WEBCAST AUCTION - Hilco Industrial

WEBCAST AUCTION - Hilco Industrial

WEBCAST AUCTION - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

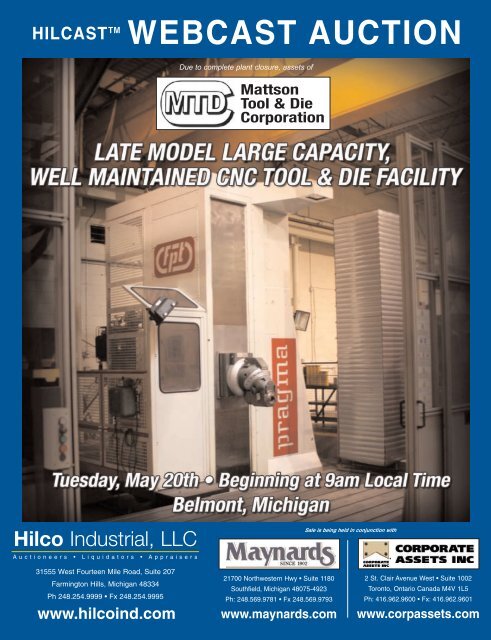

HILCAST TM<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248.254.9999 • Fx 248.254.9995<br />

www.hilcoind.com<br />

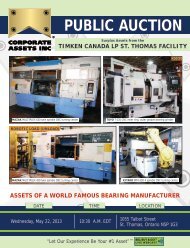

<strong>WEBCAST</strong> <strong>AUCTION</strong><br />

Due to complete plant closure, assets of<br />

Mattson<br />

Tool & Die<br />

Corporation<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph: 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

Sale is being held in conjunction with<br />

2 St. Clair Avenue West • Suite 1002<br />

Toronto, Ontario Canada M4V 1L5<br />

Ph: 416.962.9600 • Fx: 416.962.9601<br />

www.corpassets.com

2<br />

HILCAST TM <strong>WEBCAST</strong> <strong>AUCTION</strong><br />

Due to complete plant closure, assets of<br />

Mattson<br />

Tool & Die<br />

Corporation<br />

TUESDAY, MAY 20TH<br />

Beginning at 9am Local Time<br />

Preview Date<br />

Monday, May 19th<br />

9am to 4pm Local Time<br />

& Morning of the Sale<br />

Auction Location<br />

5670 W. River Road NE<br />

Belmont, MI 49306-9763<br />

Bid Live in person, or on the web at<br />

www.hilcoind.com<br />

Directions to Sale<br />

From Grand Rapids Gerald R. Ford Int’l Airport:<br />

Exit airport to Patterson Ave. Turn Right on Patterson<br />

Ave., Go 1/2 Mile to 36th Street, Turn Right on 36th<br />

Street, Proceed to I-96. Travel West on I-96 13 Miles to<br />

US 131 North, Exit #31B. Take US 131 North 2 Miles to<br />

1st Exit, West River Dr., Exit #91. Turn Left on West<br />

River Dr., Proceed 2 Miles to Sale Site on Right. Watch<br />

for auction signs & parking.<br />

Travel Information<br />

Airlines:<br />

American Airlines . . . . . . . . . . . . . 800.433.7300<br />

Northwest Airlines . . . . . . . . . . . . . 800.225.2525<br />

United Airlines . . . . . . . . . . . . . . . . 800.241.6522<br />

Delta Airlines . . . . . . . . . . . . . . . . . 800.221.1212<br />

Southwest Airlines . . . . . . . . . . . . . 800.435.9792<br />

Hotels:<br />

Springhill Suites . . . . . . . . . . . . . . 616.785.1600<br />

Holiday Inn Express . . . . . . . . . . . 616.647.4100<br />

Hampton Inn . . . . . . . . . . . . . . . . . 616.647.1000<br />

(Grand Rapids Int’l Airport Hotels - Approx. 15 Miles)<br />

(Downtown Grand Rapids Hotels - Approx. 10 Miles)<br />

Further Information<br />

• A buyer’s premium will be in effect.<br />

The auction will be conducted in English,<br />

accepting U.S. Currency only.<br />

• Removal Deadline is Friday, June 6, 2008<br />

with Hours of Removal between 8am to<br />

4pm Monday thru Friday. No removal will<br />

occur on Monday, May 26th. After June<br />

6th at 4pm buyer will incur a cost of $500<br />

daily for entry into the facility.<br />

• For further information please contact<br />

Steve Wolf at 616.233.0702 or<br />

Email swolf@hilcoind.com<br />

In Canada, please contact<br />

John Sharpe at 416.962.9600 or<br />

Email jsharpe@corpassets.com<br />

• For Payment & Customer Service<br />

please contact:<br />

Sandi Neely at 248.254.9999 x16<br />

or Email sneely@hilcoind.com<br />

2004<br />

CNC GANTRY MILL • COLUMN CNC MILL<br />

CNC GANTRY MILLING MACHINE – HIGH SPEED<br />

1 – PARPAS DIAMOND HIGH SPEED CNC GANTRY MILLING MACHINE, S/N D1A/28<br />

(2004), 3 + 2-Axis, Fixed Table Working Surface 90.5” x 63.0”, Travels: 90” X, 60” Y, 40”<br />

Z, A&C Axis TOE24 Dual-Rotation Electric-Spindle Head, Continuous A-Axis Every .001<br />

Degree ± 105 Degree, Continuous C-Axis Every .001 Degree ± 370 Degree, Spindle<br />

Speed Range 3000 – 24,000 RPM, 24 KW, HSK 63A Spindle Taper, 24-Position<br />

Automatic Tool Changer Magazine, Feed Rate 1600 IPM, Distance Horizontal Spindle<br />

Nose to Table Top 13” – 52.3”, Distance Vertical Spindle Nose to Table Top 1” – 40”,<br />

Heidenhain CNC Control<br />

2003<br />

TRAVELING COLUMN CNC MILLING MACHINE<br />

1 – FPT PRAGMA M40 CNC TRAVELING COLUMN MILLING/BORING MACHINE,<br />

S/N PM4003051 (2003), 157” x 98-1/4” T-Slotted Floor Plate, Travels: 157” X, 78.5” Y,<br />

47” Z, 3 + 2 Axis, (1) Universal Head, With Spindle Speeds to 5000 RPM & ISO 50<br />

Taper, (1) High Speed Universal Head, With Spindle Speeds to 24,000 RPM & HSK-63A<br />

Taper, 30-Station Automatic Tool Changer on Column, Auxillary 12 + 12 Tool Magazine,<br />

Fidia C10 Controls, In-Floor Chip Conveyor, Spindle Oil Chiller, 36-HP<br />

For more information, visit us on the web @ www.hilcoind.com

CNC VERTICAL MILLING MACHINES • VERTICAL MACHINING CENTERS<br />

2002<br />

TO 2003<br />

VIEW OF RÖDERS RFM 1000/2, RFM 600/2 & RP800<br />

HIGH SPEED CNC VERTICAL MILLING MACHINES<br />

TARUS<br />

MODEL H5-8412<br />

HIGH SPEED<br />

DUAL COLUMN<br />

VERTICAL<br />

CNC MILLING<br />

MACHINE<br />

1996<br />

(1 OF 2) SHARNOA MODEL HPM 40<br />

CNC VERTICAL MACHINING CENTERS<br />

CNC HIGH SPEED DUAL COLUMN<br />

VERTICAL MILLING MACHINE<br />

1 – TARUS MODEL H5-8412 HIGH SPEED DUAL COLUMN VERTICAL CNC<br />

MILLING MACHINE, S/N HSDC2002052 (2002), Universal Head, 3 + 2-Axis,<br />

Capabilities: 84” X Axis, 120” Y Axis, 54” Z Axis, Table Size 72” x 120”, 96” Between<br />

Columns, Tarus Model TPI 2000 CNC Controls, Spindle Speeds to 10,000 RPM<br />

CNC BED TYPE MILLING MACHINE<br />

1 – FPT TYPE LEM936 CNC UNIVERSAL BED TYPE MILLING MACHINE,<br />

S/N 93694016 (1994), Table Size 137.8” x 36.2”, Travels: 118” X, 39” Y, 47” Z,<br />

Spindle Speeds to 3000 RPM, 30-HP Spindle Motor, 17,000-LB. Table Load<br />

Capacity, Universal Head, Heidenhain 407 Controls, Spindle Oil Chiller, CAT 50<br />

Spindle Taper, Manual Tool Change<br />

HIGH SPEED CNC VERTICAL MILLING MACHINES<br />

1 – RÖDERS MODEL RFM 1000/2 HIGH SPEED CNC VERTICAL MILLING MACHINE,<br />

S/N 88882-51 (2002), Table Size 39-1/4” x 47”, Travels: 39.4” X, 32” Y, 19.6” Z, Spindle<br />

Speeds to 36,000 RPM, 1200 IPM Feed Rate, HSK-E50 Spindle Taper, TAE-015<br />

Spindle Oil Chiller, Full Interlocked Enclosures, 18-Position Auto Tool Changer<br />

1 – RÖDERS MODEL RP800 HIGH SPEED CNC VERTICAL MILLING MACHINE, S/N<br />

10512-90 (2003), Table Size 35-1/2” x 27-1/2”, Travels: 32” X, 24” Y, 16” Z, Spindle<br />

Speeds to 36,000 RPM, 2400 IPM Feed Rate, HSK-E50 Spindle Taper, TAE-015<br />

Spindle Oil Chiller, Full Interlocked Enclosures, 30-Position Auto Tool Changer<br />

2 – RÖDERS MODEL RFM 600/2 HIGH SPEED CNC VERTICAL MILLING MACHINES,<br />

S/Ns 10172-245 (2003), 88265-97 (2000), Table Size 27-1/2” x 21-1/2”, Travels: 23.6”<br />

X, 17.7” Y, 11.8” Z, Spindle Speeds to 42,000 RPM, 1200 IPM Feed Rate, HSK-E40<br />

Spindle Taper, TAE-015 Spindle Oil Chiller, Full Interlocked Enclosures (S/N 10172-245,<br />

With Type 32.00 Mini Probe Head), 18-Position Auto Tool Changer<br />

2 – RÖDERS TEC MODEL ISG2000 HIGH SPEED TOOLING HEAT SHRINK FIT<br />

HEATERS, S/Ns 0419 (2002), NA<br />

Quantity Assortment of HSK-40 & HSK 50 Heat Shrink Fit Tool Holders<br />

FPT TYPE<br />

LEM936<br />

CNC BED<br />

TYPE<br />

MILLING<br />

MACHINE<br />

2004<br />

MAKINO S33 CNC VERTICAL<br />

MACHINING CENTER<br />

CNC VERTICAL MACHINING CENTERS<br />

2 – SHARNOA MODEL HPM 40 CNC VERTICAL MACHINING<br />

CENTERS, S/Ns 120D056 (1996), 120E110 (1996), Table<br />

Size 21-1/2” x 47”, Travels: 40” X, 24” Y, 22” Z, Spindle<br />

Speeds to 8000 RPM, 2,200-LB. Table Capacity, CAT 40<br />

Spindle Taper, 28-HP, 30-Position Automatic Tool Changer,<br />

Sharnoa Tiger 6 CNC Controls, Standard Coolant, With<br />

Additional Auxiliary High Pressure Coolant, Enclosures<br />

2 – SHARNOA MODEL SVC-52D CNC VERTICAL MACHINING<br />

CENTERS, S/Ns 391115205 (1992), 391085206 (1991), Table<br />

Size 28” x 55”, Travels: 51” X, 29.5” Y, 36.5” Z, 4000-LB. Table<br />

Capacity, Spindle Speeds to 3500 RPM, 20-Position<br />

Automatic Tool Changer, CAT 50 Spindle Taper, 20-HP<br />

(15/11 KW), CAT 40 Taper, Sharnoa Tiger 5 CNC Controls,<br />

Coolant, (1991 Unit, With Updated Controls)<br />

1 – SHARNOA SDC-40S/7.5 CNC VERTICAL MACHINING<br />

CENTER, S/N 187094002, Table Size 27-1/2” x 51”, Travels:<br />

39” X, 29.5” Y, 29.5” Z, Spindle Speeds to 3500 RPM, 15-HP<br />

(11 KW), 30-Position Automatic Tool Changer, Sharnoa Tiger<br />

4 CNC Controls, Coolant<br />

1 – MAKINO S33 CNC VERTICAL MACHINING CENTER,<br />

S/N V7252 (2004), With Automatic Rotary Pallet Changer,<br />

Travels: X=25.59", Y=19.68", Z=17.72", 400-Lbs. Pallet Load<br />

Capacity, 130-13,000 RPM Spindle Speed Range, CAT 40<br />

Spindle Taper, 30-HP Spindle Drive Motor, 1575 IPM Rapid<br />

Traverse & Cutting Feedrate, 30 ATC Tool Changer, Makino<br />

Pro-3 (Fanuc 16iM) CNC Control, 30-Position Side-Mounted<br />

Auto Tool Changer, Built-In Auto Rotary Pallet Changer<br />

To schedule an auction, please contact us at 248.254.9999 3

CNC GUN DRILL • CNC BORING MILL • SPOTTING PRESSES<br />

MORI SEIKI MODEL SH-50<br />

CNC HORIZONTAL MACHINING CENTER<br />

TARUS MODEL TPTCGD 408S<br />

CNC HORIZONTAL GUN DRILL<br />

CNC HORIZONTAL MACHINING CENTER<br />

1 – MORI SEIKI MODEL SH-50 CNC HORIZONTAL MACHINING<br />

CENTER, S/N 542 (1996), (2) 19.69 x 19.69 Pallets, 1-Degree<br />

Indexing, 60 ATC, Thru Spindle Coolant, BT-40 Taper, 12,000<br />

RPM Spindle Speed, Travels: X=24.8, Y=23.62, Z=25.59,<br />

Chip Conveyor, Fanuac MSC-516 Control<br />

EDM ELECTRODE DRILL<br />

1 – CHARMILLES MODEL SH2 EDM ELECTRODE DRILL, S/N<br />

NA, Work Tank Size 21” x 17” x 10”, Worktable Size 13” x 10”,<br />

300mm Z-Axis, Cabinet Base, With Self-Contained Dielectric<br />

Fluid System, Mitutoyo 2-Axis Programmable Readout<br />

HORIZONTAL GRAPHITE DRILLS<br />

1 – HORIZONTAL PRECISION GRAPHITE DRILL, MFG’R NA,<br />

24” x 12” Table, With 24” x 12” x 3-1/4” Sub-Table, Variable<br />

Speed<br />

1 – WESTHOFF HORIZONTAL PRECISION DRILL, S/N NA,<br />

Variable Speed<br />

CNC HORIZONTAL GUN DRILL<br />

1 – TARUS MODEL TPTCGD 408S CNC HORIZONTAL GUN<br />

DRILL, S/N TPTCGDCNC1023005258 (1994), Table Size 60”<br />

x 106”, Travels 100” X Axis, 54” Y Axis, 47.125” Z Axis, Hole<br />

Diameter Range 1/8” – 2-1/2” Diameter, 84” Drilling Stroke,<br />

3500 RPM, Milling, Drilling & Chamfering Spindle, With CAT 50<br />

Spindle Taper, Tarus MBX-92-G/486 In-Ground Coolant<br />

System, Chip Removal Conveyor<br />

Quantity of Gun Drill Accessories Including, Gun Drills, Bushings,<br />

Lista 96” High 5-Compartment Gun Drill Storage Cabinet<br />

CINCINNATI GILBERT 5” TABLE TYPE<br />

CNC HORIZONTAL BORING MILL<br />

NOMURA MODEL B-100WP 4” TABLE TYPE<br />

HORIZONTAL BORING MILL<br />

4-POST HYDRAULIC SPOTTING PRESS & MTD 200-74-108 200-TON 4-POST<br />

HYDRAULIC SPOTTING PRESS<br />

CNC HORIZONTAL BORING MILL<br />

1 – CINCINNATI GILBERT 5” TABLE TYPE CNC HORIZONTAL<br />

BORING MILL, S/N 325-J, 5” Spindle Bar Diameter, Table Size<br />

48” x 135”, Travels: X-120”, Y-96”, Z-43”, W-48”, 43” Spindle,<br />

Spindle Speeds 15 – 1500 RPM, 30-HP Spindle Drive Motor, No.<br />

50 Spindle Taper, With Power Drawbar, (2) Floor Type Outboard<br />

Table Supports, Hanson Model 3T1P1C Spindle Oil Chiller,<br />

Coolant, Teleflex Retractable Steel Way Covers, Heidenhain CNC<br />

Controls, Pendant Controller<br />

HORIZONTAL BORING MILL<br />

1 – NOMURA MODEL B-100WP 4” TABLE TYPE HORIZONTAL<br />

BORING MILL, S/N 3861, 4” Spindle Bar Diameter, Table Size 48”<br />

x 96”, Travels: 70.5” Vertical, 97” Table, 42.9” Saddle,<br />

27” Spindle, 13,200-LB. Table Capacity, 18-Spindle Speeds<br />

21 – 1200 RPM, 15 KW Spindle Motor, No. 50 Taper Spindle, with<br />

Power Drawbar, Pendant Control, Outboard Type Table Supports,<br />

Telescopic Way Covers, Sony 3-Axis Readout<br />

SPOTTING PRESSES<br />

1 – MTD MODEL 200-74-108 200-TON 4-POST HYDRAULIC<br />

SPOTTING PRESS, S/N NA, Bed Size Between Posts 88” LR x 54”<br />

FB, Shut Height to Bed Range 40” – 88”, Drilled & Tapped Ram &<br />

Bed, Top-Mounted Hydraulics, Floor Standing<br />

1 – HAMILTON 150-TON 4-POST HYDRAULIC SPOTTING PRESS,<br />

S/N NA, Hydraulic Sliding Bolster Size 60” x 96”, 67” Maximum<br />

Daylight, With (2) Advantage Sentra 2000HE Temperature<br />

Controllers, Water Manifolds, T-Slotted Ram & Bed, Top-Mounted<br />

Hydraulics, Floor Standing<br />

1 – 4-POST HYDRAULIC SPOTTING PRESS, Bed Size Between<br />

Tie Bars 49” LR x 25” FB, 28” LR x 32” Hydraulic Shuttle Table<br />

(F – B), External Hydraulic Unit<br />

4 For more information, visit us on the web @ www.hilcoind.com

CHARMILLES ROBOFORM 85 4-AXIS<br />

CNC DIE SINKER RAM TYPE EDM<br />

CNC DIE SINKER EDMS • CNC WIRE CUT EDMS<br />

2003<br />

CHARMILLES ROBOFORM 400<br />

CNC DIE SINKER RAM TYPE EDM<br />

ONA TECHNO H600 4-AXIS<br />

CNC DIE SINKER RAM TYPE EDM<br />

CHARMILLES ROBOFORM 40 4-AXIS<br />

CNC DIE SINKER RAM TYPE EDM<br />

1999<br />

CHARMILLES ROBOFIL 310<br />

5-AXIS CNC WIRE CUT EDM<br />

CNC DIE SINKER EDMS<br />

1 – CHARMILLES ROBOFORM 85 4-AXIS CNC DIE SINKER RAM TYPE EDM, S/N 725039 (2003),<br />

Worktable Size 31—1/2” x 47”, Travels: 31.5” X, 23.62” Y, 19.68” Z, C-Axis Rotary Work Head, With<br />

Hirschmann Rotary Chuck, Work Tank Size 59.05” x 42.51” x 23.22”, Automatic Drop Door, 7-Position<br />

Linear Tool Changer, 9259-LB. Table Load Capacity, 220-LB. Electrode Head Capacity, Dielectric<br />

Fluid System, With (8) Replaceable Paper Cartridge Filters, Charmilles CNC Control Cabinet<br />

1 – ONA TECHNO H600 4-AXIS CNC DIE SINKER RAM TYPE EDM, S/N 8786/9909 (1999), Worktable<br />

Size 31-1/2” x 47”, Work Tank Size 42” x 68” x 24”, Travels: 39.3” X, 23.6” Y, 28.3” Z, Rotary C-Axis<br />

Head, With Hirschmann Rotary Chuck, 8-Position Linear Tool Changer, Techno 120 CNC Control<br />

Cabinet, Swing-Away Door Enclosures, Self-Contained Dielectric Fluid System, With Cartridge<br />

Filtration<br />

1 – ONA MODEL DATIC PD6.120S1 GANTRY TYPE CNC DIE SINKER RAM TYPE EDM,<br />

S/N 7872/9711 (1997), Worktable Size 46-1/2” x 98-1/2”, Work Tank Size 126” x 59.1” x 37.6”,<br />

Travels: 78.7” X, 39.4” Y, 23.6” Z, 22,000-LB. Table Load Capacity, 2200-LB. Electrode Head<br />

Capacity, Maximum Work Piece Height 49.2”, Datic S120 CNC Control Cabinet, Dielectric Fluid<br />

System, With Granite Type Filtration, Ionoplus 3000 Synthetic Dielectric Fluid<br />

1 – ONA MODEL DATIC PD6.240A3 GANTRY TYPE CNC DIE SINKER RAM TYPE EDM,<br />

S/N 7772/9711 (1997), Work Table Size 59” x 98”, Work Tank Size 157.5” x 78.7” x 49.2”, Travels:<br />

59.1” X, 39.4” Y, 23.6” Z, 33,000-LB. Table Load Capacity, 6600-LB. Electrode Head Capacity,<br />

Maximum Work Piece Height 59.1”, Datic S120 CNC Control Cabinet, Dielectric Fluid System, With<br />

Granite Filtration, Ionoplus 3000 Synthetic Dielectric Fluid<br />

1 – CHARMILLES ROBOFORM 40 4-AXIS CNC DIE SINKER RAM TYPE EDM, S/N 4.5309 (1994),<br />

Work Table Size 27.5” x 19.6”, Travels: 19.68” X, 15.74” Y, 17.71” Z, 360 Degree C, Maximum Part<br />

Dimensions 14.56” x 39.37” x 27.55”, Work Tank Dimensions 48” X, 32” Y, 18.75” Z, Table Load<br />

Capacity 2200-LBS., Electrode Head Capacity 220-LBS., Erowa Rotary Work Head, Dielectric<br />

System, With (6) Replaceable Cartridge Filters, Charmilles CNC Control Cabinet<br />

1 – CHARMILLES ROBOFORM 400 CNC DIE SINKER RAM TYPE EDM, S/N 75097, Work Table Size<br />

22” x 31-1/2”, Travels 17.7” X, 12.6” Y, 22.5” Z, Rotary Head C-Axis, Work Tank Size 44.5” x 31.5” X<br />

16.25”, 1100-LB. Table Load Capacity, 44-LB. Electrode Head Capacity, 40-Position Rotary<br />

Automatic Tool Changer, Fire Suppression System, Dielectric Fluid System, With Replaceable<br />

Cartridge Filters, Charmilles CNC Control Cabinet<br />

ONA MODEL DATIC PD6.240A3 GANTRY TYPE<br />

CNC DIE SINKER RAM TYPE EDM<br />

1999<br />

1997<br />

(1 OF 3) CHARMILLES ROBOFIL 510<br />

5-AXIS CNC WIRE CUT EDMS<br />

CNC WIRE CUT EDMS<br />

3 – CHARMILLES ROBOFIL 510<br />

5-AXIS CNC WIRE CUT<br />

EDMs, S/Ns 550832 (1999),<br />

550824 (1999), 550230 (1995),<br />

Maximum Part Dimensions<br />

47.2” x 27.5” x 15.7” Height,<br />

Maximum Part Weight<br />

4408-LBS., Travels: 27.5” X,<br />

15.7” Y, 15.7” Z, 27.5” U, 15.7”<br />

V, Automatic Wire Threading,<br />

Dielectric System, With (10)<br />

Replaceable Cartridge Filters,<br />

Charmilles CNC Controls<br />

1 – CHARMILLES ROBOFIL 310<br />

5-AXIS CNC WIRE CUT EDM,<br />

S/N 360144/6.2653 (1996),<br />

Maximum Part Dimension 33.5”<br />

x 19.7” x 15.7” Height,<br />

Maximum Part Weight<br />

2207-LBS., Travels 17.5” X,<br />

9.8” Y, 15.7” Z, 15.7” U, 9.8” V,<br />

Automatic Wire Threading,<br />

Dielectric System, With<br />

(8) Replaceable Cartridge<br />

Filters, Charmilles CNC<br />

Controls<br />

EDM TOOLING<br />

Quantity of EDM Tooling Including,<br />

Erow & Hirschmann, System 3R &<br />

Mecatool<br />

To schedule an auction, please contact us at 248.254.9999 5

BRIDGEPORT SERIES II SPECIAL<br />

2-HP VARIABLE SPEED<br />

VERTICAL MILLING MACHINE<br />

STANDARD-MODERN SERIES 4000 MODEL 17,<br />

17” X 80” ENGINE LATHE<br />

VERTICAL MILLING MACHINES • LATHES<br />

(2) BRIDGEPORT 1-1/2-HP VARIABLE SPEED<br />

VERTICAL MILLING MACHINES<br />

CLAUSING COLCHESTER 15,<br />

15” X 54” ENGINE LATHE<br />

VERTICAL MILLING MACHINES<br />

1 – BRIDGEPORT SERIES II SPECIAL 2-HP VARIABLE SPEED<br />

VERTICAL MILLING MACHINE, S/N 2633S, Table Size 11” x 58”,<br />

Spindle Speeds 60 – 4200, Bridgeport Power Table Feed, Anilam<br />

Wizard 2-Axis Readout<br />

1 – BRIDGEPORT SERIES I 2-HP VARIABLE SPEED VERTICAL<br />

MILLING MACHINE, S/N 12BR213425, Table Size 9” x 42”, Bridgeport<br />

Power Table Feed, Spindle Speeds 60 – 4200 RPM, Anilam Mini<br />

Wizard Readout<br />

1 – BRIDGEPORT 1-1/2-HP VARIABLE SPEED VERTICAL MILLING<br />

MACHINE, S/N 12BR-163194, Table Size 9” x 42”, Bridgeport Power<br />

Table Feed, Spindle Speeds 60 – 4200 RPM, Anilam Readout<br />

1 – BRIDGEPORT 1-1/2-HP VARIABLE SPEED VERTICAL MILLING<br />

MACHINE, S/N 12BR-180849, Table Size 9” x 42”, Spindle Speeds<br />

60 – 4200 RPM, 7” Column Riser, Anilam Mini Wizard 2-Axis Readout<br />

1 – BRIDGEPORT 1-1/2-HP VARIABLE SPEED VERTICAL MILLING<br />

MACHINE, S/N 12BR132959, Table Size 9” x 42”, Spindle Speeds<br />

60 – 4200 RPM<br />

2 – ACER ULTIMA MODEL 3VS 3-HP VARIABLE SPEED VERTICAL<br />

MILLING MACHINES, S/Ns 9366752 (1993), 9366751 (1993), Table<br />

Size 9” x 42”, Spindle Speeds 60 – 4200 RPM, Mitutoyo Readout,<br />

Servo Type 140 Power Table Feed<br />

1 – ALLIANT MODEL ALLIANT-RT2 2-HP VARIABLE SPEED<br />

VERTICAL MILLING MACHINE, S/N 71111712, Table Size 9” x 42”,<br />

Spindle Speeds 60 – 4500 RPM, Anilam Wizard 211 Readout<br />

1 – ALLIANT MODEL 1-1/2-TMV VARIABLE SPEED VERTICAL<br />

MILLING MACHINE, S/N 73U84422, Table Size 9” x 42”,<br />

Spindle Speeds 60 – 4500 RPM<br />

ACER ULTIMA MODEL 3VS 3-HP<br />

VARIABLE SPEED VERTICAL MILLING MACHINES<br />

FEELER “HIGH ACCURACY” MODEL ETL-8<br />

DOVETAIL BED TOOLROOM LATHE<br />

DRILLS<br />

1 – KNUTH MODEL KSR40 RADIAL TYPE DRILLING<br />

MACHINE, S/N 134070 (2005), Maximum Drilling<br />

Capacity 40mm, Stationary T-Slotted Worktable Size 20”<br />

x 47”, Motorized Height/Swing/In-Out Travels, Spindle<br />

Speeds 50 – 1250 RPM<br />

1 – JOHANSSON RADIAL TYPE DRILLING MACHINE,<br />

S/N 32291, 3/1.5-HP, 8-Spindle Speeds 160 – 2400 RPM<br />

Power-Down Feed, 6” Column Diameter, (1) 26” x 48”<br />

Adjustable Height Table, (1) 24” x 20-1/2” T-Slotted Base<br />

1 – IKEDA MODEL RM-1375 5’ ARM X 13” RADIAL DRILL,<br />

S/N 79076, 12-Spindle Speeds 30 – 1500 RPM,<br />

9-Spindle Feeds .003 - .040<br />

1 – LELAND-GIFFORD 24” SLIDING HEAD DRILL,<br />

S/N 10312, Spindle Speeds 430 – 1800 RPM, 37” x 25”<br />

Adjustable Table<br />

LATHES<br />

1 – STANDARD-MODERN SERIES 4000 MODEL 17,<br />

17” X 80” ENGINE LATHE, S/N 5241, 12-Spindle<br />

Speeds 40 – 1600 RPM, Quick Change Threading, 3”<br />

Hole-Thru-Spindle, Taper Attachment, 12” 3-Jaw Chuck<br />

1 – CLAUSING COLCHESTER 15, 15” X 54” ENGINE<br />

LATHE, S/N 6-0015-14966, Spindle Speeds 25 – 2000<br />

RPM, Quick Change Threading, 2-1/8” Hole-Thru-<br />

Spindle, Removable Chip Pan, 10” 3-Jaw Chuck<br />

1 – FEELER “HIGH ACCURACY” MODEL ETL-8<br />

DOVETAIL BED TOOLROOM LATHE, S/N TL82039,<br />

Variable Speed 135 – 2955 RPM, Variable Power<br />

Carriage Travel Collet Drawbar<br />

6 For more information, visit us on the web @ www.hilcoind.com

SURFACE, OD/ID, PIN CUT-OFF & TOOL GRINDERS • SAWS<br />

KENT MODEL SGS-3012AHD 48” X 124”<br />

DOUBLE COLUMN AUTOMATIC HYDRAULIC PRECISION<br />

SURFACE GRINDING MACHINE<br />

2005<br />

KNUTH MODEL KSR40<br />

RADIAL TYPE<br />

DRILLING MACHINE<br />

KENT MODEL KGC-600H 10” X 24”<br />

PLAIN OD/ID GRINDER<br />

SURFACE GRINDERS<br />

1 – KENT MODEL SGS-3012AHD 48” X 124”<br />

DOUBLE COLUMN AUTOMATIC<br />

HYDRAULIC PRECISION SURFACE<br />

GRINDING MACHINE, S/N 910556-1 (1991),<br />

3-Piece Electromagnetic Chuck Size 47-1/4”<br />

x 118-1/4”, Grinding Size Range 118”L x<br />

47.2”W x 18.7”H, Maximum Table Travel<br />

122.0”, Maximum Wheel Head Cross Travel<br />

47.24”, Distance Table Top & Wheel Center<br />

25.59”, Hydraulic Power Overhead Wheel<br />

Dresser, Pendant Type Microcomputer<br />

Controller, 15-HP Wheel Head & Hydraulic<br />

Motors, External Recirculation & Filtration<br />

Unit, With 9” Magnetic Separator & 27” Paper<br />

Media Filter<br />

1 – GALLMEYER & LIVINGSTON “GRAND<br />

RAPIDS” MODEL 480, 12” X 30”<br />

HYDRAULIC SURFACE GRINDER,<br />

S/N 480150, Electromagnetic Chuck,<br />

External Coolant Unit<br />

1 – OKAMOTO MODEL ACCUGAR 124, 12” X<br />

24” AUTOMATIC HYDRAULIC SURFACE<br />

GRINDER, S/N 7895, Electromagnetic<br />

Chuck, Power Elevation, External Coolant<br />

2 – ACER MODEL AGS-618, 6” X 18”<br />

HAND FEED SURFACE GRINDERS,<br />

S/Ns 97000972 (1997), 97080859 (1997),<br />

Permanent Magnetic Chucks<br />

1 – KENT MODEL KGS-200 6” X 12” HAND<br />

FEED SURFACE GRINDER, S/N 830710-14,<br />

Permanent Magnetic Chuck, Over Head<br />

Dresser<br />

GALLMEYER & LIVINGSTON “GRAND RAPIDS”<br />

480, 12” X 30” HYDRAULIC SURFACE GRINDER<br />

(2) ACER MODEL AGS-618,<br />

6” X 18” HAND FEED<br />

SURFACE GRINDERS<br />

OD/ID GRINDER<br />

1 – KENT MODEL KGC-600H 10” X 24”<br />

PLAIN OD/ID GRINDER, S/N 820650<br />

(1992), Universal Motorized Headstock,<br />

With 5” 3-Jaw Chuck, Swing-Down<br />

Motorized ID Spindle, 1-1/2” x 12” OD<br />

Wheel Size, Hydraulic Table Feed,<br />

Coolant<br />

PIN CUT-OFF & GRINDER<br />

1 – IPSCO INTERNATIONAL MODEL<br />

PCO-Z PIN CUT-OFF & GRIND<br />

MACHINE, S/N 97008 (1997)<br />

TOOL GRINDERS<br />

3 – DECKEL MODEL SOE SINGLE LIP<br />

TOOL GRINDERS, S/Ns 86-6074, 96-<br />

8305, 78-4158<br />

1 – GORTON MODEL 375 TOOL &<br />

CUTTER GRINDER, S/N 74J51582<br />

1 – K O LEE MODEL B923A TOOL &<br />

CUTTER GRINDER, S/N NA<br />

1 – OPTIMA BENCH TYPE OPTICAL<br />

TOOL GRINDER, S/N B1528<br />

1 – CUTTERMASTER MODEL FCG-30<br />

BENCH TOP END MILL GRINDER,<br />

S/N 1154B<br />

LAPPING MACHINE<br />

1 – SPITFIRE MODEL SP-888-24PNLC<br />

24” DIAMETER 3-STATION LAPPING<br />

MACHINE, S/N 7810-24PNLC-1694,<br />

(3) 11” Diameter Work Head Stations<br />

OKAMOTO MODEL ACCUGAR 124,<br />

12” X 24” AUTOMATIC HYDRAULIC<br />

SURFACE GRINDER<br />

ARMSTRONG BLUM MARVEL SERIES 8<br />

MARK II TILT-FRAME UNIVERSAL<br />

VERTICAL BANDSAW<br />

SAWS<br />

1 – ARMSTRONG BLUM MARVEL<br />

SERIES 8 MARK II TILT-FRAME<br />

UNIVERSAL VERTICAL BANDSAW,<br />

S/N 828852, Power Feed, Manual Tilt,<br />

Coolant<br />

1 – ARMSTRONG BLUM MARVEL<br />

8/E4 TILT-FRAME UNIVERSAL<br />

VERTICAL BANDSAW, S/N 811342<br />

1 – DOALL MODEL 2612-2H<br />

26” VERTICAL CONTOUR<br />

BANDSAW, S/N 206-69293,<br />

Hydraulic Power Feed Table,<br />

Variable Blade Speeds 25 – 6000<br />

FPM, Blade Welder & Grinder<br />

1 – DOALL ML 16” VERTICAL<br />

BANDSAW, S/N 458924, Blade<br />

Speeds 50 – 1600 FPM, Blade<br />

Welder/Grinder<br />

1 – KALAMAZOO MACHINE TOOL<br />

12”, 2.5 KW COLD SAW,<br />

S/N 970792001, Miter Cut<br />

1 – 10” ABRASIVE CUT-OFF SAW<br />

1 – SEARS CRAFTSMAN 10” TABLE<br />

SAW, S/N 7309-P0347<br />

1 – TSI 14” VERTICAL BANDSAW,<br />

S/N 82431<br />

To schedule an auction, please contact us at 248.254.9999 7

CMMS • INSPECTION • GENERATOR • PROCESS WATER COOLING<br />

2000<br />

BROWN & SHARPE GLOBAL STATUS 122210 CNC<br />

BRIDGE TYPE COORDINATE MEASURING MACHINE<br />

1998<br />

CATERPILLAR SR4 500 KW DIESEL EMERGENCY<br />

STANDBY AC POWER GENERATOR<br />

STARRETT MODEL HGC-2018-16<br />

BRIDGE TYPE COORDINATE<br />

MEASURING MACHINE<br />

PROCESS ENGINEERING COOLANT<br />

RECIRCULATION UNIT<br />

COORDINATE MEASURING MACHINES<br />

1 – BROWN & SHARPE MODEL GLOBAL STATUS 122210 CNC<br />

BRIDGE TYPE COORDINATE MEASURING MACHINE,<br />

S/N 1200-6504 (2000), Granite Table Size 55” x 125”, Measuring<br />

Range 86” X, 48” Y, 40” Z, Renishaw PH10MQ Touch Probe Head,<br />

Renishaw PHC10-2 Probe Head Controller, Joystick Operators<br />

Control, PC Unit, PC-DMIS for Windows Software<br />

1 – STARRETT MODEL HGC-2018-16 BRIDGE TYPE COORDINATE<br />

MEASURING MACHINE, S/N B-1099, Granite Table Size 30” x 26”,<br />

Measuring Range 20” X, 18” Y, 16” Z, Renishaw MIP Touch Probe,<br />

PC Unit, Starrett Software<br />

INSPECTION<br />

1 – STARRETT 58” X 102” X 18” PINK GRANITE SURFACE PLATE,<br />

S/N 85337<br />

1 – 48” X 72” X 10” BLACK GRANITE SURFACE PLATE<br />

1 – STARRETT 36” X 48” X 6” PINK GRANITE SURFACE PLATE,<br />

S/N 948533<br />

1 – 24” x 36” BLACK GRANITE SURFACE PLATE<br />

1 – MITUTOYO NO. 192-697, 0 – 24” DIGITAL HEIGHT GAUGE<br />

2 – SPI 24” DIGIMATIC DIGITAL HEIGHT GAUGES<br />

1 – SPI 24” VERNIER DIGITAL HEIGHT GAUGE<br />

1 – MITUTOYO NO. 570-236, 40” DIGIMATIC DIGITAL HEIGHT GAUGE<br />

1 – MITUTOYO 40” VERNIER HEIGHT GAUGE<br />

1 – MITUTOYO 24” VERNIER HEIGHT GAUGE<br />

1 – MITUTOYO 18” VERNIER HEIGHT GAUGE<br />

2 – MITUTOYO & SPI 0 – 18” DIAL HEIGHT GAUGES<br />

1 – FIE MODEL R ROCKWELL HARDNESS TESTER, S/N 77/490<br />

Quantity of Micrometers, Calipers, Dial Indicators, Gage Block Sets,<br />

Pin Gages, etc.<br />

TRINCO MODEL 60X48SL/BP<br />

60” X 48” 4-HOLE ABRASIVE<br />

DRY BLAST CABINET<br />

TORIT DOWN-FLO<br />

DUST COLLECTOR<br />

HEATCRAFT MODEL ARC30B2DC<br />

PROCESS COOLING WATER CHILLER<br />

STAND-BY AC – POWER GENERATOR<br />

1 – CATERPILLAR 500 KW DIESEL EMERGENCY<br />

STANDBY AC POWER GENERATOR (NEW 1988)<br />

GENERATOR MODEL SR4, S/N 5NA11271, Generator<br />

Data: 625 KVA, 500 KW, 60 HZ, 3-Phase – 10 Wire, 480<br />

Volt – 752 Amps, Engine Data: Model 3412 V-12 CAT<br />

Diesel, S/N 81Z22963, Rated 749-HP @ 558.5 KW @<br />

1800 RPM, Liquid Cooled Radiator, With Direct Fresh Air<br />

Inlet, With:<br />

• CATERPILLAR SYSTEMS MICROPROCESSOR<br />

CONTROL PANEL, 110-Volt Recirculating Hot Water<br />

Heater, Open Skid Mounted Base, With Cushion Dampers,<br />

Mounted Upon 102”W x 20’L x 16”H Skid Base<br />

Self-Contained Diesel Fuel Tank, With Automatic Transfer<br />

Switch (Less then 100 Hrs - Actual Hrs NA)<br />

PROCESS COOLING WATER EQUIPMENT<br />

1 – HEATCRAFT MODEL ARC30B2DC PROCESS<br />

COOLING WATER CHILLER, S/N A97M00013, 4-Zone<br />

Cooling Fans, (2) Compressors<br />

1 – HEATCRAFT MODEL AFD 26 COOLING TOWER,<br />

S/N T97L00897, 3-Zone Cooling Fans<br />

1 – PROCESS ENGINEERING COOLANT RECIRCULATION<br />

UNIT & HOLDING TANK, S/N NA, (1) 7.5 & (1) 1.5-HP<br />

Recirculation Pumps, Tank Size 44” x 44” x 44” Skid Base<br />

8 For more information, visit us on the web @ www.hilcoind.com

2004<br />

ABRASIVE BLAST CABINETS • WELDING • VEHICLES<br />

VIEW OF WELDING EQUIPMENT<br />

GMC ENVOY XUV 4X4 SPORT UTILITY VEHICLE<br />

1995<br />

AIR FILTRATION UNITS<br />

1 – TORIT DOWN-FLO MODEL SDF-6 7-1/2-HP CARTRIDGE TYPE DUST<br />

COLLECTOR, S/N IG427011-001, (6) Replaceable Cartridge Filters,<br />

Torit Checkerboard Programmable Controls<br />

1 – TORIT DONALDSON DOWN-FLO MODEL T 2-4-OD 7.5-HP DUST<br />

COLLECTOR, S/N IG592883-001, Pneumatic Pulse Jet Type,<br />

(6) Replaceable Cartridge Filters<br />

1 – AERCOLOGY MDVH-6000 5-HP MEDIA FILTER/MIST COLLECTOR, S/N 48491<br />

1 – AERCOLOGY MODEL FDV-2500B MEDIA FILTER, S/N 15583<br />

1 – TORIT DONALDSON 75 1-HP CABINET TYPE DUST COLLECTOR, S/N 202849<br />

ABRASIVE BLAST CABINETS<br />

1 – TRINCO MODEL 60X48SL/BP 60” X 48” 4-HOLE ABRASIVE DRY BLAST<br />

CABINET, S/N 60828-4, Flip Top & Side Door, With BP2 Dust Collector<br />

1 – TRINCO MODEL 60X24SL/BP2 60” X 24” 4-HOLE ABRASIVE DRY BLAST<br />

CABINET, S/N 35416-0, Side Doors & Flip Top, With BP2 Dust Collector<br />

1 – TRINCO MODEL 36/BP2 36” ABRASIVE DRY BLAST CABINET, S/N 14423-8<br />

WELDING EQUIPMENT<br />

1 – MILLER SYNCROWAVE 351 CONSTANT CURRENT AC/DC ARC<br />

WELDING POWER SUPPLY, S/N KD546898, With Miller Coolmate<br />

4-Water Cooling Unit, Cart, Tig Welding Leads<br />

1 – MILLER SYNCROWAVE 250 CC-AC/DC WELDING POWER SUPPLY,<br />

S/N KH427242, With Miller Coolmate 4-Water Cooler, Cart, Tig Welding<br />

Leads<br />

1 – LINDE MODEL V1-252 CV/DC WELDING POWER SUPPLY,<br />

S/N B78C13680, With Linde Wire Feeder<br />

1 – BONAL TECHNOLOGIES META-LAX MODEL 900-2A STRESS RELIEF<br />

& WELD CONDITIONING UNIT, S/N 1553, With 42” x 84” T-Slotted Table<br />

1 – MICRO AIR MODEL MC1500 PORTABLE WELDING FUME EXHAUST<br />

UNIT, S/N 47718 (2000)<br />

2 – OXYGEN/ACETYLENE TORCH CUTTING SETS<br />

GMC SIERRA 2500HD SLE 4X4, GMC SIERRA 2500 SLT 4X4 EXTENDED CAB &<br />

GMC SIERRA 2500 SL PICK UP TRUCKS<br />

TO 2003<br />

GMC TOP KICK TRI-AXLE & GMC C6500 SINGLE AXLE FLATBED STAKE TRUCKS<br />

1998<br />

FLATBED STAKE TRUCKS<br />

1 – 1995 GMC TOP KICK TRI-AXLE FLATBED STAKE<br />

TRUCK, VIN: 1GDT7H4J9SJ525738, 51,000-LB.<br />

GVWR Rating, 11,000-LB. Front, 40,000-LB. Rears,<br />

CAT 3116 275-HP Diesel, Fuller 9-Speed, Live<br />

Tandem, Hendrickson Multi-Leaf Spring Suspension,<br />

Air Lift Pusher Axle, 16’ Wood Deck Flatbed, With<br />

14” Sides, Air Brakes, 11R22.5 Tires (161,501 Miles)<br />

1 – 1998 GMC C6500 SINGLE AXLE FLATBED STAKE<br />

TRUCK, VIN: 1GDJ6H1JXWJ503977, 25,950<br />

GVWR, 8100-LB. Front, 17,850-LB. Rear, CAT 3116<br />

185-HP Diesel, 6-Speed, Hydraulic Brakes, 16’<br />

Wood Deck Flatbed, With 14” Sides, A/C,<br />

225/70R22.5 Tires (201,516 Miles)<br />

SPORT UTILITY VEHICLE<br />

1 – 2004 GMC ENVOY XUV 4X4 SPORT UTILITY<br />

VEHICLE, VIN: 1GKET12SX4617024S, PW/PL/PS,<br />

CD/Cassette (66,378 Miles)<br />

PICK UP TRUCKS<br />

1 – 2003 GMC SIERRA 2500HD SLE 4X4 PICK UP<br />

TRUCK, VIN: 1GTHK24183E250069, Standard Cab,<br />

Duramax Diesel, Automatic, Cloth Seats, PW/PL/PS,<br />

Cruise, DC, A/C (107,925 Miles)<br />

1 – 2002 GMC SIERRA 2500 SLT 4X4 EXTENDED CAB<br />

PICK UP TRUCK, VIN: 1GTGK29U02Z269706, Vortec<br />

6.0L V-8 Gas Engine, Automatic, Leather Seats,<br />

PW/PL/PS, Cruise, CD, A/C (096,129 Miles)<br />

1 – 1999 GMC SIERRA 2500 SL PICK UP TRUCK,<br />

VIN: 1GTGC24U8XE535587, 2WD, Standard Cab,<br />

6.0L Vortec V8 Gas Engine, Automatic, Cruise, PL,<br />

Cassette, A/C (209,317 Miles)<br />

To schedule an auction, please contact us at 248.254.9999 9

RIGHT ANGLE PLATES<br />

1/2” X 96 1/2” X 48” X 3 3/4”<br />

AIR FILTRATION • CRANES • FORKLIFTS<br />

10 & 20-TON X APPROXIMATELY 54’ SPAN TOP RIDING<br />

DOUBLE GIRDER BRIDGE CRANES<br />

HOT RUNNER TEMPERATURE CONTROLS<br />

1 – D-M-E MODEL MFP240, 24-VOLT ELECTRIC HOT RUNNER<br />

TEMPERATURE CONTROLLER, S/N FC23818, Cart Mounted, With 45 KVA<br />

Transformer<br />

1 – D-M-E 2-ZONE ELECTRIC HOT RUNNER TEMPERATURE CONTROLLER,<br />

MODEL & S/N NA, Cart Mounted, With Transformer<br />

BRIDGE CRANES<br />

1 – 20-TON X APPROXIMATELY 54’ SPAN TOP RIDING DOUBLE<br />

GIRDER BRIDGE CRANE, Class C Single Speeds, 6-Way Pendant Controls<br />

1 – 10-TON X APPROXIMATELY 54’ SPAN TOP RIDING DOUBLE<br />

GIRDER BRIDGE CRANE, Class C Single Speeds, 6-Way Pendant Controls<br />

1 – SHAW BOX 10-TON X APPROXIMATELY 54’ SPAN TOP RIDING<br />

DOUBLE GIRDER BRIDGE CRANE, Class C Single Speeds, 6-Way<br />

Pendant Controls<br />

Bridge Crane Accessories Including, Chain Slings, Eyebolts, (2) Mechanical<br />

Dial Face Crane Scales, (3) Electromagnetic Lifting Magnets<br />

FORKLIFTS<br />

1 – AUTOLIFT 30,000-LB. CAPACITY FORKLIFT, S/N NA, LPG, Solid Tires,<br />

2-Stage Mast, Direct Hydraulic Lift, 126” Mast Height, Hydraulic Power Fork<br />

Positioning, 6’ Forks<br />

1 – HYSTER MODEL S100XLBCS 10,000-LB. CAPACITY FORKLIFT,<br />

S/N D004D07566W, LPG, Solid Tires, 209” Lift, 3-Stage Mast, 99” Mast<br />

Height, Side Shift, 60” Forks<br />

1 – HYSTER MODEL S100E 10,000-LB. CAPACITY FORKLIFT,<br />

S/N C004D08822G, LPG, Solid Tires, 158.5” Lift, 3-Stage Mast, Side Shift,<br />

48” Forks<br />

1 – YALE MODEL GC-52-20/24-UP 2650-LB. CAPACITY FORKLIFT,<br />

S/N AH-114651, LPG, Solid Tires, 2-Stage Mast<br />

AERIAL WORK PLATFORMS<br />

1 – MAYVILLE ENGINEERING MODEL 1948HT SELF-PROPELLED<br />

ELECTRIC SCISSORS LIFT WORK PLATFORM, S/N 61XX 54,<br />

19’ Maximum Height, 1500-LB. Capacity, Platform Size 44” x 96”<br />

1 – ECONOMY HI-JACKER MODEL HJ-15-M MECHANICAL TELESCOPIC<br />

WORK PLATFORM, S/N 41574, 15 Ft. Maximum Height, 300-LB. Capacity<br />

Bid Live In Person or<br />

By Phone Via the Web at<br />

www.hilcoind.com<br />

AUTOLIFT 30,000-LB. CAPACITY FORKLIFT<br />

MATERIAL HANDLING<br />

1 – BIG JOE MODEL 1086 HYDRAULIC LIFT<br />

CART, S/N 144<br />

1 – BIG JOE LIFT CART, Model & S/N NA<br />

1 – THERN MODEL 543 1-TON CAPACITY<br />

PORTABLE HYDRAULIC SHOP CRANE,<br />

S/N 54782818<br />

1 – AFF MODEL 590 1760-LB. CAPACITY<br />

HYDRAULIC TRANSMISSION JACK, With 24”<br />

Diameter Rotary Table Surface<br />

MACHINE ACCESSORIES<br />

1 – NIKKEN CNC200 AUTO TABLE 8” 4TH AXIS<br />

SERVO INDEXING ATTACHMENT, With<br />

Tailstock<br />

1 – PAIR 36-1/2” X 96-1/2” X 48” X 3-3/4”<br />

T-SLOTTED RIGHT ANGLE PLATES<br />

2 – PAIRS 20-1/2” X 48” X 30” X 3” DRILLED &<br />

TAPPED RIGHT ANGLE PLATES<br />

1 – 71” X 48” X 2-1/4” DRILLED & TAPPED<br />

SUB-PLATE<br />

1 – 48” X 36” T-SLOTTED SINE PLATE<br />

1 – 53” X 71” T-SLOTTED SINE PLATE<br />

1 – 9” X 46” DRILLED & TAPPED SINE PLATE<br />

1 – 14” X 28” DRILLED & TAPPED SINE PLATE<br />

Large Quantity Machine Accessories Including, Kurt<br />

Machine Vises, Angle Plates, Precision Machine<br />

Vises, Sine Plates, Dividing Heads, Grinding<br />

Attachments, Dressers, Whirly-Gigs, Collets,<br />

Bridgeport Tooling, CAT 50 & 40/BT 50 Taper Tool<br />

Holders, HSK Taper Tool Holders, Diamond Coated<br />

Carbide High-Speed Cutters, Drills, Taps, End Mills,<br />

Carbide Inserts, Insert Cutters, Drill Chucks, Drill<br />

Sleeves, No. 50 MT Tool Holders, Large Quantity<br />

Precision Machined & Ground Set-Up Blocks, Risers,<br />

Hold Downs, Clamping Tooling, General Tool & Die<br />

Shop Machine Accessories<br />

A Buyer’s Premium of 13.5%<br />

for all onsite sales & 16% for all<br />

webcast sales will be in effect.<br />

10 For more information, visit us on the web @ www.hilcoind.com

MISCELLANEOUS MACHINES/SHOP & FACTORY<br />

HYSTER MODELS S100XLBCS & S100E<br />

10,000-LB. CAPACITY FORKLIFTS<br />

VIEW OF MISCELLANEOUS SHOP & FACTORY EQUIPMENT<br />

VIEW OF CAT 50 TAPER TOOLING<br />

Hilcast TM Webcast Technology<br />

MAYVILLE ENGINEERING MODEL 1948HT<br />

SELF-PROPELLED ELECTRIC<br />

SCISSORS LIFT WORK PLATFORM<br />

FLEX ARM PORTABLE<br />

ARTICULATED ARM PNEUMATIC<br />

TAPPING MACHINE<br />

(2) MILWAUKEE PORTABLE MAGNETIC<br />

BASE DRILL PRESSES<br />

MISCELLANEOUS MACHINES/SHOP & FACTORY<br />

1 – FLEX ARM PORTABLE ARTICULATED ARM PNEUMATIC TAPPING MACHINE,<br />

S/N 013217, Mounted on Portable 30” x 60” T-Slotted Steel Table<br />

1 – HDT MODEL DS-20, 20” VERTICAL DISC SANDER/GRINDER, S/N 2020037<br />

1 – HYDROTEK PRO-LINE PORTABLE HOT WATER PRESSURE WASHER, S/N NA,<br />

AC Electric Pump, Diesel Fired Burner<br />

1 – POWERMATIC MODEL 30 6” BELT/12” DISC COMBINATION GRINDER, S/N 9301080<br />

1 – RIDGID MODEL 300 POWER PIPE THREADER, S/N 7565779<br />

1 – DANLY 7-TON AIR-PRESS, S/N 88S-998-0-05, 7-Ton Capacity at 80 PSI, Stroke<br />

3-1/4”, Daylight Bed to Slide 9-7/8”, Die Space 11” x 9” Bench Mounted<br />

1 – GLENDO ACCU-FINISH 6” DISC GRINDER, S/N AF 282<br />

2 – MILWAUKEE PORTABLE MAGNETIC BASE DRILL PRESSES<br />

1 – FACTORY CAT MODEL 34 PUSH-TYPE FLOOR SWEEPER<br />

1 – MONODE ELECTROLYTE ELECTRIC ETCHER/MARKER, With 150-C Power Unit<br />

Large Quantity General Shop & Factory Supplies, (Over 40) Wilton Bench Vises, Workbenches,<br />

Crib Supplies, Perishable Tool Cutters, Machine Accessories, etc.<br />

OFFICES<br />

(3) Gestetner 1802d Copiers, Gestetner F530 Fax, Printex Forms Pro 4503 Forms Printer,<br />

Océ 7056 Blueprint Copier, HP Design Jet 800 Plotter, PC’s, Printers, Office Furniture<br />

Hilcast TM Webcast Technology allows bidders to speak directly with the auctioneer and eliminates the mouse from the auction process.<br />

Our new technology speeds up the process while providing real time ability to confirm bids directly with the auctioneer – as if you were on<br />

the auction floor. Buyers choice, option & privilege? No Problem! Just tell the auctioneer what you want.<br />

Visit www.hilcoind.com to register as a new member at any time, even on auction day. Preview the assets with detailed photographs, lot catalogs with indepth<br />

descriptions, and even view or download a virtual brochure prior to the auction. At the time of the auction, listen to the Auctioneer live on the web and/or phone while<br />

the current asset up for bid is displayed on your computer screen. It’s convenient, simple, free, & IT WORKS!<br />

Please note when participating in an auction that all assets are being sold as is, where is, with all faults. All Buyers will be responsible for timely removal of assets<br />

along with shipping and rigging charges for all purchases. Complete terms and conditions are available on our website at www.hilcoind.com.<br />

To schedule an auction, please contact us at 248.254.9999 11

Atlanta • Birmingham • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX) • Leeds (UK)<br />

London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Southampton (UK) • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 248.254.9999<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Forwarding Service Requested<br />

HILCAST TM<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> Trading, Co. • Headquarters 5 Revere Drive, Ste. 430 • Northbrook, IL 60062<br />

All rights reserved • Printed in USA • MATT3309 • IL License #044000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

<strong>WEBCAST</strong> <strong>AUCTION</strong><br />

– Real Estate Available by Private Negotiation –<br />

Mattson<br />

Tool & Die<br />

Corporation<br />

5670 W. River Road NE<br />

Belmont, MI 49306-9763<br />

41,064 Sq. Ft. Including Multiple Cranes,<br />

Heavy Electrical Power, (1) Loading Dock,<br />

(11) Drive-In Doors and<br />

8,508 Sq. Ft. Office Space<br />

Questions regarding the sale of the real estate should be directed to:<br />

Herb Mattson - Telephone: 616.784.1290<br />

Terms of Sale<br />

A buyer’s premium is in effect. Everything will be sold<br />

to the highest bidder for cash, in accordance with the<br />

Auctioneer’s customary “Terms of Sale”, copies of<br />

which will be posted on the premises of the sale and<br />

subject to additional terms announced the day of<br />

sale. All items will be sold “as is, where-is” without<br />

any warranties, express or implied. Although<br />

obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the<br />

accuracy of the information herein contained.<br />

Bidders are encouraged to thoroughly inspect the<br />

items on which they intend to bid prior to sale.<br />

Absolutely no items will be removed until the day<br />

after the conclusion of the sale and payment is made<br />

in full. Subject to additions, deletions and prior sale.<br />

Payment: ALL PURCHASES MUST BE PAID IN<br />

FULL ON THE DAY OF THE <strong>AUCTION</strong>. If you intend<br />

to pay by wire transfer, we will accept payment the<br />

day after the sale ONLY IF a deposit of 25% of total<br />

purchases is made on the day of the sale. Contact<br />

our office for wire transfer instructions. Only cash,<br />

wire transfer or certified check, payable to <strong>Hilco</strong><br />

<strong>Industrial</strong>, LLC will be accepted. Company checks<br />

payable to <strong>Hilco</strong> <strong>Industrial</strong> LLC will be accepted only<br />

if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales<br />

tax. Purchasers claiming exemptions from taxes<br />

must provide proof satisfactory to the Auctioneer of<br />

their entitlement to claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees<br />

payment to <strong>Hilco</strong> <strong>Industrial</strong>, LLC from<br />

(Company Name). This guarantee will be valid<br />

for purchases made at the Auction of Mattson<br />

Tool & Die Corporation on May 20, 2008