CHILLED FOOD

CHILLED FOOD

CHILLED FOOD

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NEUTRAL SERVICES<br />

<strong>CHILLED</strong> <strong>FOOD</strong><br />

How to keep your warehouse cool without warming the planet<br />

DHL Neutral Services was engaged by a large chilled food distribution centre in the east<br />

of England to analyse the operation’s carbon footprint and create recommendations for<br />

the reduction of its carbon emissions and related operational cost savings.<br />

Background<br />

The DHL-owned site, situated close to<br />

the motorway, is managed on behalf of<br />

a major food manufacturer, to deliver<br />

chilled food goods to supermarket<br />

distribution centres in southern and<br />

central England. Over 30 million cases<br />

pass through the warehouse every year.<br />

Goods are transported to the site from<br />

either the manufacturer’s local factory,<br />

using two shuttle tractor-and-trailers, or<br />

from third-party suppliers. The site also<br />

uses a tug unit for moving these trailers,<br />

and fuel for these vehicles is stored on<br />

site. All onward distribution to customers<br />

is via third-party haulage, and an onsite<br />

transport manager liaises with the<br />

30-40 carriers used. The site consists of<br />

a 15,000m2 fully chilled warehouse and<br />

operates 24 hours a day, 7 days a week,<br />

employing around 135 staff per shift and<br />

utilising 41 items of electrically powered<br />

mechanical handling equipment (MHE).<br />

The site also acts as a despatch centre<br />

for waste goods that have passed their<br />

‘distribute by’ date or failed qualitycontrol<br />

testing.<br />

Assess<br />

As the fi rst step in DHL Neutral<br />

Services’ comprehensive process, the<br />

site completed a Carbon Footprint<br />

Assessment (CFA) in July 2007 using<br />

DHL Neutral Services’ web-based<br />

tool to calculate its overall carbon<br />

emissions and their source. Following<br />

this, in November 2007, DHL Neutral<br />

Services sent a Carbon Action Team to<br />

conduct detailed on-site data collection<br />

and evaluation of all construction,<br />

engineering, power consumption and<br />

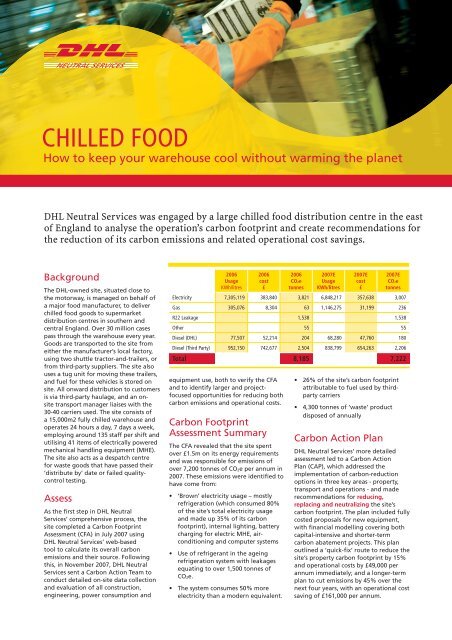

2006<br />

Usage<br />

KWh/litres<br />

2006<br />

cost<br />

£<br />

equipment use, both to verify the CFA<br />

and to identify larger and projectfocused<br />

opportunities for reducing both<br />

carbon emissions and operational costs.<br />

Carbon Footprint<br />

Assessment Summary<br />

The CFA revealed that the site spent<br />

over £1.5m on its energy requirements<br />

and was responsible for emissions of<br />

over 7,200 tonnes of CO2e per annum in<br />

2007. These emissions were identifi ed to<br />

have come from:<br />

• ‘Brown’ electricity usage – mostly<br />

refrigeration (which consumed 80%<br />

of the site’s total electricity usage<br />

and made up 35% of its carbon<br />

footprint), internal lighting, battery<br />

charging for electric MHE, airconditioning<br />

and computer systems<br />

• Use of refrigerant in the ageing<br />

refrigeration system with leakages<br />

equating to over 1,500 tonnes of<br />

CO2e.<br />

• The system consumes 50% more<br />

electricity than a modern equivalent.<br />

2006<br />

CO2e<br />

tonnes<br />

2007E<br />

Usage<br />

KWh/litres<br />

2007E<br />

cost<br />

£<br />

• 26% of the site’s carbon footprint<br />

attributable to fuel used by thirdparty<br />

carriers<br />

• 4,300 tonnes of ‘waste’ product<br />

disposed of annually<br />

Carbon Action Plan<br />

2007E<br />

CO2e<br />

tonnes<br />

Electricity 7,305,119 383,840 3,821 6,848,217 357,638 3,007<br />

Gas 305,076 8,304 63 1,146,275 31,199 236<br />

R22 Leakage 1,538 1,538<br />

Other 55 55<br />

Diesel (DHL) 77,507 52,214 204 68,280 47,760 180<br />

Diesel (Third Party) 952,150 742,677 2,504 838,799 654,263 2,206<br />

Total 8,185 7,222<br />

DHL Neutral Services’ more detailed<br />

assessment led to a Carbon Action<br />

Plan (CAP), which addressed the<br />

implementation of carbon-reduction<br />

options in three key areas - property,<br />

transport and operations - and made<br />

recommendations for reducing,<br />

replacing and neutralizing the site’s<br />

carbon footprint. The plan included fully<br />

costed proposals for new equipment,<br />

with fi nancial modelling covering both<br />

capital-intensive and shorter-term<br />

carbon abatement projects. This plan<br />

outlined a ‘quick-fi x’ route to reduce the<br />

site’s property carbon footprint by 15%<br />

and operational costs by £49,000 per<br />

annum immediately; and a longer-term<br />

plan to cut emissions by 45% over the<br />

next four years, with an operational cost<br />

saving of £161,000 per annum.

Quick Gains<br />

Reduce<br />

DHL Neutral Services recommended<br />

that carbon footprint and operational<br />

cost reductions were to be achieved<br />

through: a) replacement of all current<br />

high-pressure sodium internal lighting<br />

with lower temperature Amalgam<br />

fl uorescent-based tubes to provide<br />

better-quality lighting, operational<br />

cost savings of £14,000 per annum<br />

and a carbon emissions saving of<br />

144 CO2e tonnes; b) installation of a<br />

heating control system in the front<br />

offi ce area to amalgamate heating<br />

and air-conditioning together into a<br />

single system for effi cient environment<br />

control, to save around £3,000 and 31<br />

tonnes of CO2e per year; c) installation.<br />

of voltage-optimising on the site’s 1500<br />

kVA transformers to optimise incoming<br />

voltage, potentially saving £32,000 of<br />

energy costs and 310 tonnes of CO2e.<br />

Together these reduction strategies<br />

will deliver a 15% site property carbon<br />

footprint reduction and a saving<br />

over £49,000 of operational costs,<br />

with payback in 4 years. All these<br />

technologies are to be fully effective<br />

within seven months of project<br />

instigation.<br />

Further effi ciencies could also be<br />

delivered by an in-depth network<br />

optimisation study to look at potential<br />

improvements in third-party carrier<br />

selection and management, and<br />

increasing backhauling effi ciencies in<br />

order to minimise cost and maximise<br />

carbon savings.<br />

Capital (£) Saving (£)<br />

per annum<br />

CO2e Saving<br />

(with green tariff)<br />

CO2e Saving<br />

(without green tariff)<br />

Despite recent improvements in the area<br />

of waste disposal management – costing<br />

the site around £5m per year for<br />

disposal of over 4,500 tonnes of waste –<br />

additional cost and carbon savings could<br />

also be made: fi rst, through greater<br />

effi ciency and speed in the supply chain,<br />

involving better order-tracking and<br />

use of early warning systems for any<br />

changes; and second, by advances in<br />

disposal methods and routing.<br />

However, the most the most critical<br />

action identifi ed by DHL Neutral Services<br />

in reducing the carbon footprint and<br />

operational cost of the site, was the<br />

urgent replacement of the current<br />

ineffi cient refrigeration systems with<br />

a zero or minimal global warming<br />

potential (GWP) refrigerant equivalent.<br />

This would be in advance of EU<br />

legislation banning the use of certain<br />

refrigerants by 2014, and would deliver<br />

considerable cost and carbon benefi ts.<br />

Initiating the change immediately,<br />

ahead of the deadline, would reduce<br />

the site carbon footprint by 45% and<br />

save £161,000 of operational costs per<br />

year in terms of both maintenance<br />

of the old system and ineffi cient use<br />

of electricity. The project could be<br />

completed in around 18 months and the<br />

capital cost estimate obtained by DHL<br />

Neutral Services was £400,000 lower<br />

than the previous competitive tender.<br />

Other factors in the decision to proceed<br />

included the potential negative publicity<br />

issues surrounding the use of certain<br />

refrigerants and its leakage rates, the<br />

possibility of a complete system failure,<br />

and the increasing cost of maintenance<br />

during the UK’s ever-warmer summer<br />

months.<br />

Replace<br />

Payback<br />

period<br />

(years) Other benefi ts<br />

Voltage Optimising - 1500 kVA 96,888 31,569 0 310 3.1 Improved power quality<br />

Heating Management System 14,268 3,000 31 31 4.8 Energy usage visability<br />

Amalgam Lighting 83,180 14,000 0 144 5.9 Improved lighting quality<br />

Total 194,336 48,569 31 485 4<br />

Assess<br />

Reduce<br />

Neutralize<br />

Replace<br />

����������<br />

�����������������<br />

DHL Neutral Services<br />

Contact Us<br />

If you would like more details of how we can<br />

help reduce your carbon footprint, please<br />

contact DHL Neutral Services Ltd. by phone<br />

or email:<br />

Telephone: + 44 (0)1344 428128<br />

Email: enquiries@theneutralgroup.com<br />

DHL Neutral Services instigated the<br />

switch of the site’s electrical supply to<br />

DHL’s own 100% sustainable electricity<br />

until November 2008. This will result in<br />

a cost saving of £21,000 and deliver a<br />

carbon saving of 3,500 CO2e tonnes.<br />

Given the high energy usage of the site,<br />

a wind turbine would be an attractive<br />

replacement strategy. DHL Neutral<br />

Services performed an initial feasibility<br />

study into potential for a wind turbine<br />

on site. Given the tight site boundaries,<br />

locality of housing and a low wind speed<br />

data, DHL Neutral Services classifi ed this<br />

site as not feasible for a wind turbine.<br />

Neutralize<br />

DHL Neutral Services recommends<br />

the use of neutralization through<br />

the purchase of Certifi ed Emission<br />

Reduction certifi cates only after the<br />

implementation of all appropriate<br />

reduction and replacement strategies.<br />

After adoption of the short termmeasures,<br />

the current cost to this site<br />

of neutralizing their remaining carbon<br />

emissions would be £59,000. Following<br />

installation of the new refrigeration<br />

system, these costs would drop to<br />

£32,000.<br />

DHL Neutral Services is an in-house carbon-consultancy practice established to<br />

accelerate the commitment of business operations to reduce carbon emissions.<br />

Our mission is to create and execute greenhouse gas reduction strategies<br />

exclusively for DHL and our customers by assessing, reducing, replacing and in<br />

some cases neutralizing direct and indirect CO2e emissions.<br />

We achieve this by means of projects that provide short-term fi nancial return or<br />

can be fi nanced with minimal operational impact to a client site.<br />

We offer a range of services and solutions including carbon supply-chain<br />

consultancy, emission-reduction plans and Carbon Reduction Implementation<br />

Programmes.<br />

DHL Neutral Services Ltd.<br />

Ocean House<br />

The Ring<br />

Bracknell<br />

Berkshire RG12 1AN<br />

United Kingdom<br />

www.theneutralgroup.com<br />

Printed on recycled, FSC certifi ed<br />

paper using vegetable based inks.