English

English

English

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

technology report 02<br />

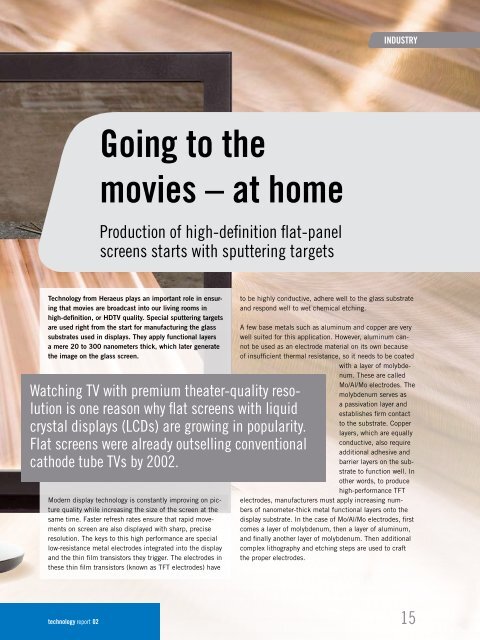

Going to the<br />

movies – at home<br />

Production of high-definition flat-panel<br />

screens starts with sputtering targets<br />

Technology from Heraeus plays an important role in ensuring<br />

that movies are broadcast into our living rooms in<br />

high-definition, or HDTV quality. Special sputtering targets<br />

are used right from the start for manufacturing the glass<br />

substrates used in displays. They apply functional layers<br />

a mere 20 to 300 nanometers thick, which later generate<br />

the image on the glass screen.<br />

Watching TV with premium theater-quality resolution<br />

is one reason why flat screens with liquid<br />

crystal displays (LCDs) are growing in popularity.<br />

Flat screens were already outselling conventional<br />

cathode tube TVs by 2002.<br />

Modern display technology is constantly improving on picture<br />

quality while increasing the size of the screen at the<br />

same time. Faster refresh rates ensure that rapid movements<br />

on screen are also displayed with sharp, precise<br />

resolution. The keys to this high performance are special<br />

low-resistance metal electrodes integrated into the display<br />

and the thin film transistors they trigger. The electrodes in<br />

these thin film transistors (known as TFT electrodes) have<br />

INDUSTRY<br />

to be highly conductive, adhere well to the glass substrate<br />

and respond well to wet chemical etching.<br />

A few base metals such as aluminum and copper are very<br />

well suited for this application. However, aluminum cannot<br />

be used as an electrode material on its own because<br />

of insufficient thermal resistance, so it needs to be coated<br />

with a layer of molybdenum.<br />

These are called<br />

Mo/Al/Mo electrodes. The<br />

molybdenum serves as<br />

a passivation layer and<br />

establishes firm contact<br />

to the substrate. Copper<br />

layers, which are equally<br />

conductive, also require<br />

additional adhesive and<br />

barrier layers on the substrate<br />

to function well. In<br />

other words, to produce<br />

high-performance TFT<br />

electrodes, manufacturers must apply increasing numbers<br />

of nanometer-thick metal functional layers onto the<br />

display substrate. In the case of Mo/Al/Mo electrodes, first<br />

comes a layer of molybdenum, then a layer of aluminum,<br />

and finally another layer of molybdenum. Then additional<br />

complex lithography and etching steps are used to craft<br />

the proper electrodes.<br />

15