You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Winkhaus</strong> UK Ltd<br />

2950 Kettering Parkway, Kettering,<br />

Northants NN15 6XZ<br />

Tel: +44 (0)1536 316091<br />

Fax: +44 (0)1536 419091<br />

www.winkhaus.co.uk<br />

email: enquiries@winkhaus.co.uk<br />

<strong>Winkhaus</strong> <strong>VS6</strong><br />

Master Keyed Profile Cylinders<br />

The preferred choice.<br />

in<br />

Doors

<strong>Winkhaus</strong> <strong>VS6</strong> Master Keyed Profile Cylinders<br />

The preferred choice.<br />

Whenever choosing a Master Key System, 3 elements are critical<br />

to the successful selection and implementation of that new system.<br />

They are...<br />

1. Durability<br />

Is the cylinder, key and actual design of the system to such a<br />

standard that it will continue to perform at the highest level, day in<br />

- day out?<br />

2. Security<br />

Is the system good enough to not only restrict known persons gaining<br />

access internally but also prevent unauthorised external entry?<br />

3. Flexibility<br />

Will the master key system be able to grow over time in the same<br />

way that the end users needs increase and can the cylinder supplier<br />

fulfil these needs quickly?<br />

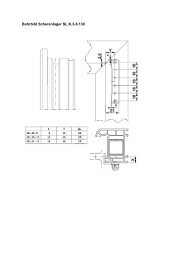

Housing pins<br />

Core pins<br />

Circlip<br />

Housing and finishes<br />

Coupling<br />

Cam<br />

Lateral pins<br />

Springs<br />

The <strong>Winkhaus</strong> <strong>VS6</strong> cylinder is made using only high quality raw<br />

materials. These are then made into the various components needed<br />

to make each cylinder in our state of the art manufacturing plant.<br />

German engineering is used to guarantee the precise tolerances that<br />

are essential when making our profile cylinder. There is absolutely no<br />

margin for error.<br />

In continual tests the <strong>VS6</strong> still functions perfectly after 250,000<br />

operations (exceeding Grade 5 BS EN 1303 Standard). It is<br />

considered that this is the equivalent of over 200 years operation!<br />

The <strong>Winkhaus</strong> Key is plated with nickel silver. When used its metallic<br />

properties act as a lubricant to the cylinder. The base metal of the key<br />

is hardened steel to maximise its strength. The key bow is designed<br />

to make turning the key much easier especially for the elderly and<br />

arthritic.<br />

Core<br />

Core armouring and<br />

special options<br />

Braille Pads<br />

Multi Key Profiles<br />

All <strong>Winkhaus</strong> <strong>VS6</strong> cylinders use multi profile<br />

technology. This means that if one master key<br />

is lost then the security of the whole system<br />

is not compomised. All these profiles are<br />

protected by patents.<br />

Internal Pins<br />

Inside all <strong>VS6</strong> cylinders the first set of pins are<br />

made of hardened steel for drill protection. All<br />

other pins are made of hardened bronze. Also<br />

anti pick pins are used to make the cylinder<br />

virtually tamper proof.<br />

Lateral Pins<br />

As well as the 6 vertical pins the <strong>Winkhaus</strong> <strong>VS6</strong><br />

also incorporates up to 10 lateral pins. These<br />

not only increase the security of the cylinder<br />

against picking they allow up to 24,000,000<br />

possible differs.<br />

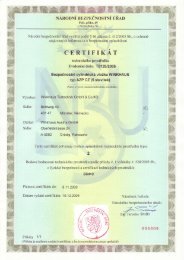

Security Cards<br />

Every new <strong>Winkhaus</strong> <strong>VS6</strong> system that is<br />

produced is issued with a unique security<br />

card. Whenever replacement keys or cylinders<br />

are needed this MUST be shown for the order<br />

to be processed.<br />

Cylinder Armoring<br />

All <strong>Winkhaus</strong> <strong>VS6</strong> cylinder can be supplied<br />

with our DA option which offers a hardened<br />

steel core and housing armouring. This protects<br />

against drilling, twisting and pulling to Grade 5<br />

BS EN 1303.<br />

Variety of Types<br />

As well as being durable and secure <strong>Winkhaus</strong><br />

cylinders also boast one other important<br />

element - compatability. All our cylinders have<br />

been designed to fit into the industry standard<br />

and most popular architectural hardware. The<br />

large selection that we offer inludes both Euro<br />

and British Oval profiles.<br />

Alternative Turns<br />

The <strong>Winkhaus</strong> <strong>VS6</strong> thumbturn cylinder is<br />

available using a variety of different turns.<br />

These have been specially designed to cater<br />

for different applications. New designs are<br />

constantly being developed. These turns are<br />

available in Nickel Plated and Matt Brass as<br />

standard with other finishes to order.<br />

Whenever an inquiry for a <strong>Winkhaus</strong> <strong>VS6</strong><br />

system is made there are people available on<br />

the phone dedicated to master keying. They<br />

will talk a customer through the requirements<br />

of their new system step by step.<br />

When all the details are clear a custom designed<br />

structure plan and keyplan are prepared and<br />

sent to the customer - usually within one hour.<br />

The structure plan is an easy to understand<br />

graphical representation of the system which is<br />

complemented by the more technical keyplan.<br />

When all parties agree that the system has been<br />

designed correctly this is confirmed by returning<br />

a signed copy of the customer keyplan. The<br />

system is then manufactured.<br />

After the system has been designed it is then<br />

sent into production in our purpose built<br />

premises.<br />

1) Using specialised software the system coding is inputted into a<br />

central computer which checks all the details to ensure they are<br />

correct.<br />

2) This data is then sent to the different machines and the keys are<br />

made.<br />

3) The key undergoes various tests to ensure that it meets the strict<br />

guidelines in quality that have been laid down.<br />

4) The cylinders are then assembled. The operator once again checks<br />

the system as it is made.<br />

5) Then, when the whole system is completed a fourth and final<br />

check is carried out to make sure that it is totally correct.<br />

By implementing these checking procedures the quality and reliability<br />

of the <strong>Winkhaus</strong> <strong>VS6</strong> is such that mistakes are virtually<br />

impossible.