Radial Drilling Machines - Weiler Werkzeugmaschinen GmbH

Radial Drilling Machines - Weiler Werkzeugmaschinen GmbH

Radial Drilling Machines - Weiler Werkzeugmaschinen GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3110<br />

4390<br />

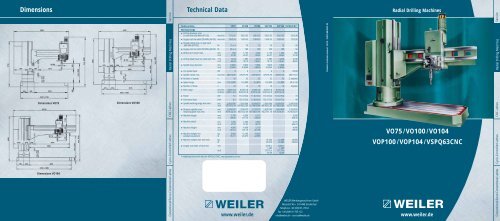

Dimensions Technical Data<br />

<strong>Radial</strong> <strong>Drilling</strong> <strong>Machines</strong><br />

970 315 386<br />

700<br />

510<br />

555<br />

420<br />

3690<br />

3240 x 1120<br />

Dimensions VO75<br />

(6210)<br />

1050 470 530 3470<br />

4000<br />

min. 710<br />

min. 473<br />

5350 x 1800<br />

1614<br />

2310<br />

Ø 100<br />

Ø 110<br />

4095<br />

Dimensions VO104<br />

1120<br />

400<br />

541<br />

475<br />

260 380<br />

350 max. 2720<br />

max. 2000<br />

max. 5130<br />

max. 4090<br />

3810<br />

878 442 580<br />

615<br />

550<br />

4320<br />

min. 570<br />

Ø 110<br />

3680 x 1400<br />

1985<br />

2565<br />

2515<br />

Dimensions VO100<br />

1120<br />

400<br />

541<br />

475<br />

max. 2200<br />

300<br />

max. 4600<br />

Service<br />

Conventional/Servo-Conventional Lathes Cycle-Controlled Lathes CNC Lathes<br />

<strong>Radial</strong> <strong>Drilling</strong> <strong>Machines</strong><br />

Technical Data VO75 VO100 VO104 VOP100 VOP104 VSPQ63CNC*<br />

Working Range<br />

<strong>Drilling</strong> diameter max.<br />

in steel with 600 MPa (87 KSI) mm/inch 75/2.95 100/3.93 100/3.93 100/3.93 100/3.93 63/2.48<br />

In gray cast iron with 250 MPa (36 KSI)<br />

Thread cutting max. in steel with<br />

mm/inch 90/3.54 110/4.33 110/4.33 110/4.33 110/4.33 75/2.95<br />

600 MPa (87 KSI) M 75 x 4 76 76 76 76 42<br />

In gray cast iron with 250 MPa (36 KSI) M 85 x 4 100 100 100 100 56<br />

Vertical arm travel max. mm 950 1,155 1,535 1,155 1,535 800<br />

inch 37.40 45.47 60.43 45.47 60.43 31.49<br />

<strong>Drilling</strong> head travel on radial arm max. mm 1,614 1,985 3,470 1,985 3,470 2,180<br />

inch 63.54 78.15 136.61 78.15 136.61 85.82<br />

Spindle nose diameter mm 100h6 110h6 110h6 110h6 110h6<br />

inch 3.93h6 4.83h6 4.83h6 4.83h6 4.83h6<br />

I.D. spindel taper MT 5 6 6 6 6 ISO40<br />

Spindle stroke max. mm/inch 380/14.96 475/18.70 475/18.70 475/18.70 475/18.70 300/11.81<br />

Number of speeds n 16 32 32 32 32 2, stepless<br />

Speed range rpm 11.2-2,000 9-2,800 9-2,800 9-2,800 9-2,800 20-3,150<br />

Number of feeds n 16 16 16 16 16 stepless<br />

Feed range mm/rev. 0.035-2.8 0.035-2.8 0.035-2.8 0.035-2.8 0.035-2.8<br />

inch/rev. 0.0013-2.8 0.0013-2.8 0.0013-2.8 0.0013-2.8 0.0013-2.8<br />

Power kW 7.5 11.0 (15.0) 11.0 (15.0) 11.0 (15.0) 11.0 (15.0) 15<br />

Connected load kVA 9.3 12.8 (16.8) 12.8 (16.8) 13.6 (17.6) 13.6 (17.6) 40<br />

Spindle working range max./min. mm<br />

inch<br />

2,000/386 2,565/580 4,000/530 2,565/580 4,000/530<br />

78.74/15.19 100.98/22.83 157.48/20.86 100.98/22.83 157.48/20.86<br />

2,680/500<br />

105.51/19.68<br />

Distance spindle nose/ mm 2,000/570 2,200/570 2,720/710 2,420/790 2,940/930 1,935/835<br />

mounting plate max./min. inch 78.74/22.44 86.61/22.44 107.08/27.95 95.27/31.10 115.74/36.61 76.18/32.87<br />

Machine length mm 3,700 4,500 6,210 9,280<br />

inch 145.66 177.16 244.49 365.35<br />

Machine width mm 1,456 1,456 2,050 6,775<br />

inch 57.32 57.32 80.70 266.73<br />

Machine height mm 4,090 4,600 5,130 4,040<br />

inch 161.02 181.10 201.96 159.06<br />

Machine weight incl. kg 6,900 12,100 19,500<br />

standard equipment lb 15.211 26.675 42.990<br />

Machine weight with two beds kg 16,500 22,400 18,000<br />

lb 36.876 49.383 39.683<br />

Length and width of each bed mm 3,500 x 3,500 x<br />

1,280 1,280<br />

inch 137.79 x 137.79 x<br />

50.39 50.39<br />

* Additional technical data for VSPQ 63 CNC, see separate brochure<br />

www.weiler.de<br />

Technical variations reserved · 03/12 · 5.0915.08.90.01.02<br />

VO75 /VO100 /VO104<br />

VOP100 /VOP104 /VSPQ63CNC<br />

WEILER <strong>Werkzeugmaschinen</strong> <strong>GmbH</strong><br />

Mausdorf 46 • D-91448 Emskirchen<br />

Telephone +49 (0)9101-705-0<br />

Fax +49 (0)9101-705-122<br />

info@weiler.de • service@weiler.de www.weiler.de<br />

Service<br />

Conventional/Servo-Conventional Lathes Cycle-Controlled Lathes CNC Lathes<br />

<strong>Radial</strong> <strong>Drilling</strong> <strong>Machines</strong>

<strong>Radial</strong> <strong>Drilling</strong> <strong>Machines</strong><br />

Machine frame<br />

The main components of the machine frame are<br />

made from high quality gray cast iron. The base<br />

has a large surface for mounting work pieces,<br />

tables or fixtures. All housing and radial arm<br />

guides are hardened and ground. The opposite<br />

surfaces are scraped.<br />

Automatic swivelling of the machine<br />

column<br />

The machine column can be swivelled manually<br />

or automatically. Automatic swivelling is controlled<br />

by a direction controller on the control panel.<br />

Releasing the direction controller will automatically<br />

activate the brake.<br />

A separate brake release must be activated for the<br />

machine column to be swivelled manually.<br />

Headstock and drive<br />

The headstock is made from gray cast iron and is<br />

equipped with an adjustable quill. The spindle is<br />

hardened, runs in lifetime lubricated precision<br />

bearings and is known for its high truth and<br />

smooth operation. A hydromechanical stop locks<br />

the headstock on the radial arm.<br />

The gear steps, spindle speeds and feeds can be<br />

selected on the control panel and shifted by means<br />

of the spindle start lever. The drilling depth is set<br />

with a revolving deephole scale and a positive<br />

stop. The allowable drilling capacity is monitored<br />

by a safety feed clutch to avoid machine overloads.<br />

A start-up clutch provides a smooth and gentle<br />

spindle start. A magnetic brake on the shaft below<br />

the drive motor slows down and stops the main<br />

spindle.<br />

Automatic movement of the headstock<br />

This automatic function supports the operator in<br />

moving the headstock. The desired travel direction<br />

is selected by means of a direction control lever.<br />

The accurate adjustment for the exact position is<br />

done with the handwheel.<br />

Machine with traveling column<br />

The drilling machine types VO100 / VO104 / VOP100 /<br />

VOP104 can be delivered with a traveling spindle<br />

slide mounted on the stable machine bed.<br />

The standard slide travel is 4,500 mm (14‘9“) and<br />

can be lengthened by an additional 3,500 mm<br />

(11‘6“).<br />

Even models with multiple drilling units are<br />

available.<br />

Electrical equipment<br />

The clearly laid out operator panel<br />

with emergency stop switch and<br />

locking device switch is mounted on<br />

the machine housing.<br />

The electrical system is built in accordance<br />

with EN 60 204-1. The operating<br />

voltage is 3 x 400 V / 50 Hz.<br />

The main drive is monitored by an<br />

overload relay and thermistors.<br />

Standard accessories<br />

Pushout wedges<br />

Oil can<br />

Groove cleaner<br />

Lighting<br />

Operating keys<br />

Machine transport equipment<br />

Operating manual<br />

Extra accessories<br />

Clamping fixtures<br />

Operator and maintenance platform<br />

Coolant attachment<br />

Cube table VB8<br />

Tilting table VC8<br />

Machine vise 160 mm<br />

Spindle reduction sleeves<br />

Application fields<br />

Numerically controlled radial drilling<br />

machine VSPQ 63 CNC with 4-axis control,<br />

automatic tool changer and tool storage<br />

for 24 tools.<br />

Optional machine version<br />

As per agreement with the customer<br />

Execution in inch system<br />

Electrical system according to customer<br />

specifications, 400 V, 50 Hz<br />

Special paint<br />

Tropical execution<br />

The work pieces are clamped onto cast iron<br />

clamping plates.<br />

The number and combinations can be selected<br />

according to customer specification and<br />

the necessary technology.<br />

Cube table VB8<br />

Top mounting surface: 1,000 x 700 mm<br />

(39 3/8“ x 27 1/2“)<br />

Side mounting surface: 1,000 x 500 mm<br />

(39 3/8“ x 19 5/8“)<br />

Weight: 410 kg (905 lbs)<br />

Tilting table VC8<br />

Top mounting surface: 750 x 600 mm<br />

(29 1/2“ x 23 5/8“)<br />

Side mounting surface: 750 x 550 mm<br />

(29 1/2“ x 21 5/8“)<br />

Weight: 420 kg (930 lbs)