Quick, Cost-Effective Emulsion-Breaking Solutions for Demanding ...

Quick, Cost-Effective Emulsion-Breaking Solutions for Demanding ...

Quick, Cost-Effective Emulsion-Breaking Solutions for Demanding ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

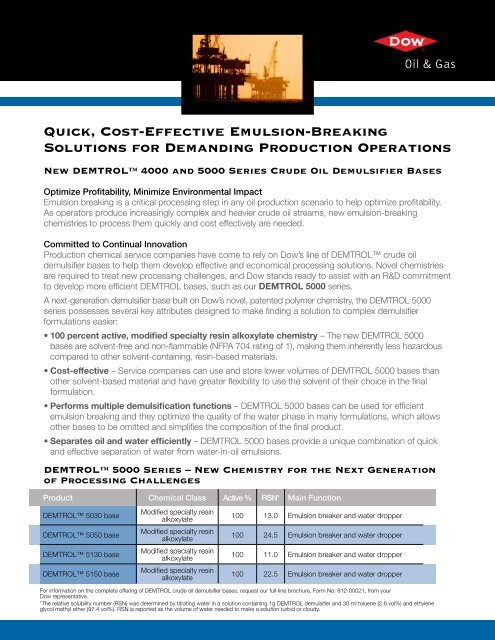

<strong>Quick</strong>, <strong>Cost</strong>-<strong>Effective</strong> <strong>Emulsion</strong>-<strong>Breaking</strong><br />

<strong>Solutions</strong> <strong>for</strong> <strong>Demanding</strong> Production Operations<br />

New DEMTROL 4000 and 5000 Series Crude Oil Demulsifier Bases<br />

Optimize Profitability, Minimize Environmental Impact<br />

<strong>Emulsion</strong> breaking is a critical processing step in any oil production scenario to help optimize profitability.<br />

As operators produce increasingly complex and heavier crude oil streams, new emulsion-breaking<br />

chemistries to process them quickly and cost effectively are needed.<br />

Committed to Continual Innovation<br />

Production chemical service companies have come to rely on Dow’s line of DEMTROL crude oil<br />

demulsifier bases to help them develop effective and economical processing solutions. Novel chemistries<br />

are required to treat new processing challenges, and Dow stands ready to assist with an R&D commitment<br />

to develop more efficient DEMTROL bases, such as our DEMTROL 5000 series.<br />

A next-generation demulsifier base built on Dow’s novel, patented polymer chemistry, the DEMTROL 5000<br />

series possesses several key attributes designed to make finding a solution to complex demulsifier<br />

<strong>for</strong>mulations easier:<br />

• 100 percent active, modified specialty resin alkoxylate chemistry – The new DEMTROL 5000<br />

bases are solvent-free and non-flammable (NFPA 704 rating of 1), making them inherently less hazardous<br />

compared to other solvent-containing, resin-based materials.<br />

• <strong>Cost</strong>-effective – Service companies can use and store lower volumes of DEMTROL 5000 bases than<br />

other solvent-based material and have greater flexibility to use the solvent of their choice in the final<br />

<strong>for</strong>mulation.<br />

• Per<strong>for</strong>ms multiple demulsification functions – DEMTROL 5000 bases can be used <strong>for</strong> efficient<br />

emulsion breaking and they optimize the quality of the water phase in many <strong>for</strong>mulations, which allows<br />

other bases to be omitted and simplifies the composition of the final product.<br />

• Separates oil and water efficiently – DEMTROL 5000 bases provide a unique combination of quick<br />

and effective separation of water from water-in-oil emulsions.<br />

DEMTROL 5000 Series – New Chemistry <strong>for</strong> the Next Generation<br />

of Processing Challenges<br />

Product Chemical Class Active % RSN 1 Main Function<br />

DEMTROL 5030 base<br />

DEMTROL 5050 base<br />

DEMTROL 5130 base<br />

DEMTROL 5150 base<br />

Modified specialty resin<br />

alkoxylate<br />

Modified specialty resin<br />

alkoxylate<br />

Modified specialty resin<br />

alkoxylate<br />

Modified specialty resin<br />

alkoxylate<br />

100 13.0 <strong>Emulsion</strong> breaker and water dropper<br />

100 24.5 <strong>Emulsion</strong> breaker and water dropper<br />

100 11.0 <strong>Emulsion</strong> breaker and water dropper<br />

100 22.5 <strong>Emulsion</strong> breaker and water dropper<br />

For in<strong>for</strong>mation on the complete offering of DEMTROL crude oil demulsifier bases, request our full-line brochure, Form No: 812-00021, from your<br />

Dow representative.<br />

1 The relative solubility number (RSN) was determined by titrating water in a solution containing 1g DEMTROL demulsifier and 30 ml toluene (2.6 vol%) and ethylene<br />

glycol methyl ether (97.4 vol%). RSN is reported as the volume of water needed to make a solution turbid or cloudy.

2••<br />

Bottle Test Results<br />

Bottle tests were per<strong>for</strong>med at 60°C on samples of API grade 12 crude oil with a basic sediment<br />

and water (BS&W) of 40. A demulsifier dosage of 60 parts per million was used. As shown in<br />

Figure 1, the DEMTROL 5150 crude oil demulsifier base exhibited faster water separation than a<br />

competitive <strong>for</strong>mulated product.<br />

Figure 1: Bottle Tests – Water Drop Results, in ml/min<br />

Water Drop (ml/min)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0 20 40 60 80 100 120 140 160 180 200<br />

Time in Minutes<br />

DEMTROL 5150<br />

Competitive Formulated Demulsifier<br />

Figure 2: Bottle Tests – BS&W and Residual <strong>Emulsion</strong> Results, %<br />

BS&W, %<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Blank Competitive Formulated<br />

Demulsifier<br />

Demulsifier<br />

DEMTROL 5150<br />

Blank<br />

BS&W Final<br />

Figure 2 shows the BS&W and<br />

residual emulsion results from<br />

the bottle tests in Figure 1.<br />

Residual <strong>Emulsion</strong>

Figure 3: BS&W Comparative Results <strong>for</strong> Select Demulsifiers<br />

BS&W, %<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Blank<br />

Bottle Tests Results <strong>for</strong> DEMTROL 5000 Series vs. Other<br />

Demulsifier Bases and Formulated Demulsifier<br />

API 12 oil and BS&W 40 @ 60°C and demulsifier dosage of 60 ppm<br />

APFR Alkoxylate Base<br />

DEMTROL 5130<br />

Epoxy Resin Alkoxylate Base<br />

DEMTROL 5050<br />

DEMTROL 5030<br />

Polyol Block Copolymer Base<br />

DEMTROL 5150<br />

Blank<br />

DEMTROL 5000<br />

Series<br />

Generic Base<br />

Demulsifier<br />

Competitive<br />

Formulated<br />

Demulsifier<br />

Competitive Formulated Demulsifier<br />

A separate series of bottle<br />

tests were per<strong>for</strong>med to<br />

compare the behavior of the<br />

DEMTROL 5000 series<br />

bases versus other bases<br />

and <strong>for</strong>mulated demulsifiers.<br />

As the results in Figure 3<br />

demonstrate, the DEMTROL<br />

5150 base per<strong>for</strong>ms as well<br />

as fully <strong>for</strong>mulated<br />

demulsifiers in these tests.*<br />

<strong>Solutions</strong> <strong>for</strong> a Variety of Oil Production Scenarios<br />

We are also pleased to announce the addition of the DEMTROL 4000 series of demulsifier bases to our<br />

portfolio. These amine-based, non-flammable demulsifiers are 100 percent active and solvent-free <strong>for</strong> easier<br />

handling. In addition, they exhibit excellent emulsion-breaking per<strong>for</strong>mance in oils with high salinity, such as<br />

those produced from pre-salt <strong>for</strong>mations.<br />

DEMTROL 4000 Series – Excellent Choice <strong>for</strong> Pre-Salt Formations and More<br />

Product Chemical Class Active % RSN1 Main Function<br />

DEMTROL 4017 base<br />

Amine-initiated polyol<br />

block copolymer<br />

100 13.0 Enhanced quick desalt action<br />

DEMTROL 4026 base<br />

Amine-initiated polyol<br />

block copolymer<br />

100 17.0 Enhanced quick desalt action<br />

DEMTROL 4110 base<br />

Amine-initiated polyol<br />

block copolymer<br />

100 10.0 Enhanced quick desalt action<br />

DEMTROL 4115 base<br />

Amine-initiated polyol<br />

block copolymer<br />

100 10.0 Enhanced quick desalt action<br />

DEMTROL 4120 base<br />

Amine-initiated polyol<br />

block copolymer<br />

100 11.0 Enhanced quick desalt action<br />

For in<strong>for</strong>mation on the complete offering of DEMTROL crude oil demulsifier bases, request our full-line brochure, Form No: 812-00021, from your<br />

Dow representative.<br />

1 The RSN was determined by titrating water in a solution containing 1g DEMTROL demulsifier and 30 ml toluene (2.6 vol%) and ethylene glycol methyl ether<br />

(97.4 vol%). RSN is reported as the volume of water needed to make a solution turbid or cloudy.<br />

Comprehensive <strong>Solutions</strong> <strong>for</strong> Market Needs<br />

Dow Oil & Gas is committed to maximizing value <strong>for</strong> our customers by offering innovative, customized solutions<br />

tailored to the ever-evolving needs of the oil and gas industry. Backed by the proven resources of The Dow<br />

Chemical Company, Dow Oil & Gas offers advanced chemical innovation, intimate industry knowledge and<br />

exceptional service.<br />

*For the specific crude oil tested in this study. The actual per<strong>for</strong>mance of demulsifiers containing DEMTROL 5000 series actives will vary depending on specific crude<br />

composition. A series of bottle tests and field evaluations should be conducted with DEMTROL 5000 series demulsifier <strong>for</strong>mulations to determine the most suitable<br />

<strong>for</strong>mulation and dosage <strong>for</strong> a particular crude oil stream.<br />

••3

To Learn More …<br />

U.S., Canada, Mexico: Phone: 1-800-447-4369 Fax: 989-832-1465<br />

Latin America: Phone: +55 11-5188-9222 Fax: +55-11-5188-9749<br />

Europe, Middle East: Phone Toll Free: +800-3-694-6367*<br />

Phone: +32 3-450-2240 Fax: +32 3-450-2815<br />

Asia Pacific: Phone Toll Free: +800 7776-7776*<br />

Phone: +60 3-7958-3392 Fax: +60 3 7958 5598<br />

Middle East (Dubai): Phone: +971 4 453 7000 Fax: +971 4 453 7117<br />

North Africa (Cairo): Phone: +202 2 480 1466 Fax: +202 2 480 1478<br />

*Toll-free service not available in all countries.<br />

For more in<strong>for</strong>mation, visit www.dowoilandgas.com.<br />

NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable<br />

laws may differ from one location to another and may change with time, Customer is responsible <strong>for</strong> determining whether products and<br />

the in<strong>for</strong>mation in this document are appropriate <strong>for</strong> Customer’s use and <strong>for</strong> ensuring that Customer’s workplace and disposal practices<br />

are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available<br />

<strong>for</strong> sale and/or available in all geographies where Dow is represented. The claims made may not have been approved <strong>for</strong> use in all<br />

countries. Dow assumes no obligation or liability <strong>for</strong> the in<strong>for</strong>mation in this document. References to “Dow” or the “Company” mean<br />

the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED<br />

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED..<br />

Printed in U.S. August 2012<br />

®Trademark of The Dow Chemical Company<br />

(“Dow”) or an affiliated company of Dow<br />

Form No: 812-00172-BBI0812