Tipto Twelve Beschreibung - H. Lohmann Schiffs

Tipto Twelve Beschreibung - H. Lohmann Schiffs

Tipto Twelve Beschreibung - H. Lohmann Schiffs

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

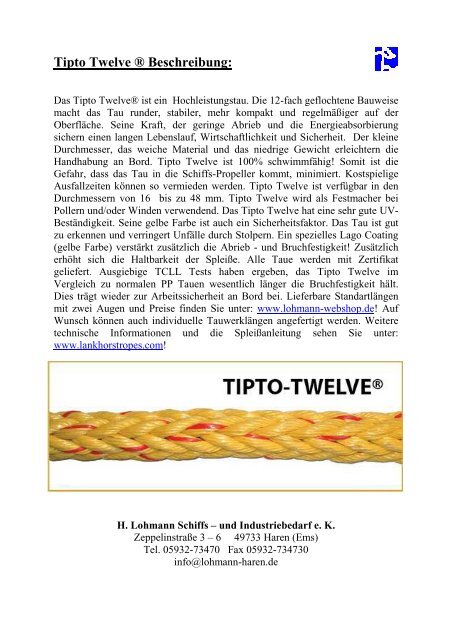

<strong>Tipto</strong> <strong>Twelve</strong> ® <strong>Beschreibung</strong>:<br />

Das <strong>Tipto</strong> <strong>Twelve</strong>® ist ein Hochleistungstau. Die 12-fach geflochtene Bauweise<br />

macht das Tau runder, stabiler, mehr kompakt und regelmäßiger auf der<br />

Oberfläche. Seine Kraft, der geringe Abrieb und die Energieabsorbierung<br />

sichern einen langen Lebenslauf, Wirtschaftlichkeit und Sicherheit. Der kleine<br />

Durchmesser, das weiche Material und das niedrige Gewicht erleichtern die<br />

Handhabung an Bord. <strong>Tipto</strong> <strong>Twelve</strong> ist 100% schwimmfähig! Somit ist die<br />

Gefahr, dass das Tau in die <strong>Schiffs</strong>-Propeller kommt, minimiert. Kostspielige<br />

Ausfallzeiten können so vermieden werden. <strong>Tipto</strong> <strong>Twelve</strong> ist verfügbar in den<br />

Durchmessern von 16 bis zu 48 mm. <strong>Tipto</strong> <strong>Twelve</strong> wird als Festmacher bei<br />

Pollern und/oder Winden verwendend. Das <strong>Tipto</strong> <strong>Twelve</strong> hat eine sehr gute UV-<br />

Beständigkeit. Seine gelbe Farbe ist auch ein Sicherheitsfaktor. Das Tau ist gut<br />

zu erkennen und verringert Unfälle durch Stolpern. Ein spezielles Lago Coating<br />

(gelbe Farbe) verstärkt zusätzlich die Abrieb - und Bruchfestigkeit! Zusätzlich<br />

erhöht sich die Haltbarkeit der Spleiße. Alle Taue werden mit Zertifikat<br />

geliefert. Ausgiebige TCLL Tests haben ergeben, das <strong>Tipto</strong> <strong>Twelve</strong> im<br />

Vergleich zu normalen PP Tauen wesentlich länger die Bruchfestigkeit hält.<br />

Dies trägt wieder zur Arbeitssicherheit an Bord bei. Lieferbare Standartlängen<br />

mit zwei Augen und Preise finden Sie unter: www.lohmann-webshop.de! Auf<br />

Wunsch können auch individuelle Tauwerklängen angefertigt werden. Weitere<br />

technische Informationen und die Spleißanleitung sehen Sie unter:<br />

www.lankhorstropes.com!<br />

H. <strong>Lohmann</strong> <strong>Schiffs</strong> – und Industriebedarf e. K.<br />

Zeppelinstraße 3 – 6 49733 Haren (Ems)<br />

Tel. 05932-73470 Fax 05932-734730<br />

info@lohmann-haren.de

FIBRE ROPES<br />

High performance ropes TIPTO-TWELVE®<br />

<strong>Tipto</strong> <strong>Twelve</strong>®, available in the<br />

diameter range of 16 mm till<br />

48 mm, is the successor of the<br />

well-known <strong>Tipto</strong> Eight®. The<br />

construction is different, the<br />

material remains<br />

the same. The 12-strand<br />

braided construction makes<br />

the rope rounder, more<br />

stable, more compact and<br />

more regular on the surface.<br />

This increases the abrasion<br />

resistance and the life-time<br />

of the rope even more.<br />

<strong>Tipto</strong> <strong>Twelve</strong>® can be used<br />

for mooring, using either<br />

bollards and/or winches. All<br />

<strong>Tipto</strong> <strong>Twelve</strong>® coils will be<br />

fitted with a quality label,<br />

stating “Original product<br />

of Lankhorst Ropes”. <strong>Tipto</strong><br />

<strong>Twelve</strong>® ropes in the range<br />

from 32 mm up to 48 mm<br />

have been upgraded with an<br />

extra marker yarn. The rope<br />

size can now easily (and<br />

above all) without mistake<br />

be identified.<br />

Green = 32 mm<br />

Brown = 36 mm<br />

Black = 40 mm<br />

Blue = 44 mm<br />

White = 48 mm<br />

The master of innovation in ropes<br />

TIPTO TWELVE®<br />

SPECIFIC GRAVITY • 0,93 CONSTRUCTION • 12-strand<br />

UV-RESISTANCE • very good plaited<br />

ABRASION RESISTANCE • very good TCLL VALUE • 70,7%<br />

CHEMICAL RESISTANCE • good COLOUR • yellow<br />

ELONGATION • see graph MARKER YARN • orange<br />

MELTING POINT • approx. 140 o C WATERABSORPTION • 0%<br />

Art.number<br />

111.516<br />

111.520<br />

111.524<br />

111.528<br />

111.532<br />

111.536<br />

111.540<br />

111.544<br />

111.548<br />

Circ.<br />

(inches)<br />

2<br />

2 1/2<br />

3<br />

3 1/2<br />

4<br />

4 1/2<br />

5<br />

5 1/2<br />

6<br />

Diameter<br />

(mm)<br />

16<br />

20<br />

24<br />

28<br />

32<br />

36<br />

40<br />

44<br />

48<br />

Weight<br />

(kg/100m)<br />

12,1<br />

18,9<br />

27,3<br />

37,3<br />

53<br />

66<br />

75,6<br />

92,4<br />

109<br />

MBF<br />

(kN)<br />

48<br />

72,8<br />

103<br />

137<br />

177<br />

222<br />

269<br />

321<br />

378<br />

Weight<br />

(lbs/100 ft)<br />

8<br />

13<br />

18<br />

25<br />

36<br />

44<br />

51<br />

62<br />

73<br />

MBF<br />

(lbs)<br />

10.791<br />

16.366<br />

23.155<br />

30.799<br />

39.791<br />

49.908<br />

60.474<br />

72.164<br />

84.978<br />

Diameter, weight and MBF (as well as other mechanical and physical properties) are determined<br />

according ISO 2307:2005. The MBF refers to the breaking strength in the rope/wire itself, without<br />

splices or any other form of termination that can be formed with or without the use of accessories/<br />

fi ttings.<br />

Min.breaking force (%)<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0 10 20 30 40<br />

Elongation (%)<br />

R-2<br />

010610

INFORMATION<br />

THE TOOLS YOU WILL NEED: Sharp knife, tape and a spike<br />

This splice is suitable for 12 strand ropes, braided one over one.<br />

SPLICE INSTRUCTIONS TIPTO TWELVE®<br />

START<br />

a. Start with measuring the length of the tail. It should at least be 12 full braiding<br />

pitches long. Wrap a tape around rope at the start point of the splice (photo 1);<br />

b. Tape the individual ends to keep yarns together. Then unlay the tail for the full 12<br />

braiding pitches;<br />

c. Bend the rope to form the eye and add eye protection if required. A seizing or<br />

whipping may be used to keep two rope parts together at the start point of the<br />

splice;<br />

d. Divide the 12 strands into 6 pairs. 3 pairs of left hand lay and 3 pairs of right hand lay<br />

strands (photo 2).<br />

SPLICING<br />

Note: always tuck right hand lay strands under right hand lay strands and left under left.<br />

A. Tuck from the fi rst pair (1R right red), the 1 st strand under 6 strands (2 right, 2 left, 2<br />

right) of the body (photo 3);<br />

B. Tuck the 2 nd right hand strand from this pair under 5 strands (photo 4);<br />

C. Continue tucking these strands under resp. the same 5 th and 6 th right hand strand of<br />

the body. (over one, under one, over one) (photo 5);<br />

D. Both strands are tucked in the same way 3 times in total. Only with the second strand<br />

a fourth tuck is made over one, under two (photo 6);<br />

E. The second pair of strands (2L, left, grey), are tucked under the 4 th and 3 rd strand of<br />

the body (photo 7). Continue here as well with tucking these strands over and under<br />

the same 4 th and 3 rd strand of the body. Again, only the second strand is tucked for a<br />

fourth time over one, under 2 (photo 8);<br />

www.lankhorstropes.com<br />

The master of innovation in ropes<br />

8<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

I-9<br />

010709

010709<br />

INFORMATION<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

www.lankhorstropes.com<br />

The master of innovation in ropes<br />

F. The third pair (3R, right, yellow), are tucked under resp. the 2 nd and 1 st strand of the<br />

body. Then follow the same procedure as described before (photo 9 + 10);<br />

G. The fourth pair (4L, left, black), go under resp. the 1 st and 2 nd strands of the body<br />

(calculated from the tucks made at F) Then follow same procedure (photo 11 + 12);<br />

H. The fi fth set (5R, right, white), are both tucked under one strand, then follow same<br />

procedure (photo 13+14);<br />

I. The last pair (6L, left, blue) are tucked under resp. 2 and 3 strands, then follow the<br />

same procedure (photo 15+16);<br />

J. The splice is now fi nished. Tape the two most close laying ends together (if the<br />

procedure has been followed correctly then such a pair will consists out of a left<br />

and right hand laid strand) and cut off the over length (photo 17).<br />

THE SPLICE IS NOW COMPLETE.<br />

I-10