multiPlas - Dynardo GmbH

multiPlas - Dynardo GmbH

multiPlas - Dynardo GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

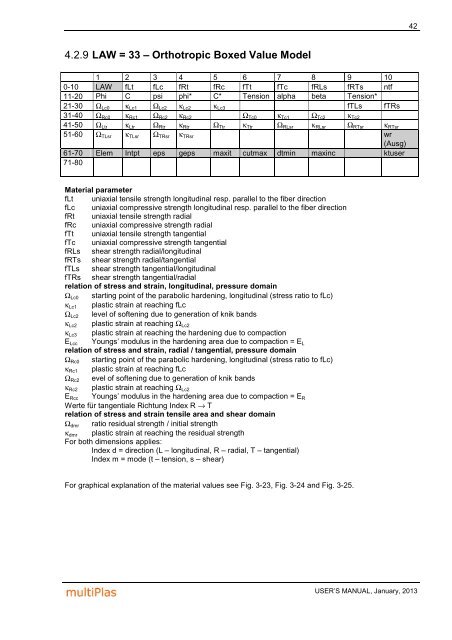

4.2.9 LAW = 33 – Orthotropic Boxed Value Model<br />

1 2 3 4 5 6 7 8 9 10<br />

0-10 LAW fLt fLc fRt fRc fTt fTc fRLs fRTs ntf<br />

11-20 Phi C psi phi* C* Tension alpha beta Tension*<br />

21-30 ΩLc0 κLc1 ΩLc2 κLc2 κLc3 fTLs fTRs<br />

31-40 ΩRc0 κRc1 ΩRc2 κRc2 ΩTc0 κTc1 ΩTc2 κTc2<br />

41-50 ΩLtr κLtr ΩRtr κRtr ΩTtr κTtr ΩRLsr κRLsr ΩRTsr κRTsr<br />

51-60 ΩTLsr κTLsr ΩTRsr κTRsr wr<br />

(Ausg)<br />

61-70 Elem Intpt eps geps maxit cutmax dtmin maxinc ktuser<br />

71-80<br />

Material parameter<br />

fLt uniaxial tensile strength longitudinal resp. parallel to the fiber direction<br />

fLc uniaxial compressive strength longitudinal resp. parallel to the fiber direction<br />

fRt uniaxial tensile strength radial<br />

fRc uniaxial compressive strength radial<br />

fTt uniaxial tensile strength tangential<br />

fTc uniaxial compressive strength tangential<br />

fRLs shear strength radial/longitudinal<br />

fRTs shear strength radial/tangential<br />

fTLs shear strength tangential/longitudinal<br />

fTRs shear strength tangential/radial<br />

relation of stress and strain, longitudinal, pressure domain<br />

ΩLc0 starting point of the parabolic hardening, longitudinal (stress ratio to fLc)<br />

κLc1 plastic strain at reaching fLc<br />

ΩLc2 level of softening due to generation of knik bands<br />

κLc2 plastic strain at reaching ΩLc2<br />

κLc3 plastic strain at reaching the hardening due to compaction<br />

ELcc Youngs’ modulus in the hardening area due to compaction = EL<br />

relation of stress and strain, radial / tangential, pressure domain<br />

ΩRc0 starting point of the parabolic hardening, longitudinal (stress ratio to fLc)<br />

κRc1 plastic strain at reaching fLc<br />

ΩRc2 evel of softening due to generation of knik bands<br />

κRc2<br />

ERcc<br />

plastic strain at reaching ΩLc2<br />

Youngs’ modulus in the hardening area due to compaction = ER<br />

Werte für tangentiale Richtung Index R → T<br />

relation of stress and strain tensile area and shear domain<br />

ratio residual strength / initial strength<br />

Ωdmr<br />

κdmr<br />

plastic strain at reaching the residual strength<br />

For both dimensions applies:<br />

Index d = direction (L – longitudinal, R – radial, T – tangential)<br />

Index m = mode (t – tension, s – shear)<br />

For graphical explanation of the material values see Fig. 3-23, Fig. 3-24 and Fig. 3-25.<br />

42<br />

USER’S MANUAL, January, 2013