HORIZONTAL DIRECTIONAL DRILLING - Nacap

HORIZONTAL DIRECTIONAL DRILLING - Nacap

HORIZONTAL DIRECTIONAL DRILLING - Nacap

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

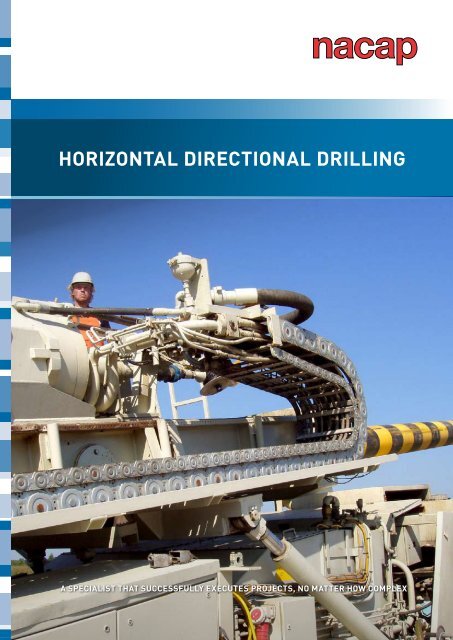

horizontal directional drilling<br />

a specialist that successfully executes projects, no matter how complex

2 w e h a v e th e k n o w l e d g e to h a n d l e y o u r pr o j e c t<br />

no matter how complex<br />

we have the knowledge<br />

to handle your project

<strong>Nacap</strong> is an expert in the field of horizontal directional drilling (HDD).<br />

We have used this specialist technique all over the world, solving the<br />

most difficult challenges. Because of our expertise we always find the<br />

most efficient and economical solution for every drilling problem.<br />

We have extensive knowledge of the industry and experience in the field,<br />

to be able to guarantee professionalism and high quality service. We use<br />

our own modern and well maintained equipment to handle your project.<br />

Benefits of horizontal<br />

directional drilling<br />

We have established ourselves as the<br />

leader in HDD industry. HDD constitutes<br />

an important component of many pipeline<br />

construction projects. For more than<br />

twenty years we have employed this<br />

drilling technique as an environmentally<br />

friendly, safe, realiable and efficient<br />

alternative to conventional construction<br />

methods. Horizontal directional drilling<br />

is more efficient, often more economical,<br />

faster and, above all, has much less<br />

impact on the environment. It is also<br />

widely used in the oil and gas, power<br />

and telecommunications industries for<br />

bringing pipelines and cables ashore or<br />

taking them offshore.<br />

The characteristics of HDD make it the<br />

best solution for many customer needs;<br />

in some cases it provides the only practical<br />

solution. <strong>Nacap</strong> uses horizontal<br />

directional drilling for, among others:<br />

• Waterways<br />

• Nature reserves<br />

• Major roads and traffic junctions<br />

• Railways<br />

• Industrial sites<br />

• Densely populated regions<br />

and urban areas<br />

• Landfalls and outfalls<br />

• Flood plains and bogs<br />

• Unstable soil conditions<br />

• For getting below contaminated<br />

ground.<br />

environmentally friendly<br />

with minimal disturBance<br />

The traditional method of constructing<br />

a pipeline, in which a trench is excavated,<br />

can lead to major obstructions<br />

and objections amongst various authorities<br />

and in different areas. Horizontal<br />

directional drilling avoids breaking open<br />

or causing damage to these areas and<br />

it minimises the impact to the surroundings<br />

of the works.<br />

ThaILaND<br />

sai noi-north/south<br />

Bangkok power plants<br />

gas pipeline project<br />

Installation of 44 crossings by HDD<br />

technology. Total length of 45,000 m<br />

(up to 2 km per crossing). This required<br />

the use of three rigs – one of 180, 275<br />

and 300 tonnes. Major challenges of the<br />

project were the heavy traffic, difficult<br />

access and densely populated and<br />

congested areas.

4 w e h a v e th e ri g h t to o l s fo r th e jo b<br />

no matter how complex<br />

we have the right tools for the job<br />

our specialist equipment -<br />

standard and custom Built<br />

<strong>Nacap</strong>’s success is partly attributable<br />

to the inhouse development and the<br />

use of specialist HDD equipment. Feedback<br />

from projects is integrated in the<br />

design and development of equipment<br />

on a continous basis.<br />

The resulting improvements in effici<br />

ency and safety contribute to environ<br />

mentally friendly and timely project<br />

completion, critical issues for <strong>Nacap</strong>’s<br />

clients.<br />

The rigs used by <strong>Nacap</strong> are purposebuilt<br />

for tropical and remote locations<br />

and feature computer controlled drilling.<br />

With 9 drilling rigs worldwide, we are<br />

able to meet all of our customers'<br />

requirements. We have developed<br />

several drilling machines ourselves.<br />

These machines have a pulling capacity<br />

of up to 400Te.<br />

To date we have completed more than<br />

700 HDD crossings around the world<br />

in all types of ground conditions for<br />

cables & pipes up to 1,200 mm (48”) in<br />

diameter and over 2,000 m.

hdd in steps<br />

• a pilot hole is drilled according to the pro<br />

file design. Directional control is achieved<br />

by using the survey steering tool system.<br />

The survey probe installed in the drilling<br />

assembly measures the survey data required<br />

for steering the drilling tool along<br />

the design profile<br />

• The hole is then enlarged and conditioned<br />

in stages using a sequence of reamers/<br />

flycutters/hole openers to the required<br />

diameter for receiving the product pipe<br />

• The product pipe is then pulled into the<br />

hole by the rig<br />

UNITeD KINgDoM<br />

Barton stacey to<br />

lockerley pipeline project<br />

In this project an HDD of 1,125 meter had<br />

to be constructed under a sensitive<br />

location, the river Test. This river harbours<br />

the famous trout fishing industry and<br />

therefore any chance that drilling mud<br />

would escape into the water had to be<br />

avoided. Thanks to excellent team work,<br />

the HDD crossing was completed with<br />

minimal disturbance to the environment.

6 w e h a v e th e e x p e r i e n c e<br />

no matter how complex<br />

we have the experience<br />

our extensive track record<br />

We give the highest priority to working<br />

safely, transparently and with respect<br />

for our environment. We have a con<br />

vincing track record of successfully<br />

completed projects. These projects<br />

were executed with a level of quality<br />

and professionalism that exceeded our<br />

clients’ expectations.<br />

<strong>Nacap</strong> always works with clients in<br />

order to devise the best solution. In<br />

2008, for instance, <strong>Nacap</strong> success fully<br />

completed a horizontal directional dril<br />

ling shore approach in gresik, east<br />

Java, Indonesia, as part of Kodeco’s<br />

offshore ePCI services for West Ma<br />

dura and Poleng fields. The hDD pipe<br />

string was a 2,000 m long DN400 (16”)<br />

steel gas pipeline with 1” concrete<br />

coating for buoyancy purpose. This<br />

crossing was the longest shore approach<br />

that <strong>Nacap</strong> has completed to<br />

date.<br />

Complex logistics, community issues,<br />

security concerns and strict environmental<br />

procedures were just some of<br />

the issues that confronted <strong>Nacap</strong> during<br />

the West african gas Pipeline project<br />

(WagP) and the BP Tangguh project in<br />

Irian Jaya. Permafrost, marshland,<br />

rock, humidity, densely populated or<br />

remote areas are other conditions under<br />

which projects have been completed.

the landfall method<br />

(onshore option)<br />

• a pilot hole will be drilled from onshore<br />

entry point towards offshore exit point<br />

along a planned profile assisted by down<br />

hole steering tool system<br />

• The drilled hole will be enlarged using a<br />

sequence of reamers/flycutters from<br />

onshore towards offshore<br />

• Product pipestring fabricated onshore will<br />

be pulled through the reamed hole from<br />

onshore towards offshore by a HDD rig<br />

located onboard the drill barge<br />

INDoNesIa<br />

west madura and<br />

poleng field<br />

Installation of a shore approach of a 16”<br />

submarine gas pipeline by horizontal<br />

directional drilling, measuring 2,000 m<br />

in length, as part of the “West Madura<br />

and Poleng Field” project in east Java for<br />

oil & gas operator, Kodeco energy Co Ltd.

w w w .na c a p .c o m<br />

visiting address<br />

<strong>Nacap</strong> b.v.<br />

Machlaan 5<br />

9761 TK Eelde<br />

The Netherlands<br />

mailing address<br />

<strong>Nacap</strong> b.v.<br />

P.O. Box 46<br />

9750 AA Haren<br />

The Netherlands<br />

T +31 (0)50 599 12 00<br />

F +31 (0)50 599 12 22<br />

E info@nacap.com<br />

W www.nacap.com