thru spindle coolant - Corporate Assets Inc.

thru spindle coolant - Corporate Assets Inc.

thru spindle coolant - Corporate Assets Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

®<br />

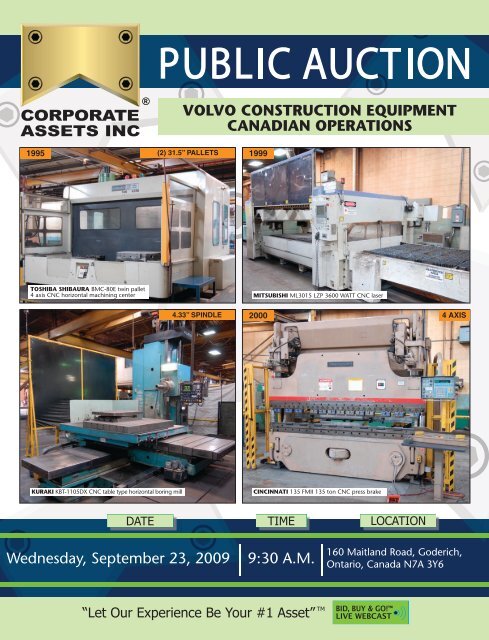

1995 (2) 31.5” PALLETS 1999<br />

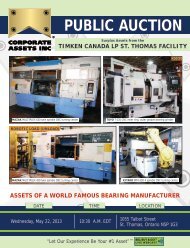

Wednesday, September 23, 2009 9:30 A.M.<br />

VOLVO CONSTRUCTION EQUIPMENT<br />

CANADIAN OPERATIONS<br />

TOSHIBA SHIBAURA BMC-80E twin pallet<br />

4 axis CNC horizontal machining center MITSUBISHI ML3015 LZP 3600 WATT CNC laser<br />

KURAKI KBT-1105DX CNC table type horizontal boring mill<br />

4.33” SPINDLE<br />

2000 4 AXIS<br />

CINCINNATI 135 FMII 135 ton CNC press brake<br />

160 Maitland Road, Goderich,<br />

Ontario, Canada N7A 3Y6

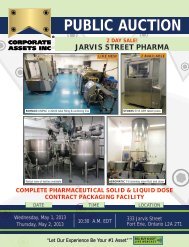

2<br />

1995<br />

TOSHIBA SHIBAURA BMC-80E twin pallet 4 axis CNC horizontal machining center<br />

View of TOSNUC 800 CNC control and <strong>spindle</strong> View of BMC-80E 60 station ATC<br />

CNC HORIZONTAL AND VERTICAL MACHINING CENTERS<br />

TOSHIBA SHIBAURA (1995) BMC-80E twin pallet 4 axis CNC horizontal machining center with TOSNUC<br />

800 CNC control, (2) 31.5”x 31.5” pallets, 15-5000 RPM, travels: X-63”, Y-39.4”, Z-47.2”, 4,400 lb max<br />

table capacity, full 4th axis, <strong>thru</strong> <strong>spindle</strong> <strong>coolant</strong>, CAT 50, 60 ATC, s/n 212563<br />

TOSHIBA SHIBAURA (1997) BMC-630 twin pallet 4 axis CNC horizontal machining center with TOSNUC<br />

888 CNC control, (2) 24.75” x 24.75” pallets, 6,000 RPM, travels: X-39.4”, Y-31.5", Z-33.5”, 2,640 lb max<br />

table capacity, full 4th axis, <strong>thru</strong> <strong>spindle</strong> <strong>coolant</strong>, CAT 50, 60 ATC, s/n 212599<br />

TOSHIBA SHIBAURA (1994) VMC-55E CNC vertical machining center with TOSNUC 777.2 CNC control,<br />

21.5” x 55” table, 24 ATC, MPC-B pallet changer with (2) 23.5” x 43.25” pallets (may be sold separately),<br />

CAT 50, <strong>coolant</strong>, chip conveyor, s/n 240744<br />

OKK MCV-630 CNC vertical machining center with FANUC 11m CNC control, 63” x 25.5” table, 24 ATC,<br />

CAT 50, 3300 lb max table capacity, OKK pallet changer with 43.5” x 48” pallet (may be sold separately),<br />

s/n 469<br />

THRU SPINDLE COOLANT<br />

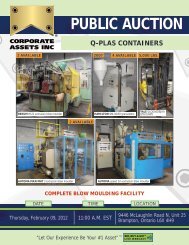

CNC LASERS<br />

MITSUBISHI (1999) ML3015 LZP 3600<br />

WATT CNC laser with MITSUBISHI LC20BP<br />

CNC control, (2) 5’ x 10’ dual pallet shuttle<br />

table, travels: X-120”, Y-60”, Z -4”, 52 KVA,<br />

PH-3 laser head, ACCUCHILLER LX2 chiller,<br />

s/n 6930 – LZPO49<br />

CINCINNATI (1996) CL-7A 2000 WATT<br />

CNC laser with GE FANUC 16-M CNC<br />

control, (2) 5’ X 10’ dual pallet shuttle<br />

tables, travels: X-122”, Y-62”, ROFIN SINAR<br />

2000 WATT resonator, KOOLANT KOOLERS<br />

chiller, s/n 49786<br />

CINCINNATI CL-7 1500 WATT CNC laser<br />

with GE FANUC 11M CNC control, ROFIN<br />

SINAR 1500 WATT resonator (new in 2000),<br />

(2) 62” x 120” burning tables, travels:<br />

X-122”, Y-62”, Z-8”, 2500 lb table capacity,<br />

APPLICATION ENGINEERING chiller, s/n<br />

1072818 (located in BRANTFORD, ON)<br />

PROXY BIDDING<br />

If you are unable to attend this auction,<br />

we would be pleased to act as your proxy.<br />

Please contact our office at (416) 962-9600<br />

or visit our website for a proxy bid form,<br />

terms and additional information.<br />

www.corpassets.com

1997<br />

TOSHIBA SHIBAURA BMC-630 twin pallet 4 axis CNC horizontal machining center<br />

1997<br />

THRU SPINDLE COOLANT<br />

><br />

View of<br />

BMC-630 60<br />

station ATC<br />

TOSHIBA SHIBAURA VMC-55E CNC vertical machining center and MPC-B pallet changer OKK MCV-630 CNC vertical machining center<br />

CNC PLASMA AND OXY/ACETYLENE<br />

BURNING TABLES<br />

MG INDUSTRIES (1991) CNC bridge type plasma cutter with (2) 20’ x 20’<br />

tables, (2) 260 amp plasma heads, 8” stroke on heads, HYPERTHERM EDGE<br />

AUTOMATION CNC control, (2) high performance HPR-260 plasma units,<br />

60’L x 25’W rails, s/n NC5318LP-84-1215 (complete rebuild 2008)<br />

SECTOR (2000) STI-100 CNC bridge type burning table with (12) oxy/<br />

acetylene cutting heads, 9” stroke on heads, (1) 12’ x 23’ table, (1) 23’ x<br />

23’ table, 50’L x 25’W rails, s/n 2K06-100-312-1045<br />

View of TOSNUC 888 CNC control<br />

TABLE TYPE HORIZONTAL BORING MILLS<br />

KURAKI KBT-1105DX CNC table type horizontal boring mill with FANUC<br />

11M CNC control, 4.33” <strong>spindle</strong> diameter, 55” x 63” table, 30” x 40”<br />

auxiliary rotary table (may be sold separately), travels: X-79”, Y-59”, Z-57”,<br />

W-25.6”, ISO 50 taper, 5-1,200 RPM, 13,900 lb max table capacity, <strong>coolant</strong>,<br />

s/n 2139<br />

SCHARMANN FB 315 horizontal boring/mill with 40 taper, 3.5” <strong>spindle</strong> dia.,<br />

36”x 36” built in rotary table, 60” vertical travel, digital readout, pendant,<br />

facing head, s/n 140096<br />

3

4<br />

1999<br />

MITSUBISHI ML3015 LZP 3600 WATT CNC laser<br />

1996<br />

CINCINNATI CL-7A 2000 WATT CNC laser<br />

(2) 5’ X 10’ DUAL PALLET BURNING TABLES<br />

(2) 5' x 10' DUAL PALLET SHUTTLE TABLES

1991<br />

MG INDUSTRIES CNC bridge type plasma cutter<br />

View of 1 of 2 plasma cutting heads View of HYPERTHERM EDGE<br />

AUTOMATION CNC control<br />

NEW RESONATOR YEAR 2000<br />

CINCINNATI CL-7 1500 WATT CNC laser (located in Brandford, ON)<br />

(2) 20' x 20' SHUTTLE TABLES<br />

COMPLETELY REBUILT IN 2008<br />

2 AVAILABLE<br />

View of HYPERTHERM HPR-260 plasma units<br />

(2) 5’ x 10’ DUAL PALLET SHUTTLE TABLES<br />

5

6<br />

2000<br />

SECTOR STI-100 CNC bridge type burning table<br />

View of SECTOR (12) oxy/acetylene cutting heads and control<br />

1999<br />

MOTOMAN SK16-6 CNC6 axis welding robot<br />

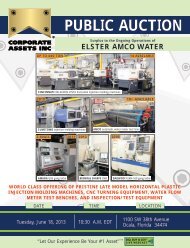

CNC PRESS BRAKES<br />

4 AVAILABLE<br />

CINCINNATI (2000) 135 FMII 135 ton 4 axis press brake with 10’ bed, 8’ between<br />

the housings, CINCINNATI FORMMASTER II 4 axis CNC control, 8” stroke, 7”<br />

throat, 2 axis heavy duty back gauge, crowning, light curtains, 25HP, s/n 51676<br />

AMADA (1996) RG50-20 50 ton press brake with 78.8” bed, 15.75” throat, 3.94”<br />

stroke, 60” between the housings, 14.58” open height, HURCO AUTOBEND 5C 2<br />

axis CNC back gauge, light curtains, s/n 508212<br />

Partial view of welders available<br />

View of MOTOMAN robot<br />

controls and welder<br />

4 AVAILABLE<br />

HYPERTHERM POWERMAX<br />

900 plasma cutter<br />

Partial view of welders available Partial view of<br />

welders available<br />

PROMECAM RG-50-20 50 ton press brake with 79” bed, 3.9” stroke,<br />

AUTOBEND 5C two access CNC back gauge s/n 2-050-20-466

55” X 63” TABLE<br />

KURAKI KBT-1105DX CNC table type horizontal boring mill<br />

84” SWING<br />

SHEAR / IRONWORKERS<br />

GEKA (2005) HYDRA-CROP 50 ton iron<br />

worker with 37 strokes in .75” cycle, 12”<br />

x .50” plate shear capacity, 4.5” x 4.5”<br />

x 3/8” angle capacity, bar shear, round<br />

up to 1.57” capacity, square up to 1.57”<br />

capacity, s/n N/A<br />

CINCINNATI (1993) 1810 mechanical<br />

shear with 10’ x 1/4” capacity, 10’ 3”<br />

between the housings, 60 SPM, AUTO-<br />

SHEAR control, s/n 40495<br />

PIRANHA (1999) SEPP-140 hydraulic<br />

single end punch with 140 ton capacity,<br />

1-1/4” punching capacity, 20.5” throat,<br />

14” open height, 16” x 36” table,<br />

tooling, s/n N/A<br />

PULLMAX (2004) X93 plate beveler, s/n<br />

T4570-04<br />

VERTICAL TURRET LATHE<br />

WEBSTER & BENNETT EM72 vertical<br />

turret lathe with 72” table, 84” swing, 5<br />

station turret, pendant, s/n 5587-2<br />

WELDING ROBOTS<br />

(4) MOTOMAN (1999) SK16-6 CNC 6<br />

axis welding robots with controls and<br />

welders, s/n G56206-5-1-8, M5K0064-<br />

0002, MMRC-0166-0007<br />

MISCELLANOUS MACHINE<br />

SHOP & FABRICATING EQUIP<br />

TOS 8N63B gap bed engine lathe with<br />

28”/42” swing, 90” between the centers,<br />

13” 3 jaw chuck, 3.25” <strong>spindle</strong> bore, quick<br />

change tool post, 1000 RPM, <strong>coolant</strong>, s/n<br />

063273239<br />

CINCINNATI BICKFORD 5’ radial arm<br />

drill with 15” column, 1750 RPM, 30” x<br />

40” x 20” box table, <strong>coolant</strong>, s/n 4NE90<br />

WEBSTER & BENNETT EM72 vertical turret lathe SCHARMANN FB 315 horizontal boring/milling machine<br />

7

8<br />

2000<br />

2 AXIS HEAVY DUTY BACK GAUGE<br />

CINCINNATI 135 FMII 135 ton CNC press brake<br />

1993<br />

10’ X .25” CAP.<br />

PACIFIC bulldozer 250 ton BD hydraulic press<br />

with 60” x 28” platens, s/n 34641LC<br />

WILSON 376 GT 60 ton hydraulic press, s/n<br />

10847001<br />

ARIES HYDRA (2001) C-02-6.00-1.5-B-PN1<br />

pneumatic press with 2 ton capacity, 6” stroke,<br />

1.5” high pressure stroke, 6” throat, 10” x 11” x<br />

2” bolster, s/n 7400<br />

AEM 370 ENCO M dry type grinding and<br />

deburring machine with 37” wide belt, 15 HP,<br />

s/n M04205<br />

MINSTER P2-30-30 high speed stamping press<br />

with 30 ton capacity, 2” stroke, 9” shut height,<br />

0-300 SPM, 19” x 30” bolster, 6” PERFECTO<br />

double roll feed, s/n N/A<br />

SCOTTI BEND-O-MATIC 140 automotive<br />

exhaust fabricator with 1.5” – 3” bending<br />

capacity, auto depth control, tooling, s/n 4569<br />

BEMA PAN-5/6 hydraulic tube end forming<br />

machine with 1.5” O.D max tube capacity, 4”<br />

stroke, 1000 pieces per hr capacity, s/n 13141<br />

WHITNEY 635-A single station fabricating<br />

punch press with 30 ton capacity, 3/8” max<br />

material thickness, 5” max punch diameter,<br />

30” x 50” max template capacity, qty of<br />

punches and dies, s/n 6350001594<br />

(3) PSR PROGRESS 1 hanging gun type spot<br />

welders with 10.5” throat, 75 KVA, CONTROLEX<br />

control, pneumatic counterbalance, 2 ton push<br />

trolley, s/n N/A<br />

DAREX (2001) SP2500 drill sharpener,<br />

s/n 263498<br />

RUSH (1991) 252 tool grinder, s/n 1546<br />

CAMMANN C96CR tap extractor, s/n 59378<br />

CINCINNATI mechanical shear POMECAM RG-50-20 50 ton press brake<br />

FMB (2004) chip saw with swivel base, s/n N/A<br />

1996 CINCINATTI A213B12 tool and cutter grinder, s/n 6D1P5LN<br />

OLIVER 600 drill grinder with 1.5 HP, s/n G8136<br />

TOLEDO truck scale with 50,000 lb capacity, s/n N/A<br />

(3) ECONOLIFT (2003) SL-46-40P hydraulic scissor lift tables, s/n N/A<br />

Large Quantity of MILLER Deltaweld mig welders with wire feeders, chillers, and booms<br />

DT INDUSTRIES (2002) P-50 projection nut welder s/n 3105<br />

(2) HYPERTHERM POWERMAX 900 plasma cutters, s/n N/A<br />

(4) KOIKE ARONSON RISI 5 welding positioners with headstock and tailstock, s/n 9346,<br />

94161, 9618, 9861<br />

AMADA RG50 50 ton press brake<br />

MISCELLANOUS MACHINE<br />

SHOP & FABRICATING EQUIP<br />

AUCTION CONDUCTED BY CORPORATE ASSETS INC.<br />

For further information contact us at:<br />

2 St. Clair Ave. W., Suite 1002, Toronto, Ontario, Canada M4V 1L5<br />

Tel: (416) 962-9600 • Fax: (416) 962-9601<br />

Email: info@corpassets.com • Web: www.corpassets.com<br />

Toronto • Montreal • Chicago

2005<br />

GEKA HYDRA-CROP 50<br />

ton iron worker<br />

MILWAUKEE 3CK universal milling machine<br />

MILWAUKEE 6411 panel saw<br />

WHITNEY 635-A 30 ton single station fabricating<br />

punch press<br />

TOS 8N63B 28”/42” x 90” gap bed engine lathe CINCINATTI BICKFORD 5' radial drill<br />

2002<br />

PSR PROGRESS 1<br />

spot welder<br />

2004<br />

ELLIOT 921 hydraulic surface grinder PULLMAX X93 beveler plate DOALL 3613-0 vertical bandsaw<br />

DT INDUSTRIES P-50 projection nut welder RUSH 252 tool grinder OLIVER 600 drill grinder<br />

MATERIAL HANDLING<br />

OVER 100 DEMAG, MENTOR, GORBEL, OBRIEN, MATERIAL HANDLING<br />

ERECTION COMPANY, SHAW BOX, and LOADLIFTER bridge cranes<br />

both single and double girder, ranging from 2 ton - 10 ton capacity, and<br />

spans from 13’ – 45’, as new as 2006.<br />

OVER 30 GORBEL, MENTOR, and OBRIEN jib arms with hoists ranging<br />

from ¼ ton – 1 ton capacity, and spans 10’ – 20’, as new as 2007.<br />

OVER 12 RAYMOND electric reach trucks ranging from 3,000 lb – 10,000 lb<br />

capacity, as new as 2008.<br />

OVER 20 HYSTER, TOYOTA, NISSAN, and CLARK forklifts ranging from<br />

2,000 lb – 12,000 lb capacity, as new as 2004.<br />

(3) TOYOTA 6BT50 electric tuggers, s/n N/A<br />

(4) TENNANT walk behind and ride on floor scrubbers as new as 2004,<br />

s/n N/A<br />

9

Partial view of forklifts<br />

View of TOYOTA tuggers<br />

10<br />

LARGE QUANTITY OF WELL MAINTAINED ROLLING STOCK<br />

Partial view of floor scrubbers Partial view of RAYMOND reach trucks<br />

Partial view of RAYMOND reach trucks<br />

View of TENNANT floor scrubbers<br />

CUSHMAN electric transport cars<br />

PAINT BOOTH AND EQUIPMENT<br />

(2) Paint Booths with down draft and exhaust systems, ANNADALE controls, 50’ x 16’<br />

(2) UNI-RAM URS 2000 solvent recycler system<br />

(5) GRACO Promix digital paint proportional mixer<br />

(8) PRO 4500SC electrostatic air spray gun<br />

OVER 20 AVAILABLE<br />

2005<br />

3 AVAILABLE<br />

HOTSY 1836SS hot<br />

water pressure washer<br />

WASH BOOTH/WASHERS<br />

INTERCLEAN (1999) 83-5407 automatic<br />

touchless wash booth system with 40’L x<br />

20’W x 12’H booth, 4 nozzle high pressure<br />

spinner arch, 60 HP pump, s/n N/A<br />

ECONOMINDER 9000 water softener system<br />

s/n N/A<br />

PROTOVEST (2005) 30 HP dryer unit, s/n N/A<br />

(3) HOTSY (2005)1836SS hot water pressure<br />

washers with 2500 psi, 510,000 btu natural<br />

gas fired burner, s/n N/A<br />

(2) EPPS (2001) 5403 pressure washers with<br />

2000 psi, 5 HP, natural gas fired, 345,000 btu,<br />

s/n 9406373

Partial view of cranes<br />

Partial view of cranes<br />

Partial view of cranes<br />

MENTOR 2 ton single girder extendable crane system<br />

MENTOR 10 ton single girder bridge crane<br />

MENTOR 5 ton single girder bridge crane<br />

OVER 100 CRANES AND JIB ARMS AVAILABLE<br />

MENTOR 10 ton single girder bridge crane<br />

GORBEL 2 ton crane systems<br />

MENTOR jib arm with hoist<br />

GORBEL jib arm with hoist<br />

BLAST EQUIPMENT<br />

AIR COMPRESSORS<br />

10 AVAILABLE<br />

30 AVAILABLE<br />

30 AVAILABLE<br />

WHEELABRATOR blast booth with PANGBORN AQ-1 shot blast unit,<br />

10' x 30' booth, s/n SVP-5-01-A10<br />

PANGBORN RG ROTO BLAST rotary table type shot blast system with<br />

8' diameter rotary table, 74 HP motor, s/n 8LKI-732<br />

COMPAIR (2001) 6125AH 125 HP rotary screw air compressor, s/n<br />

C5214A1162A65<br />

COMPAIR (2000) 100 air dryer, s/n 100 241<br />

COMPAIR (2001) 1220AS air dryer, s/n 012301<br />

COMPAIR (1998) 335TV 25 HP rotary screw air compressor, s/n<br />

V9F7282PF21<br />

COMPAIR (1990) 6100H rotary screw air compressor, s/n L017/3164<br />

HYDROVANE (2006) 178 PVAS 40 HP air compressor, s/n C22A6178K00185<br />

11

PANGBORN RG ROTO BLAST<br />

rotary table type shot blast system<br />

PACIFIC hydraulic bulldozer press<br />

SCOTTI BEND-O-MATIC 140<br />

automotive exhaust fabricator<br />

PIRANHA SEPP-140 140 ton<br />

hydraulic single end punch<br />

Surplus to the Ongoing Needs of<br />

ALDAN TOOL LTD.<br />

Tool and Die Shop<br />

Barrie, ON, Canada<br />

Tuesday, September 15, 2009<br />

10:30 A.M. EST<br />

MEMBER IN<br />

GOOD STANDING<br />

2001<br />

125 HP<br />

COMPAIR air compressor<br />

BEMA PAN-5/6 hydraulic tube end<br />

forming machine<br />

AEM 370 ENCO M dry type grinding and<br />

deburring machine<br />

ALSO: metal strapping machines, large qty of power and hand tools, drill presses, hydraulic presses, c-clamps, 6 drawer pneumatic sheet metal<br />

dispensing rack; ROTOFINISH (2004) SVP-5 vibratory deburring machine, oil/fuel dispensing station, scissor lift tables, racks, dumping hoppers,<br />

hydraulic units, flex arm tappers, vises, toolboxes, heavy duty racking, inspection equipment, and more!<br />

GODERICH TOOL & DIE LTD.<br />

CNC Machining & Turning Facility<br />

Goderich, ON, Canada<br />

Tuesday, September 22, 2009<br />

2:00 P.M. EST<br />

Inspect VOLVO CONSTRUCTION<br />

EQUIPMENT CANADIAN<br />

OPERATIONS in the morning and<br />

attend this sale in the afternoon<br />

Printed in Canada. ©2009 CORPORATE ASSETS INC. ALL RIGHTS RESERVED.<br />

View of oil and fuel<br />

dispensing center<br />

MINSTER P2-30-30<br />

30 ton high speed<br />

stamping press<br />

Partial view of inspection equipment Motorized sheet metal storage<br />

system with ANVER sheet lifter<br />

COMPAIR air compressor COMPAIR air dryer<br />

TRON INTERNATIONAL<br />

INDUSTRIES LTD.<br />

CNC Turning, Machining &<br />

Grinding Facility<br />

Mississauga, ON, Canada<br />

Tuesday, September 29, 2009<br />

10:30 A.M. EST<br />

WILSON 376 GT 60<br />

ton hydraulic press<br />

2000<br />

125 HP<br />

View of fully automatic heavy<br />

duty truck wash<br />

ARIES HYDRA<br />

C-02-6.00-1.5-B-PN1<br />

2 ton pneumatic press<br />

WHEELABRATOR<br />

blast booth<br />

Large quantity of tool<br />

cabinets available<br />

PHILLIPS TOOL & MOULD LIMITED<br />

Modern Mould Making and<br />

Machining Facility<br />

London, ON, Canada<br />

Thursday, October 1, 2009<br />

10:30 A.M. EST

AUCTION DETAILS<br />

INSPECTION<br />

Monday, September 21, 2009 and Tuesday<br />

September 22, 2009 from 9:00 A.M. to 5:00 P.M.<br />

and morning of auction day.<br />

REMOVAL<br />

Small items by Thursday, September 24, 2009<br />

by 5:00 P.M.<br />

Remaining items by Thursday, October 8, 2009<br />

by 5:00 P.M.<br />

DIRECTIONS<br />

Visit our website at www.corpassets.com<br />

click on Upcoming Auctions: Volvo Construction<br />

Equipment button, click on Map tab and get<br />

directions by accessing the pop up address info box.<br />

ACCOMMODATIONS & CAR RENTALS<br />

Please visit our website for details at<br />

www.corpassets.com<br />

PAYMENT<br />

Please visit our website for details at<br />

www.corpassets.com<br />

A Buyer’s Premium will apply at this sale.<br />

We<br />

Accept<br />

Visit our website for specifi c terms and conditions.<br />

TERMS<br />

<strong>Corporate</strong> <strong>Assets</strong> <strong>Inc</strong>. assumes no liability for<br />

errors or omissions in this brochure. <strong>Corporate</strong><br />

<strong>Assets</strong> <strong>Inc</strong>. expressly reserves the right to<br />

determine the manner of conducting the auction as<br />

it may deem appropriate. All subject to prior sale.<br />

APPRAISAL SERVICES<br />

What’s the real value of your equipment? If<br />

you require a detailed appraisal for banking,<br />

insurance, or internal purposes, consult with the<br />

certifi ed experts at <strong>Corporate</strong> <strong>Assets</strong> <strong>Inc</strong>. We<br />

provide appraisal services anywhere in the world<br />

for all types of industrial manufacturing and<br />

processing equipment.<br />

• We will appraise one machine or<br />

your complete plant<br />

• Going Concern, Fair Market or<br />

Liquidation Values<br />

Call us in complete confi dence today<br />

with your requirements.<br />

Phone: (416) 962-9600<br />

Fax: (416) 962-9601<br />

Email: appraisals@corpassets.com<br />

AUCTION CONDUCTED BY<br />

CORPORATE ASSETS INC.<br />

For further information contact us at:<br />

2 St. Clair Ave. W., Suite 1002<br />

Toronto, Ontario, Canada M4V 1L5<br />

Tel: (416) 962-9600 • Fax: (416) 962-9601<br />

Email: info@corpassets.com<br />

Web: www.corpassets.com<br />

Toronto • Montreal • Chicago