Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab

Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab

Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Paper No. 524<br />

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB †<br />

V.N. HEGGADE*, R.K. MEHTA** & R. PRAKASH***<br />

SYNOPSIS<br />

Currently <strong>in</strong> vogue fast track construction has encouraged the adoption <strong>of</strong> pre-tension technology for urban flyovers. After hav<strong>in</strong>g<br />

successfully experimented pretensioned spans for River <strong>Bridge</strong> upto span <strong>of</strong> 30 m <strong>in</strong> Hadakiya <strong>Bridge</strong> <strong>in</strong> Gujarat, the technology was first<br />

time extended upto 35m spans for Beas <strong>and</strong> <strong>Sutlej</strong> river bridges <strong>in</strong> <strong>Punjab</strong>. The <strong>in</strong>herent peculiarities such as s<strong>in</strong>gle stage prestress<strong>in</strong>g,<br />

transfer <strong>of</strong> prestress through bond between concrete <strong>and</strong> cables by obviation <strong>of</strong> grout<strong>in</strong>g <strong>and</strong> sheath<strong>in</strong>g ducts, tension<strong>in</strong>g <strong>of</strong> tendons before<br />

the concrete is cast <strong>and</strong> transfer <strong>of</strong> prestress after the atta<strong>in</strong>ment <strong>of</strong> required strength <strong>in</strong> concrete derive certa<strong>in</strong> advantages <strong>in</strong> favour <strong>of</strong><br />

pretension<strong>in</strong>g <strong>in</strong> terms <strong>of</strong> durability, quantity reduction, construction speed, design <strong>and</strong> construction expediency. However, <strong>in</strong> the Indian<br />

scenario there are no codal guidel<strong>in</strong>es account<strong>in</strong>g for these peculiarities for bridges. The enumeration with illustration is <strong>in</strong>tended to<br />

provide basis for formulat<strong>in</strong>g guidel<strong>in</strong>es for pretension<strong>in</strong>g <strong>in</strong> bridge build<strong>in</strong>g. The Paper also deliberates on optimization <strong>of</strong> beam cross<br />

section <strong>in</strong> relation to lateral stability dur<strong>in</strong>g transfer <strong>of</strong> prestress account<strong>in</strong>g for cast<strong>in</strong>g imperfections, h<strong>and</strong>l<strong>in</strong>g <strong>and</strong> erection <strong>of</strong> beams<br />

before the beams are transversly stiffened by deck slab which may help the code makers to have fresh look on the guidel<strong>in</strong>es for lateral<br />

stability <strong>of</strong> the prestressed beams.<br />

1. DESCRIPTION OF THE PROJECT<br />

The project consisted <strong>of</strong> design <strong>and</strong> construction <strong>of</strong> highlevel<br />

bridge across the river <strong>Sutlej</strong> <strong>in</strong>clud<strong>in</strong>g approaches <strong>and</strong><br />

guide-bunds connect<strong>in</strong>g Nakodar <strong>and</strong> Jagraon. The<br />

construction <strong>of</strong> the bridge facilitates <strong>in</strong> reduction <strong>of</strong> the distance<br />

between the towns by 50 km, reduction <strong>in</strong> traffic <strong>of</strong> NH-1 due to<br />

traffic from Rajkot, Maler Kotla <strong>and</strong> Jal<strong>and</strong>ar <strong>and</strong> reduction <strong>of</strong><br />

traffic <strong>in</strong> the city <strong>of</strong> Ludhiana. The bridge proper, 810 m long<br />

between the <strong>in</strong>ner faces <strong>of</strong> dirt walls is made up <strong>of</strong> 23 spans <strong>of</strong><br />

35.20 m, while the approaches <strong>of</strong> lengths 1369 m <strong>and</strong> 1115 m on<br />

Nakodar side <strong>and</strong> Jagraon side respectively flanked the bridge<br />

proper.<br />

The ma<strong>in</strong> flow is conf<strong>in</strong>ed <strong>and</strong> guided through the bridge<br />

l<strong>in</strong>ear waterway without caus<strong>in</strong>g damage to the bridge <strong>and</strong> its<br />

approaches by provision <strong>of</strong> divergent guide-bunds along the<br />

river flow, upstream <strong>and</strong> downstream on both the banks.<br />

The superstructure <strong>of</strong> 35.20 m span bridge consisted <strong>of</strong> 6nos.<br />

precast pretensioned concrete beams spaced at 2.15 m<br />

centres <strong>and</strong> cast-<strong>in</strong>-situ RCC deck slab. The width <strong>of</strong> the<br />

carriageway has been kept 7.50 m flanked either side by 2 m<br />

wide cycle track mak<strong>in</strong>g the total width <strong>of</strong> the bridge deck to be<br />

12.95 m <strong>in</strong>clud<strong>in</strong>g crash barriers <strong>and</strong> steel rail<strong>in</strong>gs. The vehicular<br />

way is separated from cycle ways by crash barriers while<br />

cyclists are protected by steel rail<strong>in</strong>gs from be<strong>in</strong>g toppled over.<br />

The beams were simply supported on POT-cum-PTFE bear<strong>in</strong>gs<br />

hav<strong>in</strong>g slab steel expansion jo<strong>in</strong>ts between the spans. The<br />

abutments were solid non spill-through types to go with same<br />

family <strong>of</strong> plate type piers flar<strong>in</strong>g towards pier cap <strong>in</strong> the direction<br />

* Head <strong>of</strong> Technical Mgt.<br />

** Dy. Manager (Tech)<br />

*** Project Manager<br />

Gammon India Ltd., Mumbai<br />

E-mail : vnh@gammon<strong>in</strong>dia.com<br />

† Written comments on this Paper are <strong>in</strong>vited <strong>and</strong> will be received upto 30 th Sept., 2006.<br />

<strong>of</strong> river flow (transverse) to m<strong>in</strong>imise the size <strong>of</strong> the RCC cap.<br />

The piers were founded on 6 m dia well foundations while the<br />

abutments were rest<strong>in</strong>g on 7 m dia wells. The detail <strong>of</strong> the<br />

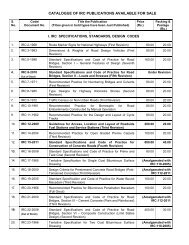

general features <strong>of</strong> the bridge is given <strong>in</strong> Fig. 1.<br />

2. DETAILS OF THE CONTRACT<br />

<strong>Punjab</strong> Infrastructure Development Board, on behalf <strong>of</strong><br />

<strong>Punjab</strong> PWD provided developmental outl<strong>in</strong>e proposal with<br />

the condition that the contractor should submit his own<br />

proposal with the approximate dimensions <strong>of</strong> various<br />

components <strong>of</strong> the bridge structure to fairly establish that the<br />

technical requirement were met with. The tender proposal <strong>of</strong><br />

the contractors were to <strong>in</strong>clude certa<strong>in</strong> obligatory conditions<br />

such as length <strong>of</strong> the bridge, approaches <strong>and</strong> guide-bunds,<br />

carriageway <strong>and</strong> cycle track width requirements, l<strong>in</strong>ear water<br />

way <strong>and</strong> vertical clearance <strong>and</strong> type <strong>of</strong> foundations, <strong>and</strong><br />

formation levels. The departmental outl<strong>in</strong>e proposal had the<br />

span <strong>of</strong> 40.50 m <strong>and</strong> the variation <strong>in</strong> span length was permitted<br />

up to ±20 per cent. The contractor had to give detailed design<br />

calculations <strong>and</strong> draw<strong>in</strong>gs <strong>in</strong> support <strong>of</strong> his proposal after the<br />

award <strong>of</strong> the work to comply with the design requirements<br />

stipulated <strong>in</strong> tender documents. Qualified eng<strong>in</strong>eers<br />

supplemented by <strong>in</strong>dependent quality control consultant <strong>in</strong><br />

l<strong>in</strong>e with ISO requirements were supervis<strong>in</strong>g the execution <strong>of</strong><br />

the job.<br />

Some <strong>of</strong> the salient design parameters specified <strong>in</strong> the tender<br />

documents are as below:<br />

River hydraulics

144<br />

• <strong>Design</strong> discharge : 18912 Cumecs<br />

• Maximum mean velocity : 4.87 m/sec<br />

• High flood level : RL 227.868<br />

• Depth <strong>of</strong> water at lowest : 3.0m<br />

water level<br />

• Scour level : RL 204.255<br />

Seismicity<br />

• Seismic zone : IV<br />

• Seismic coefficient : 0075G<br />

• Permissible <strong>in</strong>crease <strong>in</strong> SBC : 25 per cent<br />

• Permissible <strong>in</strong>crease <strong>in</strong> stress : As per IRC: 6<br />

Soil parameter<br />

• λ (dry) : 1.8 t/m 3<br />

• φ (angle <strong>of</strong> <strong>in</strong>ternal friction) : 30 0<br />

• δ (Friction between soil <strong>and</strong> face): 20 0<br />

• SBC for well foundation : 75 t/m 2 gross at<br />

found<strong>in</strong>g level.<br />

Material<br />

• For condition <strong>of</strong> exposure : Moderate<br />

• Concrete grades<br />

⇒For pretensioned beams : M40<br />

⇒For well foundation : M30<br />

⇒Re<strong>in</strong>forcements : HYSD bars<br />

conform<strong>in</strong>g to<br />

IS:1786<br />

HEGGADE, MEHTA & PRAKASH ON<br />

Fig. 1. General arrangement <strong>of</strong> <strong>Sutlej</strong> bridge<br />

Load<strong>in</strong>g<br />

• Live load :IRC 70R s<strong>in</strong>gle lane<br />

or Class-A 2 lanes<br />

• Footpath live load : As per IRC: 6<br />

• Cycle track load<strong>in</strong>g : As per IRC: 6<br />

Miscellaneous<br />

• Type <strong>of</strong> bear<strong>in</strong>gs : POT <strong>and</strong> POT cum<br />

PTFE<br />

• Wear<strong>in</strong>g coat : 25 mm thick mastic<br />

asphalt over 40 mm<br />

thick bitum<strong>in</strong>ous<br />

concrete<br />

• Cycle track <strong>and</strong> parapet : As per<br />

departmental<br />

draw<strong>in</strong>g<br />

• S<strong>of</strong>tware package : STAAD III -<br />

Release 22.0<br />

3. CONCEPTUALISATION<br />

In many <strong>of</strong> the river bridges <strong>in</strong> <strong>Punjab</strong> upto 45 m spans, the<br />

slab girder system with cast <strong>in</strong>situ post-tensioned beams are<br />

successfully adopted. Beyond 45 m, upto even 65 m cast <strong>in</strong>situ<br />

box girders are adopted. However, recently <strong>in</strong> vogue fast track

construction conceptualisation facilitates expeditious<br />

construction. The conventional cast <strong>in</strong>situ construction <strong>and</strong><br />

its expediencies like stag<strong>in</strong>g/trestle support for superstructure<br />

<strong>in</strong> the riverbed is not only time-consum<strong>in</strong>g, also susceptible to<br />

flood damages, consequently reduc<strong>in</strong>g productive work<strong>in</strong>g<br />

period <strong>in</strong> a season.<br />

In the recent years, the flyovers <strong>in</strong> urban areas especially<br />

<strong>in</strong> metropolitan cities are realised by precast construction. The<br />

various options <strong>in</strong> segmental <strong>and</strong> non-segmental technology<br />

is exploited <strong>in</strong> precast construction us<strong>in</strong>g post-tension<strong>in</strong>g or<br />

pre-tension<strong>in</strong>g.<br />

In case <strong>of</strong> <strong>Sutlej</strong> <strong>Bridge</strong>, among the various options<br />

available, f<strong>in</strong>ally the competition was between post-tensioned<br />

versus pre-tensioned beams. In this particular context, pretensioned<br />

beams had certa<strong>in</strong> advantages <strong>and</strong> also peculiarities<br />

vis-à-vis its counterpart.<br />

The <strong>in</strong>herent peculiarities such as s<strong>in</strong>gle-stage<br />

prestress<strong>in</strong>g, transfer <strong>of</strong> prestress through bond between<br />

concrete <strong>and</strong> cables by obviation <strong>of</strong> grout<strong>in</strong>g, sheath<strong>in</strong>g ducts,<br />

tension<strong>in</strong>g <strong>of</strong> tendons before the concrete is cast <strong>and</strong> transfer<br />

<strong>of</strong> prestress after the atta<strong>in</strong>ment <strong>of</strong> required strength <strong>in</strong> concrete,<br />

warrants specially designed cast<strong>in</strong>g bed which should be<br />

capable <strong>of</strong> impart<strong>in</strong>g required quantum <strong>of</strong> prestress<strong>in</strong>g force.<br />

These peculiarities derive certa<strong>in</strong> advantages <strong>in</strong> favour <strong>of</strong><br />

pretensioned beams <strong>in</strong> terms <strong>of</strong> durability, quantity reduction,<br />

construction speed, design <strong>and</strong> construction expediency. As<br />

the pretensioned girders are manufactured <strong>in</strong> factory like<br />

environment where the bond<strong>in</strong>g between concrete <strong>and</strong> tendons<br />

is direct due to the absence <strong>of</strong> grout<strong>in</strong>g <strong>in</strong>side the sheath<strong>in</strong>g<br />

duct, the better durability <strong>and</strong> corrosion resistance is achieved.<br />

The absence <strong>of</strong> the cables <strong>in</strong> the web <strong>and</strong> the elim<strong>in</strong>ation <strong>of</strong> end<br />

blocks <strong>and</strong> blisters to house the anchorages, allows the section<br />

optimisation from strength criteria alone. This helps <strong>in</strong> reduc<strong>in</strong>g<br />

concrete quantities render<strong>in</strong>g <strong>in</strong> lighter beams, facilitat<strong>in</strong>g <strong>in</strong><br />

attenuation <strong>in</strong> cost <strong>of</strong> h<strong>and</strong>l<strong>in</strong>g, transportation <strong>and</strong> erection.<br />

The value eng<strong>in</strong>eer<strong>in</strong>g carried out dur<strong>in</strong>g<br />

conceptualisation stage for <strong>Sutlej</strong> <strong>Bridge</strong> revealed that for the<br />

same span <strong>of</strong> 35.40 m <strong>and</strong> number <strong>of</strong> beams <strong>of</strong> six on the cross<br />

section (Fig. 2), the quantities for pre-tensioned girders are<br />

substantially lesser than post-tensioned beams.<br />

Fig. 2. <strong>Pre</strong>-tension<strong>in</strong>g vis-a-vis post-tension<strong>in</strong>g VE for <strong>Sutlej</strong><br />

bridge<br />

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB<br />

145<br />

From the design angle, pre-tension<strong>in</strong>g uses the prestress<br />

efficiently on smaller sections with higher eccentricities,<br />

reduces the immediate losses like friction, wobble <strong>and</strong> slip,<br />

reduces <strong>in</strong>itial mass on substructure <strong>and</strong> foundation due to<br />

seismic <strong>and</strong> reduces steel congestion <strong>in</strong> end blocks <strong>and</strong><br />

anchorage zones. <strong>Construction</strong>-wise, the activities associated<br />

with post-tension<strong>in</strong>g such as thread<strong>in</strong>g <strong>of</strong> cable <strong>in</strong>side the<br />

sheath<strong>in</strong>g, grout<strong>in</strong>g operation <strong>and</strong> number <strong>of</strong> prestress<strong>in</strong>g<br />

operations is elim<strong>in</strong>ated.<br />

Though the pretensioned technology has been used<br />

extensively for flyovers <strong>and</strong> ROBs for the span range <strong>of</strong> 18 to<br />

22 m, for the first time for bridge across river Surajbari <strong>in</strong> Gujarat<br />

the technology was adopted with 26 m spans <strong>in</strong> India, which<br />

withstood the otherwise catastrophic earthquake <strong>in</strong> Gujarath<br />

on 26 th January 2001. Perhaps, it was but natural for <strong>Sutlej</strong> <strong>and</strong><br />

Beas <strong>Bridge</strong>s <strong>in</strong> <strong>Punjab</strong> to extend the span length up to 35 m as<br />

a part <strong>of</strong> evolutionary process, on the basis <strong>of</strong> experience ga<strong>in</strong>ed<br />

through the fast track flyovers <strong>and</strong> Surajbari <strong>Bridge</strong>.<br />

4. FOUNDATIONS<br />

Before the award <strong>of</strong> the job, as a part <strong>of</strong> tender documents<br />

a thorough soil <strong>in</strong>vestigation was carried out by the department<br />

to arrive at soil characteristics, soil bear<strong>in</strong>g capacity <strong>and</strong><br />

found<strong>in</strong>g levels along the bridge alignment (Fig. 3). Overall<br />

seven numbers <strong>of</strong> boreholes were drilled for depths up to 40 m<br />

<strong>and</strong> st<strong>and</strong>ard penetration tests were performed as per IS:2131<br />

to arrive at ‘N’ values. Silt factors were calculated on the basis<br />

<strong>of</strong> particle size distribution follow<strong>in</strong>g the pr<strong>in</strong>ciples <strong>of</strong> Lacey’s<br />

silt factor. On the basis <strong>of</strong> soil <strong>in</strong>vestigation, the subsoil strata<br />

were divided <strong>in</strong>to 3 dist<strong>in</strong>ct zones.<br />

Around 12 m below the ground level along the alignment a<br />

silty clay strata <strong>of</strong> average b<strong>and</strong> depth <strong>of</strong> around 12 m,<br />

designated as Zone-2 was s<strong>and</strong>wiched between s<strong>and</strong>y strata<br />

designated as Zone-1 <strong>and</strong> Zone-3. Average value <strong>of</strong> s<strong>and</strong>y<br />

strata was around 34 0 while clayey strata had undra<strong>in</strong>ed shear<br />

strength <strong>of</strong> around 1.50 kg/cm 2 (Cu). On the basis <strong>of</strong> 75 mm<br />

maximum settlement criteria, the bear<strong>in</strong>g pressure at found<strong>in</strong>g<br />

level <strong>in</strong> s<strong>and</strong>y strata after pass<strong>in</strong>g through the clayey strata<br />

was specified as 75T/m 2 on conservative side. The silt factor<br />

for Zone-1 varied from 0.62 to 1.07 while for Zone-3 the same<br />

was rang<strong>in</strong>g between 0.35 to 1.01. The design scour depths<br />

near the piers <strong>and</strong> abutments were evaluated on the basis <strong>of</strong><br />

maximum discharge, river regime <strong>and</strong> velocity <strong>of</strong> the river.<br />

In all 22 numbers <strong>of</strong> piers were supported on 32 m deep<br />

<strong>and</strong> 6 m dia well foundations (Fig. 4), consist<strong>in</strong>g <strong>of</strong> 2.1 m deep<br />

kerb, 1.5 m deep well cap. The ste<strong>in</strong><strong>in</strong>g thickness <strong>of</strong> 1.05 m is<br />

tapered to 0.75 m at scour depth <strong>of</strong> around 18 m, below the top<br />

<strong>of</strong> the well cap.<br />

The thickness <strong>of</strong> the ste<strong>in</strong><strong>in</strong>g was decided by us<strong>in</strong>g the<br />

relationship given <strong>in</strong> IRC:78 to facilitate smooth s<strong>in</strong>k<strong>in</strong>g by<br />

gravity without excessive Kent ledge <strong>and</strong> damage to ste<strong>in</strong><strong>in</strong>g

146<br />

HEGGADE, MEHTA & PRAKASH ON<br />

Fig. 3. Bore hole details along bridge alignment<br />

Fig. 4. Typical well foundation for <strong>Sutlej</strong>

due to differential earth pressure, s<strong>and</strong> blow <strong>and</strong> sudden drop,<br />

etc. it was ensured that the stresses at different levels <strong>of</strong> ste<strong>in</strong><strong>in</strong>g<br />

dur<strong>in</strong>g service conditions <strong>and</strong> construction stage were with<strong>in</strong><br />

permissible limits. As the well foundations were to be plugged<br />

on soil, the grip for side earth resistance below the scour level<br />

was ensured to be <strong>of</strong> the maximum depth <strong>of</strong> scour below the<br />

design scour. As normally, well cannot be sunk to the precise<br />

verticality, the design catered for the cumulative moment effect<br />

<strong>of</strong> 1 <strong>in</strong> 80 tilts <strong>and</strong> 150 mm shift apart from account<strong>in</strong>g for other<br />

severe load comb<strong>in</strong>ation. The side earth resistance was<br />

calculated by Bombay Committee Method with the passive<br />

resistance factor <strong>of</strong> safeties <strong>of</strong> 2.0 <strong>and</strong> 1.6 for normal <strong>and</strong> seismic<br />

conditions respectively. The well cap was designed <strong>and</strong> detailed<br />

as uniformly thick plate for the external reactions <strong>and</strong> reaction<br />

components at the bottom <strong>of</strong> the pier with boundary condition<br />

as partially fixed at supports on well ste<strong>in</strong><strong>in</strong>g all around.<br />

The river bed level varied between RL 222 m to 225.50 m<br />

hav<strong>in</strong>g deep channel between the pies P3 <strong>and</strong> P10 with the low<br />

water level be<strong>in</strong>g at RL 223.723 m. Up to the deep channel i.e.<br />

P10, the service road was made up to A/R <strong>and</strong> wells up to P10<br />

were started simultaneously. After the monsoon was over, on<br />

recession <strong>of</strong> floods, the service road was made on A/L side <strong>and</strong><br />

with the help <strong>of</strong> the site made temporary bridge between P8 <strong>and</strong><br />

P10; the wells were tackled <strong>in</strong> the channel.<br />

Initially, the well s<strong>in</strong>k<strong>in</strong>g was planned with four cranes.<br />

However, the s<strong>and</strong>wiched clayey strata necessitated overall<br />

eight cranes, as the s<strong>in</strong>k<strong>in</strong>g through the same was consum<strong>in</strong>g<br />

almost 7 to 15 days per metre depth.<br />

Most <strong>of</strong> the well foundations were constructed<br />

conventionally on l<strong>and</strong>, barr<strong>in</strong>g a couple <strong>in</strong> deep channels,<br />

which warranted s<strong>and</strong> isl<strong>and</strong>s.<br />

In the conventional construction (Photo 1.), the cutt<strong>in</strong>g<br />

edge fabricated <strong>of</strong> mild steel was laid on the ground level <strong>and</strong><br />

curb with required re<strong>in</strong>forcements was concreted. The material<br />

<strong>in</strong>side was gradually scooped out with grabs to facilitate s<strong>in</strong>k<strong>in</strong>g<br />

under its own weight. As the s<strong>in</strong>k<strong>in</strong>g proceeded, the ste<strong>in</strong><strong>in</strong>g<br />

was built up <strong>in</strong> lifts, normally <strong>of</strong> around 2.5 m to further the<br />

s<strong>in</strong>k<strong>in</strong>g due to <strong>in</strong>crease <strong>in</strong> weight.<br />

Photo 1. Curb re<strong>in</strong>forcements & cutt<strong>in</strong>g edge<br />

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB<br />

147<br />

S<strong>in</strong>ce the bed pr<strong>of</strong>ile was hav<strong>in</strong>g large variations, almost<br />

all wells were required to be sunk up to 5 m below the ground<br />

level (Photo 2.) <strong>and</strong> 3.0 m below the water level. The circular<br />

c<strong>of</strong>ferdam except a small flare to accommodate piers was cast<br />

up to water level.<br />

Photo 2. C<strong>of</strong>ferdam with flare to accomodate pier<br />

Had the well cap level been fixed at ground level or LWL,<br />

the job could have been completed three to four months earlier<br />

<strong>and</strong> substantial additional expenditure as a consequence <strong>of</strong><br />

tak<strong>in</strong>g well cap below ground level could have been saved.<br />

As the c<strong>of</strong>ferdam was quite th<strong>in</strong> compared to ste<strong>in</strong><strong>in</strong>g, the<br />

non-availability <strong>of</strong> required weight hampered the s<strong>in</strong>k<strong>in</strong>g. This<br />

called for the creation <strong>of</strong> the sump below the found<strong>in</strong>g level to<br />

facilitate gradual s<strong>in</strong>k<strong>in</strong>g. At P16 location, the sump required<br />

was 3 m to enable last 1.80 m s<strong>in</strong>k<strong>in</strong>g. In the process the well<br />

jumped <strong>and</strong> sunk by 3.70 m at one go render<strong>in</strong>g the ste<strong>in</strong><strong>in</strong>g top<br />

almost 8 m (Photo 3.) below bed level.<br />

Photo 3. <strong>Construction</strong> <strong>of</strong> well cap below GL<br />

To raise the ste<strong>in</strong><strong>in</strong>g to the required level, the extensive<br />

shor<strong>in</strong>g, cont<strong>in</strong>uous dewater<strong>in</strong>g, protection with wire crated<br />

boulders, etc. had to be resorted to apart from stabilis<strong>in</strong>g the 6<br />

m deep false walls by adequate structural brac<strong>in</strong>gs.<br />

To circumvent the creation <strong>of</strong> sump to s<strong>in</strong>k last 1.2 m depth<br />

at P3 location, the other measures such as air jett<strong>in</strong>g, water<br />

jett<strong>in</strong>g <strong>and</strong> Kent ledge on top <strong>of</strong> false wall were attempted.<br />

F<strong>in</strong>ally after 4 months, the comb<strong>in</strong>ed effect <strong>of</strong> 450 t Kent ledge,<br />

5 m excavations outside the well <strong>and</strong> dewater<strong>in</strong>g yielded the<br />

well to the required depth.

148<br />

Though the aggregate s<strong>in</strong>k<strong>in</strong>g <strong>of</strong> 854 m was accomplished<br />

<strong>in</strong> a short period <strong>of</strong> 620 days, the good eng<strong>in</strong>eer<strong>in</strong>g practice <strong>of</strong><br />

fix<strong>in</strong>g the well cap at LWL/bed level, would have reduced the<br />

s<strong>in</strong>k<strong>in</strong>g duration, efforts <strong>and</strong> its f<strong>in</strong>ancial ramification quite<br />

considerably.<br />

At the every alternative well location, after reach<strong>in</strong>g the<br />

found<strong>in</strong>g level, the soil <strong>in</strong>vestigation was carried out up to 9 m<br />

depths to deduce ‘C’ <strong>and</strong> φ values to confirm the soil bear<strong>in</strong>g<br />

capacities. Bottom plugg<strong>in</strong>g was carried out by shift<strong>in</strong>g the<br />

concrete from batch<strong>in</strong>g plants through buckets <strong>and</strong> plac<strong>in</strong>g<br />

by tremie pipes. After hav<strong>in</strong>g done the recuperation test for<br />

soundness <strong>of</strong> plug after 14 days, the s<strong>and</strong> fill<strong>in</strong>g <strong>and</strong><br />

<strong>in</strong>termediate plugs were expedited. With the help <strong>of</strong><br />

irrecoverable shutter<strong>in</strong>g supported on precast beams <strong>and</strong><br />

c<strong>of</strong>ferdam, each well cap was completed with<strong>in</strong> five to six days<br />

<strong>in</strong>clud<strong>in</strong>g re<strong>in</strong>forcement fix<strong>in</strong>g <strong>and</strong> concret<strong>in</strong>g.<br />

5. PIERS<br />

The RCC piers were <strong>of</strong> wall type flar<strong>in</strong>g from well cap to<br />

accommodate the pier cap, with the concrete characteristic<br />

strength <strong>of</strong> 35 N/mm 2 . Though the grade <strong>of</strong> the concrete is<br />

same as that <strong>of</strong> used for well cap, the mix had to be made little<br />

richer with higher workability <strong>in</strong> order to enable smooth<br />

placement <strong>of</strong> concrete for the th<strong>in</strong> sections. A system <strong>of</strong><br />

formwork consist<strong>in</strong>g <strong>of</strong> steel channels <strong>and</strong> shutter<strong>in</strong>g was used<br />

<strong>in</strong> piers, which was concreted <strong>in</strong> two stages (Photo 4).<br />

Photo 4. Shutter<strong>in</strong>g Arrangement for Pier<br />

The height <strong>of</strong> the first lift was 3.25 m <strong>and</strong> after concret<strong>in</strong>g<br />

the first lift, the balance second lift shutter<strong>in</strong>g was fixed<br />

immediately <strong>in</strong> 3 to 5 hours. The grout leakage through the<br />

jo<strong>in</strong>ts <strong>of</strong> shutter<strong>in</strong>g was totally avoided by judicious plann<strong>in</strong>g<br />

dur<strong>in</strong>g the fabrication <strong>of</strong> shutter<strong>in</strong>g such as overlapp<strong>in</strong>g <strong>of</strong><br />

plates, etc. The concret<strong>in</strong>g for each lift was carried out <strong>in</strong><br />

cont<strong>in</strong>uous operation without the cold jo<strong>in</strong>t. By virtue <strong>of</strong> large<br />

shutter<strong>in</strong>g <strong>and</strong> m<strong>in</strong>imum number <strong>of</strong> lifts <strong>in</strong> concret<strong>in</strong>g, the surface<br />

texture <strong>of</strong> the concrete pier has been <strong>of</strong> excellent quality.<br />

6. SUPERSTRUCTURE<br />

6.1 Choice <strong>of</strong> Cross Section<br />

Due to the obvious advantages enumerated <strong>in</strong><br />

Conceptualisation Para, the an isotropic deck was considered<br />

HEGGADE, MEHTA & PRAKASH ON<br />

to be made up <strong>of</strong> 35.40 m long precast pretensioned beams,<br />

transversely held by 200 mm thick RCC deck slab. Though the<br />

design-wise <strong>and</strong> from aesthetical considerations, the<br />

<strong>in</strong>termediate diaphragms could have been avoided, the same<br />

has been provided to satisfy contractual requirement which<br />

are <strong>in</strong> fact structurally redundant.<br />

As there are no design criteria laid down <strong>in</strong> IRC st<strong>and</strong>ards<br />

for pretension<strong>in</strong>g, <strong>in</strong>variably IRC:18 meant for post-tensioned<br />

construction is adopted <strong>and</strong> <strong>in</strong>sisted upon, for pretension<br />

construction also. The present post-tensioned Code IRC:18<br />

prescribes work<strong>in</strong>g stress method <strong>of</strong> design <strong>and</strong> permissible<br />

stresses seem to be on highly conservative side. The<br />

comparable AASHTO-94, the st<strong>and</strong>ard that is also based on<br />

allowable stress method (ASD) design, allows at least 33 per<br />

cent higher flexural stresses dur<strong>in</strong>g transfer <strong>and</strong> 25 per cent<br />

higher flexural stresses dur<strong>in</strong>g service condition. To worsen<br />

the matter further, the ‘IRC’ stipulates 20 per cent additional<br />

time dependent losses, 3 times 1000 h relaxation losses, m<strong>in</strong>imum<br />

80 per cent <strong>of</strong> characteristic strength at full transfer <strong>of</strong> prestress,<br />

those perhaps are rationalised for post-tensioned construction<br />

on the basis <strong>of</strong> past experience, where prestress transfer is<br />

feasible <strong>in</strong> stages.<br />

Universally, though generally there are no separate codes<br />

for post-tension<strong>in</strong>g <strong>and</strong> pre-tension<strong>in</strong>g, the prestress<strong>in</strong>g code<br />

itself give separate design parameters such as time dependent<br />

loss parameters, permissible stresses <strong>and</strong> transmission length<br />

for pre-tension<strong>in</strong>g, etc. In view <strong>of</strong> this the author had suggested<br />

to IRC Code Mak<strong>in</strong>g Committee to make IRC: 18 a common<br />

code for prestressed concrete road bridges common for both<br />

pretensioned <strong>and</strong> post tensioned concrete with the separate<br />

design parameters wherever relevant <strong>and</strong> applicable, which is<br />

yet to be taken <strong>in</strong>to cognisance.<br />

Selection <strong>of</strong> the beam cross section for long span<br />

pretensioned girders warrants experience <strong>in</strong> field supervision,<br />

apart from theoretical aspects <strong>of</strong> prestressed concrete. It is<br />

expected that the optimum concrete section that is materially<br />

<strong>in</strong>fluenced by prestress<strong>in</strong>g force <strong>and</strong> load<strong>in</strong>g, is light for<br />

h<strong>and</strong>l<strong>in</strong>g <strong>and</strong> transportation, prestress<strong>in</strong>g operation <strong>and</strong><br />

concret<strong>in</strong>g friendly. The sizes <strong>of</strong> bottom <strong>and</strong> top flanges, the<br />

depth <strong>and</strong> width <strong>of</strong> web are required to be optimised on the<br />

basis <strong>of</strong> above constructability issues.<br />

The pressure l<strong>in</strong>e (resultant <strong>of</strong> stresses) <strong>in</strong> the prestressed<br />

concrete flexural member shifts its location with<strong>in</strong> the section<br />

upon the application <strong>of</strong> external loads. In simply supported<br />

beams at the midspan for service condition, the stress at the<br />

bottom-fibre is zero, i.e. no tension allowed as per codal<br />

provision. At the midspan pressure l<strong>in</strong>e is above the CG <strong>of</strong> the<br />

section, warrant<strong>in</strong>g the CG <strong>of</strong> the prestress<strong>in</strong>g force at a<br />

distance equivalent to moment divided by prestress<strong>in</strong>g force.<br />

Thus to cater for the compressive force by virtue <strong>of</strong> pressure<br />

l<strong>in</strong>e above the CG <strong>of</strong> section at the midspan, the top flange<br />

requirement is high, whereas nearly zero-stressed bottom fibre

does not require flange, apart from accommodat<strong>in</strong>g cables.<br />

Towards the supports as the moments are gradually reduced to<br />

zero, the CG <strong>of</strong> the prestress<strong>in</strong>g force can be judiciously located<br />

to be concentric to avoid any requirement <strong>of</strong> flanges.<br />

However, at the <strong>in</strong>terven<strong>in</strong>g stage before the application <strong>of</strong><br />

imposed loads <strong>in</strong>clud<strong>in</strong>g live load, the section has to store large<br />

prestress<strong>in</strong>g force at bottom fibre, which would be neutralised<br />

on application <strong>of</strong> external <strong>in</strong>termittent loads latter, br<strong>in</strong>g<strong>in</strong>g the<br />

bottom fibre stress to zero. The above calls for widen<strong>in</strong>g <strong>of</strong> the<br />

bottom flange <strong>and</strong> <strong>in</strong> fact decides the width. Thus an ‘I’ section<br />

where the pressure l<strong>in</strong>e can move larger distance without the<br />

tensile stresses is chosen for pretensioned girders. While the<br />

span to depth ratio ranges between 16 to 22, the web thickness<br />

<strong>of</strong> 150 mm is considered to be adequate for normal ‘I’ shaped<br />

beam for honeycomb-free concret<strong>in</strong>g.<br />

However, <strong>in</strong> case <strong>of</strong> <strong>Sutlej</strong> <strong>Bridge</strong> as the vertical clearance<br />

was not a constra<strong>in</strong>t, the lavish span to depth ratio <strong>of</strong> 14 was<br />

adopted to reduce the prestress<strong>in</strong>g str<strong>and</strong>s with the web<br />

thickness <strong>of</strong> 200 mm as constra<strong>in</strong>ed by IRC:18, though the same<br />

was not required by design <strong>and</strong> constructability angles.<br />

The decision on the width <strong>of</strong> the top flange is very crucial<br />

as the extremely narrow top flanges may buckle the precast<br />

beams dur<strong>in</strong>g side shift<strong>in</strong>g, transportation <strong>and</strong> h<strong>and</strong>l<strong>in</strong>g. The<br />

Indian Codes categorise the beams as slender beams when the<br />

span to top flange width ratio exceeds 60 or depth to flange<br />

width ratio exceeds 4 <strong>and</strong> specifies reduction <strong>in</strong> permissible<br />

stresses <strong>and</strong> adequate temporary restra<strong>in</strong>ts dur<strong>in</strong>g h<strong>and</strong>l<strong>in</strong>g<br />

<strong>and</strong> erection from lateral stability considerations. Normally,<br />

for the simply supported beams, the span to depth ratio <strong>of</strong> 15<br />

is considered to be optimum, <strong>and</strong> when the same is related to<br />

depth to width ratio <strong>of</strong> 4, the span to width ratio works out to<br />

be 60. In <strong>Sutlej</strong> <strong>and</strong> Beas bridges, 35 m long beams with 2.5 m<br />

depth was provided with 0.70 m top flange to keep the weight<br />

<strong>of</strong> the girder to m<strong>in</strong>imum with span to flange width ratio <strong>of</strong> 50<br />

<strong>and</strong> depth to width ratio <strong>of</strong> 3.57 satisfy<strong>in</strong>g both the<br />

considerations given <strong>in</strong> Indian Codes for slenderness. The<br />

stretch<strong>in</strong>g the slenderness to codal limits to keep the weight<br />

m<strong>in</strong>imum, was considered to be very bold especially after the<br />

classical beam collapses <strong>of</strong> Roop Narayan <strong>Bridge</strong> on National<br />

Highway No.6, where the span to width ratio 50 followed the<br />

depth to width ratio <strong>of</strong> 3 (safer than <strong>Sutlej</strong> <strong>Bridge</strong>). In his paper<br />

“A study <strong>of</strong> the failures dur<strong>in</strong>g launch<strong>in</strong>g <strong>of</strong> precast prestressed<br />

concrete beams <strong>of</strong> the Roop Narayan <strong>Bridge</strong> on National<br />

Highway No. 6”, while deliberat<strong>in</strong>g on Guyon’s contention that<br />

for the beams depths <strong>of</strong> 5 to 8 ft., the thickness <strong>of</strong> the flanges<br />

should never be less than 0.1 <strong>of</strong> the depth <strong>and</strong> width <strong>of</strong> the<br />

flanges should not be less than 0.40 <strong>of</strong> the depth for<br />

symmetrical I-beams, Mr. Seetharaman through his<br />

<strong>in</strong>vestigation concludes that the span to depth ratio should<br />

be 15 <strong>and</strong> depth to width ratio should be less than 3 for<br />

transverse rigidity <strong>of</strong> precast beams. Thus the chosen beam<br />

section for <strong>Sutlej</strong> called for thorough <strong>in</strong>vestigation <strong>and</strong><br />

justification vis-à-vis lateral stability dur<strong>in</strong>g transfer <strong>of</strong><br />

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB<br />

149<br />

prestress, h<strong>and</strong>l<strong>in</strong>g <strong>and</strong> erection <strong>of</strong> the beams before the<br />

beams are transversely rigidised by deck slab.<br />

The lateral stability <strong>of</strong> <strong>Sutlej</strong> beams dur<strong>in</strong>g h<strong>and</strong>l<strong>in</strong>g <strong>and</strong><br />

erection was ensured by extensive <strong>in</strong>vestigations on the basis<br />

<strong>of</strong> special report “lateral stability <strong>of</strong> long prestressed concrete<br />

beams” by Robert F. Mait <strong>in</strong> PCI Journal Jan-Feb 1989.<br />

The improper lift<strong>in</strong>g hook placement <strong>and</strong> cast<strong>in</strong>g<br />

imperfection cause the beam to be tilted at an <strong>in</strong>itial angle θ1 near the lift<strong>in</strong>g hook location about the roll axis (Fig. 5).<br />

Normally the cast<strong>in</strong>g imperfections considered 1:1920 <strong>in</strong> <strong>Sutlej</strong><br />

gets manifested itself by way <strong>of</strong> curvature <strong>in</strong> plan <strong>of</strong><br />

prestressed beam after detension<strong>in</strong>g. Lift<strong>in</strong>g hook placement<br />

tolerance was allowed to be 6.35 mm dur<strong>in</strong>g cast<strong>in</strong>g. The<br />

above tilt<strong>in</strong>g <strong>of</strong> beam <strong>in</strong>duces the lateral deflection about<br />

weak axis <strong>of</strong> the beam. Because <strong>of</strong> the transfer <strong>of</strong> prestress,<br />

there is already tension at the top fibre <strong>of</strong> the beam for which<br />

the tensile stress caused about the weak axis by the<br />

component <strong>of</strong> the self weight due to tilt gets added which<br />

needs to be with<strong>in</strong> the permissible limits <strong>and</strong> <strong>in</strong> fact decides<br />

the maximum tilt (θ max) to which the beam can be subjected<br />

to. After the tilt<strong>in</strong>g is <strong>in</strong>itiated by the <strong>in</strong>itial angle θ near the<br />

1<br />

support locations, the beam achieves its equilibrium with a<br />

uniform lift angle θ (shown at midspan) with CG <strong>of</strong> the mass<br />

<strong>of</strong> the deflected beam right under the roll axis.<br />

In the figure as Z approaches Y , the beam starts rotat<strong>in</strong>g<br />

o r<br />

<strong>and</strong> becomes totally unstable even without the <strong>in</strong>itial<br />

imperfection <strong>and</strong> without improper location <strong>of</strong> lift<strong>in</strong>g hook.<br />

Thus the safety aga<strong>in</strong>st the lateral buckl<strong>in</strong>g is a measure <strong>of</strong><br />

Y vis-à-vis Zo <strong>and</strong> is called gross factor <strong>of</strong> safety (FOS = Y /<br />

r r<br />

Z ) for a perfect beam without imperfection.<br />

o<br />

If one has to account for imperfections caus<strong>in</strong>g the <strong>in</strong>itial<br />

angle q <strong>and</strong> limit<strong>in</strong>g the maximum lift to θ , the factor <strong>of</strong><br />

1 max<br />

safety reduces to .<br />

However, it is more logical to deduce the factor <strong>of</strong> safety<br />

aga<strong>in</strong>st lateral stability by divid<strong>in</strong>g maximum possible tilt θ max<br />

with that <strong>of</strong> equilibrium rotation θ at midspan.<br />

Mov<strong>in</strong>g the lift<strong>in</strong>g position <strong>in</strong>wards improves the factor<br />

<strong>of</strong> safety aga<strong>in</strong>st lateral stability by virtue <strong>of</strong> reduced<br />

deflections caused by rotations about the weak axis.<br />

However, it has to be ensured that the stresses are with<strong>in</strong><br />

the limits <strong>in</strong> overhang portions.<br />

Though the very slender cross sections from lateral<br />

stability considerations was chosen <strong>in</strong> <strong>Sutlej</strong> <strong>Bridge</strong>, the same<br />

could be successfully executed by adher<strong>in</strong>g to the specified<br />

cast<strong>in</strong>g imperfections, lift<strong>in</strong>g hook location tolerance, etc.<br />

dur<strong>in</strong>g execution. The details <strong>of</strong> the same are given <strong>in</strong> Fig. 5.<br />

Unlike <strong>in</strong> post-tension<strong>in</strong>g, <strong>in</strong> case <strong>of</strong> pre-tension<strong>in</strong>g as the<br />

str<strong>and</strong>s are bonded dur<strong>in</strong>g the transfer <strong>of</strong> prestress, the

150<br />

Fig. 5. Laterial stability <strong>of</strong> long prestressed concrete beams with factor <strong>of</strong> safeties<br />

beams cannot buckle which was also taken <strong>in</strong>to cognisance<br />

dur<strong>in</strong>g lateral stability <strong>in</strong>vestigations.<br />

The lateral stability guidel<strong>in</strong>es for precast beams given <strong>in</strong><br />

Indian Codes for prestressed concrete members are similar to<br />

that <strong>of</strong> for RCC <strong>and</strong> steel beams <strong>in</strong> terms <strong>of</strong> span to depth ratio<br />

<strong>and</strong> depth to top flange width ratio. However, <strong>in</strong> the case <strong>of</strong><br />

prestressed beams, the aspect <strong>of</strong> prestress<strong>in</strong>g is a new variable<br />

<strong>and</strong> as such the same guidel<strong>in</strong>es may not be applicable for<br />

prestressed beams. In view <strong>of</strong> this the factor <strong>of</strong> safeties<br />

enumerated above may be <strong>in</strong>cluded for ensur<strong>in</strong>g the lateral<br />

stability <strong>of</strong> beams dur<strong>in</strong>g shift<strong>in</strong>g, transportation <strong>and</strong> erection<br />

<strong>of</strong> prestressed, precast beams <strong>in</strong> the prestressed concrete<br />

codes.<br />

6.2. <strong>Design</strong> <strong>of</strong> Superstructure<br />

The superstructure consists <strong>of</strong> six numbers <strong>of</strong> precast<br />

pretensioned girders spaced at 2.15 m centre to centre with 250<br />

mm thick end diaphragms to support 200 mm thick cast-<strong>in</strong>-site<br />

RCC deck cantilever<strong>in</strong>g by 1.10 m from the centre l<strong>in</strong>e <strong>of</strong> external<br />

girders on either side. The pretensioned girders <strong>in</strong> the cast<strong>in</strong>g<br />

yard were specified to be prestressed after 24 hours when the<br />

strength <strong>of</strong> the concrete was 31 MPa, while the concrete grade<br />

for the beams were M 40.<br />

The precast girders were transported to site <strong>and</strong> placed on<br />

bear<strong>in</strong>gs followed by cast<strong>in</strong>g <strong>of</strong> the end diaphragm. The RCC<br />

deck slab was cast on formwork supported on girders <strong>and</strong> the<br />

HEGGADE, MEHTA & PRAKASH ON<br />

same was removed after the sufficient atta<strong>in</strong>ment <strong>of</strong> strength <strong>in</strong><br />

the deck. Thereafter, for the further loads such as weight <strong>of</strong><br />

crash barrier, wear<strong>in</strong>g coat, rail<strong>in</strong>gs <strong>and</strong> live load, etc. the<br />

structure was assured to be a composite section. The effect <strong>of</strong><br />

differential shr<strong>in</strong>kage <strong>and</strong> temperature variation were also<br />

considered <strong>in</strong> the design.<br />

For f<strong>in</strong>d<strong>in</strong>g all the longitud<strong>in</strong>al beam reaction components,<br />

the grillage analysis (Fig. 6) was used for superimposed dead<br />

loads <strong>and</strong> live loads, the structure was idealised as a grid <strong>of</strong><br />

longitud<strong>in</strong>al <strong>and</strong> transverse members. The composite girders<br />

consist<strong>in</strong>g <strong>of</strong> precast beam <strong>and</strong> deck slab was descretised to<br />

be placed along the axis <strong>of</strong> the girder while deck slab <strong>and</strong> deck<br />

slab with diaphragm was placed as transverse grillage members<br />

along the l<strong>in</strong>e <strong>of</strong> each <strong>of</strong> end diaphragm <strong>in</strong> the structure. The<br />

slab acts to transmit applied loads to beams by spann<strong>in</strong>g<br />

transversely between them, apart from provid<strong>in</strong>g means for<br />

load shar<strong>in</strong>g between longitud<strong>in</strong>al beams. Therefore transverse<br />

members hav<strong>in</strong>g slab properties were provided to reflect the<br />

load shar<strong>in</strong>g characteristics <strong>of</strong> the deck. For the application <strong>of</strong><br />

the loads due to rail<strong>in</strong>g, the dummy longitud<strong>in</strong>al members with<br />

negligible section properties were provided at the edges <strong>and</strong><br />

transverse grillage members were cont<strong>in</strong>ued to connect them.<br />

The flar<strong>in</strong>g properties <strong>of</strong> precast beams at the end for the<br />

distance <strong>of</strong> 2.65 m from 200 mm to 300 mm thick has been<br />

accounted for <strong>in</strong> the descretisation.<br />

The grillage analysis results especially for superimposed

Fig. 6. Grillage idealisation for deck slab with girders<br />

dead loads <strong>and</strong> live loads were compared with Classical Little<br />

<strong>and</strong> Morrice method for verification, which were found to be <strong>in</strong><br />

agreement to a large extent as illustrated <strong>in</strong> Table 1.<br />

TABLE 1. GRILLAGE ANALYSIS VIA-A-VIS LITTLE & MORRICE<br />

METHOD<br />

The stresses <strong>in</strong> bottom <strong>and</strong> top fibres <strong>of</strong> the beam before<br />

<strong>and</strong> after the composite action were ensured to be with<strong>in</strong> the<br />

permissible limits as specified <strong>in</strong> IRC:18 at various temporary<br />

<strong>and</strong> service stages as tabulated <strong>in</strong> Table 2.<br />

TABLE 2. SUMMARY OF STRESSES AT MID SPAN<br />

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB<br />

In case <strong>of</strong> the pretensioned girders with straight tendons,<br />

151<br />

the prestress<strong>in</strong>g moments near the simply supported ends<br />

need to be reduced as the moments <strong>in</strong>duced by self weight<br />

<strong>and</strong> external loads gradually dim<strong>in</strong>ishes towards the supports<br />

from midspan. The same is achieved by prevent<strong>in</strong>g the portion<br />

<strong>of</strong> the tendons from bond<strong>in</strong>g, thereby prevent<strong>in</strong>g from<br />

stress<strong>in</strong>g the concrete at the ends. Normally, the bond<br />

prevention is achieved by provision <strong>of</strong> tight-fitt<strong>in</strong>g split plastic<br />

tube or heavy paper or cloth tape. However, for the accurate<br />

placement <strong>of</strong> tubes after the pre-tension<strong>in</strong>g a 20 mm dia ‘PVC’<br />

tubes were used <strong>in</strong> <strong>Sutlej</strong> <strong>Bridge</strong> as bond prevention media at<br />

the ends (Fig. 7).<br />

The length <strong>of</strong> bond prevention has to be deduced after<br />

cater<strong>in</strong>g for “transmission length” required to develop full<br />

tension <strong>in</strong> the tendons.<br />

When the pretension<strong>in</strong>g tendon is stressed, the diameter<br />

<strong>of</strong> the tendon is reduced due to poison’s effect <strong>and</strong> the orig<strong>in</strong>al<br />

diameter is rega<strong>in</strong>ed after the release <strong>of</strong> prestress. In fact this<br />

property is responsible for bond<strong>in</strong>g pretensioned wires to<br />

concrete. After the detension<strong>in</strong>g, the stress <strong>in</strong> the wire at the<br />

end is zero <strong>and</strong> maximum after certa<strong>in</strong> length, which is called<br />

“transmission length”. The Hoyer was the first German<br />

Eng<strong>in</strong>eer who developed the theory <strong>of</strong> “transmission length”<br />

due to the formation <strong>of</strong> wedge shape <strong>in</strong> prestress<strong>in</strong>g tendon<br />

where the stress gradually decreases from maximum to zero<br />

with the <strong>in</strong>crease <strong>in</strong> diameter <strong>of</strong> tendon, which is popularly<br />

referred as “Hoyer’s effect”.<br />

The transmission length depends upon number <strong>of</strong><br />

variables, the most important be<strong>in</strong>g the strength <strong>of</strong> the concrete<br />

at the time <strong>of</strong> transfer, the size <strong>of</strong> the tendon, friction between<br />

the tendon <strong>and</strong> concrete <strong>and</strong> <strong>in</strong>itial <strong>and</strong> effective stresses <strong>in</strong><br />

steel. As per the guidel<strong>in</strong>es <strong>of</strong> IS:1343, 30 times the diameter <strong>of</strong><br />

the tendon for str<strong>and</strong>s i.e. around 500 mm was considered as<br />

transmission length <strong>in</strong> the said bridge. It is <strong>in</strong>terest<strong>in</strong>g to note<br />

that the stress variation over transmission length be<strong>in</strong>g<br />

parabolic, 80 per cent <strong>of</strong> the maximum prestress is developed<br />

over half the transmission length, <strong>and</strong> as such half <strong>of</strong> the<br />

transmission length was projected beyond bear<strong>in</strong>g supports<br />

for simply supported girders.<br />

7. PRE-TENSIONING<br />

The bridge <strong>of</strong> 23 spans consisted <strong>of</strong> 138 nos, 35.2 m long,<br />

68 tonne weigh<strong>in</strong>g, prestressed beams with the depth <strong>of</strong> 2.50<br />

m. Each beam consisted <strong>of</strong> 34 nos. <strong>of</strong> str<strong>and</strong>s (tendons)<br />

conform<strong>in</strong>g to class-2 <strong>of</strong> IS:14268 with UTS <strong>of</strong> 1900 N/mm 2 .<br />

Each str<strong>and</strong> <strong>of</strong> 15.2 mm dia was made up <strong>of</strong> 7 wires with 6 wires<br />

surround<strong>in</strong>g the centre wire configuration result<strong>in</strong>g <strong>in</strong><br />

enhanced bond characteristics due to Hoyer’s effect, with net<br />

str<strong>and</strong> cross sectional area <strong>of</strong> 140 mm 2 .<br />

The key factors <strong>in</strong> the choice <strong>and</strong> capacity <strong>of</strong><br />

pretension<strong>in</strong>g bed was the availability <strong>of</strong> time for precast<strong>in</strong>g<br />

girders <strong>and</strong> the economical considerations. The cost benefit

152<br />

analysis for various capacities <strong>of</strong> long l<strong>in</strong>e pre tension<strong>in</strong>g bed<br />

was carried out as per the Table 3. S<strong>in</strong>ce the expenditure on<br />

three beams cast<strong>in</strong>g was found to be economically optimum,<br />

sav<strong>in</strong>g almost 15 months, the bed for cast<strong>in</strong>g three beams was<br />

chosen, mak<strong>in</strong>g perhaps the longest pretension<strong>in</strong>g bench <strong>in</strong><br />

the country with the length <strong>of</strong> 122.5 m, for stress<strong>in</strong>g 115 m long<br />

str<strong>and</strong>s (Fig. 8).<br />

TABLE. 3. COST BENEFIT ANALYSIS OF PRETENSIONING BENCH<br />

HEGGADE, MEHTA & PRAKASH ON<br />

Fig. 7. Debond<strong>in</strong>g arrangement for st<strong>and</strong>s at the ends<br />

The largest long l<strong>in</strong>e prestress<strong>in</strong>g bed had its own share <strong>of</strong><br />

problems. Each str<strong>and</strong> was to be stressed to 21 tonnes,<br />

warrant<strong>in</strong>g the capacity <strong>of</strong> the pretension<strong>in</strong>g bench to (2x34) =<br />

714 tonnes. It is essential to design the pretension<strong>in</strong>g bed to<br />

additional 20 per cent capacity as the prestress<strong>in</strong>g force on<br />

reaction abutment (Fig. 9) will <strong>in</strong>crease due to “long l<strong>in</strong>e bench<br />

effect” after cast<strong>in</strong>g <strong>of</strong> concrete, due to shr<strong>in</strong>kage <strong>and</strong><br />

temperature variation between the duration <strong>of</strong> cast<strong>in</strong>g <strong>of</strong><br />

concrete <strong>and</strong> detension<strong>in</strong>g. Prior to detension<strong>in</strong>g <strong>in</strong> the cast<strong>in</strong>g<br />

yard, the str<strong>and</strong>s can be stressed up to 0.80 UTS. Due to the<br />

shr<strong>in</strong>kage <strong>of</strong> concrete clubbed with reduction <strong>in</strong> temperature,<br />

shr<strong>in</strong>ks the concrete along with the str<strong>and</strong>s <strong>in</strong> the bonded length<br />

thereby elongat<strong>in</strong>g <strong>and</strong> <strong>in</strong>duc<strong>in</strong>g further stress <strong>in</strong> the unbonded<br />

length. If the <strong>in</strong>crease <strong>in</strong> stress <strong>in</strong> unbonded length before<br />

Fig. 8. <strong>Pre</strong> tension<strong>in</strong>g bench <strong>of</strong> 122.5 m, for stress<strong>in</strong>g 15 m long str<strong>and</strong>s

Fig. 9. Cross section <strong>of</strong> Bulkhead<br />

detension<strong>in</strong>g is beyond UTS, the str<strong>and</strong>s <strong>in</strong> some cases may<br />

even start snapp<strong>in</strong>g, as happened <strong>in</strong> <strong>Sutlej</strong> <strong>Bridge</strong>. The <strong>in</strong>crease<br />

<strong>in</strong> the stress <strong>of</strong> the unbonded tendon is directly proportionate<br />

to the ratio <strong>of</strong> the length <strong>of</strong> the embedded str<strong>and</strong>s to that <strong>of</strong><br />

total str<strong>and</strong> length. This is also affected by cur<strong>in</strong>g time <strong>and</strong> is<br />

more severe when the ambient temperature dur<strong>in</strong>g stripp<strong>in</strong>g is<br />

low.<br />

The key decisive factors <strong>in</strong> the choice <strong>of</strong> formwork for<br />

pretensioned girders were:<br />

(a) High resistance to damage due to rough h<strong>and</strong>l<strong>in</strong>g.<br />

(b) The precise dimension <strong>of</strong> the panels to fit together to<br />

form a large unit with ease.<br />

(c) Clean<strong>in</strong>g, sett<strong>in</strong>g, adjust<strong>in</strong>g <strong>and</strong> h<strong>and</strong>l<strong>in</strong>g ease.<br />

(d) The ability <strong>of</strong> erect<strong>in</strong>g one side <strong>in</strong>dependent <strong>of</strong> other.<br />

(e) The ability to withst<strong>and</strong> the form <strong>and</strong> other vibrations.<br />

(f) Rigid structural s<strong>of</strong>fit form to secure <strong>and</strong> hold the side<br />

form without movement dur<strong>in</strong>g concret<strong>in</strong>g.<br />

(g) The m<strong>in</strong>imum jo<strong>in</strong>ts, which can be tightly sealed to<br />

avoid leakage <strong>and</strong> bleed<strong>in</strong>g.<br />

The shutter<strong>in</strong>g panels <strong>of</strong> 3 m length were erected us<strong>in</strong>g<br />

8-ton capacity hydro crane, which was supported on ground<br />

anchors by turnbuckles. After erection <strong>of</strong> one face <strong>of</strong><br />

shutter<strong>in</strong>g the alignments to the precision could be carried out<br />

by adjustments <strong>of</strong> turnbuckles. After the erection <strong>of</strong> one face<br />

<strong>of</strong> shutter<strong>in</strong>g the alignment to the precision could be carried<br />

out by adjustment <strong>of</strong> turnbuckles. After the erection <strong>of</strong> one<br />

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB<br />

153<br />

shutter<strong>in</strong>g face, the re<strong>in</strong>forcement cages fabricated <strong>in</strong> three<br />

pieces <strong>of</strong> 11 m each were shifted to cast<strong>in</strong>g bed by hydro<br />

crane. The cages were suitably stiffened by diagonal bars<br />

dur<strong>in</strong>g transportation, which were removed once placed <strong>in</strong><br />

position <strong>in</strong> cast<strong>in</strong>g bed.<br />

HT str<strong>and</strong>s were cut to 115 m length <strong>and</strong> stacked over<br />

raised platform along the l<strong>in</strong>e <strong>of</strong> cast<strong>in</strong>g bed. While open<strong>in</strong>g<br />

the coil, HT str<strong>and</strong>s were passed through water tank to<br />

remove protective coat<strong>in</strong>g. The cables were threaded manually<br />

<strong>in</strong>sert<strong>in</strong>g through 20 mm dia ‘PVC’ pipes <strong>of</strong> required length<br />

meant for debond<strong>in</strong>g. After fix<strong>in</strong>g up the anchorages, the<br />

cables were prestressed from stress<strong>in</strong>g end <strong>in</strong> predeterm<strong>in</strong>ed<br />

sequence. The debond<strong>in</strong>g pipes were positioned <strong>and</strong> sealed<br />

with epoxy <strong>and</strong> tapes as per the draw<strong>in</strong>g after the stressed<br />

cables were anchored. The other face <strong>of</strong> the shutter<strong>in</strong>g was<br />

then lifted up <strong>and</strong> connected to already erect face by 16 mm<br />

through bolts. The gaps were filled with foams for prevent<strong>in</strong>g<br />

leakage <strong>and</strong> one end <strong>of</strong> the shutter<strong>in</strong>g was provided with 50<br />

mm wooden pack<strong>in</strong>g <strong>and</strong> thermo coal to facilitate easy removal<br />

<strong>of</strong> shutter<strong>in</strong>g after concret<strong>in</strong>g.<br />

The concrete produced by batch<strong>in</strong>g plant <strong>of</strong> capacity 30<br />

m 3 /hr as per the design mix (Table 4.) transported through a<br />

lead <strong>of</strong> 100 m by tractor trolley. As the concrete was to be<br />

placed at height <strong>of</strong> 3.5 m from supply level a mechanical mode<br />

was devised for placement. The device consisted <strong>of</strong> an<br />

automatic conveyor designed <strong>and</strong> fabricated (Fig. 10) at site<br />

<strong>in</strong> such way that it could move on a track l<strong>in</strong>e parallel to<br />

pretension<strong>in</strong>g bed, receive concrete from trolleys up to 0.50<br />

m 3 at a time, carry the concrete through conveyor for 3.50 m<br />

height <strong>and</strong> deliver to tremie for placement through funnel. The<br />

device could be electrically operated by operator seated on<br />

it, <strong>and</strong> reduced the concret<strong>in</strong>g cycle to 2 hours from manual<br />

concret<strong>in</strong>g cycle <strong>of</strong> 5 hours. The concrete compaction was<br />

achieved by poker <strong>and</strong> shutter vibrators.<br />

TABLE 4. DESIGN MIX DETAILS<br />

The transfer <strong>of</strong> prestress was <strong>in</strong>duced by cutt<strong>in</strong>g str<strong>and</strong><br />

by acetylene torch <strong>in</strong> a pre-decided sequence after concrete<br />

achieved the strength <strong>of</strong> 31 MPa. The best cycle time achieved<br />

<strong>in</strong> the beam cast<strong>in</strong>g was 66 hours though on a average time

154<br />

Fig. 10. Mechanical device for concrete placement<br />

cycle was 72 hours with the <strong>in</strong>dividual activity break-up as<br />

shown <strong>in</strong> Table 5.<br />

TABLE 5. CYCLE TIME FOR BEAM CASTING<br />

Despite the unforeseen impediments like non-availability<br />

<strong>of</strong> stack<strong>in</strong>g facilities, repairs <strong>of</strong> shutter<strong>in</strong>g panels, ma<strong>in</strong>tenance<br />

<strong>of</strong> bed alignment, <strong>and</strong> ra<strong>in</strong>, etc. the cast<strong>in</strong>g <strong>of</strong> 138 nos. <strong>of</strong><br />

beams were completed <strong>in</strong> 320 days.<br />

The pretension<strong>in</strong>g can be done either by stress<strong>in</strong>g each<br />

tendon <strong>in</strong>dividually or all together at a time. As the stress<strong>in</strong>g<br />

<strong>in</strong>dividually called for monostr<strong>and</strong> jack <strong>of</strong> 25 T capacity with<br />

a stroke 1000 mm, the <strong>in</strong>dividual stress<strong>in</strong>g <strong>of</strong> str<strong>and</strong>s was<br />

resorted to.<br />

8. BEAM ERECTION<br />

The transportation <strong>and</strong> erection <strong>of</strong> beams were<br />

accomplished (Fig. 11) by 3 pairs <strong>of</strong> side shift<strong>in</strong>g trolleys, a<br />

pair <strong>of</strong> motorised longitud<strong>in</strong>al trolleys <strong>and</strong> a pair <strong>of</strong> 35-toon<br />

capacity bed gantries. The side shift<strong>in</strong>g trolleys were used<br />

to shift the beams from cast<strong>in</strong>g bed to stack<strong>in</strong>g yard <strong>and</strong> from<br />

there to longitud<strong>in</strong>ally motorised trolleys with the help <strong>of</strong><br />

jacks. The longitud<strong>in</strong>al trolleys be<strong>in</strong>g designed at lower levels,<br />

the beams brought by side shift<strong>in</strong>g trolleys were lowered to<br />

HEGGADE, MEHTA & PRAKASH ON<br />

longitud<strong>in</strong>al trolleys.<br />

To facilitate the movement <strong>of</strong> bed gantries <strong>and</strong><br />

longitud<strong>in</strong>al trolleys, the track l<strong>in</strong>e is laid on wooden sleepers<br />

at 0.70 m c/c as per railway specification over well-prepared<br />

compacted embankments. The motorised trolleys were moved<br />

up to the span where beam was to be erected. The gantries<br />

were used at the location to lift, side shift <strong>and</strong> lower<strong>in</strong>g <strong>of</strong><br />

beam on pedestal as depicted <strong>in</strong> the Fig. 12 & 13. The lift<strong>in</strong>g<br />

was done with the aid <strong>of</strong> 750 mm stroke hydraulic jacks <strong>and</strong> 16<br />

m long suspenders. The side shift<strong>in</strong>g was done us<strong>in</strong>g the crab<br />

assembly <strong>and</strong> w<strong>in</strong>ches set on top <strong>of</strong> gantries. Prior to the<br />

lift<strong>in</strong>g <strong>of</strong> the beams, the bear<strong>in</strong>gs were fixed at the s<strong>of</strong>fit <strong>of</strong><br />

beams with sleeves already embedded dur<strong>in</strong>g concret<strong>in</strong>g. The<br />

surface irregularities were dealt by application <strong>of</strong> 2 mm thick<br />

epoxy over the bear<strong>in</strong>gs. The lowered beams were rested at<br />

about 20 mm above the pedestal <strong>and</strong> the recess was grouted<br />

us<strong>in</strong>g non-shr<strong>in</strong>k cement grout. Till the time the recess was<br />

grouted <strong>and</strong> end diaphragms were cast, the beams were placed<br />

on wooden sleepers <strong>and</strong> held by temporary brac<strong>in</strong>gs.<br />

On an average 5 hours cycle was comfortably achieved<br />

as shown <strong>in</strong> the Table 6. with the progress <strong>of</strong> 3 beams per day<br />

on a regular basis.<br />

TABLE 6. CYCLE TIME FOR BEAM ERECTION<br />

In the water spans, between A/R to P8 <strong>and</strong> P10 to A/L, the<br />

bed gantries <strong>and</strong> longitud<strong>in</strong>al trolleys were moved on railway<br />

track over specially constructed embankments with the<br />

provision <strong>of</strong> hume pipes at suitable <strong>in</strong>tervals for pass<strong>in</strong>g the<br />

water from u/s to d/s. However, not to constrict the water <strong>in</strong> a<br />

too narrow passage, a temporary service bridge was made on<br />

both sides <strong>of</strong> the piers to move the bed gantries between P8<br />

<strong>and</strong> P10. This temporary bridge had s<strong>in</strong>gle-l<strong>in</strong>e <strong>of</strong> pil<strong>in</strong>g on d/<br />

s side to cater for the movement <strong>of</strong> one leg <strong>of</strong> the gantry where<br />

as on upstream side two l<strong>in</strong>es <strong>of</strong> piles were provided to move<br />

longitud<strong>in</strong>al trolleys <strong>and</strong> transport other materials.

Fig. 12. Show<strong>in</strong>g the Erection scheme <strong>of</strong> Beam<br />

Fig. 13. Erection, side shift<strong>in</strong>g & placement<br />

The s<strong>in</strong>gle l<strong>in</strong>e <strong>of</strong> piles on downstream side was collapsed<br />

dur<strong>in</strong>g floods when the erection was <strong>in</strong> progress between P7 &<br />

A/L on Nakodar side. However, on Jagraon side the gantry<br />

was to be brought back to erect the beams on unf<strong>in</strong>ished span<br />

A/R-P22. Among the alternatives considered, provid<strong>in</strong>g a<br />

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB<br />

Fig. 11. Cast<strong>in</strong>g Yard Layout for <strong>Sutlej</strong><br />

155<br />

trolley on top <strong>of</strong> the deck slab <strong>and</strong> support<strong>in</strong>g half <strong>of</strong> the gentry<br />

(Fig. 14) on it proved to be safe, economical <strong>and</strong> fastest solution.<br />

This method was adopted for shift<strong>in</strong>g both the gantries across<br />

P8 & P10 <strong>in</strong> seven days time without any risk <strong>and</strong> just tak<strong>in</strong>g<br />

care by dropp<strong>in</strong>g plumbs at four locations on both sides <strong>of</strong> the<br />

gantry to check the evenness <strong>of</strong> the movement.<br />

Fig. 14. Transportation <strong>of</strong> gantry on deck<br />

9. BEARINGS<br />

POT <strong>and</strong> POT-cum-PTFE bear<strong>in</strong>gs were used <strong>in</strong> the <strong>Sutlej</strong><br />

<strong>Bridge</strong>. The typical bear<strong>in</strong>g layout adopted <strong>in</strong> the bridge is<br />

shown <strong>in</strong> the Fig. 15. Earlier, normally for the simply supported<br />

bridges up to two lanes, fixed bear<strong>in</strong>gs (rocker) with a small<br />

play provision on one end <strong>and</strong> free bear<strong>in</strong>gs (roller) <strong>in</strong> the<br />

longitud<strong>in</strong>al direction hav<strong>in</strong>g fixity <strong>in</strong> transverse direction has<br />

been successfully used for straight superstructure like <strong>Sutlej</strong><br />

bridge. This arrangement for bridges with small deck width can

156<br />

be still successfully adopted as expansion/contraction tak<strong>in</strong>g<br />

place <strong>in</strong> pier caps <strong>and</strong> diaphragms connect<strong>in</strong>g the superstructure<br />

are same. Nevertheless, to avoid the transverse restra<strong>in</strong>t likely<br />

to be caused by thermal effects <strong>and</strong> w<strong>in</strong>d force, a typical semi<br />

classical bear<strong>in</strong>g arrangement as shown <strong>in</strong> the layout was<br />

adopted <strong>in</strong> <strong>Sutlej</strong> <strong>Bridge</strong>. As could be seen from the layout,<br />

there were two types <strong>of</strong> bear<strong>in</strong>gs <strong>in</strong> span <strong>and</strong> these two types<br />

<strong>of</strong> bear<strong>in</strong>gs might have different plate sizes <strong>and</strong> bolt<strong>in</strong>g<br />

locations, depend<strong>in</strong>g upon the forces, rotations <strong>and</strong> movements.<br />

In the precast construction like <strong>Sutlej</strong> <strong>Bridge</strong>, the grooves have<br />

to be left <strong>in</strong> the beams at the bolt<strong>in</strong>g locations <strong>and</strong> as such the<br />

manufacture <strong>of</strong> the bear<strong>in</strong>gs have to be approved prior to the<br />

precast<strong>in</strong>g <strong>of</strong> beams. Normally, the approval <strong>of</strong> bear<strong>in</strong>g<br />

manufacture is a very high lead-time item, which was well<br />

synchronised <strong>in</strong> this project. At each pier location for a span,<br />

two central bear<strong>in</strong>gs were fixed which were guided<br />

longitud<strong>in</strong>ally on the other side, where as two extreme girders<br />

on either side were transversely guided while on other side left<br />

free. This semi classical layout helped <strong>in</strong> reduc<strong>in</strong>g the types <strong>of</strong><br />

bear<strong>in</strong>gs to suit the precast construction.<br />

HEGGADE, MEHTA & PRAKASH ON<br />

Fig. 15. Bear<strong>in</strong>g configuration for <strong>Sutlej</strong> bridge<br />

10. LOAD TESTING OF SUPERSTRUCTURE<br />

In l<strong>in</strong>e with the contract agreement, one <strong>of</strong> the spans was<br />

to be validated by load test<strong>in</strong>g to the designed IRC load<strong>in</strong>g,<br />

<strong>in</strong>clud<strong>in</strong>g impact factor. As shown <strong>in</strong> the Fig. 16 the IRC load<strong>in</strong>gs<br />

were simulated for the maximum moments <strong>in</strong> the midspan<br />

<strong>in</strong>clud<strong>in</strong>g cycle track load<strong>in</strong>gs. All the pedestals were<br />

progressively <strong>and</strong> simultaneously loaded by progressive<br />

<strong>in</strong>crements <strong>of</strong> 25 per cent <strong>of</strong> the test load <strong>and</strong> the deflections<br />

were recorded at the midspan <strong>of</strong> all girders <strong>and</strong> <strong>and</strong> ¼th<br />

span <strong>of</strong> the third girder from left side. The maximum load was<br />

susta<strong>in</strong>ed for 24 hours; dur<strong>in</strong>g the period deflection read<strong>in</strong>gs<br />

were taken at one-hour <strong>in</strong>terval for the susta<strong>in</strong>ed load<strong>in</strong>g. Then<br />

the unload<strong>in</strong>g was simultaneously carried out <strong>in</strong> 25 per cent<br />

decrements with the read<strong>in</strong>gs taken dur<strong>in</strong>g each decrement.<br />

The deflection read<strong>in</strong>gs <strong>of</strong> unloaded structure cont<strong>in</strong>ued at<br />

one-hour <strong>in</strong>terval for further 48 hours.<br />

For each stage <strong>of</strong> load<strong>in</strong>g <strong>and</strong> unload<strong>in</strong>g, the observations<br />

were made about the likely appearance <strong>of</strong> cracks, the l<strong>in</strong>earity<br />

<strong>of</strong> the load deflection curves or any other abnormalities <strong>in</strong> the

load deflection behaviour. It was ensured that the bear<strong>in</strong>gs are<br />

functional by measurement <strong>of</strong> rotation.<br />

The deflection measurements were done by suspension<br />

wire method at the required locations us<strong>in</strong>g dial gauges. In this<br />

method stools were embedded <strong>in</strong> firm ground <strong>and</strong> dial gauges<br />

<strong>of</strong> least count <strong>of</strong> 0.01mm were clamped to them. The sp<strong>in</strong>dles<br />

<strong>of</strong> the dial gauges were connected by a pair <strong>of</strong> adapters <strong>in</strong><br />

plumb l<strong>in</strong>e with GI wire. To elim<strong>in</strong>ate the effects <strong>of</strong> temperature,<br />

the deflection read<strong>in</strong>gs were taken at fixed tim<strong>in</strong>gs for all the<br />

operation <strong>of</strong> load<strong>in</strong>gs <strong>and</strong> unload<strong>in</strong>g.<br />

The maximum observed deflection for G3 girder at midspan<br />