Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab

Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab

Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

150<br />

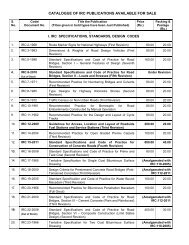

Fig. 5. Laterial stability <strong>of</strong> long prestressed concrete beams with factor <strong>of</strong> safeties<br />

beams cannot buckle which was also taken <strong>in</strong>to cognisance<br />

dur<strong>in</strong>g lateral stability <strong>in</strong>vestigations.<br />

The lateral stability guidel<strong>in</strong>es for precast beams given <strong>in</strong><br />

Indian Codes for prestressed concrete members are similar to<br />

that <strong>of</strong> for RCC <strong>and</strong> steel beams <strong>in</strong> terms <strong>of</strong> span to depth ratio<br />

<strong>and</strong> depth to top flange width ratio. However, <strong>in</strong> the case <strong>of</strong><br />

prestressed beams, the aspect <strong>of</strong> prestress<strong>in</strong>g is a new variable<br />

<strong>and</strong> as such the same guidel<strong>in</strong>es may not be applicable for<br />

prestressed beams. In view <strong>of</strong> this the factor <strong>of</strong> safeties<br />

enumerated above may be <strong>in</strong>cluded for ensur<strong>in</strong>g the lateral<br />

stability <strong>of</strong> beams dur<strong>in</strong>g shift<strong>in</strong>g, transportation <strong>and</strong> erection<br />

<strong>of</strong> prestressed, precast beams <strong>in</strong> the prestressed concrete<br />

codes.<br />

6.2. <strong>Design</strong> <strong>of</strong> Superstructure<br />

The superstructure consists <strong>of</strong> six numbers <strong>of</strong> precast<br />

pretensioned girders spaced at 2.15 m centre to centre with 250<br />

mm thick end diaphragms to support 200 mm thick cast-<strong>in</strong>-site<br />

RCC deck cantilever<strong>in</strong>g by 1.10 m from the centre l<strong>in</strong>e <strong>of</strong> external<br />

girders on either side. The pretensioned girders <strong>in</strong> the cast<strong>in</strong>g<br />

yard were specified to be prestressed after 24 hours when the<br />

strength <strong>of</strong> the concrete was 31 MPa, while the concrete grade<br />

for the beams were M 40.<br />

The precast girders were transported to site <strong>and</strong> placed on<br />

bear<strong>in</strong>gs followed by cast<strong>in</strong>g <strong>of</strong> the end diaphragm. The RCC<br />

deck slab was cast on formwork supported on girders <strong>and</strong> the<br />

HEGGADE, MEHTA & PRAKASH ON<br />

same was removed after the sufficient atta<strong>in</strong>ment <strong>of</strong> strength <strong>in</strong><br />

the deck. Thereafter, for the further loads such as weight <strong>of</strong><br />

crash barrier, wear<strong>in</strong>g coat, rail<strong>in</strong>gs <strong>and</strong> live load, etc. the<br />

structure was assured to be a composite section. The effect <strong>of</strong><br />

differential shr<strong>in</strong>kage <strong>and</strong> temperature variation were also<br />

considered <strong>in</strong> the design.<br />

For f<strong>in</strong>d<strong>in</strong>g all the longitud<strong>in</strong>al beam reaction components,<br />

the grillage analysis (Fig. 6) was used for superimposed dead<br />

loads <strong>and</strong> live loads, the structure was idealised as a grid <strong>of</strong><br />

longitud<strong>in</strong>al <strong>and</strong> transverse members. The composite girders<br />

consist<strong>in</strong>g <strong>of</strong> precast beam <strong>and</strong> deck slab was descretised to<br />

be placed along the axis <strong>of</strong> the girder while deck slab <strong>and</strong> deck<br />

slab with diaphragm was placed as transverse grillage members<br />

along the l<strong>in</strong>e <strong>of</strong> each <strong>of</strong> end diaphragm <strong>in</strong> the structure. The<br />

slab acts to transmit applied loads to beams by spann<strong>in</strong>g<br />

transversely between them, apart from provid<strong>in</strong>g means for<br />

load shar<strong>in</strong>g between longitud<strong>in</strong>al beams. Therefore transverse<br />

members hav<strong>in</strong>g slab properties were provided to reflect the<br />

load shar<strong>in</strong>g characteristics <strong>of</strong> the deck. For the application <strong>of</strong><br />

the loads due to rail<strong>in</strong>g, the dummy longitud<strong>in</strong>al members with<br />

negligible section properties were provided at the edges <strong>and</strong><br />

transverse grillage members were cont<strong>in</strong>ued to connect them.<br />

The flar<strong>in</strong>g properties <strong>of</strong> precast beams at the end for the<br />

distance <strong>of</strong> 2.65 m from 200 mm to 300 mm thick has been<br />

accounted for <strong>in</strong> the descretisation.<br />

The grillage analysis results especially for superimposed