HS-S041 - HEPA Duct Filter Housing - HS Luftfilterbau GmbH

HS-S041 - HEPA Duct Filter Housing - HS Luftfilterbau GmbH

HS-S041 - HEPA Duct Filter Housing - HS Luftfilterbau GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical Data<br />

<strong>HS</strong>-<strong>S041</strong> - <strong>HEPA</strong> <strong>Duct</strong> <strong>Filter</strong> <strong>Housing</strong><br />

<strong>HS</strong>-<strong>S041</strong> - The gastight Safetyhousing<br />

offers flexible modular design to be customized for the<br />

requirements on site and bag-in-bag-out filterchange -<br />

contaminaton free .<br />

<strong>HS</strong>-<strong>Luftfilterbau</strong> <strong>GmbH</strong><br />

Bunsenstraße 31<br />

D-24145 Kiel<br />

Germany<br />

Tel.:+49-(0)431-71953-0<br />

Fax:+49-(0)431-71953-30<br />

www.luftfilterbau.de<br />

info@luftfilterbau.de<br />

Areas of application<br />

<strong>HS</strong>-<strong>S041</strong> duct filter housings have proven in numerous<br />

applications. These housings fulfill maximum requirements<br />

in regards of safety and efficiency in the field of particle and<br />

gasfiltration. The <strong>HS</strong>-<strong>S041</strong> series is especially designed for<br />

safetyrelevant processes i.e.:<br />

● Supply- & exhaustair with pharmaceutical or biotechnological<br />

processes.<br />

● Air treatment (supply / exhaust) with medical<br />

facilities i.E. for safety environments at BSL 1 to 4<br />

installations.<br />

● Isolation wards and pandemic quarantine zones.<br />

● Nuclear processes (fulfills KTA 3601).<br />

● Exhaust air treatment for chemical processes.<br />

● Isotope laboratories.<br />

● other process air, requiring explosive protection<br />

according to ATEX standards.<br />

● Sterile air production.<br />

● Deconamination / Warfare agent destruction<br />

Filtration<br />

The <strong>HS</strong>-<strong>S041</strong> series can be equipped with pre-filtration for<br />

coarse dust removal with classes EN779:G4 to M5.<br />

The mainfilterstages might handle particle filters in classes<br />

EN779:M6 to F9 for fine dust removal. But also <strong>HEPA</strong> filters<br />

can be installed in classes EN1822:E11 to H14. Upon demand<br />

even nominal ULPA classes are available.<br />

Molecular filters can remove hazardous or radioactive gases<br />

from the air flow.<br />

Technische documents Änderungen<br />

might be subject to<br />

vorbehalten. change / issue Stand: Sept. Dezember 2011<br />

2004<br />

Key features<br />

<strong>HS</strong>-<strong>S041</strong> duct filter housings can be adapted to any individual<br />

need. The main features are:<br />

● <strong>Filter</strong>housing is made from stainless steel 1.4301,<br />

on demand higher classifiactions.<br />

● Gastight welded construction. The housing comes<br />

fully welded and pressure tested if transport<br />

limitations allow it. All connectors are then gastight<br />

welded to the filterbanks.<br />

● Standard pressure limit is up to +-100 mbar.<br />

● Optional: pressure resistant up to +- 500 mBar.<br />

● The selfregulating safety clamping frame ensures<br />

all time for tightness between filters, gasket and<br />

housing.<br />

● All surfaces are glass blasted and passivated for<br />

maximum corrosion resistance and easy decontamination.<br />

● The filter housing is made from modular design to<br />

be easily adapted to the requirements.<br />

● Loads of innovative special options are availiable.<br />

● Bypass test facilities according to DIN 1946-4 and<br />

DIN 25414.<br />

● Gastight DE<strong>HS</strong>-testports for particle<br />

measurement / In-Situ testing.<br />

● Mechanical installations ensure fail safe<br />

operation and filter change.<br />

● Temperature resistance is in accordance<br />

with additional options up to >120°C.<br />

● More safety by filter-chambers that can<br />

be safe-locked to prevent unauthorized access.<br />

Page<br />

1 / 5<br />

Document-ID<br />

01/D09<br />

Mounting Sys.<br />

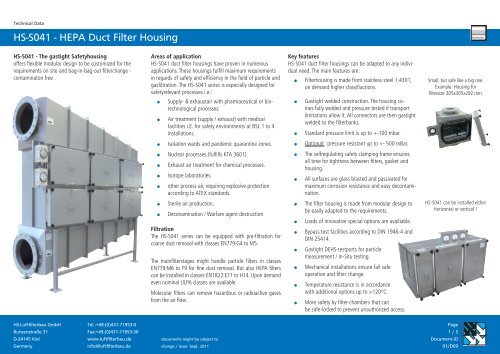

Small, but safe like a big one.<br />

Example: <strong>Housing</strong> for<br />

filtersize 305x305x292 mm.<br />

<strong>HS</strong>-<strong>S041</strong> can be installed either<br />

horizontal or vertical !

Technical Data<br />

<strong>HS</strong>-<strong>S041</strong> - <strong>HEPA</strong> <strong>Duct</strong> <strong>Filter</strong><br />

Contruction, testing & documentation<br />

<strong>HS</strong>-<strong>S041</strong> duct filter housings consist by principle from welded<br />

stainless steel (1.4301 or better). Any damages of a paint<br />

coating that occures during transport or handling with usual<br />

housings and the resulting risk of corrosion is avoided.<br />

The sheet metal thichness is 2,5 mm by standard. It can be<br />

up to 4mm in case higher pressure levels are demanded. Further<br />

reinforcement such as splines and armoring is optionally<br />

available. All surfaces are glass blasted and all welding seams<br />

are carefully passivated. All <strong>HS</strong>-<strong>S041</strong> duct filter housings<br />

are intensively tested for pressure and tightness according to<br />

the parameters of their application.<br />

<strong>HS</strong>-<strong>Luftfilterbau</strong> <strong>GmbH</strong><br />

Bunsenstraße 31<br />

D-24145 Kiel<br />

Germany<br />

The arrangement of the connecors can be<br />

defined as required.<br />

Tel.:+49-(0)431-71953-0<br />

Fax:+49-(0)431-71953-30<br />

www.luftfilterbau.de<br />

info@luftfilterbau.de<br />

DIN 25 496; 6.2(4) is respected for all weldings, meaning<br />

that stabilizing steels are used with austenitic materials.<br />

All concerning parts and welding seams are free of cracks<br />

and slits to ensure the ease of decontamination and to avoid<br />

cranny corrosion. Upon the customers request all welding<br />

seams can be tested such as for dye penetrant test or other<br />

methods.<br />

<strong>HS</strong>-<strong>S041</strong> can be shipped as single module or as fully welded<br />

ready to use housing. Single modules are supplied with hole<br />

patterns on the conection flanges according to the customers<br />

specification. Beside the usual documentations such as operational<br />

manuals and declaration of conformity we also offer<br />

added documents such as seismic stress simulations or approval<br />

documents. Welding qualification certificates and raw<br />

material certificates are part of our delivery and inspection<br />

documentation in case full documentation is required.<br />

Delivery & Installation<br />

The filterhousings are supplied as complete unit along with<br />

the connectors already welded if the transport and handling<br />

situation allows this. Otherwise the housing is supplied in<br />

easy to mount and install sections - typically for units consisting<br />

of more than 4 - 5 units. The housings are fitted with<br />

welded lifting eyes when needed.<br />

By request we allso support you for installation, inspection or<br />

final approval with our experienced staff on site.<br />

<strong>Filter</strong> clamping / maintenance<br />

The filter clamping construction is based on a uncomplicated<br />

mechanical clamping to ensure maximum safeguarding<br />

against failure. We therefore resign on pneumatic clamping<br />

or electronic controls with this particular housing type.<br />

The filter clamping construciton consists from stainless steel<br />

clamping frame operated by excenters. Additional leafsprings<br />

generate constant pressure to the filter to negate effects like<br />

aging gaskets or production related tolerances of the filters.<br />

documents might be subject to<br />

change / issue Sept. 2011<br />

Mounting Sys.<br />

The clamping construction is designed to ensure tightness even with maxmum dust loading<br />

of the filters and aging gaskets to always fulfills tightness requirements according to DIN<br />

25496, Tab. 3 at the seat of each filter element. A filter can only be clamped when placed in<br />

the correct position. The maintenance cover can only be fixed to the housing when a filter is<br />

set in correctly and is properly clamped. This ensures failsafe operation.<br />

Welded security barriers in the cover prevent a losening of the clamping in case of seismic<br />

shocks.<br />

The maintenance covers can be made lockable to prevent unauthorised access to the filterbanks.<br />

Page<br />

2 / 5<br />

Document-ID<br />

01/D09

Technical Data<br />

<strong>HS</strong>-<strong>S041</strong> - <strong>HS</strong>-<strong>HEPA</strong> <strong>Duct</strong> <strong>Filter</strong><br />

Variants & Options<br />

<strong>HS</strong>-<strong>S041</strong> housings can be customized to meet your individual<br />

requirements. A broad range of options is available<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

DE<strong>HS</strong>-Testport for injection and measurement<br />

of particles. The ports are gas tight sealed when<br />

the filter is in operation. The constuction is either<br />

made from tri-clamp-port or gas tight ball cocks.<br />

The two-groove maintenance board (bag-in-bagout<br />

filterchange) is made of a welded profile. The<br />

profile is designed to firmly fix the O-Rings and<br />

maintenance bags. The special profile prevents<br />

that O-rings and bags accidentally flip away.<br />

The optional maintenance table can be hooked<br />

simply to the matching eyes to provide more comfort<br />

during the Bag-In-Bag-Out filterchange.<br />

On demand the housings can be fitted with gastight<br />

dampers. These will shut off the housing during revision<br />

and decontamination. All dampers come with a<br />

leak-test groove to performin-situ tightness checks.<br />

An optional pressure-discharge filter allows quick<br />

pressure equalisation before a filterchange. Contaminated<br />

air is lead over a gastight pressure valve to<br />

a <strong>HEPA</strong> or ULPA safety filter.<br />

Connectors for the injection or removal of<br />

decontaminants (i.e. H 2 O 2 , formaldeyde) can be<br />

defined and installed where needed.<br />

<strong>HS</strong>-<strong>Luftfilterbau</strong> <strong>GmbH</strong><br />

Bunsenstraße 31<br />

D-24145 Kiel<br />

Germany<br />

Tel.:+49-(0)431-71953-0<br />

Fax:+49-(0)431-71953-30<br />

www.luftfilterbau.de<br />

info@luftfilterbau.de<br />

4.<br />

1.<br />

documents might be subject to<br />

change / issue June. Sept. 2011 2005<br />

2.<br />

3.<br />

1.<br />

5.<br />

6.<br />

7.<br />

10.<br />

6.<br />

8.<br />

9.<br />

6.<br />

7.<br />

8.<br />

9.<br />

9.<br />

10.<br />

Mounting Sys.<br />

Connections and adapters<br />

to the air-channels are<br />

defined by the user i.e.<br />

square-to-round. The conncectors<br />

are already gastightly<br />

welded to the corpus<br />

when feasible.<br />

The arrangement of the<br />

filterbanks may be either<br />

horizontal or vertical. The<br />

maintenance covers can be<br />

made lockable to prevent<br />

unauthorized access.<br />

Electric discharge connections<br />

are optionally installed<br />

explosion protection<br />

according to ATEX regulations.<br />

Each particlefilterstage can<br />

be equipped with a pressure<br />

gauge to monitor the<br />

saturation of the filters.<br />

Potential-free pressure<br />

switches can signal the<br />

saturation level to the<br />

maincontrol of the air<br />

handling unit.<br />

The base-rack is made<br />

from welded square profiles.<br />

The baseplates allow<br />

to fix the unit on the floors.<br />

By standard the <strong>Housing</strong><br />

offers a grounding screw<br />

(M8) to discharge eventual<br />

electrical potentials.<br />

Page<br />

3 / 5<br />

Document-ID<br />

01/D09

Technical Data<br />

<strong>HS</strong>-<strong>S041</strong> - <strong>HS</strong>-<strong>HEPA</strong> <strong>Duct</strong> <strong>Filter</strong><br />

A ( 1 : 1 )<br />

E E<br />

<strong>Filter</strong>sizes and <strong>Filter</strong>types<br />

using a leak test device. Alternatively a hardware testgroove can be Dimensions of single modules<br />

<strong>HS</strong>-<strong>S041</strong> can be equipped with different filters in accordance to the<br />

demand of air purity, safety and airflow. The table on the right side<br />

dives an overview about typical filtersizes. All filters can be fitted<br />

with an EX-protection according to ATEX upon request.<br />

Following <strong>Filter</strong>types are recommended:<br />

D<br />

Prefilter coarse dusts class EN779: G3 - M5<br />

<strong>HS</strong>-Pre-<strong>Filter</strong>-Cell 05/D04<br />

<strong>HS</strong>-Alpha Pak 55 05/D01<br />

welded to the housing. Then the filters are fitted with a flat gasket<br />

that forms a reservoir when pressed against the groove.<br />

The mounting and fixing of the covers is eased by guidiance plates .<br />

Side- / innersight of Cover & bypass leak test<br />

Gastight vent bypass test<br />

1.<br />

vent, welded piping to the<br />

test outlet in the clamping<br />

frame.<br />

Up to six filterstages can be integrated in one module if required. The height [B] is added with<br />

the combinations of several stages per corpus. The total height should not exceed 2400mm.<br />

Please contact us for individual sizing and construction.<br />

D<br />

Dimension <strong>Filter</strong> [mm] Dimensions <strong>Housing</strong> [mm] Weight [kg]<br />

Height Widths Depth A B C D w/o <strong>Filter</strong> + <strong>Filter</strong><br />

610 610 50 675 270 745 720 30 50<br />

Prefilter fine dusts class EN779: M6 - F9<br />

<strong>HS</strong>-Makro 08/D04 up to 120°C, ATEX conformity<br />

<strong>HS</strong>-Makro F 08/D04 up to 65°C<br />

C<br />

Mainfilter <strong>HEPA</strong> filter class EN1822: E10 - H14<br />

<strong>HS</strong>-Mikro S 08/D09 up to 120°C, ATEX conformity<br />

<strong>HS</strong>-Mikro SF 8 08/D09 up 7 to 65°C<br />

6<br />

Mainfilter activated carbon / gas and molecular filter<br />

F<br />

<strong>HS</strong>-A053 08/D09 high security filter<br />

<strong>HS</strong>-A055 08/D09 VOC's, odors, haz-mat<br />

B<br />

On safety critical processes we recommend the use of class E11<br />

5 F<br />

8<br />

A<br />

8<br />

F<br />

4<br />

A ( 1 : 1 )<br />

2.<br />

3.<br />

4.<br />

Gastightly fixed cover with<br />

star-screw.<br />

7<br />

Leak 7 test gasket on the<br />

filter. A possible loss of<br />

pressure in the reservoir<br />

indicates 3 a bypass over the 2<br />

filter gasket<br />

Mainenance board with<br />

two grooves to securely fix<br />

o-rings and maintenance<br />

bags.<br />

6<br />

610<br />

610<br />

305<br />

305<br />

305<br />

305<br />

305<br />

305<br />

610<br />

610<br />

610<br />

6<br />

610<br />

610<br />

610 1<br />

305<br />

305<br />

305<br />

762<br />

5<br />

F<br />

150<br />

292<br />

50<br />

150<br />

292<br />

50<br />

150<br />

292<br />

150<br />

675<br />

675<br />

5<br />

385<br />

385<br />

385<br />

385<br />

385<br />

385<br />

847<br />

380<br />

525<br />

4 270<br />

380<br />

525<br />

270<br />

380<br />

525<br />

380<br />

745<br />

745<br />

745<br />

745<br />

745<br />

440<br />

440<br />

440<br />

745<br />

4<br />

720<br />

720<br />

430<br />

430<br />

430<br />

430<br />

430<br />

430<br />

892<br />

3<br />

50<br />

65<br />

20<br />

35<br />

50<br />

10<br />

20<br />

35<br />

55<br />

C<br />

B<br />

3<br />

70<br />

85<br />

35<br />

50<br />

65<br />

20<br />

30<br />

45<br />

80<br />

2<br />

EPA filters for safety after carbon filters to remove possible abrasion<br />

of carbon particles from the airstream.<br />

E<br />

Maintenance Cover and <strong>Filter</strong>-Bypass-Test<br />

E<br />

E<br />

1.<br />

610 762<br />

E<br />

292 847 525 745 892 70 95<br />

Each maintenance cover comes with a welded hand grip. The co-<br />

DATUM<br />

Gezeichnet 10.08.2011<br />

Name<br />

ap9<br />

ver is gastightly fixed by Afour (with high pressure units: six) easy<br />

2.<br />

Kontrolliert<br />

Norm<br />

A<br />

to handle star screws. The starscrews are undetachably connected<br />

to Dthe cover. For safety the cover can only be mounted to the housing<br />

when the filter is correclty set 8in<br />

and properly clamped in 7 the<br />

D<br />

6<br />

D<br />

4.<br />

5<br />

4<br />

D<br />

Status Änderungen<br />

3<br />

DATUM Name<br />

2<br />

Dichtsitz<br />

1<br />

1<br />

A2<br />

housing.The cover also serves as reservoir for the maintenance bag.<br />

<strong>HS</strong>-<strong>S041</strong> filterunits can offer a leak test groove for bypass testing<br />

in the housing but we prefer to fit the filter with a groove gasket.<br />

A<br />

This helps to prevent malfunctions caused by damages and false<br />

3.<br />

C measure readings caused by dirt on the hardware.<br />

The test pressure is led to a test groove gasket over a gastight stain-<br />

C<br />

C<br />

C<br />

less tube. The proof of a bypass free filter clamping is detected by<br />

one stage module corpus<br />

two stage module corpus<br />

<strong>HS</strong>-<strong>Luftfilterbau</strong> <strong>GmbH</strong><br />

Bunsenstraße 31<br />

D-24145 Kiel<br />

Germany<br />

Tel.:+49-(0)431-71953-0<br />

Fax:+49-(0)431-71953-30<br />

www.luftfilterbau.de<br />

info@luftfilterbau.de<br />

B B<br />

documents might be Bsubject<br />

to<br />

B<br />

change / issue Sept. 2011<br />

B<br />

A<br />

B<br />

A<br />

D<br />

C<br />

D<br />

C<br />

B<br />

B<br />

Page<br />

4 / 5<br />

Document-ID<br />

01/D09<br />

Mounting Sys.

Technical Data<br />

<strong>HS</strong>-<strong>S041</strong> - <strong>HS</strong>-<strong>HEPA</strong> <strong>Duct</strong> <strong>Filter</strong><br />

Module combinations 1/1 1/2 1/3 1/4 1/5 1/6 2/2 2/4 2/6 2/8 2/10 2/12<br />

<strong>Filter</strong>module<br />

fitting for<br />

filtersize:<br />

Connector pair (in / out) for<br />

<strong>Filter</strong>size 610 x 610 [mm]<br />

# of Units 1 2 3 4 5 6 2 4 6 8 10 12<br />

<strong>Filter</strong> unit single line <strong>Filter</strong> unit double line<br />

Total length L [mm] 810 1565 2320 3075 3830 4585 810 1565 2320 3075 3830 4585<br />

Clear connector<br />

width<br />

Clear connector<br />

height<br />

Weight of the<br />

connectors<br />

Connector pair (in / out) for<br />

<strong>Filter</strong>size 762 x 610 [mm]<br />

b [mm] 615 615 615 615 615 615 1325 1325 1325 Status Änderungen DATUM 1325 Name 1325 1325<br />

h [mm] 200 315 400 500 630 710 200 315 400 500 630 710<br />

[kg] 30 45 65 105 130 155 40 65 90 140 175 210<br />

<strong>Filter</strong> unit single line <strong>Filter</strong> unit double line<br />

Total length L [mm] 810 1565 2320 3075 3830 4585 810 1565 2320 3075 3830 4585<br />

Clear connector<br />

width<br />

Clear connector<br />

height<br />

Weight of the<br />

connectors<br />

8<br />

8<br />

7<br />

7<br />

6<br />

6<br />

5<br />

F F<br />

Dimensions of complete housings<br />

With higher air flow rates we recommend to construct the complete housing in two lines. This may be necessary even in<br />

unfavorable structural relations. The height of the base rack [H] can be adapted to your needs. If nothing is specified we<br />

assume a height of 800 mm.<br />

<strong>HS</strong>-<strong>Luftfilterbau</strong> <strong>GmbH</strong><br />

Bunsenstraße 31<br />

D-24145 Kiel<br />

Germany<br />

5<br />

b [mm] 767 767 767 767 767 767 1629 1629 1629 1629 1629 1629<br />

h [mm] 200 315 400 500 630 710 200 315 400 500 630 710<br />

[kg] 35 50 70 110 140 170 45 75 105 155 200 135<br />

4<br />

E E<br />

E The typical E flow direction is horizontal.<br />

4<br />

3<br />

D F D<br />

F<br />

3<br />

2<br />

C E C<br />

E<br />

D D<br />

B B<br />

C<br />

DATUM Name<br />

8 8<br />

7 7<br />

6 6<br />

5 5<br />

4<br />

C<br />

Gezeichnet 02.08.2011 ap9<br />

A<br />

Kontrolliert<br />

A<br />

Tel.:+49-(0)431-71953-0<br />

Fax:+49-(0)431-71953-30<br />

www.luftfilterbau.de<br />

info@luftfilterbau.de<br />

documents might be subject to<br />

change / issue Sept. 2011<br />

Norm<br />

8<br />

2<br />

8<br />

7<br />

7<br />

1<br />

1<br />

Connector arrangement & Dimensions<br />

6 single / double line:<br />

right in / left out<br />

1<br />

A2<br />

6<br />

5<br />

F<br />

Typcial connector arrangements result like following:<br />

D<br />

5<br />

4 single D / double line:<br />

right in / right out<br />

3<br />

2<br />

single / double line:<br />

left out / right in<br />

F F<br />

C<br />

E E<br />

B<br />

D D<br />

A<br />

C C<br />

B B<br />

B B<br />

DATUM Name<br />

Gezeichnet 03.08.2011 ap9<br />

A<br />

Kontrolliert<br />

Norm<br />

DATUM Name<br />

Gezeichnet 03.08.2011 ap9<br />

A<br />

A<br />

Kontrolliert<br />

Norm<br />

1<br />

A2<br />

A<br />

8<br />

7<br />

6<br />

5<br />

4<br />

8<br />

Status Änderungen<br />

3<br />

DATUM 7 Name<br />

Status Änderungen<br />

2<br />

6<br />

5<br />

1<br />

4<br />

1<br />

A2<br />

DATUM Name<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

F<br />

H<br />

8<br />

F<br />

C<br />

B<br />

A<br />

4<br />

8<br />

E<br />

D<br />

C<br />

B<br />

A<br />

8<br />

7<br />

Individual designed connectors and other options like bypasses can be realized.<br />

L<br />

3<br />

7<br />

7<br />

B<br />

6<br />

2<br />

6<br />

6<br />

b<br />

5<br />

1<br />

5<br />

5<br />

4<br />

Mounting Sys.<br />

1 single / double line:<br />

left in / left out<br />

Page<br />

5 / 5<br />

Document-ID<br />

01/D09<br />

h<br />

4<br />

4<br />

4<br />

revision space:<br />

min. 1400 mm<br />

3<br />

Status Änderungen DATUM Name Änderungen Status DATU<br />

3 3<br />

3<br />

Status Änderungen<br />

3<br />

DATUM Name<br />

3<br />

DA<br />

Gezeichnet 03.0<br />

Kontrolliert<br />

Norm<br />

2<br />

DATUM Name<br />

Gezeichnet 16.08.2011 ap9<br />

Kontrolliert<br />

Norm<br />

2