Arsenal, Woolwich, started investigating cyclonite as<br />

an explosive to use against German U-boats that were<br />

being built with thicker hulls. Britain wanted an<br />

explosive that was more powerful than TNT. For<br />

security reasons, Britain termed cyclonite as<br />

"Research Department Explosive" (R. D. X.). The term<br />

RDX appeared in the United States in 1946, but the<br />

name RDX is given without explanation. The first<br />

public reference in the United Kingdom to the name<br />

RDX, or R.D.X. to use the <strong>of</strong>ficial title, appeared in<br />

1948; its authors were the Managing Chemist, ROF<br />

Bridgwater, the Chemical Research and Development<br />

Department, Woolwich, and the Director <strong>of</strong> Royal<br />

Ordnance Factories, Explosives; again, it was referred<br />

to as simply RDX (Gilman et al., 1953). 2<br />

Usage<br />

RDX was widely used during World War II, <strong>of</strong>ten in<br />

explosive mixtures with TNT such as Torpex,<br />

Composition B, Cyclotols, and H6. RDX was used in<br />

one <strong>of</strong> the first plastic explosives. RDX is believed to<br />

have been used in many bomb plots including<br />

terrorist plots. The bombs used in the "Dambusters<br />

Raid" contained 6,600 pounds <strong>of</strong> Torpex.<br />

RDX forms the base for a number <strong>of</strong> common military<br />

explosives:<br />

<strong>Internationale</strong> Pharmaceutica Sciencia Apr-Jun 2011 Vol 1 Issue 2<br />

• Composition A: Granular explosive consisting <strong>of</strong><br />

RDX and plasticizing wax. Such as, composition A-<br />

5 (RDX coated with 1.5% stearic acid) and<br />

composition A-3 (91% RDX coated with 9% wax)<br />

12

• Composition B: Castable mixtures <strong>of</strong> RDX and<br />

TNT<br />

• Composition C: The original composition C was<br />

used in World War II, but there have been<br />

subsequent variations including C-2, C-3, and C-4.<br />

C-4 consists <strong>of</strong> RDX (91%), a plasticizer (which can<br />

be dioctyl adipate {DOA}, diethylhexyl, or dioctyl<br />

sebacate) (5.3%), a binder, which is usually<br />

polyisobutylene (2.1%), SAE 10 non-detergent<br />

motor oil (1.6%).<br />

• Composition CH-6: 97.5% RDX, 1.5% calcium<br />

stearate, 0.5% polyisobutylene, and 0.5% graphite.<br />

• Cyclotol: Cyclotol is an explosive consisting <strong>of</strong><br />

castable mixtures <strong>of</strong> RDX and TNT.<br />

It is related to the more common Composition B,<br />

which is roughly 60% RDX and 40% TNT; various<br />

compositions <strong>of</strong> Cyclotol contain from 65% to 80%<br />

RDX. Typical ranges are from 60/40 to 80/20<br />

RDX/TNT, with the most common being 70/30,<br />

while the military mostly uses 77/23 optimized in<br />

warheads. Cyclotol is not commonly used, but was<br />

reportedly the main explosive used in at least some<br />

models <strong>of</strong> US Nuclear weapon. Sublette lists<br />

Cyclotol as the explosive in the US B28 nuclear<br />

bomb and possibly related weapons that used the<br />

common Python primary - W34, W28, W40, and<br />

W49. It was also used in the B53 nuclear bomb and<br />

associated W53 warhead.<br />

• HBX: Castable mixtures <strong>of</strong> RDX, TNT, powdered<br />

aluminium, and D-2 wax with calcium chloride<br />

• H-6: Castable mixture <strong>of</strong> RDX, TNT, powdered<br />

aluminum, and paraffin wax<br />

Pr<strong>of</strong>. Dr. Dhrubo Jyoti Sen et al: Chemistry <strong>of</strong> 1, 3, 5-Trinitroperhydro-1, 3, 5-Triazine<br />

N<br />

N<br />

N<br />

N<br />

1,3,5,7-tetraazatricyclo[3.3.1.1 3,7 ]decane<br />

Hexamine<br />

HNO 3<br />

SCHEME<br />

NO 2<br />

N<br />

• Semtex: (Trade name): Plastic demolition<br />

explosives containing RDX and PETN as major<br />

energetic components<br />

• Torpex: 42% RDX, 40% TNT and 18% powdered<br />

aluminium<br />

• PBX: RDX is also used as a major component <strong>of</strong><br />

many polymer-bonded explosives (PBX). RDX-<br />

based PBX's typically consist <strong>of</strong> RDX and a<br />

polymer/co-polymer binder. Examples <strong>of</strong> RDX-<br />

based PBX formulations include, but are not<br />

limited to: PBX-9007, PBX-9010, PBX-9205, PBX-<br />

9407, PBX-9604, PBXN-106, PBXN-3, PBXN-6,<br />

PBXN-10, PBXN-201, PBX-0280, PBX Type I,<br />

PBXC-116, PBXAF-108, etc.<br />

Outside <strong>of</strong> military applications, RDX is also used in<br />

controlled demolition to raze structures. The<br />

demolition <strong>of</strong> the Jamestown Bridge in the U.S. state<br />

<strong>of</strong> Rhode Island is one example where RDX shaped<br />

charges were used to remove the span (Hale et al.,<br />

1925). 3<br />

Properties<br />

The velocity <strong>of</strong> detonation <strong>of</strong> RDX at a density <strong>of</strong> 1.76<br />

g/cm³ is 8750 m/s.<br />

It is a colourless solid, <strong>of</strong> maximum theoretical<br />

density 1.82 g/cm³. It is obtained by reacting<br />

concentrated nitric acid with hexamine (Luo et al.,<br />

2002). 4<br />

N N<br />

O2N NO2 1,3,5-trinitro-1,3,5-triazinane<br />

RDX<br />

(CH2)6N4 + 10HNO3 → (CH2-N-NO2)3 +<br />

3CH2(ONO2)2 + NH4NO3 + 3H2O<br />

ONO 2<br />

ONO 2<br />

+<br />

+ NH 4 NO 3 H 2 O<br />

methylene dinitrate<br />

13 <strong>Internationale</strong> Pharmaceutica Sciencia Apr-Jun 2011 Vol 1 Issue 2<br />

+

It is a heterocycle and has the molecular shape <strong>of</strong> a<br />

ring. It starts to decompose at about 170°C and melts<br />

at 204°C. Its structural formula is: hexahydro-1,3,5-<br />

trinitro-1,3,5-<strong>triazine</strong> or (CH2-N-NO2)3.<br />

At room temperature, it is very stable. It burns rather<br />

than explodes and detonates only with a detonator,<br />

being unaffected even by small arms fire. It is less<br />

sensitive than pentaerythritol tetranitrate (PETN).<br />

However, it is very sensitive when crystallized, below<br />

−4°C. Under normal conditions, RDX has a figure <strong>of</strong><br />

insensitivity <strong>of</strong> exactly 80 (RDX defines the reference<br />

point.).<br />

RDX sublimes in vacuum, which limits its use in<br />

pyrotechnic fasteners for spacecraft.<br />

RDX when exploded in air has about 1.5 times the<br />

explosive power <strong>of</strong> TNT per unit weight and about 2.0<br />

times per unit volume.<br />

History<br />

RDX was used by both sides in World War II. The U.S.<br />

produced about 15,000 long tons (15,000 t) per<br />

month during WW II and Germany about 7,000 long<br />

tons (7,100 t) per month. RDX had the major<br />

advantages <strong>of</strong> possessing greater explosive power than<br />

TNT used in the First World War, and requiring no<br />

additional raw materials for its manufacture<br />

(Simmons et al., 1948). 5,6<br />

Germany<br />

Pr<strong>of</strong>. Dr. Dhrubo Jyoti Sen et al: Chemistry <strong>of</strong> 1, 3, 5-Trinitroperhydro-1, 3, 5-Triazine<br />

The discovery <strong>of</strong> RDX dates from 1898 when Georg<br />

Friedrich Henning obtained a German patent (patent<br />

No. 104280) for its manufacture, by nitrating<br />

hexamine nitrate (hexamethylenetetramine nitrate)<br />

with concentrated nitric acid. In this 1898 patent, its<br />

properties as a medical compound were mentioned;<br />

however, three further German patents obtained by<br />

Henning in 1916 proposed its use in smokeless<br />

propellants. The German military started<br />

investigating its use in 1920 and referred to it as<br />

hexogen. Research and development findings were<br />

not published further until Edmund von Herz,<br />

described as an Austrian and later a German citizen,<br />

obtained a British patent in 1921 and a U.S. patent in<br />

1922. Both patent claims were initiated in Austria;<br />

and described the manufacture <strong>of</strong> RDX by nitrating<br />

hexamethylenetetramine. The British patent claims<br />

included the manufacture <strong>of</strong> RDX by nitration, its use<br />

with or without other explosives, and its use as a<br />

bursting charge and as a initiator. The U.S. patent<br />

claim was for the use <strong>of</strong> a hollow explosive device<br />

containing RDX and a detonator cap containing RDX.<br />

In the 1930s, Germany developed improved<br />

production methods.<br />

During the Second World War, Germany used the<br />

code names W Salt, SH Salt, K-method, the E-method<br />

and the KA-method. These represented the names <strong>of</strong><br />

the developers <strong>of</strong> the various chemical processes used<br />

to prepare RDX. The W-method was developed by<br />

Wolfram in 1934 and gave RDX the code name "W-<br />

Salz". It used sulphamic acid, formaldehyde and nitric<br />

acid. SH-Salz (SH salt) was from Schnurr who<br />

developed a batch-process in 1937–38 based on<br />

nitrating hexamine. The K-method was from Knõffler<br />

and was based on adding ammonium nitrate to the<br />

hexamine / nitric acid process The E-method was<br />

developed by Ebele, in Germany, and turned out to be<br />

identical to the Ross and Schiessler process described<br />

later. The KA-method was developed by Knöffler, in<br />

Germany, and turned out to be identical to the<br />

Bachmann process described later.<br />

UK<br />

<strong>Internationale</strong> Pharmaceutica Sciencia Apr-Jun 2011 Vol 1 Issue 2<br />

In the United Kingdom (UK), RDX was manufactured<br />

from 1933 by the Research Department in a pilot<br />

plant at the Royal Arsenal in Woolwich, London; a<br />

larger pilot plant being built at the RGPF Waltham<br />

Abbey just outside London in 1939. In 1939 a twin-<br />

unit industrial-scale plant was designed to be installed<br />

at a new 700 acres (280 ha) site, ROF Bridgwater,<br />

away from London; and production <strong>of</strong> RDX started at<br />

Bridgwater on one unit in August 1941. The ROF<br />

Bridgwater plant brought in ammonia and methanol<br />

as raw materials: the methanol was converted to<br />

formaldehyde and some <strong>of</strong> the ammonia converted to<br />

nitric acid, which was concentrated for RDX<br />

production (Simmons et al., 1948). 5,6 The rest <strong>of</strong> the<br />

ammonia was reacted with formaldehyde to produce<br />

hexamine. The hexamine plant was supplied by<br />

14

Imperial Chemical Industries; and it incorporated<br />

some features based on data obtained from the United<br />

States (U.S.) (Simmons et al., 1948). 5,6 RDX was<br />

produced by continually adding hexamine and<br />

concentrated nitric acid to a cooled mixture <strong>of</strong><br />

hexamine and nitric acid in the nitrator (Simmons et<br />

al., 1948). 5,6 The RDX was purified and processed for<br />

its intended use; and recovery and reuse <strong>of</strong> some<br />

methanol and nitric acid was also carried out. The<br />

hexamine-nitration and RDX purification plants were<br />

duplicated (i.e. twin-unit) to provide some insurance<br />

against loss <strong>of</strong> production due to fire, explosion or air<br />

attack.<br />

The United Kingdom and British Empire were<br />

fighting without allies against Nazi Germany until the<br />

middle <strong>of</strong> 1941 and had to be self-sufficient. At that<br />

time (1941), the UK had the capacity to produce<br />

70 long tons (71 t) (160,000 lb) <strong>of</strong> RDX per week;<br />

both Canada, an allied country and former self-<br />

governing dominion <strong>of</strong> the British Empire, and the<br />

U.S. were looked upon to supply ammunition and<br />

explosives, including RDX. By 1942 the Royal Air<br />

Force's annual requirement was forecast to be<br />

52,000 long tons (53,000 t) <strong>of</strong> RDX, much <strong>of</strong> which<br />

came from North America (Canada and the U.S.).<br />

Canada<br />

A different method <strong>of</strong> production to the Woolwich<br />

process was found and used in Canada, possibly at the<br />

McGill University Department <strong>of</strong> Chemistry. This was<br />

based on reacting paraformaldehyde and ammonium<br />

nitrate in acetic anhydride. A UK patent application<br />

was made by Robert Walter Schiessler, Pennsylvania<br />

State College and James Hamilton Ross, at McGill,<br />

Canada, in May 1942 and the UK patent was issued in<br />

December 1947. Gilman states that the same method<br />

<strong>of</strong> production had been independently discovered by<br />

Ebele in Germany prior to Schiessler and Ross, but<br />

that this was not known by the Allies. Urbański<br />

provides details <strong>of</strong> five methods <strong>of</strong> production: this is<br />

listed as the (German) E-method.<br />

Pr<strong>of</strong>. Dr. Dhrubo Jyoti Sen et al: Chemistry <strong>of</strong> 1, 3, 5-Trinitroperhydro-1, 3, 5-Triazine<br />

UK, U.S. and Canadian production and<br />

development<br />

At the beginning <strong>of</strong> the 1940s, the major U.S.<br />

explosive manufacturers, E. I. du Pont de Nemours &<br />

Company and Hercules had several decades <strong>of</strong><br />

experience <strong>of</strong> manufacturing Trinitrotoluene (TNT)<br />

and had no wish to experiment with new explosives; a<br />

view also held by the U.S. Army Ordnance, who<br />

proposed to continue using TNT. RDX had been<br />

tested by Picatinny Arsenal in 1929 and it was<br />

regarded as too expensive and too sensitive. The Navy<br />

proposed to continue using ammonium picrate. In<br />

contrast, the view that new explosives were<br />

unnecessary was not shared by the National Defense<br />

Research Committee (NDRC), who had visited The<br />

Royal Arsenal, Woolwich. James B. Conant, chairman<br />

<strong>of</strong> Division B, wished to involve academic research<br />

into this area. Conant therefore set up an<br />

Experimental Explosives Research Laboratory at the<br />

Bureau <strong>of</strong> Mines, Bruceton, Pennsylvania using direct<br />

Office <strong>of</strong> Scientific Research and Development<br />

(OSRD) funding.<br />

In 1941, the UK's Tizard Mission visited the U.S. Army<br />

and Navy departments and part <strong>of</strong> the information<br />

handed over included details <strong>of</strong> the "Woolwich"<br />

method <strong>of</strong> manufacture <strong>of</strong> RDX and its stabilisation<br />

by mixing it with beeswax. The UK was asking that the<br />

U.S. and Canada, combined, supply 220 short tons<br />

(200 t) (440,000 lb) <strong>of</strong> RDX per day. A decision was<br />

taken by William H. P. Blandy, Chief <strong>of</strong> the Bureau <strong>of</strong><br />

Ordnance to adopt RDX for use in mines and<br />

torpedoes. Given the immediate need for RDX, the<br />

U.S. Army Ordnance, at Blandy's request, built a plant<br />

that just copied the equipment and process used at<br />

Woolwich. The result was the Wabash River<br />

Ordinance Works run by E. I. du Pont de Nemours &<br />

Company. This works had the largest nitric acid plant<br />

in the world, at that time. The Woolwich process was<br />

expensive; it needed 11 pounds <strong>of</strong> strong nitric acid for<br />

every pound <strong>of</strong> RDX.<br />

By early 1941, the NDRC was researching new<br />

processes. The Woolwich or direct nitration process<br />

has at least two serious disadvantages: (1) it used large<br />

amounts <strong>of</strong> nitric acid and (2) at least one-half <strong>of</strong> the<br />

15 <strong>Internationale</strong> Pharmaceutica Sciencia Apr-Jun 2011 Vol 1 Issue 2

formaldehyde is lost. One mole <strong>of</strong><br />

hexamethylenetetramine could produce at most one<br />

mole <strong>of</strong> RDX. At least three laboratories with no<br />

previous explosive experience were tasked to develop<br />

better production methods for RDX; they were based<br />

at Cornell, Michigan and Penn State universities.<br />

Werner Emmanuel Bachmann, from Michigan,<br />

successfully developed the "combination process" by<br />

combining the Canadian process with direct nitration.<br />

The combination process required large quantities <strong>of</strong><br />

acetic anhydride instead <strong>of</strong> nitric acid in the old<br />

British "Woolwich process". Ideally, the combination<br />

process could produce two moles <strong>of</strong> RDX from each<br />

mole <strong>of</strong> hexamethylenetetramine.<br />

Vast increases in production <strong>of</strong> RDX could not<br />

continue to rely on the use <strong>of</strong> the beeswax, first used<br />

in the Woolwich process, to desensitize the RDX. A<br />

substitute based on petroleum was developed at the<br />

Bruceton Explosives Research Laboratory (Gilman et<br />

al., 1953). 2<br />

Bachmann process<br />

Pr<strong>of</strong>. Dr. Dhrubo Jyoti Sen et al: Chemistry <strong>of</strong> 1, 3, 5-Trinitroperhydro-1, 3, 5-Triazine<br />

The NDRC tasked three companies to develop pilot<br />

plants. They were the Western Cartridge Company, E.<br />

I. du Pont de Nemours & Company and Tennessee<br />

Eastman Company, part <strong>of</strong> Eastman Kodak. The<br />

Eastman Chemical Company (TEC), Kingsport,<br />

Tennessee, a leading manufacturer <strong>of</strong> acetic<br />

anhydride, Werner Emmanuel Bachmann successfully<br />

developed a continuous-flow manufacturing process<br />

for RDX. RDX was crucial to the war effort and the<br />

current batch-production process could not keep up.<br />

In February 1942, TEC built the Wexler Bend pilot<br />

plant and began producing small amounts <strong>of</strong> RDX<br />

(Bachmann et al., 1949). 1 This led to the U.S.<br />

government authorizing TEC to design and build<br />

Holston Ordnance Works (H.O.W.) in June 1942. By<br />

April 1943, RDX was being manufactured there. At<br />

the end <strong>of</strong> 1944, the Holston plant and the Wabash<br />

River Ordinance Works (which used the Woolwich<br />

process) were making 25,000 short tons (23,000 t)<br />

(50 million pounds) <strong>of</strong> Composition B per month. The<br />

U.S. Bachmann process for RDX was found to be<br />

richer in HMX than the United Kingdom's RDX. This<br />

later led to a RDX plant using the Bachmann process<br />

being set up at ROF Bridgwater in 1955, to produce<br />

both RDX and HMX (Luo et al., 2002). 4<br />

Military compositions<br />

The United Kingdom's intention in World War II was<br />

to use "desensitised" RDX: in the original Woolwich<br />

process RDX coated with beeswax, but changed to a<br />

RDX coated with petroleum-based product, based on<br />

the work carried out at Bruceton. In the event the UK<br />

was unable to obtain sufficient RDX to meet its needs.<br />

Some <strong>of</strong> this shortfall was met by substituting a<br />

mixture <strong>of</strong> ammonium nitrate and TNT. Karl Dönitz<br />

was reputed to have claimed that "an aircraft can no<br />

more kill a U-boat than a crow can kill a mole".<br />

However, by May 1942 Wellington bombers began to<br />

deploy depth charges containing Torpex, a mixture <strong>of</strong><br />

RDX, TNT and aluminium, which had up to 50 per<br />

cent more destructive power than TNT-filled depth<br />

charges. Considerable quantities <strong>of</strong> the RDX–TNT<br />

mixture were produced at the Holston Ordnance<br />

Works, with Tennessee Eastman developing an<br />

automated mixing and cooling process based around<br />

the use <strong>of</strong> stainless steel conveyor belts.<br />

Terrorism<br />

Ahmed Ressam, the al-Qaeda Millenium Bomber,<br />

used a small quantity <strong>of</strong> RDX as one <strong>of</strong> the<br />

components in the explosives that he prepared to<br />

bomb Los Angeles International Airport on New<br />

Year's Eve 1999/2000; the combined explosives could<br />

have produced a blast forty times greater than that <strong>of</strong><br />

a devastating car bomb. RDX was main component<br />

used for the 2006 Mumbai train bombings. It was also<br />

believed to be the explosive in the 2010 Moscow<br />

Metro bombings.<br />

Conclusion<br />

<strong>Internationale</strong> Pharmaceutica Sciencia Apr-Jun 2011 Vol 1 Issue 2<br />

Trinitro derivative <strong>of</strong> reduced <strong>triazine</strong> ring is a small<br />

molecule but has tremendous explosive property.<br />

Urotropine is hexamethylene tetramine which is<br />

obtained by bubbling <strong>of</strong> air through the mixture <strong>of</strong><br />

formalin and ammonium hydroxide. This urotropine<br />

is active as urinary tract infection but when it is<br />

16

treated with nitric acid, it gets nitrated to form RDX<br />

and methylene dinitrate which has remarkable<br />

explosive property. The explosive property is approx<br />

9km/sec!<br />

References:<br />

1) Bachmann WE., Sheehan JC. A New Method <strong>of</strong><br />

Preparing the High Explosive RDX, Journal <strong>of</strong> the<br />

American Chemical Society 1949; 71(5): 1842–1845.<br />

2) Gilman H. The Chemistry <strong>of</strong> Explosives, Organic<br />

Chemistry an Advanced Treatise, III, Wiley;<br />

Chapman & Hall, 1953; 985–986.<br />

3) Hale GC. The Nitration <strong>of</strong> Hexamethylenetetramine,<br />

Journal <strong>of</strong> the American Chemical Society 1925;<br />

47(11): 2754–2763.<br />

Pr<strong>of</strong>. Dr. Dhrubo Jyoti Sen et al: Chemistry <strong>of</strong> 1, 3, 5-Trinitroperhydro-1, 3, 5-Triazine<br />

4) Luo KM, Lin SH, Chang JG, Huang TH. Evaluations<br />

<strong>of</strong> kinetic parameters and critical runaway<br />

conditions in the reaction system <strong>of</strong> hexamine-nitric<br />

acid to produce RDX in a non-isothermal batch<br />

reactor, Journal <strong>of</strong> Loss Prevention in the Process<br />

Industries 2002; 15(2): 119–127.<br />

5) Simmons WH, Forster A, Bowden RC. The<br />

Manufacture <strong>of</strong> R.D.X. in Great Britain: Part II –<br />

Raw Materials and Ancillary Processes, The<br />

Industrial Chemist 1948; 24: 530–545.<br />

6) Simmons WH, Forster A, Bowden R. (September<br />

1948), The Manufacture <strong>of</strong> R.D.X. in Great Britain:<br />

Part III – Production <strong>of</strong> the Explosive, The Industrial<br />

Chemist 1948; 24: 593–601.<br />

17 <strong>Internationale</strong> Pharmaceutica Sciencia Apr-Jun 2011 Vol 1 Issue 2