Screening and Screenings Handling Equipment

Screening and Screenings Handling Equipment

Screening and Screenings Handling Equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

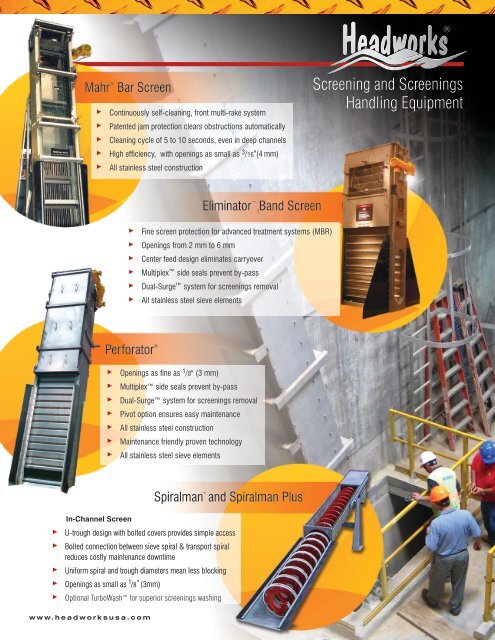

Mahr ®<br />

Bar Screen<br />

R Continuously self-cleaning, front multi-rake system<br />

R Patented jam protection clears obstructions automatically<br />

R Cleaning cycle of 5 to 10 seconds, even in deep channels<br />

R High efficiency, with openings as small as 3 /16"(4 mm)<br />

R All stainless steel construction<br />

R Fine screen protection for advanced treatment systems (MBR)<br />

R Openings from 2 mm to 6 mm<br />

R Center feed design eliminates carryover<br />

R Multiplex side seals prevent by-pass<br />

R Dual-Surge system for screenings removal<br />

R All stainless steel sieve elements<br />

Perforator ®<br />

In-Channel Screen<br />

w w w . h e a d w o r k s u s a . c o m<br />

R Openings as fine as 1 /8" (3 mm)<br />

R Multiplex side seals prevent by-pass<br />

R Dual-Surge system for screenings removal<br />

R Pivot option ensures easy maintenance<br />

R All stainless steel construction<br />

R Maintenance friendly proven technology<br />

R All stainless steel sieve elements<br />

Eliminator <br />

B<strong>and</strong> Screen<br />

Spiralman <br />

<strong>and</strong> Spiralman Plus <br />

R U-trough design with bolted covers provides simple access<br />

R Bolted connection between sieve spiral & transport spiral<br />

reduces costly maintenance downtime<br />

R Uniform spiral <strong>and</strong> trough diameters mean less blocking<br />

R Openings as small as 1 /8" (3mm)<br />

R Optional TurboWash for superior screenings washing<br />

<strong>Screening</strong> <strong>and</strong> <strong>Screening</strong>s<br />

H<strong>and</strong>ling <strong>Equipment</strong>

Internally Fed Drum Screen<br />

R 304 or 316 stainless steel wetted parts<br />

R 0.5 to 4mm wedge wire or 1 to 6mm perforated plate or wire mesh<br />

R Dual spray screen washer system<br />

R Adjustable speed control<br />

R Dual discharge inlet headbox<br />

R Solid helically arranged discharge blades<br />

R Optional TurboWash for superior screenings washing<br />

In-Channel Inclined Drum Screen<br />

Shafted Screw Compactor<br />

R Shafted screenings compaction system<br />

R Low profile <strong>and</strong> easily retrofitted<br />

R Custom designed discharge tube<br />

R Optional Grinder<br />

R Bagging module available<br />

R Reliable low-maintenance performance<br />

Conveyors/Compactors<br />

Screwpactor <br />

Transpactor <strong>and</strong> Transporter <br />

TurboDrum IF TurboDrum IH <br />

TurboDrum IN <br />

R 0.25 to 4mm wedge wire or 2 to 6mm perforated plate or wire mesh<br />

R <strong>Screening</strong>s, conveying, compaction, washing, <strong>and</strong> bagging is<br />

h<strong>and</strong>led in one unit with one motor.<br />

R Screen sizes are available for flows for up to 4600m 3 /h (29 MGD)<br />

R All in one system minimizes maintenance requirement<br />

R Optional TurboWash for superior screenings washing<br />

R Optional TurboWash for superior screenings washing<br />

R Shaftless screenings conveying/compacting system<br />

R Bagging module available<br />

R Reliable low-maintenance performance<br />

R Optional TurboWash for superior screenings washing<br />

OPTIONAL EQUIPMENT<br />

The turbulent zone of influence<br />

created by the optional TurboWash<br />

agitator loosens <strong>and</strong> emulsifies the<br />

organic BOD material on screenings.<br />

R Low maintenance <strong>and</strong> long lifecycle<br />

R Over a decade of highly effective<br />

proven technology<br />

R Ease of operation<br />

R Maximized BOD removal<br />

Horizontal Drum Screen<br />

R 1 to 4mm wedge wire or 2 to 6mm<br />

perforated plate or wire mesh<br />

R Integral conveying, compaction,<br />

washing, <strong>and</strong> bagging in one unit.<br />

R Screen sizes are available for flows up<br />

to 3.6 l/s (82 MGD)<br />

R No mechanical serviceable parts in<br />

effluent stream<br />

R Optional TurboWash available<br />

Sidehill Screen<br />

TurboStat <br />

R Capacities from 150 - 1,400 gpm<br />

R Screen openings as small as .25 mm<br />

R 304 or 316 stainless steel screen panel<br />

R Stainless steel or fiberglass body<br />

R Minimum maintenance<br />

R Optional TurboWash available<br />

TurboTank <br />

St<strong>and</strong> alone washing unit for sluice<br />

troughs or larger screenings quantities<br />

800 Wilcrest, Suite 340 | Houston, Texas 77042 | Phone: +1.713.647.6667 | E-mail: hw@headworksusa.com<br />

PATENT AND PATENTS PENDINg<br />

w w w . h e a d w o r k s u s a . c o m<br />

Copyright 2009 HW LS E 10.09