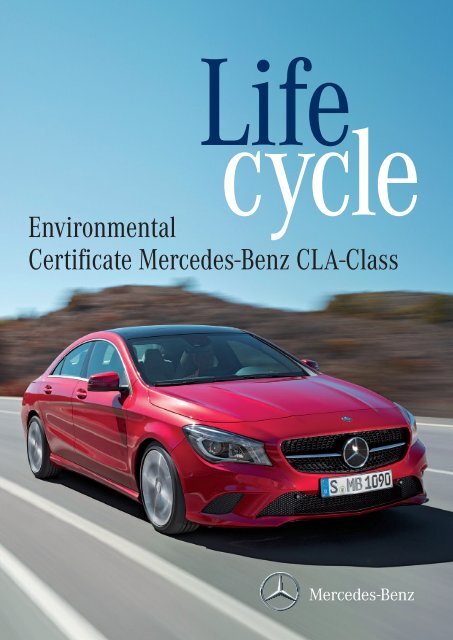

Environmental Certificate Mercedes-Benz CLA-Class

Environmental Certificate Mercedes-Benz CLA-Class

Environmental Certificate Mercedes-Benz CLA-Class

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Life<br />

cycle<br />

<strong>Environmental</strong><br />

<strong>Certificate</strong> <strong>Mercedes</strong>-<strong>Benz</strong> <strong>CLA</strong>-<strong>Class</strong><br />

1

Contents<br />

Life Cycle – the <strong>Mercedes</strong>-<strong>Benz</strong> environmental documentation 4<br />

Interview with Professor Dr Herbert Kohler 6<br />

Product description 8<br />

Validation 14<br />

1 Product documentation 15<br />

1.1 Technical data 16<br />

1.2 Material composition 17<br />

2 <strong>Environmental</strong> profile 18<br />

2.1 General environmental issues 19<br />

2.2 Life Cycle Assessment (LCA) 24<br />

2.2.1 Data basis 26<br />

2.2.2 LCA results for the <strong>CLA</strong> 180 28<br />

2.3 Design for recovery 35<br />

2.3.1 Recycling concept for the new <strong>CLA</strong>-<strong>Class</strong> 36<br />

2.3.2 Dismantling information 38<br />

2.3.3 Avoidance of potentially hazardous materials 39<br />

2.4 Use of secondary raw materials 40<br />

2.5 Use of renewable raw materials 42<br />

3 Process documentation 45<br />

4 <strong>Certificate</strong> 48<br />

5 Conclusion 49<br />

6 Glossary 50<br />

Imprint 52<br />

As at: April 2013<br />

2<br />

3

Life<br />

cycle<br />

Since the beginning of 2009, “Life Cycle” has been presenting<br />

the <strong>Environmental</strong> <strong>Certificate</strong>s for <strong>Mercedes</strong>-<strong>Benz</strong><br />

vehicles. Above all the principal aim of this documentation<br />

series is to provide the best possible service to as<br />

many interested parties as possible: on the one hand, the<br />

wide-ranging and complex subject of the “car and the<br />

environment” needs to be communicated to the general<br />

public in a manner which is easy to understand. On the<br />

other hand, however, specialists also need to have access<br />

to detailed information. “Life Cycle” fulfils this requirement<br />

with a variable concept.<br />

Those wanting a quick overview can concentrate on the<br />

short summaries at the beginning of the respective<br />

chapters. These summaries highlight the most important<br />

information in note form, while standardised graphics al-<br />

so help to simplify orientation. If more detailed information<br />

on the environmental commitment of Daimler AG is<br />

required, clearly arranged tables, graphics and informative<br />

text passages have also been provided. These elements<br />

describe the individual environmental aspects in a great<br />

deal of detail.<br />

With its service-oriented and striking “Life Cycle” documentation<br />

series, <strong>Mercedes</strong>-<strong>Benz</strong> is once again demonstrating<br />

its pioneering role in this important area - just<br />

as in the past, when in 2005 the S-<strong>Class</strong> became the very<br />

first vehicle to receive the <strong>Environmental</strong> <strong>Certificate</strong> from<br />

TÜV Süd (South German Technical Inspection Authority).<br />

4 5

Interview<br />

“Aerodynamic Leadership”<br />

Professor Kohler, the BlueEFFICIENCY edition of the new<br />

<strong>CLA</strong>-<strong>Class</strong> sets a new world record with a Cd value of 0.22<br />

and an aerodynamic drag value of 0.49 m 2 . How does the<br />

customer benefit from this?<br />

As part of our Real Life Efficiency philosophy we want to<br />

enable our customers to really reduce consumption. Good<br />

flow characteristics are tremendously important in this<br />

context, because if the Cd value can be cut by one tenthousandth,<br />

fuel consumption for the average customer<br />

is reduced by a tenth of a litre, and at very fast motorway<br />

speeds by as much as 0.4 litres per 100 kilometres. To<br />

achieve this savings effect through lightweight design<br />

measures it would be necessary to pare at least 35 kilograms<br />

off the weight of the cars. The aspiration to lead-<br />

ership in aerodynamics is an important element of our<br />

MBC 2020 product strategy– and has a long tradition at<br />

<strong>Mercedes</strong>-<strong>Benz</strong>.<br />

And how has <strong>Mercedes</strong>-<strong>Benz</strong> managed for many years to<br />

make the models in almost all vehicle categories the leaders<br />

in all aerodynamic disciplines?<br />

Through optimisation of all details in close cooperation<br />

between designers and aerodynamics specialists. A good<br />

example of the many aerodynamic refinements in the<br />

<strong>CLA</strong> are the serrated wheel spoilers on the front and rear<br />

wheel arches. The patented wheel spoilers were developed<br />

with the help of flow calculations. What is a seemingly<br />

insignificant component reduces undesirable air turbu-<br />

lence in the wheel arches in no less than three ways, by<br />

lowering linear turbulence, deflecting the airflow from the<br />

wheels and stabilising shear waves with its serrated edge.<br />

The wheel spoiler remains effective whatever the suspension<br />

level and wheel dimensions.<br />

Optionally the new <strong>CLA</strong>-<strong>Class</strong> is also available with 4MATIC<br />

permanent all-wheel drive. What effect does this system have<br />

on the vehicle’s efficiency?<br />

In comparison with the all-wheel drive versions of the<br />

competition, the system weight of the new 4MATIC is up<br />

to 25 percent lower owing to its design. These lightweight<br />

design measures and the high efficiency result in good<br />

energy efficiency.<br />

Interview with Professor Dr Herbert Kohler,<br />

Chief <strong>Environmental</strong> Officer at Daimler AG<br />

6 7

Product description<br />

Sleek as they come<br />

The <strong>CLA</strong> is set to establish a new segment,<br />

with world-leading aerodynamics (cd 0.22 for the BlueEFFICIENCY Edition),<br />

avant-garde coupé design and 4MATIC all-wheel drive (optional).<br />

As a new four-door coupé it follows the idea of the CLS,<br />

whose design concept has spawned more than its fair<br />

share of imitators since its debut in 2003.<br />

In keeping with its sporty positioning, the <strong>CLA</strong> is available<br />

with high-torque turbo engines rated at up to 155 kW<br />

(211 hp), sports suspension and 4MATIC all-wheel drive.<br />

The technical highlights of this new design icon include a<br />

new world record in aerodynamics for series production<br />

cars (Cd value: 0.22) and numerous driving assistance<br />

systems, including advanced COLLISION PREVENTION<br />

ASSIST.<br />

This radar-based assistance system provides the possibly<br />

distracted driver with visual and acoustic warnings of<br />

identified obstacles and prepares the adaptive Brake Assist<br />

system for precision braking. Braking is initiated as<br />

soon as the driver steps emphatically on the brake pedal.<br />

When an impending danger of collision is identified, the<br />

COLLISION PREVENTION ASSIST system calculates the<br />

precise braking force ideally needed to avoid an accident<br />

and makes the best possible use of any distance remaining.<br />

As a new feature, COLLISION PREVENTION ASSIST<br />

affords protection from typical rear-end collisions in<br />

dangerous traffic situations in the <strong>CLA</strong> from a speed of<br />

only 7 km/h (previously: above 30 km/h).<br />

The highlights of the new <strong>CLA</strong>-<strong>Class</strong><br />

• Avant-garde coupé design<br />

• Establishes a new segment<br />

• New world record in aerodynamics for series<br />

production cars (cd value: 0.22)<br />

• Powerful and efficient turbo engines<br />

• ECO start/stop function as standard<br />

• Numerous driving assistance systems, including<br />

advanced COLLISION PREVENTION ASSIST<br />

• New-generation 4MATIC permanent<br />

all-wheel-drive system (optional)<br />

• Seamless iPhone ® integration<br />

8<br />

9

Five lines and packages which vary greatly in character<br />

are available to individualise the striking mid-range coupé<br />

(length/width/height: 4630/1777/1437 millimetres).<br />

The style rebel: exterior design<br />

Its breathtakingly sporty proportions and powerfully<br />

dynamic design idiom, with its interplay between concave<br />

and convex surfaces, give this four-door coupé its unmistakable<br />

look.<br />

The vehicle’s striking features include the bonnet with its<br />

powerdomes, set right into the front end, and the diamond<br />

radiator grille. The light modules and LEDs behind the<br />

headlamp cover glass have been arranged in such a way<br />

as to create the characteristic “flare effect” for the daytime<br />

running lamps and indicators. This light signet<br />

defines the car’s energetic appearance and shapes<br />

a new <strong>Mercedes</strong> face.<br />

Its breathtakingly sporty proportions and powerfully dynamic design idiom,<br />

with its interplay between concave and convex surfaces, give this four-door<br />

coupé its unmistakable look.The vehicle’s striking features include the bonnet<br />

with its powerdomes, set right into the front end, and the diamond radiator grille.<br />

Numerous details indicate that on a design level the <strong>CLA</strong><br />

represents a further development of that modern classic,<br />

the <strong>Mercedes</strong>-<strong>Benz</strong> CLS. Three prominent lines give structure<br />

to the vehicle when viewed from the side: the front<br />

structural edge over the wings flows towards the rear end<br />

in a characteristic dropping line. Another, more sinewy<br />

line spans the shoulder muscle above the rear axle, while<br />

the third feature line extends in a sweeping curve from<br />

the front wheel towards the rear. Together, these lines<br />

lend depth and dynamism to the side profile.<br />

The width-emphasizing rear end radiates power and<br />

athleticism, featuring an interplay between convex and<br />

concave surfaces and edges. The gently sloping roof<br />

contour and the pronounced, hallmark curvature of the<br />

rear window provide the <strong>CLA</strong> with a coupé-style character<br />

from the rear, too. The athletic impression from the rear<br />

results from the drawn-in C-pillars in conjunction<br />

with the shoulder muscle over<br />

the rear wheel arch linings.<br />

The tail lights are<br />

framed by the muscular<br />

lines of the shoulders<br />

which extend into the<br />

rear end, the horizontal orientation of the lights emphasizing<br />

the rear’s powerful and aesthetic breadth. The light<br />

functions feature an arrow-style arrangement.<br />

“Cool touch” effect: the interior<br />

The exterior’s progressive, sporty appearance is continued<br />

inside the vehicle. The interior additionally derives a very<br />

special quality feel from the design idiom, the selection of<br />

high-quality materials and the available combinations of<br />

materials. All trim surfaces are galvanised, resulting in a<br />

metallic finish.<br />

The instrument panel incorporates five round vents. The<br />

outer rings of the round vents have a high-quality electroplated<br />

finish. The airflow direction is governed by a<br />

galvanised insert that reveals a meticulous attention to<br />

detail. The free-standing display screen features a black<br />

piano-lacquer-look front panel and, in combination with<br />

COMAND Online, a flush-fitting silver frame. The <strong>CLA</strong> is<br />

fitted with integral seats in the front and rear, underscoring<br />

its sporty character. The rear bench seat emphasizes<br />

the outer seats (2+1-seater).Coloured contrasting stitching<br />

is available, according to the selected interior appointment<br />

options. A fibre-optic cable in the opening between head<br />

restraint and backrest is optionally available as part of the<br />

ambient lighting.<br />

Sleek as they come: new record Cd value<br />

With a Cd value of 0.23, the <strong>CLA</strong> sets a new benchmark –<br />

both within the <strong>Mercedes</strong>-<strong>Benz</strong> model range and among<br />

all production vehicles. The drag area, Cd x A – which<br />

is crucial to fuel consumption at around 60 km/h and<br />

above – also leads the field, at 0.51 m 2 . The <strong>CLA</strong> 180 Blue-<br />

EFFICIENCY Edition even manages to better these top<br />

values with its Cd figure of 0.22, and when it comes to the<br />

drag area, Cd x A, the four-door coupé crosses a magical<br />

line: it is just 0.49 m².<br />

The good air flow characteristics, which are a major<br />

contributory factor to the vehicle’s low fuel consumption<br />

in everyday conditions, result from numerous aerodynamic<br />

optimisation measures. These include a low A-pillar<br />

shoulder with adapted A-pillar geometry, aerodynamically<br />

optimised exterior mirrors, streamlined rear section,<br />

wheels designed for low aerodynamic drag and serrated<br />

wheel spoilers on the front and rear wheel arches.<br />

10 11

Numerous driving assistance systems offer support in the <strong>CLA</strong> and reduce<br />

the driver’s workload. Standard-fit features for the Coupé include ATTENTION<br />

ASSIST drowsiness detection and radar-based COLLISION PREVENTION ASSIST.<br />

Optional extras include DISTRONIC PLUS radar-based adaptive cruise control,<br />

Speed Limit Assist and Active Parking Assist (photos from left to right).<br />

Extensive underbody panelling, additional panelling in<br />

the middle area of the rear axle and an aerodynamically<br />

optimised rear silencer followed by a diffuser improve the<br />

flow of air under the underbody. When it comes to aeroacoustics<br />

too, i.e. noise level comfort, the four-door coupé<br />

leads the way.<br />

Smart safety: advanced assistance systems<br />

Numerous driving assistance systems offer support in the<br />

<strong>CLA</strong> and reduce the driver’s workload. Standard-fit features<br />

for the coupé include ATTENTION ASSIST drowsiness<br />

detection and radar-based COLLISION PREVENTION<br />

ASSIST with adaptive Brake Assist, which now helps<br />

to protect the <strong>CLA</strong> from collisions from a speed of only<br />

7 km/h (previously: over 30 km/h).<br />

This feature combines with DISTRONIC PLUS to become<br />

COLLISION PREVENTION ASSIST PLUS, incorporating an<br />

additional function: when a danger of collision persists<br />

and the driver fails to respond, the system is able to carry<br />

out autonomous braking at speeds of up to 200 km/h,<br />

thereby reducing the severity of collisions with slow or<br />

stationary vehicles. The system also brakes in response to<br />

stationary vehicles at a speed of up to 30 km/h and is able<br />

to prevent rear-end collisions at speeds of up to 20 km/h.<br />

Established assistance systems, such as the Lane Tracking<br />

package with Blind Spot Assist and Lane Keeping Assist<br />

or Adaptive Highbeam Assist, are also available for the<br />

<strong>CLA</strong>. Active Parking Assist (optional) enables automatic<br />

parking in lengthways and crossways parking spaces.<br />

Designed for dynamism: the chassis and suspension<br />

The chassis of the <strong>CLA</strong> features a McPherson front axle<br />

and independent multi-link rear suspension, featuring<br />

three control arms and one trailing arm per wheel. This<br />

means that longitudinal and lateral dynamics are virtually<br />

independent of one another. A <strong>CLA</strong>-specific feature is the<br />

flexible decoupling of the rear axle carrier, which benefits<br />

ride comfort. Wheel carriers and spring links are made<br />

of aluminium, in order to reduce unsprung masses. Two<br />

chassis and suspension set-ups are available: the comfort<br />

suspension and the optional sports suspension for sporty<br />

yet comfortable handling. The latter entails lowering of<br />

the body by 15 mm (front) and 10 mm (rear).<br />

Irrespective of the selected chassis, all <strong>CLA</strong> variants<br />

come with the Direct Steer system. This electromechanical<br />

power steering offers improved feedback to the driver<br />

in comparison to conventional systems and makes an<br />

important contribution towards overall efficiency, as the<br />

steering assist function only requires energy when the<br />

steering wheel is actually turned.<br />

High tractive power reserves and outstanding agility:<br />

4MATIC all-wheel drive<br />

The <strong>CLA</strong> from <strong>Mercedes</strong>-<strong>Benz</strong> is optionally available with<br />

a new generation of the 4MATIC permanent all-wheel<br />

drive system featuring fully variable torque distribution.<br />

Similar to the other 4MATIC versions, this completely<br />

new development boasts high tractive power reserves and<br />

outstanding agility combined with superlative driving<br />

safety and energy efficiency.<br />

The components of the new 4MATIC include the power<br />

take-off to the rear axle that is integrated into the 7G-DCT<br />

automated dual clutch transmission, and the rear-axle<br />

gear with integrated, electrohydraulically controlled multidisc<br />

clutch. This set-up enables fully variable distribution<br />

of the drive torque between front and rear axle. Additional<br />

benefits of this design are a lower system weight compared<br />

with what is available from the competition as well<br />

as high efficiency.<br />

All set for the future: powerful and efficient drive<br />

The petrol engines with a displacement of 1.6 and 2.0<br />

litres cover an output spectrum ranging from 90 kW<br />

(122 hp) in the <strong>CLA</strong> 180 through 115 kW (156 hp) in the<br />

<strong>CLA</strong> 200 to 155 kW (211 hp) in the <strong>CLA</strong> 250. The two<br />

diesel engines combine dynamic low-end torque with<br />

the utmost efficiency: the <strong>CLA</strong> 200 CDI generates<br />

100 kW (136 hp), with a maximum torque of 300 Nm<br />

(available from September 2013). The <strong>CLA</strong> 220 CDI has a<br />

displacement of 2.2 litres and delivers 125 kW (170 hp)<br />

and 350 Nm of torque, while emitting only 109 g of CO 2<br />

per kilometre. All the engines feature the ECO start/stop<br />

function as standard. The engines are combined with<br />

a six-speed manual transmission or with the 7G-DCT<br />

dual clutch automatic transmission, which reconciles<br />

comfort and sportiness in inimitable fashion.<br />

The <strong>CLA</strong> from <strong>Mercedes</strong>-<strong>Benz</strong> is optionally available with a<br />

new generation of the 4MATIC permanent all-wheel drive system<br />

featuring fully variable torque distribution. Similar to the other 4MATIC<br />

versions, this completely new development boasts high tractive power reserves and<br />

outstanding agility combined with superlative driving safety and energy efficiency<br />

“Always on”: the multimedia systems<br />

The latest multimedia generation deployed in the <strong>CLA</strong><br />

boasts new functions, additional apps and a modified<br />

graphic colour scheme. The COMAND Online multimedia<br />

system has also been extended. The latest generation<br />

offers improved, photo-realistic map display, an additional<br />

Bluetooth ® profile (to enable the internet to be accessed<br />

via iPhone ® , for example), the display of images additionally<br />

in bmp and png formats and the real-time transfer<br />

of traffic data.<br />

Daimler’s Digital Drive Style app concept,<br />

which together with the Drive Kit Plus for<br />

the iPhone ® enables seamless integration<br />

of the iPhone ® into the vehicle, has<br />

been extended. The high-resolution colour<br />

display has a diagonal of 17.8 cm. Where<br />

the audio equipment is concerned, too,<br />

new forms of visualisation bring a fresh<br />

look and more convenient operation. The<br />

Cover Flow function, for instance, sorts the<br />

cover images of the stored music albums in<br />

a carousel-like form.<br />

12 13

Validation:<br />

Validation<br />

The following report gives a comprehensive, accurate and appropriate account on the basis of reliable and<br />

reproducible information.<br />

Mandate and basis of verification:<br />

The following environmental product information of Daimler AG, named as „<strong>Environmental</strong>-<strong>Certificate</strong> <strong>Mercedes</strong>-<br />

<strong>Benz</strong> <strong>CLA</strong>-<strong>Class</strong>“ with statements for the passenger vehicle types <strong>CLA</strong> 180, <strong>CLA</strong> 180 BlueEFFICIENCY Edition,<br />

<strong>CLA</strong> 200, <strong>CLA</strong> 250 and <strong>CLA</strong> 220 CDI was verified by TÜV SÜD Management Service GmbH. If applicable, the<br />

requirements outlined in the following directives and standards were taken into account:<br />

EN ISO 14040 and 14044 regarding life cycle assessment (principles and general requirements, definition<br />

of goal & scope, inventory analysis, life cycle impact assessment, interpretation, critical review)<br />

EN ISO 14020 (environmental labels and declarations – general principles) and EN ISO 14021 (criteria for<br />

self-declared environmental claims)<br />

ISO technical report ISO TR 14062 (integration of environmental aspects into product design and<br />

development<br />

Independence and objectivity of verifier:<br />

TÜV SÜD Group has not concluded any contracts regarding consultancy on product-related environmental aspects<br />

with Daimler AG either in the past or at present. TÜV SÜD Management Service GmbH is not economically<br />

dependent or otherwise involved in any way with the Daimler AG.<br />

Process and depth of detail of verification:<br />

Verification of the environmental report covered both document review and interviews with key functions and<br />

persons in charge of the design and development of the new <strong>CLA</strong>-<strong>Class</strong>.<br />

Key statements included in the environmental information, such as weight, emissions and fuel consumption were<br />

traced back to primary measuring results or data and confirmed.<br />

The reliability of the LCA (life cycle assessment) method applied was verified and confirmed by means of an external<br />

critical review in line with the requirements of EN ISO 14040/44.<br />

TÜV SÜD Management Service GmbH<br />

Munich, 2013-04-18<br />

Dipl.-Ing. Michael Brunk Dipl.-Ing. Ulrich Wegner<br />

Head of Certification Body<br />

<strong>Environmental</strong> Verifier <strong>Environmental</strong> Verifier<br />

Responsibilities:<br />

Full responsibility for the contents of the following report rests with Daimler AG. TÜV SÜD Management Service<br />

GmbH had the task to review the available information for correctness and credibility and validate it provided the<br />

pertinent requirements were satisfied.<br />

1 Product documentation<br />

This section documents significant environmentally relevant specifications<br />

of the different variants of the <strong>CLA</strong>-<strong>Class</strong> referred to in the statements<br />

on general environmental topics (Chapter 2.1).<br />

The detailed analysis of materials (Chapter 1.2), Life Cycle Assessment (Chapter 2.2),<br />

and the recycling concept (Chapter 2.3.1) refer to the <strong>CLA</strong> 180 with standard equipment.<br />

14 15

1.1 Technical data<br />

The table below shows essential technical data<br />

for the variants of the <strong>CLA</strong>-<strong>Class</strong>. The relevant environmental aspects<br />

are explained in detail in the environmental profile in Chapter 2.<br />

Characteristics <strong>CLA</strong> 180 <strong>CLA</strong> 180 <strong>CLA</strong> 200 <strong>CLA</strong> 250 <strong>CLA</strong> 220 CDI<br />

BlueEFFICIENCY<br />

Edition<br />

Engine type Petrol engine Petrol engine Petrol engine Petrol engine Diesel engine<br />

No. of cylinders 4 4 4 4 4<br />

Displacement (effective) [cc] 1595 1595 1595 1991 2143<br />

Output [kW] 90 90 115 155 125<br />

Emissions standard fulfilled EU 6 EU 6 EU 6 EU 6 EU 6<br />

Weight (without driver and luggage) [kg] 1320 1315 1320 – –<br />

– – 1355* 1405* 1450*<br />

Exhaust emissions [g/km]<br />

CO2** 130–126 118 131–127 – –<br />

– – 129–122* 144–142* 117–109*<br />

NOX 0.0128 0.0151 0.0128 – –<br />

– – 0.0124* 0.0293* 0.0650*<br />

CO 0.1011 0.1474 0.1011 – –<br />

– – 0.1773* 0.2959* 0.1577*<br />

HC (for petrol engine) 0.0438 0.0431 0.0438 – –<br />

– – 0.0411* 0.0338* –<br />

NMHC (for petrol engine) 0.0383 0.0365 0.0383 – –<br />

– – 0.0365* 0.0298* –<br />

HC+NOX (for diesel engine) – – – – 0.0855*<br />

Particulate matter 0.00011 0.00026 0.00011 – –<br />

– – 0.00032* 0.00059* 0.00116*<br />

Particle number [1/km] 2.32 E11 3.82 E11 2.31 E11 – –<br />

4.39 E11* 1.6 E11* 1.57 E09*<br />

Fuel consumption NEDC 5.6–5.4 5.0 5.7–5.5 – –<br />

combined [l/100km]** – – 5.5–5.2* 6.2–6.1* 4.5–4.2*<br />

Driving noise [dB(A)] 74 73 74 – –<br />

– – 73* 73* 73*<br />

NEDC fuel consumption for basic variant <strong>CLA</strong> 180 with manual transmission and standard tyres 5.4 l/100 km<br />

*Values with dual-clutch automatic transmission<br />

**Values depending on tyres<br />

1.2 Material composition<br />

The weight and material data for the <strong>CLA</strong> 180 were determined on the basis of internal documentation<br />

of the components used in the vehicle (parts list, drawings). The “kerb weight according to DIN”<br />

(without driver and luggage, 90 percent fuel tank filling) served as a basis for the recycling rate and<br />

Life Cycle Assessment. Figure 1-1 shows the material composition of the <strong>CLA</strong> 180<br />

in accordance with VDA 231–106.<br />

Steel/ferrous materials account for slightly over half of the<br />

vehicle weight (54.9 percent) in the <strong>CLA</strong>-<strong>Class</strong>. These are<br />

followed by polymer materials at 19.6 percent and light<br />

alloys as the third-largest group (12.7 percent). Service<br />

fluids comprise around 4.4 percent. The proportions of<br />

non-ferrous metals and of other materials (first and foremost<br />

glass) are somewhat lower, at about 3.5 percent and<br />

about 3.6 percent, respectively. The remaining materials –<br />

process polymers, electronics, and special metals – contribute<br />

about one percent to the weight of the vehicle. In<br />

this study, the material class of process polymers largely<br />

comprises materials for painting.<br />

16 17<br />

Steel/ferrous<br />

materials 54.9 %<br />

Figure 1-1: Composition of materials <strong>CLA</strong> 180<br />

The polymers are divided into thermoplastics, elastomers,<br />

duromers and non-specific plastics, with the thermoplastics<br />

accounting for the largest proportion, at 14.1 percent.<br />

Elastomers (predominantly tyres) are the second-largest<br />

group of polymers with 3.9 percent.<br />

The service fluids include oils, fuel, coolant, refrigerant,<br />

brake fluid and washer fluid. Only circuit boards with<br />

components are included in the electronics group. Cables<br />

and batteries are categorised according to their material<br />

composition.<br />

Light alloys 12.7 %<br />

Non-ferrous metals 3.5 %<br />

Special metals 0.02 %<br />

Process polymers 1.1 %<br />

Other materials 3.6 %<br />

Electronics 0.1 %<br />

Service fluids 4.4 %<br />

Polymer materials 19.6 %<br />

Thermoplastics 14.1 %<br />

Elastomers 3.9 %<br />

Duromers 0.7 %<br />

Other Plastics 0.9 %

2 <strong>Environmental</strong> profile<br />

The environmental profile documents general environmental features of the <strong>CLA</strong>-<strong>Class</strong><br />

with regard to such matters as fuel consumption, emissions or environmental management<br />

systems. It also presents specific analyses of environmental performance, such as the<br />

Life Cycle Assessment, the recycling concept and the use of secondary and<br />

renewable raw materials.<br />

2.1 General environmental issues<br />

The <strong>CLA</strong>-<strong>Class</strong> range currently comprises four petrol<br />

models with highly precise piezo injection and one diesel<br />

variant. The entry-level <strong>CLA</strong> 180 model analysed features<br />

the latest-generation 4-cylinder petrol engine (M 270)<br />

and has a very low fuel consumption of 5.6–5.4 l/100 km<br />

– depending on tyres. Implementing additional consumption-reducing<br />

measures reduced the fuel consumption<br />

of the <strong>CLA</strong> 180 “BlueEFFICIENCY Edition” even further<br />

to 5.0 l/100km.<br />

Fuel consumption in the <strong>CLA</strong> 220 CDI diesel variant<br />

is 4.5–4.2 l/100 km, equivalent to CO 2 emissions of<br />

117 and 109 g/km respectively.<br />

The fuel efficiency benefits are ensured by an intelligent<br />

package of measures. These extend to optimisation<br />

measures in the drive system, energy management and<br />

aerodynamics, as well as to tyres with optimised rolling<br />

resistance, weight reduction through lightweight construction<br />

techniques and driver information to encourage<br />

an energy-saving driving style.<br />

Contributory factors to improved<br />

environmental performance<br />

• Downsizing strategy for the engines.<br />

• Fuel consumption shown on the display.<br />

• Special “eco driver training” from <strong>Mercedes</strong>-<strong>Benz</strong>.<br />

• Certified environment management system at<br />

Kecskemét plant.<br />

• Reuse of used replacement parts.<br />

• <strong>Environmental</strong>ly compatible vehicle disposal<br />

free of charge.<br />

18<br />

19

Friction-optimised<br />

downsizing engines<br />

with turbocharger<br />

Alternator management<br />

Optimised belt drive<br />

with decoupler<br />

Clutch<br />

Air conditioning<br />

compressor<br />

Regulated fuel<br />

and oil pump<br />

Radiator shutter,<br />

depending on model<br />

Figure 2-1: Consumption-reducing measures for the new <strong>CLA</strong>-<strong>Class</strong><br />

Friction-optimised<br />

transmissions with<br />

high-geared configurations<br />

ECO start/stop system<br />

The most important measures include (see above):<br />

• For all petrol and diesel powertrains: friction-optimised<br />

downsized engines with turbocharging, direct injection<br />

and thermal management; petrol engines with<br />

CAMTRONIC (<strong>CLA</strong> 180 and <strong>CLA</strong> 200).<br />

• Friction-optimised 6-speed manual transmission and<br />

7-speed dual clutch automatic transmission, both<br />

featuring high-geared configurations.<br />

• The ECO start/stop function as standard for all<br />

engine variants.<br />

• Aerodynamic optimisation by optimised diffusor,<br />

means of spoilers at the sides of the rear window,<br />

optimised underbody and rear axle panelling,<br />

radiator shutter and Aero hub caps.<br />

• Use of tyres with optimised rolling resistance.<br />

Reduced-friction<br />

wheel bearings<br />

Weight optimisation through<br />

the use of lightweight materials<br />

Optimised aerodynamics:<br />

Optimised diffuser, spoilers at sides of rear window,<br />

optimised underbody and rear axle panelling, radiator<br />

shutter and optimised wheels and hub caps.<br />

<strong>CLA</strong>180 BlueEFFICIENCY Edition:<br />

Additional aerodynamic measures, transmission<br />

with high-geared configuration, lowered suspension.<br />

ECO display in instrument cluster<br />

Tyres with low<br />

rolling resistance<br />

• Wheel bearings with substantially reduced friction.<br />

• Weight optimisation through the use of lightweight<br />

materials.<br />

• Regulated fuel and oil pump are able to adjust pump<br />

output according to required load.<br />

• Intelligent generator management in conjunction with<br />

an efficient generator ensures that consumers are<br />

powered from the battery during acceleration, while<br />

during braking part of the resulting energy is<br />

recuperated and stored back in the battery.<br />

• Highly efficient air conditioning compressor with<br />

optimised oil management, reduced displacement and<br />

magnetic clutch which avoids friction losses.<br />

• Optimised belt drive with decoupler.<br />

With a cd value of 0.23,<br />

the <strong>CLA</strong> 180 sets a new benchmark.<br />

The drag area cd x A – which is crucial in terms of wind<br />

resistance – also leads the field, at 0.51 m 2 . The good air<br />

flow characteristics, which are a major contributory factor<br />

to the vehicle’s low fuel consumption in everyday conditions,<br />

result from numerous aerodynamic optimisation<br />

measures.<br />

These include a low A-pillar shoulder with adapted<br />

A-pillar geometry, aerodynamically optimised exterior<br />

mirror housings and rear shape, wheel trims designed for<br />

low aerodynamic drag and serrated wheel spoilers on the<br />

front and rear wheel arches.<br />

The <strong>CLA</strong> 180 BlueEFFICIENCY Edition, which is due to hit<br />

the streets in June, even manages to better this value with<br />

its cd value of 0.22, and when it comes to the drag area,<br />

the four-door coupé crosses a magical line with its 0.49 m 2 .<br />

The good air flow characteristics result from numerous aerodynamic<br />

optimisation measures. The patented wheel spoiler<br />

was developed with the help of airflow analysis. Extensive<br />

underbody panelling, additional panelling in the middle area of<br />

the rear axle and an aerodynamically optimised rear silencer<br />

improve the flow of air under the underbody.<br />

In addition to the improvements to the vehicle, the driver also<br />

has a decisive influence on fuel consumption. For this reason, a<br />

display in the middle of the instrument cluster shows the current<br />

fuel consumption level. This easy-to-read bar indicator reacts<br />

spontaneously as soon as the driver takes his foot off the accelerator<br />

and uses the engine’s overrun cut-off, for example. The<br />

<strong>CLA</strong>-<strong>Class</strong> Owner’s Manual also includes additional tips for an<br />

economical and environmentally friendly driving style.<br />

Furthermore, <strong>Mercedes</strong>-<strong>Benz</strong> offers its customers “Eco Driver<br />

Training”. The results of this training course show that adopting<br />

an efficient and energy-conscious style of driving can help to<br />

reduce the fuel consumption of a car by up to 15 percent.<br />

20 21

The <strong>CLA</strong>-<strong>Class</strong> is also fit for the future when it comes to<br />

its fuels. The EU plans include an increasing proportion<br />

of biofuels. It goes without saying that the <strong>CLA</strong>-<strong>Class</strong> will<br />

meet these requirements: in the case of petrol engines,<br />

a bioethanol content of 10 % (E 10) is permitted. A 10 %<br />

biofuel component is also permitted for diesel engines in<br />

the form of 7 % biodiesel (B 7 FAME) and 3 % high-quality,<br />

hydrogenated vegetable oil.<br />

High efficiency is achieved in terms of exhaust gas<br />

emissions, too. All new engines already meet the requirements<br />

of the Euro 6 emissions standard which comes into<br />

force in 2014. The petrol engines even better the much<br />

more stringent diesel particulate limit in the Euro 6 standard<br />

with no additional exhaust aftertreatment. The <strong>CLA</strong><br />

220 CDI is equipped with multiple exhaust gas recirculation,<br />

which reduces nitrogen oxide emissions.<br />

The <strong>CLA</strong>-<strong>Class</strong> is produced at the new <strong>Mercedes</strong> plant in<br />

Kecskemét (Hungary). Right from the start, this production<br />

facility has had an environmental management system<br />

certified to EU eco-audit regulations and ISO Standard<br />

14001. The paint technology used for the <strong>CLA</strong>-<strong>Class</strong>, for<br />

example, is not only state of the art but also stands out<br />

by virtue of its high levels of environmental friendliness,<br />

efficiency and quality, which are achieved thanks<br />

to consistent use of water-based paints. <strong>Environmental</strong>ly<br />

friendly technologies are also used to generate energy at<br />

the Kecskemét plant. The plant’s two combined heat and<br />

power units use clean natural gas to supply electricity and<br />

heating. Heat recovery in the ventilation systems in the<br />

production halls plays an equally important role, since<br />

this reduces the amount of fuel used significantly<br />

High environmental standards are also firmly established<br />

in the environmental management systems in the sales<br />

and after-sales sectors at <strong>Mercedes</strong>-<strong>Benz</strong>. At dealer level,<br />

<strong>Mercedes</strong>-<strong>Benz</strong> meets its product responsibility with the<br />

MeRSy recycling system for workshop waste, used parts<br />

and warranty parts and packaging materials. The take-back<br />

system introduced in 1993 also means that <strong>Mercedes</strong>-<strong>Benz</strong><br />

is a model for the automotive industry where workshop<br />

waste disposal and recycling are concerned.<br />

This exemplary service by an automotive manufacturer<br />

is implemented right down to customer level. The waste<br />

materials produced in our outlets during servicing and repairs<br />

are collected, reprocessed and recycled via a network<br />

operating throughout Germany. <strong>Class</strong>ic components include<br />

bumpers, side panels, electronic scrap, glass and tyres.<br />

The reuse of parts also has a long tradition at <strong>Mercedes</strong>-<br />

<strong>Benz</strong>. The <strong>Mercedes</strong>-<strong>Benz</strong> Used Parts Center (GTC) was<br />

established back in 1996. With its quality-tested used<br />

parts, the GTC is an integral part of the service and parts<br />

operations for the <strong>Mercedes</strong>-<strong>Benz</strong> brand and makes an<br />

important contribution to the appropriately priced repair<br />

of <strong>Mercedes</strong>-<strong>Benz</strong> vehicles.<br />

Although the reuse of <strong>Mercedes</strong> passenger cars lies<br />

in the distant future in view of their long service life,<br />

<strong>Mercedes</strong>-<strong>Benz</strong> offers a new, innovative procedure for<br />

the rapid disposal of vehicles in an environmentally<br />

friendly manner and free of charge. For convenient<br />

disposal, a comprehensive network of collection points<br />

and dismantling facilities is available to <strong>Mercedes</strong><br />

customers. Owners of used cars can find out all the<br />

important details relating to the return of their vehicles<br />

via the free phone number 00800 1 777 7777.<br />

The <strong>Mercedes</strong>-<strong>Benz</strong> <strong>CLA</strong> is the first car to be built exclusively<br />

at the new plant in Kecskemét, Hungary. The factory was inaugurated<br />

in the spring of 2012, and production of the <strong>CLA</strong> started<br />

on 3 January 2013.<br />

22 23

2.2 Life Cycle Assessment (LCA)<br />

The environmental compatibility of a vehicle is determined by the environmental burden caused<br />

by emissions and the consumption of resources throughout the vehicle’s lifecycle (cf. Figure 2-2).<br />

The standardised tool for evaluating a vehicle’s environmental compatibility is the Life Cycle<br />

Assessment. It comprises the total environmental impact of a vehicle from the cradle to the<br />

grave, in other words from raw material extraction through production and use up to recycling.<br />

Down to the smallest detail<br />

• With life cycle assessment, <strong>Mercedes</strong>-<strong>Benz</strong> registers<br />

all of the effects of a vehicle on the environment –<br />

from development via production and operation<br />

through to disposal.<br />

• For a complete assessment, within each life cycle<br />

phase all environmental impacts are accounted for.<br />

• Many emissions arise not so much during driving,<br />

but in the course of fuel production – for example<br />

non-methane hydrocarbon (NMVOC)* and sulphur<br />

dioxide emissions.<br />

• The detailed analysis also includes the consumption<br />

and processing of bauxite (aluminium production),<br />

iron and copper ore.<br />

* NMVOC (non-methane volatile organic compounds)<br />

The elements of a Life Cycle Assessment are:<br />

1. Goal and scope definition<br />

define the objective and scope of an LCA.<br />

2. Inventory analysis<br />

encompasses the material and energy flows<br />

throughout all stages of a vehicle’s life: how many<br />

kilograms of raw material are used, how much<br />

energy is consumed, what wastes and emissions<br />

are produced, etc.<br />

3. Impact assessment<br />

gauges the potential effects of the product on<br />

the environment, such as global warming potential,<br />

summer smog potential, acidification potential,<br />

and eutrophication potential.<br />

4. Interpretation<br />

draws conclusions and makes recommendations.<br />

In the development of <strong>Mercedes</strong>-<strong>Benz</strong> passenger cars,<br />

life cycle assessments are used in the evaluation and<br />

comparison of different vehicles, components, and<br />

technologies.<br />

The DIN EN ISO 14040 and DIN EN ISO 14044 standards<br />

prescribe the procedure and the required elements.<br />

Figure 2-2: Overview of the Life Cycle Assessment<br />

24 25

2.2.1 Data basis<br />

The ECE basic variant is analysed in the Life Cycle<br />

Assessment. The <strong>CLA</strong> 180 with manual transmission<br />

(90 kW) served as the basic variant for the new<br />

<strong>CLA</strong>-<strong>Class</strong>. The main parameters of the LCA are shown<br />

in the table below.<br />

Project objectives<br />

Project objectives • Life Cycle Assessment of the new <strong>CLA</strong>-<strong>Class</strong> as the ECE basic variant with <strong>CLA</strong> 180 engine.<br />

Project scope<br />

• Verification of attainment of the objective “environmental compatibility” and communication.<br />

Functional equivalent • <strong>CLA</strong>-<strong>Class</strong> passenger car (basic variant, weight in acc. with DIN 70020).<br />

System boundaries • Life Cycle Assessment for car production, use and recycling.<br />

• The scope of assessment is only to be extended in the case of elementary flows (resources, emissions, non-recyclable materials).<br />

Data basis • Weight data of car: MB parts list (date of revision: 01/2013).<br />

• Materials information for model-relevant, vehicle-specific parts:<br />

MB parts list, MB internal documentation systems, IMDS, technical literature.<br />

• Vehicle-specific model parameters (bodyshell, paintwork, catalytic converter, etc.): MB specialist departments.<br />

• Location-specific energy supply: MB database.<br />

• Materials information for standard components: MB database.<br />

• Use (fuel consumption, emissions): type approval/certification data.<br />

Use (mileage): MB specification.<br />

• Recycling model: state of the art (also see Chapter 2.3.1).<br />

• Material production, energy supply, manufacturing processes and transport:<br />

GaBi database as at SP18 (http://documentation.gabi-software.com); MB database.<br />

Allocations • For material production, energy supply, manufacturing processes, and transport, reference is made to GaBi databases<br />

and the allocation methods they employ.<br />

• No further specific allocations.<br />

Table 2-1: Life Cycle Assessment basic conditions<br />

The fuel has a sulphur content taken to be 10 ppm.<br />

Combustion of one kilogram of fuel thus yields 0.02 grams<br />

of sulphur dioxide emissions. The use phase is calculated<br />

on the basis of a mileage of 160,000 kilometres.<br />

Project scope (continued)<br />

Cut-off criteria • For material production, energy supply, manufacturing processes, and transport, reference is made to GaBi databases<br />

and the cut-off criteria they employ.<br />

• No explicit cut-off criteria. All available weight information is processed.<br />

• Noise and land use are currently not available as life cycle inventory data and are therefore not taken into account.<br />

• “Fine dust” and particulate matter and emissions are not analysed. Major sources of particulate matter (mainly tyre and brake<br />

abrasion) are not dependent on vehicle type. Vehicle care and maintenance are not relevant to the comparison.<br />

Assessment • Life cycle, in conformity with ISO 14040 and 14044 (LCA).<br />

Analysis parameters • • Material composition according to VDA 231-106.<br />

• Life cycle inventory: consumption of resources as primary energy, emissions, e.g. CO 2 , CO, NOx, SO 2 , NMVOC, CH 4 , etc.<br />

• Impact assessment: abiotic depletion potential (ADP), global warming potential (GWP), photochemical ozone creation potential<br />

(POCP), eutrophication potential (EP), acidification potential (AP).<br />

These impact assessment parameters are based on internationally accepted methods. They are modelled on categories<br />

selected by the European automotive industry, with the participation of numerous stakeholders, in an EU project under the<br />

name LIRECAR. The mapping of impact potentials for human toxicity and ecotoxicity does not yet have sufficient scientific<br />

backing today and therefore will not deliver useful results.<br />

• Interpretation: sensitivity analyses of car module structure; dominance analysis over life cycle.<br />

Software support • MB DfE-Tool. This tool models a car with its typical structure and typical components, including their manufacture,<br />

and is adapted with vehicle-specific data on materials and weights. It is based on the LCA software GaBi 4.4<br />

(http://www.pe-international.com/gabi).<br />

Evaluation • Analysis of lifecycle results according to phases (dominance). The manufacturing phase is evaluated based on the<br />

underlying car module structure. Contributions of relevance to the results will be discussed.<br />

Documentation • Final report with all basic conditions.<br />

The LCA includes the environmental impact of the<br />

recovery phase on the basis of the standard processes<br />

of drying, shredding, and recovery of energy from the<br />

shredder light fraction (SLF). <strong>Environmental</strong> credits are<br />

not granted.<br />

26 27

2.2.2 LCA results for the <strong>CLA</strong> 180<br />

Over the entire life cycle of the <strong>CLA</strong> 180, the life cycle<br />

inventory analysis yields for example a primary energy<br />

consumption of 436 gigajoules (corresponding to the energy<br />

content of around 13,350 litres of petrol), an environmental<br />

input of approx. 30 tonnes of carbon dioxide (CO 2),<br />

around 16 kilograms of non-methane volatile organic<br />

compounds (NMVOC), around 18 kilograms of nitrogen<br />

oxides (NO x) and 28 kilograms of sulphur dioxide (SO 2). In<br />

addition to an analysis of the overall results, the distribution<br />

of individual environmental factors on the various<br />

phases of the life cycle is investigated. The relevance of<br />

the respective life cycle phases depends on the particular<br />

environmental impact under consideration. For CO 2 emissions,<br />

and likewise for primary energy consumption, the<br />

use phase dominates with a share of 80 and 75 percent<br />

respectively (see Figure 2-3/2-4).<br />

CO2emissions [t/car]<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

5.5<br />

24.0<br />

0.5<br />

Production Use Recycling<br />

POCP [kg ethene equiv.]<br />

28 29<br />

ADP fossil [GJ]<br />

EP [kg phosphate equiv.]<br />

AP [kg SO2-equiv.]<br />

GWP100 [t CO2-equiv.]<br />

CH4 [kg]<br />

SO2 [kg]<br />

NMVOC [kg]<br />

NOX [kg]<br />

CO [kg]<br />

Primary energy demand [GJ]<br />

Figure 2-3: Overall carbon dioxide emissions (CO2) in tons Figure 2-4: Share of life cycle phases for selected parameters<br />

However, it is not the use of the vehicle alone which<br />

determines its environmental compatibility. Some environmentally<br />

relevant emissions are caused principally<br />

by manufacturing, for example SO 2 and NO x emissions<br />

(see Figure 2-4). The production phase must therefore be<br />

included in the analysis of ecological compatibility. It is<br />

not actual operation, but rather fuel production which is<br />

now the dominant factor for a variety of emissions, such<br />

as NMVOC and NO x emissions, and for closely associated<br />

environmental effects such as photochemical ozone creation<br />

potential (POCP: summer smog, ozone) and acidification<br />

potential (AP).<br />

CO2 [t]<br />

Car production Fuel production Operation Recycling<br />

0 % 10 % 20 % 30 % 40 % 50 % 60 % 70 % 80 % 90 % 100 %<br />

For comprehensive and thus sustainable improvement of<br />

the environmental impacts associated with a vehicle, the<br />

end-of-life phase must also be considered. In the interests<br />

of energy efficiency it is expedient to use or initiate<br />

recycling cycles. For a complete assessment, within each<br />

life cycle phase all environmental inputs are accounted<br />

for. In addition to the results presented above it has also<br />

been determined, for example, that municipal waste and<br />

tailings (first and foremost ore processing residues and<br />

overburden) arise primarily from the production phase,<br />

while special and hazardous waste is caused for the most<br />

part by fuel production during the usage phase.<br />

<strong>Environmental</strong> burdens in the form of emissions into water<br />

result from vehicle manufacturing, in particular owing<br />

to the output of heavy metals, NO 3- and SO 4 2- ions as well<br />

as the factors AOX, BOD and COD.<br />

To enable an assessment of the relevance of the respective<br />

environmental impacts, the impact categories fossil<br />

abiotic depletion potential (ADP), eutrophication potential<br />

(EP), photochemical ozone creation potential (summer<br />

smog, POCP), global warming potential (GWP) and acidification<br />

potential (AP) are presented in normalised form for<br />

the life cycle of the <strong>CLA</strong> 180.<br />

8<br />

397<br />

4<br />

45<br />

31<br />

37<br />

28<br />

16<br />

18<br />

52<br />

436<br />

30

8,00E-10<br />

7,00E-10<br />

6,00E-10<br />

5,00E-10<br />

4,00E-10<br />

3,00E-10<br />

2,00E-10<br />

1,00E-10<br />

0,00E-10<br />

Figure 2-5: Normalised life cycle [–/car]<br />

Normalisation involves assessing the LCA results in relation<br />

to a higher-level reference system in order to obtain a<br />

better understanding of the significance of each indicator<br />

value. Europe served as the reference system here. The<br />

total annual values for Europe (EU 25+3) were employed<br />

for the purposes of normalisation, breaking down the<br />

life cycle of the <strong>CLA</strong> 180 over one year. In relation to the<br />

annual European values, the <strong>CLA</strong> 180 reveals the greatest<br />

proportion for fossil ADP, followed by GWP (cf. Figure 2-5).<br />

The relevance of these two impact categories on the basis<br />

of EU 25 +3 is therefore greater than that of the remaining<br />

impact categories examined. The proportion is the lowest<br />

in eutrophication.<br />

Recycling<br />

Use<br />

Production<br />

ADP (fossil) EP POCP GWP AP<br />

In addition to the analysis of overall results, the distribution<br />

of selected environmental effects on the production<br />

of individual modules is investigated. Figure 2-6 shows by<br />

way of example the percentage distribution of carbon dioxide<br />

and sulphur dioxide emissions for different modules.<br />

While bodyshell manufacturing features predominantly<br />

in terms of carbon dioxide emissions, due to the mass<br />

share, when it comes to sulphur dioxide it is modules<br />

with precious and non-ferrous metals and glass that are of<br />

greater relevance, since these give rise to high emissions<br />

of sulphur dioxide in material production.<br />

Total vehicle (painting)<br />

Passenger cell/bodyshell<br />

0 % 5 % 10 % 15 % 20 % 25 %<br />

Emissions for car production [%]<br />

30 31<br />

Flaps/wings<br />

Doors<br />

Cockpit<br />

Mounted external parts<br />

Mounted internal parts<br />

Seats<br />

Electrics/electronics<br />

Tyres<br />

Operation of the vehicle<br />

Fuel system<br />

Hydraulics<br />

Engine/transmission periphery<br />

Engine<br />

Transmission<br />

Steering<br />

Front axle<br />

Rear axle<br />

Figure 2-6: Distribution of selected parameters (CO2 and SO2) to modules<br />

CO2 [%]<br />

SO2 [%]<br />

New <strong>CLA</strong>-<strong>Class</strong><br />

Production overall<br />

CO 2 5.5 t<br />

SO 2 14.2 kg

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

Bauxite<br />

[kg]<br />

Iron ore<br />

[kg]**<br />

Mixed ores<br />

[kg]*/**<br />

* Above all for extraction of the elements lead, copper and zinc<br />

**In the form of ore concentrate<br />

Material resources [kg/car] Energy resources [GJ/car]<br />

Figure 2-7: Consumption of selected material and energy resources [units/car]<br />

Figure 2-7 shows the consumption of relevant material<br />

and energy resources. When it comes to the demand<br />

for material resources, such as iron ore and bauxite,<br />

car production dominates. However, energy resources<br />

(particularly crude oil) are consumed predominantly<br />

in the use phase.<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Lignite<br />

[GJ]<br />

Hard coal<br />

[GJ]<br />

Crude oil<br />

[GJ]<br />

Natural gas<br />

[GJ]<br />

Uranium<br />

[GJ]<br />

Renewable<br />

energy<br />

resources<br />

[GJ]<br />

Tables 2-2 and 2-3 present an overview of further LCA<br />

parameters. The lines with grey shading indicate superordinate<br />

impact categories; they group together emissions<br />

with the same effects and quantify their contribution to<br />

the respective impacts over a characterisation factor, e.g.<br />

contribution to global warming potential in kilograms of<br />

CO 2 equivalent.<br />

32 33<br />

Input parameters<br />

Resources, ores New <strong>CLA</strong>-<strong>Class</strong> Comments<br />

Bauxite [kg] 439 Aluminium production.<br />

Dolomite [kg] 1 Magnesium production.<br />

Iron ore [kg]** 743 Steel production.<br />

Mixed ores (esp. Cu, Pb, Zn) [kg]** 83 esp. electrics (cable harnesses, battery) and zinc.<br />

Rare earth ores/precious metal ores [kg]** 0.9 Engine/transmission peripherals (catalytic converter load).<br />

Energy sources<br />

ADP fossil* [GJ] 397 esp. fuel consumption.<br />

Primary energy [GJ]<br />

Proportionately<br />

436 Approx. 75 % due to usage.<br />

Lignite [GJ] 9.9 Approx. 84 % due to car production.<br />

Natural gas [GJ] 49 Approx. 47 % due to usage.<br />

Crude oil [GJ] 321 Approx. 93 % due to usage.<br />

Hard coal [GJ] 28 Approx. 94 % due to car production.<br />

Uranium [GJ] 18 Approx. 86 % due to car production.<br />

Renewable energy resources [GJ]<br />

Table 2-2: Overview of LCA parameters (I)<br />

9.7 Approx. 82 % due to car production.<br />

Output parameters<br />

Emissions into air New <strong>CLA</strong>-<strong>Class</strong> Comments<br />

GWP* [t CO2 equiv.] 31 esp. due to CO2 emissions.<br />

AP* [kg SO2 equiv.] 45 esp. due to SO2 emissions.<br />

EP* [kg phosphate equiv.] 4 esp. due to NOX emissions.<br />

POCP* [kg ethene equiv.] 8 esp. due to NMVOC emissions.<br />

CO2 [t] 30 esp. due to driving operation.<br />

CO [kg] 52 Around 62 % due to car production.<br />

NMVOC [kg] 16 Around 73 % due to use, of which approx. 39 % driving operation.<br />

CH4 [kg] 37 Around 33 % due to car production. The remainder esp. due to fuel production.<br />

Driving operation accounts for only around 2 %.<br />

NOX [kg] 18 Around 52 % due to car production. The remainder due to car use.<br />

Driving operation accounts for approx. 12 % of total nitrogen oxide emissions.<br />

SO2 [kg] 28 Due to car and fuel production in roughly equal amounts.<br />

Emissions into water<br />

BSB [kg] 0.3 Approx. 77 % due to car production.<br />

Hydrocarbons [kg] 0.2 Approx. 73 % due to use.<br />

NO3 - [g] 1042 Approx. 59 % due to use.<br />

PO4 3- [g] 24 Approx. 55 % due to use.<br />

SO4 2- [kg] 14 Approx. 50 % due to production.<br />

Table 2-3: Overview of LCA parameters (II)<br />

* CML 2001, date of revision: November 2009<br />

** In the form of ore concentrate

2.3 Design for recovery<br />

With the adoption of the European ELV Directive (2000/53/EC) on 18 September 2000,<br />

the conditions for recovery of end-of-life vehicles were revised.<br />

The aims of this directive are to avoid vehicle-related<br />

waste and encourage the take-back, reuse and recycling<br />

of vehicles and their components. The resulting requirements<br />

for the automotive industry are as follows:<br />

• Establishment of systems for collection of end-of-life<br />

vehicles (ELVs) and used parts from repairs.<br />

• Achievement of an overall recovery rate of 95 percent<br />

by weight by 01.01.2015 at the latest.<br />

• Evidence of compliance with the recycling rate<br />

as part of type approval for new passenger cars as of<br />

December 2008.<br />

• Take-back of all ELVs free of charge<br />

from January 2007.<br />

• Provision of dismantling information to<br />

ELV recyclers within six months of market launch.<br />

• Prohibition of lead, hexavalent chromium, mercury<br />

and cadmium, taking into account the exceptions in<br />

Annex II.<br />

The <strong>CLA</strong>-<strong>Class</strong> already meets the recovery rate of<br />

95 percent by weight, effective 01.01.2015.<br />

• End-of-life vehicles have been taken back by <strong>Mercedes</strong>-<strong>Benz</strong><br />

free of charge since January 2007.<br />

• Heavy metals such as lead, hexavalent chromium, mercury<br />

or cadmium have been eliminated in accordance with the<br />

requirements of the ELV Directive.<br />

• <strong>Mercedes</strong>-<strong>Benz</strong> already currently has a highly<br />

efficient take-back and recycling network.<br />

• By reselling certified used parts,<br />

the <strong>Mercedes</strong> Used Parts Center makes an important<br />

contribution to the recycling concept.<br />

• As early as the development phase of the <strong>CLA</strong>-<strong>Class</strong>,<br />

attention was paid to separation and ease of dismantling<br />

of relevant thermoplastic components.<br />

• Detailed dismantling information is available to all<br />

ELV recyclers in electronic form via the<br />

International Dismantling Information System (IDIS).<br />

34<br />

35

2.3.1 Recycling concept for the new <strong>CLA</strong>-<strong>Class</strong><br />

The calculation procedure is regulated in ISO standard 22628,<br />

“Road vehicles – Recyclability and recoverability – calculation method”.<br />

The calculation model reflects the real ELV recycling<br />

process and is divided into four stages:<br />

1. Pre-treatment (removal of all service fluids, tyres, the<br />

battery and catalytic converters, ignition of airbags).<br />

2. Dismantling (removal of replacement parts and/or<br />

components for material recycling).<br />

3. Separation of metals in the shredder process.<br />

4. Treatment of non-metallic residual fraction<br />

(shredder light fraction – SLF).<br />

The recycling concept for the <strong>CLA</strong>-<strong>Class</strong> was devised in<br />

parallel with development of the vehicle; the individual<br />

components and materials were analysed for each stage<br />

of the process. The volume flow rates established for each<br />

stage together yield the recycling and recovery rates<br />

for the entire vehicle. With the process chain described<br />

below, overall a material recyclability rate of 85 percent<br />

and a recoverability rate of 95 percent were verified on<br />

the basis of the ISO 22628 calculation model for the new<br />

<strong>CLA</strong>-<strong>Class</strong> as part of the vehicle type approval process<br />

(see Figure 2-8).<br />

At the ELV recycler’s premises, the fluids, battery, oil<br />

filter, tyres, and catalytic converters are removed as part<br />

of the pre-treatment process. The airbags are triggered<br />

with a device that is standardised among all European car<br />

manufacturers. During dismantling, the prescribed parts<br />

are first removed according to the European ELV Directive.<br />

To improve recycling, numerous components and assemblies<br />

are then removed and are sold directly as used spare<br />

parts or serve as a basis for the manufacturing of replacement<br />

parts.<br />

In addition to used parts, materials that can be recycled<br />

using economically appropriate procedures are selectively<br />

removed in the vehicle dismantling process. These include<br />

components of aluminium and copper as well as selected<br />

large plastic components.<br />

During the development of the <strong>CLA</strong>-<strong>Class</strong>, these components<br />

were specifically prepared for subsequent recycling.<br />

In addition to material purity, attention was also paid to<br />

ease of dismantling of relevant thermoplastic components<br />

such as bumpers, wheel arch linings, outer sills, underfloor<br />

panelling and engine compartment coverings.<br />

R = (m +m +m +m )/m x 100 > 85 percent<br />

cyc P D M Tr V<br />

R = R + m /m x 100 > 95 percent<br />

cov cyc Te V<br />

Figure 2-8: Material flows in the <strong>CLA</strong>-<strong>Class</strong> recycling concept<br />

In addition, all plastic parts are marked in accordance<br />

with international nomenclature. In the subsequent shredding<br />

of the residual body, the metals are first separated for<br />

recycling in the raw material production processes. The<br />

largely organic remaining portion is separated into different<br />

fractions for environment-friendly treatment in raw<br />

material or energy recovery processes.<br />

ELV recycler Shredder operators<br />

1) in acc. with 2000/53/EC<br />

2) SLF = shredder light fraction<br />

36 37<br />

Vehicle mass: m V<br />

Pre-treatment: m P<br />

Fluids<br />

Battery<br />

Tires<br />

Airbags<br />

Catalytic converters<br />

Oil filter<br />

Dismantling: m D<br />

Prescribed parts 1 ),<br />

Components for<br />

recovery<br />

and recycling<br />

Segregation<br />

of metals: m M<br />

Residual metal<br />

SLF 2 ) treatment<br />

m Tr = recycling<br />

m Te = energy recovery

2.3.2 Dismantling information<br />

Dismantling information plays an important role for ELV<br />

recyclers when it comes to implementing the recycling concept.<br />

Figure 2-9: Screenshot of the IDIS software<br />

For the <strong>CLA</strong>-<strong>Class</strong> too, all necessary information is provided<br />

in electronic form via the International Dismantling<br />

Information System (IDIS).This IDIS software provides<br />

vehicle information for ELV recyclers, on the basis of<br />

which vehicles can be subjected to environmentally<br />

friendly pretreatment and recycling techniques at the<br />

end of their operating lives.<br />

The system presents model-specific data both graphically<br />

and in text form. In pre-treatment, specific information is<br />

provided on service fluids and pyrotechnic components. In<br />

the other areas, material-specific information is provided<br />

for the identification of non-metallic components.<br />

The current version (January 2013) covers 843 models and<br />

1753 variants from 75 car brands. The IDIS data are made<br />

available to ELV recyclers and incorporated into the software<br />

six months after the respective market launch.<br />

2.3.3 Avoidance of potentially hazardous materials<br />

The avoidance of hazardous substances is a matter of top<br />

priority in the development, manufacturing, use, and<br />

recycling of <strong>Mercedes</strong>-<strong>Benz</strong> vehicles.<br />

For the protection of humans and the environment,<br />

substances and substance classes whose presence is not<br />

permitted in materials or components of <strong>Mercedes</strong>-<strong>Benz</strong><br />

passenger cars have been listed in our internal standard<br />

(DBL 8585) since 1996. This standard is already made<br />

available to the designers and materials experts at the<br />

advanced development stage for both the selection of<br />

materials and the definition of manufacturing processes.<br />

The continual reduction of interior emissions<br />

is a key aspect of the development of components<br />

and materials for <strong>Mercedes</strong>-<strong>Benz</strong> vehicles.<br />

The heavy metals lead, cadmium, mercury, and hexavalent<br />

chromium, which are prohibited by the ELV Directive of<br />

the EU, are also included here. To ensure compliance with<br />

the ban on heavy metals in accordance with the legal<br />

requirements, <strong>Mercedes</strong>-<strong>Benz</strong> has modified and adapted<br />

numerous processes and requirements both internally<br />

and with suppliers.<br />

The new <strong>CLA</strong>-<strong>Class</strong> complies with valid regulations. For<br />

example, lead-free elastomers are used in the drive system,<br />

along with lead-free pyrotechnic initiators, cadmiumfree<br />

thick film pastes, and surfaces free of hexavalent<br />

chromium in the interior, exterior, and assemblies.<br />

Materials used for components in the passenger compartment<br />

and boot are also subject to emission limits that are<br />

likewise laid down in the DBL 8585 standard as well as in<br />

delivery conditions for the various components. The continual<br />

reduction of interior emissions is a major aspect of<br />

component and material development for <strong>Mercedes</strong>-<strong>Benz</strong><br />

vehicles.<br />

38 39

2.4 Use of secondary raw materials<br />

In the <strong>CLA</strong>-<strong>Class</strong>, 42 components with an overall weight<br />

of 30.8 kilograms can be manufactured partly from highquality<br />

recycled plastics.<br />

• These include wheel arch linings and underbody panelling.<br />

• Wherever possible, secondary raw materials are derived<br />

from vehicle-related waste streams: The wheel arch<br />

linings are made from reprocessed starter batteries and<br />

bumper coverings. Waste products from the production of<br />

dashboards are reprocessed to produce the battery holders.<br />

Component <strong>CLA</strong>-<strong>Class</strong><br />

weight in kg 30.8<br />

In addition to the requirements for attainment of<br />

recycling rates, manufacturers are obliged by Article 4,<br />

Paragraph 1 (c) of the European ELV Directive 2000/53/EC<br />

to make increased use of recycled materials in vehicle production<br />

and thereby to establish or extend the markets for<br />

recycled materials. To comply with these stipulations, the<br />

specifications books for new <strong>Mercedes</strong> models prescribe<br />

continuous increases in the share of the secondary raw<br />

materials used in car models.<br />

The main focus of the recycled material research accompanying<br />

vehicle development is on thermoplastics. In<br />

contrast to steel and ferrous materials, to which secondary<br />

materials are already added at the raw material stage, recycled<br />

plastics must be subjected to a separate testing and<br />

approval process for the relevant component. Accordingly,<br />

details of the use of secondary raw materials in passenger<br />

cars are only documented for thermoplastic components,<br />

as only this aspect can be influenced during development.<br />

The quality and functionality requirements placed on a<br />

component must be met both with secondary raw materials<br />

and with comparable new materials. To safeguard passenger<br />

car production even when shortages are encountered<br />

on the recycled materials market, new materials<br />

may also be used as an option.<br />

In the <strong>CLA</strong>-<strong>Class</strong>, 42 components with an overall weight<br />

of 30.8 kilograms can be manufactured partly from highquality<br />

recycled plastics. Typical areas of use are wheel<br />

arch linings and underbody panels, which consist for<br />

the most part of polypropylene. Figure 2-10 shows the<br />

components for which the use of secondary raw materials<br />

is approved.<br />

A further objective is to obtain secondary raw materials<br />

wherever possible from vehicle-related waste flows, so as<br />

to achieve closed cycles. To this end, established processes<br />

are applied for the <strong>CLA</strong>-<strong>Class</strong>. A secondary raw material<br />

comprised of reprocessed starter batteries and bumper<br />

panelling is used for the wheel arch linings, for example.<br />

The process for manufacturing battery holders is new and<br />

being used in this class for the first time at <strong>Mercedes</strong>-<br />

<strong>Benz</strong>. Waste products from the production of dashboards<br />

are reprocessed so that the high-quality plastic can be<br />

recuperated. This is then processed further in the MuCell ®<br />

(Micro Cellular Foam Injection Moulding) procedure,<br />

which is where the finest of gas bubbles are worked into<br />

the plastic, causing its density and consequently the<br />

weight of the components produced from it to be reduced.<br />

Figure 2-10: Use of secondary raw materials in the new <strong>CLA</strong>-<strong>Class</strong><br />

Figure 2-11: Use of secondary raw materials, taking the wheel arch lining as an<br />

example (ashere in the current B-<strong>Class</strong>).<br />

As a result the advantages for the environment are twofold,<br />

through the use of the recycled plastic and through<br />

the reduction of weight.<br />

40 41

2.5 Use of renewable raw materials<br />

Component <strong>CLA</strong>-<strong>Class</strong><br />

weight in kg 19<br />

In automotive production, the use of renewable raw<br />

materials is concentrated primarily in the vehicle interior.<br />

Conventional natural materials such as coconut, cellulose<br />

and wood fibres, wool and natural rubber are also used<br />

as standard in the <strong>CLA</strong>-<strong>Class</strong>, of course. The use of these<br />

natural materials gives rise to a whole range of advantages<br />

in automotive production:<br />

• Compared with glass fibre, natural fibres normally<br />

result in a reduced component weight.<br />

• Renewable raw materials help to reduce the con-<br />

sumption of fossil resources such as coal, natural gas<br />

and crude oil.<br />

• They can be processed by means of conventional<br />

technologies. The resulting products are generally<br />

readily recyclable.<br />

• If recycled in the form of energy they have an almost<br />

neutral CO 2 balance, as only as much CO 2 is released<br />

as the plant absorbed during its growth.<br />

In the <strong>CLA</strong>-<strong>Class</strong>, a total of 16 components with a combined<br />

weight of 19 kg are produced using natural materials.<br />

Figure 2-12 shows the components in the new <strong>CLA</strong>-<br />

<strong>Class</strong> which are produced using renewable raw materials.<br />

Raw material Use<br />

Wood Base for door panelling<br />

Coconut fibres, wool Padding for driver’s and<br />

and natural rubber front passenger’s backrest<br />