Shell Corena AP - Parsian Super Lubricants

Shell Corena AP - Parsian Super Lubricants

Shell Corena AP - Parsian Super Lubricants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

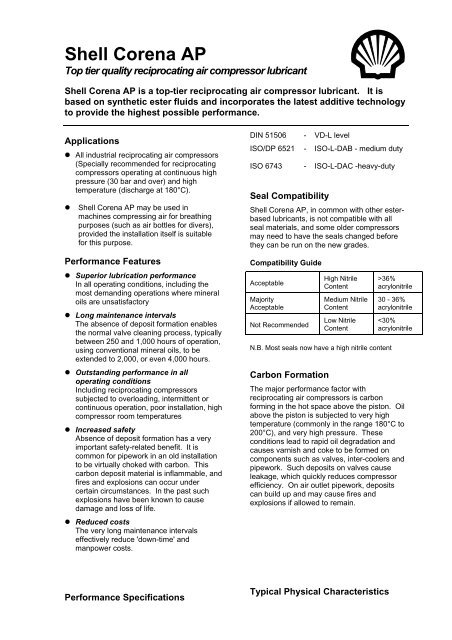

<strong>Shell</strong> <strong>Corena</strong> <strong>AP</strong><br />

Top tier quality reciprocating air compressor lubricant<br />

<strong>Shell</strong> <strong>Corena</strong> <strong>AP</strong> is a top-tier reciprocating air compressor lubricant. It is<br />

based on synthetic ester fluids and incorporates the latest additive technology<br />

to provide the highest possible performance.<br />

Applications<br />

All industrial reciprocating air compressors<br />

(Specially recommended for reciprocating<br />

compressors operating at continuous high<br />

pressure (30 bar and over) and high<br />

temperature (discharge at 180°C).<br />

<strong>Shell</strong> <strong>Corena</strong> <strong>AP</strong> may be used in<br />

machines compressing air for breathing<br />

purposes (such as air bottles for divers),<br />

provided the installation itself is suitable<br />

for this purpose.<br />

Performance Features<br />

<strong>Super</strong>ior lubrication performance<br />

In all operating conditions, including the<br />

most demanding operations where mineral<br />

oils are unsatisfactory<br />

Long maintenance intervals<br />

The absence of deposit formation enables<br />

the normal valve cleaning process, typically<br />

between 250 and 1,000 hours of operation,<br />

using conventional mineral oils, to be<br />

extended to 2,000, or even 4,000 hours.<br />

Outstanding performance in all<br />

operating conditions<br />

Including reciprocating compressors<br />

subjected to overloading, intermittent or<br />

continuous operation, poor installation, high<br />

compressor room temperatures<br />

Increased safety<br />

Absence of deposit formation has a very<br />

important safety-related benefit. It is<br />

common for pipework in an old installation<br />

to be virtually choked with carbon. This<br />

carbon deposit material is inflammable, and<br />

fires and explosions can occur under<br />

certain circumstances. In the past such<br />

explosions have been known to cause<br />

damage and loss of life.<br />

Reduced costs<br />

The very long maintenance intervals<br />

effectively reduce 'down-time' and<br />

manpower costs.<br />

Performance Specifications<br />

DIN 51506 - VD-L level<br />

ISO/DP 6521 - ISO-L-DAB - medium duty<br />

ISO 6743 - ISO-L-DAC -heavy-duty<br />

Seal Compatibility<br />

<strong>Shell</strong> <strong>Corena</strong> <strong>AP</strong>, in common with other esterbased<br />

lubricants, is not compatible with all<br />

seal materials, and some older compressors<br />

may need to have the seals changed before<br />

they can be run on the new grades.<br />

Compatibility Guide<br />

Acceptable<br />

Majority<br />

Acceptable<br />

Not Recommended<br />

High Nitrile<br />

Content<br />

Medium Nitrile<br />

Content<br />

Low Nitrile<br />

Content<br />

N.B. Most seals now have a high nitrile content<br />

Carbon Formation<br />

>36%<br />

acrylonitrile<br />

30 - 36%<br />

acrylonitrile<br />

<strong>Shell</strong> <strong>Corena</strong> <strong>AP</strong>68 <strong>AP</strong>100<br />

Kinematic Viscosity<br />

@ 40°C cSt<br />

S004L<strong>AP</strong>W.00E 0699<br />

68<br />

100<br />

Viscosity Index 94 79<br />

Density @ 15°C kg/l 0.986 0.982<br />

Flash Point (PMCC) °C 224 222<br />

Pour Point °C -51 -39<br />

Breathing Air<br />

<strong>Shell</strong> <strong>Corena</strong> <strong>AP</strong> may be used in machines<br />

compressing air for breathing purposes (such<br />

as air bottles for divers) provided strict<br />

conditions are adhered to. All compressor<br />

units for such purposes should include<br />

subsidiary air clean-up apparatus following the<br />

compressor, to ensure that the produced air is<br />

fit for breathing.<br />

Running-In<br />

<strong>Shell</strong> recommend that mineral oils are used<br />

for running-in new equipment in accordance<br />

with manufacturers' recommendations,<br />

typically this will be for 100 hours followed by<br />

oil filter replacement and the oil change.<br />

Health & Safety<br />

<strong>Shell</strong> <strong>Corena</strong> <strong>AP</strong> is unlikely to present any<br />

significant health or safety hazard when<br />

properly used in the recommended<br />

application, and good standards of industrial<br />

and personal hygiene are maintained.<br />

After skin contact, wash immediately with<br />

soap and water.<br />

For further guidance on Product Health &<br />

Safety refer to your <strong>Shell</strong> Representative.<br />

Protect the environment<br />

Take used oil to an authorised collection point.<br />

Do not discharge into drains, soil or water.