QualiPlate™ Kit for Cholinesterase - EnviroLogix

QualiPlate™ Kit for Cholinesterase - EnviroLogix

QualiPlate™ Kit for Cholinesterase - EnviroLogix

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

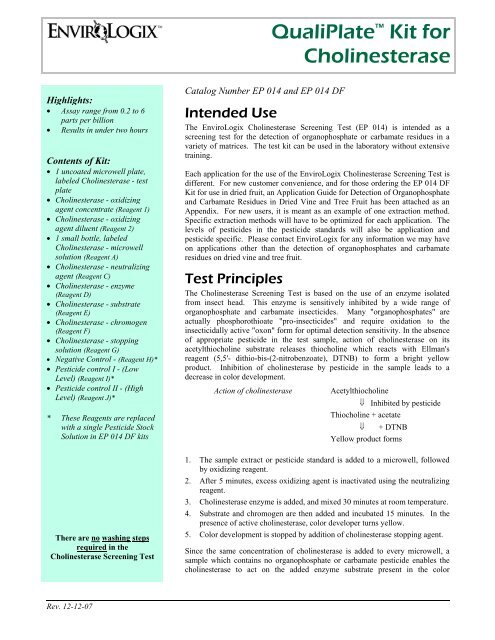

Highlights:<br />

• Assay range from 0.2 to 6<br />

parts per billion<br />

• Results in under two hours<br />

Contents of <strong>Kit</strong>:<br />

• 1 uncoated microwell plate,<br />

labeled <strong>Cholinesterase</strong> - test<br />

plate<br />

• <strong>Cholinesterase</strong> - oxidizing<br />

agent concentrate (Reagent 1)<br />

• <strong>Cholinesterase</strong> - oxidizing<br />

agent diluent (Reagent 2)<br />

• 1 small bottle, labeled<br />

<strong>Cholinesterase</strong> - microwell<br />

solution (Reagent A)<br />

• <strong>Cholinesterase</strong> - neutralizing<br />

agent (Reagent C)<br />

• <strong>Cholinesterase</strong> - enzyme<br />

(Reagent D)<br />

• <strong>Cholinesterase</strong> - substrate<br />

(Reagent E)<br />

• <strong>Cholinesterase</strong> - chromogen<br />

(Reagent F)<br />

• <strong>Cholinesterase</strong> - stopping<br />

solution (Reagent G)<br />

• Negative Control - (Reagent H)*<br />

• Pesticide control I - (Low<br />

Level) (Reagent I)*<br />

• Pesticide control II - (High<br />

Level) (Reagent J)*<br />

* These Reagents are replaced<br />

with a single Pesticide Stock<br />

Solution in EP 014 DF kits<br />

There are no washing steps<br />

required in the<br />

<strong>Cholinesterase</strong> Screening Test<br />

Rev. 12-12-07<br />

Catalog Number EP 014 and EP 014 DF<br />

QualiPlate <strong>Kit</strong> <strong>for</strong><br />

<strong>Cholinesterase</strong><br />

Intended Use<br />

The <strong>EnviroLogix</strong> <strong>Cholinesterase</strong> Screening Test (EP 014) is intended as a<br />

screening test <strong>for</strong> the detection of organophosphate or carbamate residues in a<br />

variety of matrices. The test kit can be used in the laboratory without extensive<br />

training.<br />

Each application <strong>for</strong> the use of the <strong>EnviroLogix</strong> <strong>Cholinesterase</strong> Screening Test is<br />

different. For new customer convenience, and <strong>for</strong> those ordering the EP 014 DF<br />

<strong>Kit</strong> <strong>for</strong> use in dried fruit, an Application Guide <strong>for</strong> Detection of Organophosphate<br />

and Carbamate Residues in Dried Vine and Tree Fruit has been attached as an<br />

Appendix. For new users, it is meant as an example of one extraction method.<br />

Specific extraction methods will have to be optimized <strong>for</strong> each application. The<br />

levels of pesticides in the pesticide standards will also be application and<br />

pesticide specific. Please contact <strong>EnviroLogix</strong> <strong>for</strong> any in<strong>for</strong>mation we may have<br />

on applications other than the detection of organophosphates and carbamate<br />

residues on dried vine and tree fruit.<br />

Test Principles<br />

The <strong>Cholinesterase</strong> Screening Test is based on the use of an enzyme isolated<br />

from insect head. This enzyme is sensitively inhibited by a wide range of<br />

organophosphate and carbamate insecticides. Many "organophosphates" are<br />

actually phosphorothioate "pro-insecticides" and require oxidation to the<br />

insecticidally active "oxon" <strong>for</strong>m <strong>for</strong> optimal detection sensitivity. In the absence<br />

of appropriate pesticide in the test sample, action of cholinesterase on its<br />

acetylthiocholine substrate releases thiocholine which reacts with Ellman's<br />

reagent (5,5'- dithio-bis-(2-nitrobenzoate), DTNB) to <strong>for</strong>m a bright yellow<br />

product. Inhibition of cholinesterase by pesticide in the sample leads to a<br />

decrease in color development.<br />

Action of cholinesterase Acetylthiocholine<br />

⇓ Inhibited by pesticide<br />

Thiocholine + acetate<br />

⇓ + DTNB<br />

Yellow product <strong>for</strong>ms<br />

1. The sample extract or pesticide standard is added to a microwell, followed<br />

by oxidizing reagent.<br />

2. After 5 minutes, excess oxidizing agent is inactivated using the neutralizing<br />

reagent.<br />

3. <strong>Cholinesterase</strong> enzyme is added, and mixed 30 minutes at room temperature.<br />

4. Substrate and chromogen are then added and incubated 15 minutes. In the<br />

presence of active cholinesterase, color developer turns yellow.<br />

5. Color development is stopped by addition of cholinesterase stopping agent.<br />

Since the same concentration of cholinesterase is added to every microwell, a<br />

sample which contains no organophosphate or carbamate pesticide enables the<br />

cholinesterase to act on the added enzyme substrate present in the color

Items Not Provided<br />

• distilled water (or equivalent)<br />

<strong>for</strong> preparation of calibrators<br />

• application sheet pertaining<br />

to sample type<br />

• microplate reader<br />

• microwell plate mixer<br />

• test tube <strong>for</strong> diluting<br />

oxidizing agent<br />

• automatic pipettes (1-20,<br />

20-200, 200-1000,<br />

1000-5000 µL)<br />

• 12-channel pipette<br />

(20-200 µL)<br />

• marking pens <strong>for</strong> labeling<br />

• timer or wristwatch<br />

a Since extraction methods very often<br />

involve a dilution of sample into<br />

extraction solvent, this dilution must<br />

be taken into account when<br />

determining pesticide levels in the<br />

sample. To calculate the<br />

concentration of pesticide on the<br />

sample, multiply the concentration of<br />

pesticide in the sample extract by any<br />

dilution factor incurred during<br />

extraction. The matrix used <strong>for</strong> these<br />

values was 100% methanol.<br />

b Water samples containing<br />

organophosphates must be collected<br />

in the presence of a minimum of 10%<br />

methanol.<br />

Rev. 12-12-07<br />

QualiPlate <strong>Kit</strong> <strong>for</strong> <strong>Cholinesterase</strong><br />

Page 2 of 6<br />

developer. There<strong>for</strong>e, in the absence of organophosphate or carbamate a dark<br />

yellow color <strong>for</strong>ms. Significant levels of the pesticides will inhibit the action of<br />

the enzyme, resulting in a paler yellow sample.<br />

As with all competitive immunoassays, sample concentration is inversely<br />

proportional to color development.<br />

Darker color = Lower concentration Lighter color = Higher concentration<br />

Per<strong>for</strong>mance Characteristics<br />

The <strong>Cholinesterase</strong> Screening Test is sensitive to a wide range of<br />

organophosphate and carbamate pesticides; other insecticides, fungicides <strong>for</strong><br />

powdery or downy mildew or botrytis control, and herbicides are not detected. It<br />

is important to recognize that different compounds are detected with differing<br />

sensitivities (refer to Table I). Thus, unless the particular pesticide used or<br />

suspected to be used on the sample being tested is known, it is important to<br />

confirm positive results using instrumental (gas chromatography) analyses to<br />

enable identification of the residue present. Where it has been established that<br />

only a single organophosphate or carbamate is present, the test can be used in<br />

conjunction with appropriate standards <strong>for</strong> semi-quantitative testing.<br />

Of the major insecticides used or potentially used, the test detects chlorpyrifos,<br />

methidathion and diazinon with high sensitivity, carbaryl with moderate<br />

sensitivity, and carbofuran residues with lower sensitivity. If samples are being<br />

screened <strong>for</strong> carbamates only (carbaryl, carbofuran), the oxidizing and<br />

neutralizing agent steps can be deleted. Under these conditions, organo(thio)phosphates<br />

are not detected.<br />

Limit of Detection<br />

Limits of detection (15 % inhibition of color development, after oxidizing step)<br />

when organophosphate or carbamate residues are in sample extract or water as<br />

indicated are listed below. See Appendix or specialized product application<br />

guide <strong>for</strong> detection limits in specific samples.<br />

Sensitivity<br />

in Sample<br />

Extract<br />

(ppb) a<br />

Sensitivity<br />

in water<br />

(ppb) b<br />

Sensitivity<br />

in Sample<br />

Extract<br />

(ppb) a<br />

Sensitivity<br />

in water<br />

(ppb) b<br />

Organophosphates<br />

acephate >100,000 methacrifos 500<br />

azinphos-ethyl 5 methamidophos 500<br />

azinphos-methyl 50 10 methidathion 50<br />

chlorfenvinphos 100 mevinphos 50<br />

chlorpyrifos 0.5 0.5 parathion 500 500<br />

chlorpyr-methyl 0.5 parathion-methyl 500<br />

coumaphos 5 phorate 500<br />

diazinon 10 5 phosmet 50<br />

dichlorvos 5 pirimiphos-ethyl 50 100<br />

dimethoate 50,000 pirimiphos-methyl 50<br />

ethion 1000 propetamphos >1000<br />

fenitrothion 200 quinalphos 5<br />

malathion 100 100 triazophos 0.5<br />

Carbamates<br />

carbaryl 1000 100 carbofuran 100 100

Rev. 12-12-07<br />

Preparation of Solutions<br />

QualiPlate <strong>Kit</strong> <strong>for</strong> <strong>Cholinesterase</strong><br />

Page 3 of 6<br />

Sample extraction and preparation of standards in sample matrix<br />

An application sheet specific <strong>for</strong> the sample type to be tested must be obtained<br />

from <strong>EnviroLogix</strong>. For new customer convenience, the Application Sheet <strong>for</strong><br />

Detection of Organophosphate and Carbamate Residues in Dried Vine and Tree<br />

Fruit has been attached as an Appendix. Contact Technical Services <strong>for</strong> your<br />

customized application sheet.<br />

Dilution of Oxidizing agent concentrate (1 % Br2 in 1 M NaBr)<br />

(Caution, this reagent is caustic, handle with care)<br />

On the day of use, <strong>for</strong> each plate, dilute 0.3 mL of Oxidizing agent (Reagent 1) in<br />

2.7 mL oxidizing agent diluent (Reagent 2). Label the diluted oxidizing agent<br />

Reagent B. Discard unused diluted oxidizing agent as it is only stable <strong>for</strong> 24<br />

hours. If less than one plate will be run in one day, dilute only enough oxidizing<br />

agent <strong>for</strong> the number of strips to be used in one day. The volume required per<br />

strip is 0.2 mL (dilute 20 μL in 180 μL) or the required multiple of this dilution<br />

depending on the number of strips to be used.<br />

Chromogen solution (Reagent F)<br />

This reagent may have a yellow precipitate. Just prior to pipetting this reagent,<br />

mix the vial by swirling or inverting to resuspend the precipitate. Re-mix while<br />

pipetting as necessary.<br />

Note: Water used <strong>for</strong> reagents and effect of ambient temperature<br />

The quality of the water and significant variation in laboratory temperature can<br />

influence the total color produced in the assay. The key factor affecting assay<br />

color is the concentration of the enzyme reagent. Please consult <strong>EnviroLogix</strong><br />

be<strong>for</strong>e altering assay conditions.<br />

Pesticide Controls<br />

When an extraction application has not yet been established, three pesticide<br />

controls are provided with this kit. A Negative Control (Reagent H) that contains<br />

only methanol with no pesticide, low pesticide control that contains 10 ppb<br />

diazinon (Reagent I) and a high pesticide control that contains 50 ppb diazinon<br />

(Reagent J). These controls are provided <strong>for</strong> new customers who may not have<br />

negative and positive samples containing known levels of organophosphate or<br />

carbamate pesticides, but would like to see how the assay works. These controls<br />

are not intended to be used in the analysis of sample extracts. In order to properly<br />

analyze sample extracts, pesticide standards, both negative and positive must be<br />

prepared using negative extracts of the matrix to be tested. See below <strong>for</strong> more<br />

in<strong>for</strong>mation concerning the preparation of sample specific pesticide standards<br />

and the extraction of samples.<br />

Preparation of Pesticide Standards<br />

and Extraction of Samples<br />

Each application <strong>for</strong> the use of the <strong>EnviroLogix</strong> <strong>Cholinesterase</strong> Screening Test is<br />

different. For new customer convenience, the Application Sheet <strong>for</strong> Detection of<br />

Organophosphate and Carbamate Residues in Dried Vine and Tree Fruit has been<br />

attached as an Appendix. The inclusion of this application sheet is meant only as<br />

an example of how pesticides are extracted from fruit and how to prepare sample

NC = Negative Control<br />

LO = Reagent I, low level control<br />

HI = Reagent J, high level control<br />

S = Sample extracts<br />

Rev. 12-12-07<br />

QualiPlate <strong>Kit</strong> <strong>for</strong> <strong>Cholinesterase</strong><br />

Page 4 of 6<br />

specific pesticide standards. The application sheet explains how to make<br />

pesticide standards from fruit known to be free of organophosphate and<br />

carbamate residues using a pesticide stock that can be obtained from<br />

<strong>EnviroLogix</strong>. The dried fruit application sheet also describes how to extract<br />

organophosphate and carbamate residues from fruit. Specific extraction methods<br />

will have to be optimized <strong>for</strong> each application. The levels of pesticides in the<br />

pesticide standards will also be application and pesticide specific. Please contact<br />

<strong>EnviroLogix</strong> <strong>for</strong> any in<strong>for</strong>mation we may have on applications other than the<br />

detection of organophosphates and carbamate residues on dried vine and tree<br />

fruit.<br />

How to Per<strong>for</strong>m the Test<br />

NOTE: If microwell plate mixer is not used, gently mix the microwell plate by<br />

swirling in a circular motion 20-30 seconds after the addition of oxidizing agent<br />

(Reagent B), enzyme solution (Reagent D) and chromogen (Reagent F) and then<br />

incubate <strong>for</strong> designated time on bench top.<br />

1. Allow all reagents to reach ambient temperature (at least 22°C) prior to<br />

starting the assay. Cold reagents will result in low OD readings. Remove<br />

the plate from the plastic bag. Any strips that will not be used should be<br />

removed from the holder and returned to the plastic bag. (This is best done<br />

by pressing strip up from the bottom of the holder.)<br />

2. Add 120 µL of microwell solution (Reagent A) to each well.<br />

3. Add 20 µL of extract containing pesticide standard or pesticide controls<br />

(Reagents H, I and J) and sample extracts to each microwell, in duplicate,<br />

using Figure 1 as a guide. Mix microwell contents by swirling <strong>for</strong> 2-3<br />

seconds.<br />

Figure 1. Example of a typical plate setup:<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

A NC NC S5 S5 S13 S13 S21 S21 S29 S29 S37 S37<br />

B LO LO S6 S6 S14 S14 S22 S22 S30 S30 S38 S38<br />

C HI HI S7 S7 S15 S15 S23 S23 S31 S31 S39 S39<br />

D NC NC S8 S8 S16 S16 S24 S24 S32 S32 S40 S40<br />

E S1 S1 S9 S9 S17 S17 S25 S25 S33 S33 NC NC<br />

F S2 S2 S10 S10 S18 S18 S26 S26 S34 S34 LO LO<br />

G S3 S3 S11 S11 S19 S19 S27 S27 S35 S35 HI HI<br />

H S4 S4 S12 S12 S20 S20 S28 S28 S36 S36 NC NC<br />

4. Make sure that you have diluted the orange oxidizing agent concentrate<br />

(Reagent 1) in oxidizing agent diluent (Reagent 2), immediately be<strong>for</strong>e use.<br />

Immediately add 20 µL of DILUTED oxidizing agent (Reagent B) to each<br />

microwell. Gently mix by swirling the contents of the plate <strong>for</strong> 2-3 seconds.<br />

5. Mix the plates on the microwell plate mixer <strong>for</strong> 5 minutes, then add 20 µL<br />

neutralizing reagent (Reagent C) to each microwell. Mix gently. (NOTE:<br />

If carbamates are the only pesticides being screened the oxidation and<br />

neutralization step may be eliminated.)<br />

6. Immediately add 20 µL cholinesterase enzyme solution (Reagent D). Mix<br />

gently on the microwell plate mixer <strong>for</strong> 30 min at room temperature.<br />

7. Add 20 µL of substrate (Reagent E) and 20 µL of chromogen (Reagent F)<br />

to each microwell. Swirl the plate gently <strong>for</strong> a few seconds, then mix on the

Precautions and<br />

Notes<br />

• Store all QualiPlate <strong>Kit</strong><br />

components at 4°C to 8°C (39°F<br />

to 46°F) when not in use (except<br />

<strong>for</strong> microtiter plate, store this at<br />

room temperature).<br />

• Do not store test kit components<br />

<strong>for</strong> more than 4 hours at ambient<br />

temperatures.<br />

• Do not expose QuantiPlate <strong>Kit</strong><br />

components to temperatures<br />

greater than 37°C (99°F) or<br />

less than 2°C (36°F).<br />

• Allow all reagents to reach<br />

ambient temperature (18°C to<br />

27°C or 64°F to 81°F) be<strong>for</strong>e<br />

use.<br />

• Do not use kit components<br />

after the expiration date.<br />

• Do not use reagents or test<br />

well strips from one QualiPlate<br />

<strong>Kit</strong> with reagents or test well<br />

strips from a different<br />

QualiPlate <strong>Kit</strong>.<br />

• Do not expose Substrate to<br />

sunlight during pipetting or<br />

while incubating in the test<br />

wells.<br />

• As with all tests, it is<br />

recommended that results be<br />

confirmed by an alternate<br />

method when necessary.<br />

• The assay has been optimized<br />

to be used with the protocol<br />

provided in the kit. Deviation<br />

from this protocol may<br />

invalidate the results of the<br />

test.<br />

• Observe any applicable<br />

regulations when disposing of<br />

samples and kit reagents.<br />

Rev. 12-12-07<br />

QualiPlate <strong>Kit</strong> <strong>for</strong> <strong>Cholinesterase</strong><br />

Page 5 of 6<br />

microwell plate mixer <strong>for</strong> 15 minutes. A yellow color develops.<br />

8. After 15 minutes have elapsed, add 20 µL of stopping solution (Reagent G)<br />

to each microwell and mix well. This will arrest the yellow color<br />

development. Read the microwells at 415 nm (ideal) or 405 nm in a<br />

microplate reader. Read the microwells within 30 minutes of stopping the<br />

assay.<br />

Important: At no stage of the procedure are components tipped out of the<br />

microwells or are the microwells washed. Washing will invalidate the<br />

procedure.<br />

Sample Results and Interpretation<br />

If a yellow color does not develop in the pesticide-free fruit extract microwells<br />

within 5 minutes and you have added color developer, the test is invalid and must<br />

be repeated.<br />

Note that this test does not provide the identity of the pesticide in the sample, but<br />

rather an indication that the sample contains an organophosphate or carbamate<br />

pesticide in excess of the "low standards". For identification of the particular<br />

residues present, subsequent analysis of the sample by gas-liquid<br />

chromatography (GLC) is required.<br />

The interpretation of results is specific to the each application. For an example<br />

of a detailed discussion of how to interpret results, see the Sample results and<br />

interpretation section of the attached Application Sheet <strong>for</strong> the detection of<br />

organophosphate and carbamate residues in dried vine and tree fruit.<br />

Below is sample data <strong>for</strong> the pesticide controls (Reagents H, I and J).<br />

Figure 2. Illustrative calculations<br />

Sample Absorbance<br />

% Inhibition<br />

of Negative<br />

Control Pesticide Concentration<br />

Negative<br />

Control<br />

1.040 0<br />

No pesticide present, the highest<br />

absorbance possible in the assay<br />

Low<br />

Control<br />

0.720 30.8<br />

Low pesticide standard (10 ppb<br />

diazinon in standard extract)<br />

High<br />

Control<br />

0.173 83.4<br />

High pesticide standard (50 ppb<br />

diazinon in standard extract)<br />

Actual values may vary; this data is <strong>for</strong> demonstration purposes only.

For Technical Support<br />

Contact Us At:<br />

<strong>EnviroLogix</strong><br />

500 Riverside Industrial<br />

Parkway<br />

Portland, ME 04103-1486<br />

USA<br />

Tel: (207) 797-0300<br />

Toll Free: 866-408-4597<br />

Fax: (207) 797-7533<br />

e-mail:<br />

info@envirologix.com<br />

website:<br />

www.envirologix.com<br />

Rev. 12-12-07<br />

LIMITED WARRANTY<br />

QualiPlate <strong>Kit</strong> <strong>for</strong> <strong>Cholinesterase</strong><br />

Page 6 of 6<br />

<strong>EnviroLogix</strong> Inc. (“<strong>EnviroLogix</strong>”) warrants the products sold hereunder (“the Products”)<br />

against defects in materials and workmanship when used in accordance with the<br />

applicable instructions <strong>for</strong> a period not to extend beyond a product’s printed expiration<br />

date. If the Products do not con<strong>for</strong>m to this Limited Warranty and the customer notifies<br />

<strong>EnviroLogix</strong> in writing of such defects during the warranty period, including an offer by<br />

the customer to return the Products to <strong>EnviroLogix</strong> <strong>for</strong> evaluation, <strong>EnviroLogix</strong> will repair<br />

or replace, at its option, any product or part thereof that proves defective in materials or<br />

workmanship within the warranty period.<br />

ENVIROLOGIX MAKES NO OTHER WARRANTIES, EXPRESSED OR IMPLIED,<br />

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF<br />

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The warranty<br />

provided herein and the data, specifications and descriptions of <strong>EnviroLogix</strong> products<br />

appearing in <strong>EnviroLogix</strong> published catalogues and product literature are <strong>EnviroLogix</strong>’<br />

sole representations concerning the Products and warranty. No other statements or<br />

representations, written or oral, by <strong>EnviroLogix</strong>’ employees, agents or representatives,<br />

except written statements signed by a duly authorized officer of <strong>EnviroLogix</strong> Inc., are<br />

authorized; they should not be relied upon by the customer and are not a part of the<br />

contract of sale or of this warranty.<br />

<strong>EnviroLogix</strong> does not warrant against damages or defects arising in shipping or handling,<br />

or out of accident or improper or abnormal use of the Products; against defects in products<br />

or components not manufactured by <strong>EnviroLogix</strong>, or against damages resulting from such<br />

non-<strong>EnviroLogix</strong> made products or components. <strong>EnviroLogix</strong> passes on to customer the<br />

warranty it received (if any) from the maker thereof of such non-<strong>EnviroLogix</strong> made<br />

products or components. This warranty also does not apply to Products to which changes<br />

or modifications have been made or attempted by persons other than pursuant to written<br />

authorization by <strong>EnviroLogix</strong>.<br />

THIS WARRANTY IS EXCLUSIVE. The sole and exclusive obligation of <strong>EnviroLogix</strong><br />

shall be to repair or replace the defective Products in the manner and <strong>for</strong> the period<br />

provided above. <strong>EnviroLogix</strong> shall not have any other obligation with respect to the<br />

Products or any part thereof, whether based on contract, tort, strict liability or otherwise.<br />

Under no circumstances, whether based on this Limited Warranty or otherwise, shall<br />

<strong>EnviroLogix</strong> be liable <strong>for</strong> incidental, special, or consequential damages.<br />

This Limited Warranty states the entire obligation of <strong>EnviroLogix</strong> with respect to the<br />

Products. If any part of this Limited Warranty is determined to be void or illegal, the<br />

remainder shall remain in full <strong>for</strong>ce and effect.<br />

<strong>EnviroLogix</strong>, the <strong>EnviroLogix</strong> logo, and QualiPlate are trademarks of <strong>EnviroLogix</strong> Inc.<br />

Acknowledgments<br />

Product licensed from CSIRO Plant Industry, Canberra, Australia. Test<br />

development was partly funded by the Dried Fruits R&D Council and the Grape<br />

& Wine R&D Corporation of Australia.<br />

This assay is produced and distributed under an exclusive technology license<br />

from CSIRO Plant Industry (Australia).<br />

© <strong>EnviroLogix</strong> Inc. 2007

~ APPENDIX ~<br />

Application Guide<br />

QualiPlate <strong>Kit</strong> <strong>for</strong> <strong>Cholinesterase</strong><br />

Application Guide <strong>for</strong> the Detection of Organophosphate and<br />

Carbamate Residues in Dried Vine and Tree Fruit<br />

Intended Use<br />

This application guide describes the procedure <strong>for</strong> preparing negative control fruit extracts, fruit extract pesticide standards<br />

and the extraction of pesticide residues from fruit. Directions <strong>for</strong> the interpretation of assay results are also included in this<br />

guide. This <strong>Kit</strong> varies slightly from the main QualiPlate <strong>Kit</strong> <strong>for</strong> <strong>Cholinesterase</strong> in that a Pesticide Stock Solution is supplied<br />

instead of Reagents H, I and J. Follow the instructions in the main product insert to per<strong>for</strong>m the assay.<br />

Be<strong>for</strong>e You Start<br />

You will need several items:<br />

pesticide free fruit (of the same type to be tested)<br />

pesticide standard stock (Supplied by <strong>EnviroLogix</strong>)<br />

blender <strong>for</strong> fruit (optional)<br />

orbital shaker<br />

balance <strong>for</strong> weighing fruit<br />

automatic pipettes (1-20, 20-200)<br />

marking pens <strong>for</strong> bottles of fruit extract<br />

timer or wristwatch<br />

glass bottles/ conical flasks <strong>for</strong> extracting fruit<br />

methanol (analytical reagent grade) <strong>for</strong> extraction of the pesticide from the fruit<br />

100 mL and 1 L measuring cylinders<br />

How to prepare fruit extract pesticide standards and extract the pesticide<br />

from fruit<br />

Introduction<br />

Prior to per<strong>for</strong>ming the <strong>EnviroLogix</strong> Organophosphate Screening Test, fruit extract pesticide standards must be prepared<br />

and pesticides must be extracted from fruit samples. Fruit extract pesticide standards must be prepared from the same type<br />

of fruit being tested.<br />

Pesticide free fruit to be used in the preparation of pesticide fruit standards are extracted using exactly the same method<br />

(and extraction solvent) as the samples to be tested. You will need to prepare a negative, low and high pesticide standard<br />

<strong>for</strong> each fruit type being tested.<br />

Preparation of pesticide standards and extraction of dried vine fruit<br />

Where both the organochlorine and the cholinesterase tests are to be run on the same vine fruit sample, extract the vine fruit<br />

and prepare vine fruit pesticide standards with 100 % methanol. This extracts 70 - 90 % of the organochlorine but only 40-<br />

60 % of the organophosphate or carbamate from vine fruit (which is still sufficient <strong>for</strong> screening purposes). If the test is to<br />

be per<strong>for</strong>med <strong>for</strong> organophosphates and carbamates only, 80 % methanol should be used <strong>for</strong> both vine fruit extract pesticide<br />

standards and extracting organophosphates from vine fruit samples. This extracts over 80% of the target residues from the<br />

sample.<br />

Rev. 12-12-07 A-1

APPENDIX Application Guide~Dried Vine & Tree Fruit<br />

There are two extraction methods that may be used in making the vine fruit extract pesticide standards and extracting<br />

pesticides from vine fruit samples: an overnight soak method or a faster omnimixer technique. The fruit sample size,<br />

extraction method and equipment to be used depends on the particular time and per<strong>for</strong>mance requirements of the user.<br />

Preparation of pesticide standards (dried vine fruit)<br />

The Pesticide Stock Solution containing diazinon (“Diazinon”, “Gesapon”) is supplied with this kit. A low fruit extract<br />

standard (low level of organophosphate) and a high fruit extract standard (higher level of organophosphate) are prepared<br />

from the Pesticide Stock Solution. A negative control (negative fruit extract) will also need to be prepared. The fruit<br />

extract standards and negative control are made in the following manner:<br />

1. Add 20 grams of pesticide-free vine fruit (grapes, sultanas, currants or raisins) to each of three conical flasks. (If the<br />

faster omnimixer method of extract preparation is to be used, chop fruit as described in step 6B below.)<br />

2. To prepare the low level standard, add 20 μL of the pesticide standard stock to the fruit in the first conical flask. This<br />

will produce a final concentration that represents 0.1 ppm diazinon in fruit.<br />

3. To prepare the high level standard, add 200 μL of the pesticide standard stock to fruit in a second available flask . This<br />

will produce a final concentration that represents 1.0 ppm diazinon in fruit. The Australian MRL <strong>for</strong> diazinon in grapes<br />

is currently 0.5 ppm.<br />

4. Add no pesticide standard to the third conical flask; this will be the negative pesticide control.<br />

5. Add 100 mL of 80% or 100% methanol (see explanation of methanol concentration above) to each conical flask. (To<br />

prepare 1 L of 80% methanol, fill a 1L measuring cylinder to the 800 mL mark with methanol. Add water to the 1 L<br />

mark.)<br />

6. One of two methods may be used to prepare fruit extract pesticide standards:<br />

A. Overnight soaking of the sultanas is the simplest method. Whole sultanas (20 g) are shaken 30-60 min in 100 mL<br />

of 80 % or 100 % methanol, swirled by hand <strong>for</strong> 1 minute, then incubated (no shaking) 18-24 hours (overnight) at<br />

room temperature.<br />

B. Rapid blending of sultanas. Sultanas (20 g) are lightly chopped with a sharp knife and blended in 100 mL of 80 %<br />

or 100 % methanol <strong>for</strong> 2 minutes using an Omnimixer.<br />

Pesticide free fruit to be used in the preparation of pesticide fruit standards are extracted using exactly the same method<br />

(and extraction solvent) as the samples to be tested. If covered to prevent evaporation, the extracts of the fruit containing<br />

pesticide standards are stable <strong>for</strong> 48 hours at room temperature. These standards should be prepared and analysed at the<br />

same time as the sample grape, sultana or currant extracts being tested.<br />

Extracts should not require filtration be<strong>for</strong>e use, but just settling. Do not disturb the sediment in the bottom of extraction jar<br />

when pipetting extract. Note that other solvents such as methylated spirits should not be used as they interfere with the test,<br />

and produce erroneous results.<br />

Since action levels vary between markets, results obtained should be interpreted with respect to the target end-market.<br />

Extraction of pesticides from dried vine fruit samples<br />

Be<strong>for</strong>e they can be analysed in the test, organophosphates and carbamates must be extracted from the sultanas using either<br />

80 or 100% methanol (see explanation of methanol concentration in introduction section). Use exactly the same method of<br />

extraction of pesticides from fruit samples as was used to prepare fruit extract pesticide standards. Choose one of the two<br />

methods listed below.<br />

1. Overnight soaking of the sultanas is the simplest method. Whole sultanas (20 g) are shaken 30-60 min in 100 mL of 80<br />

% or 100 % methanol, swirled by hand <strong>for</strong> 1 minute, then incubated (no shaking) 18-24 hours (overnight) at room<br />

temperature.<br />

2. Rapid blending of sultanas. Sultanas (20 g) are lightly chopped with a sharp knife and blended in 100 mL of 80 % or<br />

100 % methanol <strong>for</strong> 2 minutes using an Omnimixer.<br />

Note : Role of fruit type Samples should be compared to zero, low and high-pesticide standards of the same fruit type (e.g.<br />

Carina currant extracts must be compared against standards prepared in Carina currant extract).<br />

Rev. 12-12-07 A-2

APPENDIX Application Guide~Dried Vine & Tree Fruit<br />

There are five main groups:<br />

- dipped sultanas, dipped raisins, - natural sultanas/ raisins, Zante currants, Carina currants<br />

Carina currants are larger and darker than Zante currants; the color of the methanol extract is darker and a purple color. For<br />

more accurate results these should be distinguished from one another and separate standards run <strong>for</strong> each type of fruit.<br />

Although the sensitivity of the assay is similar in each dried fruit type, the color produced in pesticide-free controls (i.e.<br />

zero-pesticide standards) can vary slightly but significantly. For example, Carina currants may produce 15 % higher color in<br />

pesticide-free standards than Zante currants, while sultanas produce even lower color. The percentage inhibition of color<br />

produced by the low and high pesticide standard is usually slightly lower (5-10 %) with currants and naturals than with<br />

dipped sultanas.<br />

Preparation of pesticide standards and extraction of dried tree fruit<br />

Preparation of pesticide standards (dried tree fruit)<br />

The Pesticide Stock Solution containing diazinon (“Diazinon”, “Gesapon”) is supplied with this kit. A low fruit extract<br />

standard (low level of organophosphate) and a high fruit extract standard (higher level of organophosphate) are prepared<br />

from the Pesticide Stock Solution. A negative control (negative fruit extract) will also need to be prepared. The fruit<br />

extract standards and negative control are made in the following manner:<br />

1. Add 40 grams of pesticide-free tree fruit to each of three conical flasks.<br />

2. To prepare the low level standard, add 40 μL of the pesticide standard stock to the fruit in the first conical flask. This<br />

will produce a final concentration that represents 0.1 ppm diazinon in fruit.<br />

3. To prepare the high level standard, add 400 μL of the pesticide standard stock to fruit in a second available flask . This<br />

will produce a final concentration that represents 1.0 ppm diazinon in fruit.<br />

4. Add no pesticide standard to the third conical flask; this will be the negative pesticide control.<br />

5. The dried tree fruit must be swelled with distilled (or equivalent) water by soaking 40 g fruit in 40 mL water <strong>for</strong> four to<br />

six hours.<br />

6. After swelling, add 160 mL of methanol and extract overnight while shaking.<br />

Pesticide free fruit to be used in the preparation of pesticide fruit standards are extracted using exactly the same method<br />

(and extraction solvent) as the samples to be tested. If covered to prevent evaporation, the extracts of the fruit containing<br />

pesticide standards are stable <strong>for</strong> 48 hours at room temperature. These standards should be prepared and analysed at the<br />

same time as the sample dried tree fruit extracts being tested.<br />

Extracts should not require filtration be<strong>for</strong>e use, but just settling. Do not disturb the sediment in the bottom of extraction jar<br />

when pipetting extract. Note that other solvents such as methylated spirits should not be used as they interfere with the test,<br />

and produce erroneous results.<br />

Since action levels vary between markets, results obtained should be interpreted with respect to the target end-market.<br />

Extraction of pesticides from dried tree fruit samples Be<strong>for</strong>e they can be analysed in the test, organophosphates and<br />

carbamates must be extracted from the dried tree fruit using the procedure listed in steps 5 and 6 above.<br />

Sample results and interpretation<br />

If a yellow color does not develop in the pesticide-free fruit extract microwells within 5 minutes after you have added color<br />

developer, the test is invalid and must be repeated.<br />

1. Measure and record the absorbance of each microwell. Average the absorbance of each pair of duplicate wells.<br />

Compare the means of absorbances obtained with each sample to that of the means of the negative control (pesticidefree<br />

fruit extract), and to the pesticide standards.<br />

2. If the Absorbance of the sample is less than the Absorbance of the chosen pesticide standard by at least 0.1 unit, the<br />

sample contains organophosphate or carbamate greater than or equal to the limits shown in Table I (page 5) <strong>for</strong> dried<br />

vine fruit and Table II (page 6) <strong>for</strong> dried tree fruit in this insert. It is recommended that fruit providing absorbance<br />

values below that provided by the low pesticide standard be considered as potentially contaminated fruit.<br />

Rev. 12-12-07 A-3

APPENDIX Application Guide~Dried Vine & Tree Fruit<br />

3. If fruit is to be retested, it is best that it be re-extracted <strong>for</strong> testing. If this is not possible, and the extract is to be retested<br />

the next day, it is recommended that the liquid extract be taken off the fruit and stored in a sealed glass container. This<br />

is especially important with currants, as the extract continues to get darker with time.<br />

4. Note that this test does not provide the identity of the pesticide in the sample, but rather an indication that the sample<br />

contains an organophosphate or carbamate pesticide in excess of the "low standards". For identificaton of the particular<br />

residues present, subsequent analysis of the sample by gas-liquid chromatography (GLC) is required.<br />

Sample Data<br />

Sample Absorbance Interpretation<br />

Control 1.06 zero pesticide-in-fruit standard - mean of 4 controls<br />

Low standard 0.67 low pesticide standard (0.1 ppm diazinon-in-fruit)<br />

High standard 0.38 high pesticide standard (1 ppm diazinon-in-fruit)<br />

S1 0.97 Since the difference between the sample absorbance and the control<br />

is less that 0.1, this is considered to be a negative test.<br />

Residues are within acceptable limits.<br />

S2 0.60 Concentration is more than the low pesticide standard - positive test.<br />

Notes • The “action” inhibition level must be determined by the industry. The low calibrator contains 0.1 ppm diazinon,<br />

which is 20 % of the Australian MRL <strong>for</strong> that compound.<br />

Table I: Limits of detection (15 % inhibition of color development, after oxidizing step) in grapes and sultanas of<br />

organophosphates and carbamate insecticides used in Australia.<br />

Compound Sensitivity: limit of detection in grapes and sultanas (ppm) a<br />

Aust. MRL Grapes Sultanas Currants<br />

Major compounds<br />

Organophosphates<br />

Chlorpyrifos (Lorsban) 0.01 b 0.0002 0.001 0.002<br />

Diazinon (Basudin) 0.5 0.05 0.05 0.05<br />

Methidathion (Supracide) 0.5 0.1 0.1 0.2<br />

Carbamates<br />

Carbaryl (Bugmaster, Sevin) 5 0.5 0.5 0.5<br />

Methomyl (Lannate, Nudrin, Marlin) 2 1 1 1.5<br />

Minor use compounds<br />

Azinphos-methyl 2<br />

Dimethoate 2 1.5 1 1<br />

Fenitrothion (Folithion, Sumithion) 0.5 0.2 0.5 0.5<br />

Maldison (Malathion, Hymal) 8 0.1 0.1 0.2<br />

Methiocarb (Baysol, Mesurol) 0.1<br />

Parathion 0.5 0.1 0.1 0.2<br />

Parathion-methyl 1 0.5 0.5<br />

Promecarb (Carbamult) 0.2 0.02 0.1<br />

Prothiofos (Tokuthion) 2<br />

Trichlofon 0.1<br />

a This assumes extraction of over 80 % of the target residues from the sample, using 80 % methanol. If 100 % methanol is<br />

used as the extractant, the sensitivity is approximately halved.<br />

b Recently increased <strong>for</strong> grapes and sultanas<br />

Rev. 12-12-07 A-4

APPENDIX Application Guide~Dried Vine & Tree Fruit<br />

Table II: Limits of detection (20 % inhibition of color development, after oxidizing step) in dried tree fruit of<br />

organophosphates and carbamate insecticides used in Australia.<br />

Compound Sensitivity: limit of detection in dried tree fruit (ppm)<br />

Major compounds<br />

Peaches Prunes Apricot Pears<br />

Organophosphates<br />

Diazinon (Basudin) 0.04 0.06 0.1 0.02<br />

Carbamates<br />

Carbaryl (Bugmaster, Sevin) 0.2 0.5 1.0 0.5<br />

Rev. 12-12-07 A-5