Historical Perspective of the Heck Reaction

Historical Perspective of the Heck Reaction

Historical Perspective of the Heck Reaction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

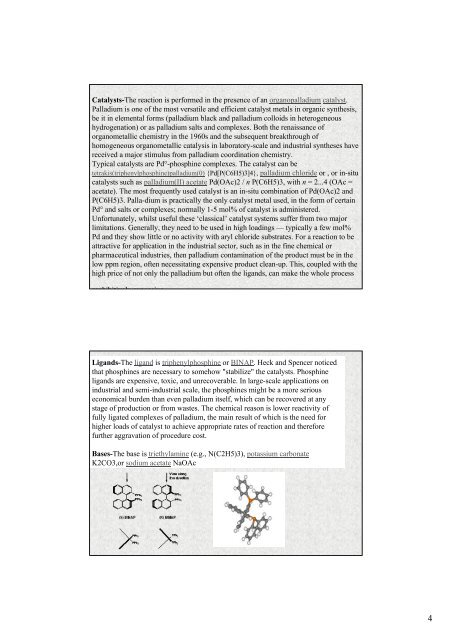

Catalysts-The reaction is performed in <strong>the</strong> presence <strong>of</strong> an organopalladium catalyst.<br />

Palladium is one <strong>of</strong> <strong>the</strong> most versatile and efficient catalyst metals in organic syn<strong>the</strong>sis,<br />

be it in elemental forms (palladium black and palladium colloids in heterogeneous<br />

hydrogenation) or as palladium salts and complexes. Both <strong>the</strong> renaissance <strong>of</strong><br />

organometallic chemistry in <strong>the</strong> 1960s and <strong>the</strong> subsequent breakthrough <strong>of</strong><br />

homogeneous organometallic catalysis in laboratory-scale and industrial syn<strong>the</strong>ses have<br />

received a major stimulus from palladium coordination chemistry.<br />

Typical catalysts are Pd°-phosphine complexes. The catalyst can be<br />

tetrakis(triphenylphosphine)palladium(0) {Pd[P(C6H5)3]4}, palladium chloride or , or in-situ<br />

catalysts such as palladium(II) acetate Pd(OAc)2 / n P(C6H5)3, with n = 2...4 (OAc =<br />

acetate). The most frequently used catalyst is an in-situ combination <strong>of</strong> Pd(OAc)2 and<br />

P(C6H5)3. Palla-dium is practically <strong>the</strong> only catalyst metal used, in <strong>the</strong> form <strong>of</strong> certain<br />

Pd° and salts or complexes; normally 1-5 mol% <strong>of</strong> catalyst is administered.<br />

Unfortunately, whilst useful <strong>the</strong>se ‘classical’ catalyst systems suffer from two major<br />

limitations. Generally, <strong>the</strong>y need to be used in high loadings — typically a few mol%<br />

Pd and <strong>the</strong>y show little or no activity with aryl chloride substrates. For a reaction to be<br />

attractive for application in <strong>the</strong> industrial sector, such as in <strong>the</strong> fine chemical or<br />

pharmaceutical industries, <strong>the</strong>n palladium contamination <strong>of</strong> <strong>the</strong> product must be in <strong>the</strong><br />

low ppm region, <strong>of</strong>ten necessitating expensive product clean-up. This, coupled with <strong>the</strong><br />

high price <strong>of</strong> not only <strong>the</strong> palladium but <strong>of</strong>ten <strong>the</strong> ligands, can make <strong>the</strong> whole process<br />

prohibitively expensive<br />

Ligands-The ligand is triphenylphosphine or BINAP. <strong>Heck</strong> and Spencer noticed<br />

that phosphines are necessary to somehow "stabilize" <strong>the</strong> catalysts. Phosphine<br />

ligands are expensive, toxic, and unrecoverable. In large-scale applications on<br />

industrial and semi-industrial scale, <strong>the</strong> phosphines might be a more serious<br />

economical burden than even palladium itself, which can be recovered at any<br />

stage <strong>of</strong> production or from wastes. The chemical reason is lower reactivity <strong>of</strong><br />

fully ligated complexes <strong>of</strong> palladium, <strong>the</strong> main result <strong>of</strong> which is <strong>the</strong> need for<br />

higher loads <strong>of</strong> catalyst to achieve appropriate rates <strong>of</strong> reaction and <strong>the</strong>refore<br />

fur<strong>the</strong>r aggravation <strong>of</strong> procedure cost.<br />

Bases-The base is triethylamine (e.g., N(C2H5)3), potassium carbonate<br />

K2CO3,or sodium acetate NaOAc<br />

4