Trendsetter 800 II Trendsetter 800 II Quantum ... - Bob Weber, Inc.

Trendsetter 800 II Trendsetter 800 II Quantum ... - Bob Weber, Inc.

Trendsetter 800 II Trendsetter 800 II Quantum ... - Bob Weber, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

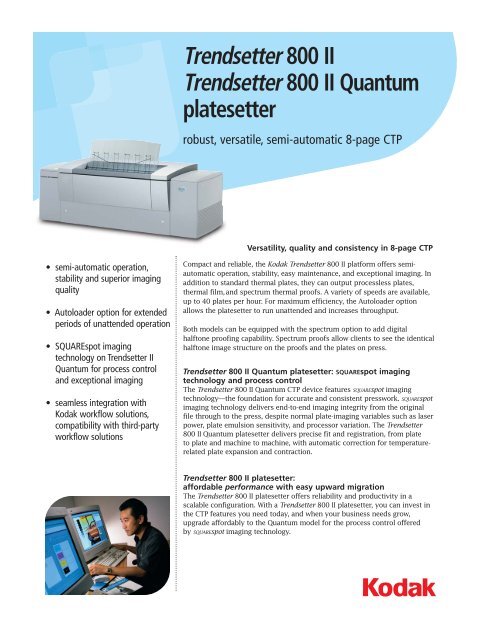

• semi-automatic operation,<br />

stability and superior imaging<br />

quality<br />

• Autoloader option for extended<br />

periods of unattended operation<br />

• SQUAREspot imaging<br />

technology on <strong>Trendsetter</strong> <strong>II</strong><br />

<strong>Quantum</strong> for process control<br />

and exceptional imaging<br />

• seamless integration with<br />

Kodak workflow solutions,<br />

compatibility with third-party<br />

workflow solutions<br />

Trendse ter <strong>800</strong> <strong>II</strong><br />

Trendse ter <strong>800</strong> <strong>II</strong> <strong>Quantum</strong><br />

platesetter<br />

robust, versatile, semi-automatic 8-page CTP<br />

Versatility, quality and consistency in 8-page CTP<br />

Compact and reliable, the Kodak <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> platform offers semiautomatic<br />

operation, stability, easy maintenance, and exceptional imaging. In<br />

addition to standard thermal plates, they can output processless plates,<br />

thermal film, and spectrum thermal proofs. A variety of speeds are available,<br />

up to 40 plates per hour. For maximum efficiency, the Autoloader option<br />

allows the platesetter to run unattended and increases throughput.<br />

Both models can be equipped with the spectrum option to add digital<br />

halftone proofing capability. Spectrum proofs allow clients to see the identical<br />

halftone image structure on the proofs and the plates on press.<br />

<strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> <strong>Quantum</strong> platesetter: SQUAREspot imaging<br />

technology and process control<br />

The <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> <strong>Quantum</strong> CTP device features SQUAREspot imaging<br />

technology—the foundation for accurate and consistent presswork. SQUAREspot<br />

imaging technology delivers end-to-end imaging integrity from the original<br />

file through to the press, despite normal plate-imaging variables such as laser<br />

power, plate emulsion sensitivity, and processor variation. The <strong>Trendsetter</strong><br />

<strong>800</strong> <strong>II</strong> <strong>Quantum</strong> platesetter delivers precise fit and registration, from plate<br />

to plate and machine to machine, with automatic correction for temperaturerelated<br />

plate expansion and contraction.<br />

<strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> platesetter:<br />

affordable performance with easy upward migration<br />

The <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> platesetter offers reliability and productivity in a<br />

scalable configuration. With a <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> platesetter, you can invest in<br />

the CTP features you need today, and when your business needs grow,<br />

upgrade affordably to the <strong>Quantum</strong> model for the process control offered<br />

by SQUAREspot imaging technology.

Trendse ter <strong>800</strong> <strong>II</strong> / Trendse ter <strong>800</strong> <strong>II</strong> <strong>Quantum</strong> platesetter<br />

robust, versatile, semi-automatic 8-page CTP<br />

Protect your investment with an easy upgrade path<br />

As your business grows, your <strong>Trendsetter</strong> platesetter<br />

can grow with you. You can upgrade a <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong><br />

platesetter to a <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> <strong>Quantum</strong> platesetter.<br />

Both <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> platesetter models can be<br />

*Spectrum and Autoloader are not available together<br />

(cont.)<br />

upgraded in performance by increasing<br />

the imaging speed and adding the Autoloader. And the<br />

spectrum halftone proofing option can be added, for<br />

perfectly matched digital proofs.<br />

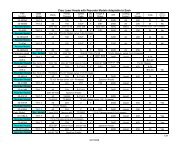

<strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> / <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> <strong>Quantum</strong> platesetter Product Specifications<br />

General Specifications<br />

Technology<br />

Load/unload systems<br />

Spectrum proofing*<br />

Chemical-free plate imaging<br />

Performance<br />

Imaging time, based on maximum media size<br />

(depends on media sensitivity; based on<br />

1030 mm / 40.5 in plate width)<br />

Throughput, without Autoloader<br />

Throughput, with Autoloader*<br />

Repeatability<br />

Accuracy<br />

Registration<br />

Workflow connectivity<br />

<strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> <strong>Quantum</strong> platesetter <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> platesetter<br />

830 nm thermal imaging platesetter, semi-automatic, external drum<br />

Semi-automatic, automatic loading available with Autoload option, up to 50 plates (without interleaf)<br />

Option<br />

Option<br />

S speed: 3.2 min<br />

F speed: 2 min<br />

V speed: 1.25 min<br />

X speed: 1.12 min<br />

S speed: 15 plates per hr<br />

F speed: 22 plates per hr<br />

V speed: 30 plates per hr<br />

X speed: 35 plates per hr<br />

S speed: 16 plates per hr<br />

F speed: 24 plates per hr<br />

V speed: 34 plates per hr<br />

X speed: 38 plate per hr with C/L,<br />

40 plates per hr with A/L<br />

± 2.5 microns (5 microns in total) between two plates imaged by the same platesetter (at large plate<br />

size)<br />

± 10 microns (20 microns in total) between two plates imaged by different <strong>Trendsetter</strong> platesetters,<br />

maximum format (for plates imaged on the same model platesetter using the same imaging<br />

technology; <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong>: at constant temperature)<br />

± 12.5 microns (25 microns in total) between image and edge (at largest plate size)<br />

Kodak Brisque workflow system<br />

Kodak Prinergy workflow system<br />

Connection to third-party workflow systems<br />

Option<br />

Option<br />

S speed: 3.2 min<br />

F speed: 2 min<br />

V speed: 1.25 min<br />

X speed: 1.12 min<br />

S speed: 15 plates per hr<br />

F speed: 22 plates per hr<br />

V speed: 30 plates per hr<br />

X speed: 35 plates per hr<br />

S speed: 16 plates per hr<br />

F speed: 24 plates per hr<br />

V speed: 34 plates per hr<br />

X speed: 38 plate per hr with C/L, 40 plates per<br />

hr with A/L<br />

2

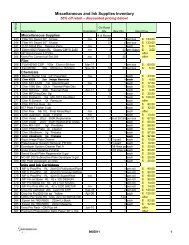

<strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> / <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> <strong>Quantum</strong> platesetter Product Specifications<br />

cont’d<br />

Imaging Specifications<br />

Resolution<br />

Screening<br />

Maximum image area, around drum x along<br />

drum<br />

Maximum image area with Autoloader, around<br />

drum x along drum<br />

Media Specifications<br />

Media type<br />

Plate sizes: Along drum x around drum,<br />

without Autoloader<br />

Plate sizes: Along drum x around drum,<br />

with Autoloader*<br />

Media thickness<br />

Physical Specifications<br />

Operating environment<br />

Temperature<br />

Humidity<br />

Electrical requirements<br />

Voltage and current<br />

Power<br />

Standards conformance<br />

Electrical/mechanical<br />

Laser<br />

Electro Magnetic Compatibility<br />

Physical Characteristics<br />

Size (HxWxD), without Autoloader<br />

Size (HxWxD), with Autoloader<br />

96 dpmm (2,400 dpi)<br />

450 lpi max. linescreen<br />

Staccato 20 series screen sets<br />

option: Staccato 10 series screen sets<br />

824 x 1,143 mm (32.46 x 45 in)<br />

799 x 1,118 mm (31.46 x 44 in)<br />

Thermal IR-sensitive aluminum plate, 830 nm<br />

Thermal IR-sensitive film, 830 nm<br />

Min: 229 x 305 mm (9 x 12 in)<br />

Max: 1,143 x 838 mm (45 x 33 in)<br />

Min: 394 x 521 (15.5 x 20.5 in)<br />

Max: 1,118 x 813 mm (32 x 44 in)<br />

Plates: 0.15 to 0.40 mm (6 to 16 mil)<br />

Film: 0.18 mm (7 mil) min<br />

17 to 30°C (63 to 86°F)<br />

20 to 70% relative humidity (non-condensing)<br />

200 to 240 VAC (+6% / -10%)<br />

20A<br />

CSA 950/UL 1950, EN 60950/IEC 950<br />

<strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> devices are class 1 laser products and fully comply with EN 60825-1 and US Federal<br />

Regulations 21 CFR 1040.10 - CDRH.<br />

FCC Part 15 (Class A); EN 55022/CISPR-22 (Class A); EN 55082-2/EIC 1000-4-2, 1000-4-3, 1000-4-4,<br />

1000-4-6, 1000-4-8<br />

914 x 2,743 x 1,092 mm (36 x 108 x 43 in)<br />

1,575 x 2,743 x 1,092 mm (62 x 108 x 43 in)<br />

*In Manual Bypass Mode, minimum plate size is 229 x 305 mm (9 x 12 in)<br />

<strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> <strong>Quantum</strong> platesetter <strong>Trendsetter</strong> <strong>800</strong> <strong>II</strong> platesetter<br />

200 lpi max. linescreen<br />

option: Staccato 25 series screen sets<br />

3

Let’s Talk<br />

Contact your Kodak representative to find out more about Kodak digital prepress solutions, and to select the <strong>Trendsetter</strong><br />

<strong>800</strong> <strong>II</strong> platesetter model and options that best serve your current and future business needs.<br />

© Copyright 2005 Kodak, <strong>Trendsetter</strong>, SQUAREspot, Brisque and Prinergy are trademarks of Kodak. Other company and brand, product and service<br />

names are for identification purposes only and may be trademarks or registered trademarks of their respective holders. Data subject to change<br />

without notice.<br />

Canada<br />

3700 Gilmore Way<br />

Burnaby, British Columbia<br />

Canada V5G 4M1<br />

T. +1.604.451.2700<br />

F. +1.604.437.9891<br />

USA<br />

3 Federal Street<br />

Billerica, MA 01821<br />

USA<br />

T. +1.978.439.7000<br />

F. +1.978.439.7031<br />

graphics.kodak.com<br />

Asia Pacific<br />

3/F 625 King's Road<br />

North Point<br />

Hong Kong<br />

T. +852.2882.1011<br />

F. +852.2881.8897<br />

About Kodak’s Graphic Communications Group (GCG)<br />

Kodak's Graphic Communications Group is one of the three strategic business units of<br />

Eastman Kodak Company, the world leader in imaging technology and color science. The<br />

Graphic Communications Group provides customers with breakthrough products and<br />

services designed to operate in blended production and printing environments. The<br />

company offers the broadest portfolio of technologies, products and services for the<br />

graphic communications market. Kodak's solutions include image capture systems;<br />

professional color, copydot, and high-speed document scanning systems; workflow and<br />

color management software; thermal imaging devices for film, plates, and proofs; highquality<br />

proofing media, printing plates, and recording film; high-volume continuous inkjet<br />

printing systems; digital color and black-and-white presses; wide-format inkjet printers;<br />

data storage products; and professional services.<br />

Europe, Africa, Middle East<br />

Waterloo Office Park<br />

Drève Richelle 161<br />

B-1410 Waterloo<br />

Belgium<br />

T. +32.2.352.2511<br />

F. +32.2.351.0915<br />

Israel<br />

P.O. Box 330<br />

Herzlia Industrial Park<br />

46103 Herzlia B<br />

Israel<br />

T. +972.9.959.7222<br />

F. +972.9.950.2922<br />

Japan<br />

1-17-8, Higashi-Ikebukuro<br />

Toshima-ku<br />

Tokyo, 170-0013<br />

Japan<br />

T. +81.3.5954.9050<br />

F. +81.3.5954.9055<br />

01/09 Part No. 75-0682D