TDI Transportation Guidelines - Polyurethanes - American ...

TDI Transportation Guidelines - Polyurethanes - American ...

TDI Transportation Guidelines - Polyurethanes - American ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ALLIANCE FOR THE<br />

POLYURETHANES<br />

INDUSTRY<br />

A BUSINESS UNIT OF THE AMERICAN PLASTICS COUNCIL<br />

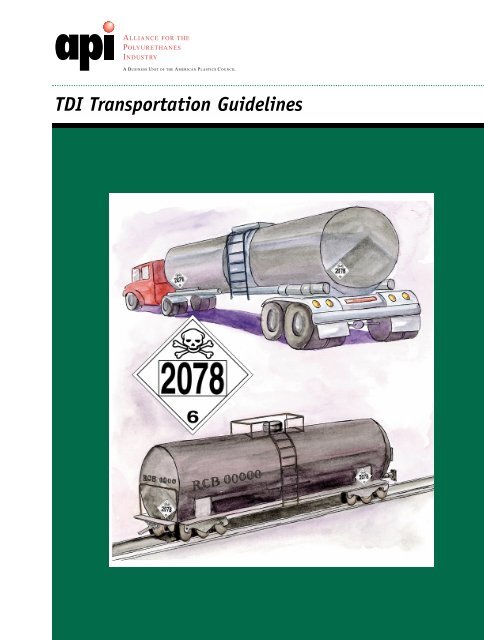

<strong>TDI</strong> <strong>Transportation</strong> <strong>Guidelines</strong>

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

c o n t e n t s<br />

Chapter 1 Introduction ..................................................................................................................1<br />

1.1 Purpose ........................................................................................................................1<br />

1.2 Safe Handling Precautions .............................................................................................1<br />

1.3 Transport and Distribution Regulations ...........................................................................1<br />

1.4 Scope ...........................................................................................................................1<br />

1.5 Exceptions ....................................................................................................................1<br />

1.6 Use of <strong>Guidelines</strong>..........................................................................................................1<br />

1.7 Transport Contracting Responsibility...............................................................................1<br />

1.8 Evaluation Application...................................................................................................2<br />

1.9 Interpretation Caveat ....................................................................................................2<br />

Chapter 2 Properties, Hazards and Safety Information for <strong>TDI</strong>...........................................................3<br />

2.1 Product Identification and Exposure Limits .....................................................................3<br />

2.2 Typical Physical Data .....................................................................................................3<br />

2.3 Reactivity Data .............................................................................................................3<br />

2.4 Health Effects — Short Term..........................................................................................4<br />

2.5 Health Effects — Long Term ..........................................................................................4<br />

2.6 First Aid Procedures ......................................................................................................5<br />

2.7 Disposal .......................................................................................................................6<br />

2.8 Recommended Formulations for Decontaminant Solutions ................................................8<br />

Chapter 3 Safety Auditing of Tank Truck Carriers and Bulk Tank Operators .........................................9<br />

3.1 Carrier’s Capability: Assessment and Control ...................................................................9<br />

3.2 Carrier Safety Audits .....................................................................................................9<br />

3.3 Carrier Safety Audit Procedure .......................................................................................9<br />

3.4 Meeting Safety and Regulatory Standards........................................................................9<br />

3.5 Scope ...........................................................................................................................9<br />

Chapter 4 Design and Construction of <strong>Transportation</strong> Equipment.....................................................11<br />

4.1 Rail Tank Cars (RTCS)...................................................................................................11<br />

4.2 Cargo Tanks (Tank Trucks) and Inter-Modal Bulk Tank Containers (ISOTainers) .................11<br />

4.3 Intermediate Bulk Containers (IBCS) ............................................................................12<br />

4.4 Drums.........................................................................................................................13<br />

Chapter 5 HAZMAT Training ..........................................................................................................17<br />

5.1 Training Requirements .................................................................................................17<br />

5.2 Specific Requirements for <strong>TDI</strong> ......................................................................................17<br />

5.3 Driver Criteria for Transporting <strong>TDI</strong>...............................................................................17<br />

5.4 Certified Drivers..........................................................................................................18<br />

Chapter 6 Personal Protective Equipment for Loading or Unloading <strong>TDI</strong> ...........................................19<br />

Chapter 7 Loading Operations ......................................................................................................21<br />

7.1 Compliance with Transport Regulations.........................................................................21<br />

7.2 CRITERIA for Loading Facilities and Transport Equipment ...............................................21<br />

7.3 Design and Construction of Transport Equipment ...........................................................21<br />

7.4 Availability of Written Operating Instructions ...............................................................21<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

iii

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

c o n t e n t s<br />

7.5 Availability of Personal Protective Equipment................................................................21<br />

7.6 Inspection of the Bulk Transport Equipment..................................................................22<br />

7.7 Inspection List: Modifications ......................................................................................24<br />

Chapter 8 Transport of <strong>TDI</strong> by Rail ................................................................................................25<br />

8.1 RESPONSIBILITIES of Rail Tank Carrier...........................................................................25<br />

8.2 Emergency Intevention ................................................................................................25<br />

8.3 Inter-Modal Movements ...............................................................................................25<br />

Chapter 9 Transport OF <strong>TDI</strong> by Road ..............................................................................................27<br />

9.1 Routing ......................................................................................................................27<br />

9.2 Safe Parking................................................................................................................27<br />

9.3 Severe Weather Conditions ...........................................................................................27<br />

9.4 Delays or Accidents .....................................................................................................28<br />

9.5 Inspections During Transport........................................................................................28<br />

Chapter 10 Transport of <strong>TDI</strong> by Water Vessel .................................................................................29<br />

10.1 Approved Containers..................................................................................................29<br />

10.2 Parties Involved ........................................................................................................29<br />

10.3 Safety Audits ............................................................................................................29<br />

Chapter 11 Unloading Operations for Tank Trucks and Rail Tank Cars...............................................31<br />

11.1 Criteria for Discharge Facilities ..................................................................................31<br />

11.2 Design, Location and Checks ......................................................................................31<br />

11.3 Criteria for Discharge Hoses .......................................................................................31<br />

11.4 Operating Procedures.................................................................................................31<br />

11.5 Protective Equipment for Operators ............................................................................31<br />

11.6 Inspection of the Bulk Reception Facilities .................................................................31<br />

Chapter 12 Required Shipping Information for <strong>TDI</strong>.........................................................................33<br />

12.1 <strong>TDI</strong>’S Hazardous Materials Classification......................................................................33<br />

12.2 Summary of <strong>TDI</strong> Hazard Information ...........................................................................34<br />

12.3 Preparedness and Emergency Response .......................................................................35<br />

12.4 Principles of Emergency Response Scheme ..................................................................35<br />

12.5 Technical Communications..........................................................................................35<br />

a p p e n d i c e s<br />

Appendix 1: Sample Certificate of Receipt ...................................................................................1-1<br />

Appendix 2: <strong>Guidelines</strong> for the Unloading of Tank Trucks (A Suggested Checklist) ..........................2-1<br />

Appendix 3: <strong>Guidelines</strong> for the Unloading of Rail Tank Cars (A Suggested Checklist) ......................3-1<br />

Appendix 4: <strong>Guidelines</strong> for Customer Bulk Storage Facilities (A Suggested Checklist) .....................4-1<br />

iv Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 1: Introduction<br />

1.1 Purpose<br />

These <strong>Guidelines</strong> have been prepared by the Alliance for the <strong>Polyurethanes</strong> Industry (API). They are intended<br />

to summarize both regulatory requirements affecting the transport and distribution of toluene diisocyanate<br />

(<strong>TDI</strong>), and relevant industry safety recommendations.<br />

1.2 Safe Handling Precautions<br />

Although <strong>TDI</strong> is a hazardous material, the hazard may be minimized if appropriate precautions are observed.<br />

Storage and handling of <strong>TDI</strong> are regulated by the United States Occupational Safety and Health<br />

Administration (OSHA). The United States Environmental Protection Agency (EPA) regulates the release,<br />

clean-up, and waste disposal of <strong>TDI</strong>, and emissions of <strong>TDI</strong> during transfer, storage, and use. Individual states<br />

may also have regulations that affect <strong>TDI</strong> transfer, storage and disposal.<br />

1.3 Transport and Distribution Regulations<br />

The transport of <strong>TDI</strong> is subject to strict regulations within the United States by the Department of<br />

<strong>Transportation</strong> (DOT). In addition, export shipments are regulated by various international organizations that<br />

establish specific transport requirements that must be observed by all parties.<br />

1.4 Scope<br />

These <strong>Guidelines</strong> take into account the transportation of <strong>TDI</strong> in bulk tank trucks, rail tank cars, intermediate<br />

bulk containers (IBCs), and drums. They cover most aspects of transport from loading to delivery point.<br />

Recommendations are denoted by the use of the word “should;” regulatory requirements are indicated by<br />

use of the word “must.”<br />

1.5 Exceptions<br />

These <strong>Guidelines</strong> do not deal with bulk movement of <strong>TDI</strong> in ocean chemical tankers or inland waterway barges.<br />

1.6 Use of <strong>Guidelines</strong><br />

It is API’s goal to promote the safe transportation and distribution of <strong>TDI</strong>. API encourages the use of these<br />

<strong>Guidelines</strong> as a means of achieving this goal.<br />

1.7 Transport Contracting Responsibility<br />

When offering <strong>TDI</strong> for distribution, companies should arrange transport with reputable, experienced carriers,<br />

to facilitate the safe transport.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

1

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

1.8 Evaluation Application<br />

It is the individual responsibility of users of these <strong>Guidelines</strong> to evaluate and apply them, taking into account<br />

all specific circumstances of their own situation.<br />

1.9 Interpretation Caveat<br />

No part of these <strong>Guidelines</strong> may be interpreted in a way that would conflict with existing international and/or<br />

national legislation. Standards may change, and legal provisions always have precedence over any part of<br />

these <strong>Guidelines</strong>. Consult with appropriate legal experts to verify applicable requirements.<br />

2 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 2: Properties, Hazards and Safety Information for <strong>TDI</strong><br />

2.1 Product Identification and Exposure Limits<br />

1 Permissible Exposure Limit<br />

2 Threshold Limit Value (TLV is a registered trademark of ACGIH)<br />

3 Time Weighted Average (8 hr. TWA)<br />

4 Short Term Exposure Limit (15 min. STEL)<br />

5 Intended Change by ACGIH<br />

2.2 Typical Physical Data<br />

2.3 Reactivity Data<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

CAS No. OSHA PEL 1 ACGIH TLV 2<br />

Toluene-2,4-diisocyanate 5 584-84-9 0.020 ppm (as ceiling) 0.005ppm (TWA 3 ), 0.020ppm (STEL 4 ), sensitizer<br />

Toluene-2,6-diisocyanate 5 91-08-7 0.005ppm (TWA 3 ), 0.020ppm (STEL 4 ), sensitizer<br />

Toluene-2,4/2,6-diisocyanate unspecified isomers 26471-62-5<br />

Appearance liquid<br />

Boiling point about 250°C (482°F)<br />

Color colorless to pale yellow<br />

Density (pounds/gallon) 10.2<br />

Freezing point: 2,4 <strong>TDI</strong> 22°C (72°F)<br />

Freezing Point: 2,4/2,6 <strong>TDI</strong> (80:20 mixture) 14°C (53.6°F)<br />

Odor sharp, pungent<br />

Odor Threshold 0.2-0.4 ppm<br />

Solubility in water not soluble; reacts with the evolution of CO2<br />

Specific gravity 1.22 (77°/77°F)<br />

Vapor density 6(air=1)<br />

Vapor pressure 0.016 mm Hg @ 20°C<br />

Viscosity 3.0(mPa,cps) @ 20°C (68°F)<br />

Flash Point 135°C (295°F)<br />

Auto-ignition >600°C<br />

Explosion limits — Lower 0.9% v/v (118°C)<br />

Explosion limits — Upper 9.5% v/v 302°F (150°C)<br />

Thermal degradation >250°C<br />

Hazardous degradation products CO, CO2, NOx, HCN<br />

Materials to avoid water, alcohols, amines, acids, bases<br />

3

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

2.4 Health Effects - Short Term<br />

Typically, there are four routes of potential exposure: inhalation, skin contact, eye contact and ingestion.<br />

Inhalation<br />

Inhalation of <strong>TDI</strong> vapors may cause irritation of the mucous membranes of the nose, throat or trachea,<br />

breathlessness, chest discomfort, difficult breathing and reduced pulmonary function. It is important to avoid<br />

exposure above the TLV to minimize the possibility of respiratory sensitization.<br />

Tests have shown that the least detectable odor level of <strong>TDI</strong> is approximately 0.2-0.4ppm. This odor<br />

threshold is significantly higher than the OSHA Permissible Exposure Limit (PEL) of 0.02 ceiling. If an<br />

individual can smell <strong>TDI</strong>, overexposure has most likely occurred.<br />

Airborne overexposure, well above the PEL, may result additionally in eye irritation, headache, chemical<br />

bronchitis, asthma-like findings, or pulmonary edema. <strong>TDI</strong> has also been reported to cause hypersensitivity<br />

pneumonitis, which is characterized by flu-like symptoms, the onset of which may be delayed.<br />

Skin Contact<br />

Skin contact may discolor the skin or cause redness, swelling, blistering and burns. <strong>TDI</strong> is categorized by<br />

DOT as a moderate irritant based on a rabbit skin test. Also, skin contact may cause an allergic contact<br />

dermatitis and may play a role in respiratory sensitization.<br />

Eye Contact<br />

Eye contact with <strong>TDI</strong> may result in conjunctival irritation and corneal opacity.<br />

Ingestion<br />

Ingestion is not a normal industrial route of entry unless contaminated food or tobacco products are<br />

inadvertently ingested. Good hygiene practices do not allow food or tobacco products to be consumed<br />

during the use of <strong>TDI</strong>. If <strong>TDI</strong> is ingested, severe irritation of the mucous membrane of the mouth, esophagus<br />

and stomach may occur.<br />

2.5 Health Effects - Long Term<br />

Inhalation<br />

Control of <strong>TDI</strong> exposure to the recommended guidelines (0.005 ppm as Time-Weighted Average, 0.020 ppm<br />

as Short Term Exposure Limit) is believed to protect against sensitization. However, if an individual has<br />

become sensitized to <strong>TDI</strong>, an asthma-like response may then result from very low exposures to <strong>TDI</strong> (See<br />

Medical Surveillance section.)<br />

Animal inhalation toxicology studies demonstrate that <strong>TDI</strong> is irritating to the respiratory tract at<br />

concentrations substantially greater than the exposure guideline. A teratology study in rats showed minimal<br />

fetal and maternal toxicity at 0.5 ppm, with no effects at 0.1 ppm. There were no teratogenic effects<br />

(malformations) even at the highest exposure tested (0.5 ppm). (1) <strong>TDI</strong> caused no reproductive toxicity at the<br />

highest concentration tested in a rat study (0.3 ppm). (2)<br />

(1) Tyl et al., (1999). Toxicol Sci. 52(2):248-57.<br />

(2) Tyl et al., (1999). Toxicol Sci. 52(2):258-68.<br />

4 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Carcinogenicity<br />

Long-term inhalation studies (i.e., rat, and mouse) reveal no indications of carcinogenic potential; (3)<br />

intragastric intubation of high and toxic doses of <strong>TDI</strong> in corn oil led to increased incidents of tumors. (4) Based<br />

on the oral study, the U.S. National Toxicology Program considers <strong>TDI</strong> to be an anticipated human<br />

carcinogen. IARC lists <strong>TDI</strong> as group 2B (possibly carcinogenic to humans). Industrial experience in humans<br />

has not shown any link between <strong>TDI</strong> exposure and cancer development. The inhalation studies in animals are<br />

more relevant and therefore are probably a more reliable indicator of effects in humans.<br />

Medical Surveillance<br />

Post-offer, pre-placement examinations and periodic medical surveillance of employees are essential<br />

elements in any program designed to ensure the health and safety of those who work with <strong>TDI</strong>. The postoffer,<br />

pre-placement examination should include a respiratory health history, a clinical examination, and a<br />

baseline pulmonary function testing. Where appropriate, regular medical check-ups (including spirometry)<br />

may aid in the early detection of any respiratory related effects. Individuals with respiratory problems, such<br />

as asthma or chronic lung disease, may be susceptible to having respiratory problems when exposed to <strong>TDI</strong>.<br />

Individual assessments should be made to determine whether an individual can perform his or her job<br />

without threatening the health or safety of that individual or others.<br />

Exposure control to prevent sensitization, and medical surveillance to detect sensitization as early as<br />

possible are believed to be the most important aspects of <strong>TDI</strong> safe handling.<br />

2.6 First Aid Procedures<br />

All employees working in areas where contact with <strong>TDI</strong> is possible should be thoroughly trained in the<br />

administration of appropriate first aid procedures. Experience has demonstrated that prompt administration<br />

of such aid can be important in minimizing the possible adverse effects of accidental exposure.<br />

Inhalation<br />

Promptly move the affected person away from the contaminated area to fresh air. Keep the affected person<br />

calm and warm, but not hot. If breathing is difficult, oxygen may be administered by a qualified person. If<br />

breathing stops, a qualified individual give artificial respiration and seek medical attention immediately.<br />

Skin Contact<br />

In the event of skin contact, wash thoroughly with soap and flowing water for at least fifteen minutes (A<br />

recent study has indicated that corn oil or polyglycol-based cleaners may remove MDI more effectively than<br />

soap and water, and this may also apply to <strong>TDI</strong>. (5) Cleaning soon after contamination was also important.).<br />

Promptly remove all contaminated clothing (including shoes) while washing. If the skin is burned or irritated,<br />

seek medical attention. Decontaminate clothing prior to re-use by soaking the garments in an 8 percent<br />

ammonia solution for one hour prior to laundering with hot water and detergent. Destroy all contaminated<br />

leather items including shoes, belts, and watchbands.<br />

(3) Loeser, E. (1983), Toxicology Letters 15:71-81.<br />

(4) National Toxicology Program (1986) Toxicology and Carcinogenesis Studies of Commercial Grade 2,4 (80%)-and 2,6 (20%)-Toluene<br />

diisocyanate (CAS No. 26417-62-5) in “F 344/N Rats and B6C3F1 Mice (Gavage Studies),” NTP Technical Report Series No. 251.<br />

(5) Wester et al. (1999). Toxicol Sci. 1999 Mar;48(1):1-4.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

5

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Eye Contact<br />

If liquid <strong>TDI</strong> comes in contact with the eyes, irrigate immediately and continuously with low-pressure flowing<br />

water, preferably from an eyewash fountain, remove contact lenses, if present, and continue eye irrigation for<br />

at least fifteen minutes. Seek medical attention at once.<br />

Ingestion<br />

Do not induce vomiting! In the event <strong>TDI</strong> is ingested, have the affected person drink large amounts (i.e., 2-3<br />

glasses) of water or milk. Immediately transport to a medical facility and inform medical personnel about the<br />

nature and extent of the exposure.<br />

Note to Physician: There is no specific antidote for <strong>TDI</strong>. Care should be supportive and treatment based<br />

on the judgment of the physician in response to the reaction of the patient. Post-incident checks are needed.<br />

2.7 Disposal<br />

Disposal of Waste <strong>TDI</strong><br />

Waste Toluene Diisocyanate (<strong>TDI</strong>) is listed as a hazardous waste (U - 223) under 40 CFR § 261.33(f) of EPA’s<br />

Resource Conservation and Recovery Act (RCRA) regulations and requires special handling for disposal.<br />

However, the easiest and most convenient way to handle excess <strong>TDI</strong> is to react it with polyol to produce a<br />

low-quality foam, which then can be sold or used as a manufactured product. (CAUTION: The <strong>TDI</strong>/polyol<br />

reaction is exothermic, which may cause spontaneous combustion.)<br />

Note: Generators may treat <strong>TDI</strong> “on site” as long as treatment occurs in tanks and containers which meet<br />

the accumulation provisions in 40 CFR § 262.34 as well as the unit standards in subparts I and J of § 262.5.<br />

Thermal treatment such as detonation or open burning, however, are precluded from the exemption.<br />

Another way to dispose of waste <strong>TDI</strong> is to react the material with a liquid decontaminant. The waste <strong>TDI</strong><br />

should be added slowly or in increments, under mechanical stirring, to the decontaminant, which should be<br />

contained in an open-top drum. (Note: Be sure this process is conducted in a well ventilated area or<br />

outdoors.) Allow the reacted material to stand for 48 hours. Decant the liquid and dispose of both the liquid<br />

and solid materials as hazardous wastes — that is, in full compliance with all applicable federal, state, and<br />

local laws and regulations.<br />

Disposal of Empty Containers<br />

Briefly, there are three options available for disposing of steel drums which last contained <strong>TDI</strong>. Disposal must<br />

be in compliance with all applicable federal, state, and local laws and regulations.<br />

Steel drums may be sent to:<br />

• a drum reconditioner for reuse,<br />

• a scrap metal dealer; or,<br />

• an approved landfill.<br />

6 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Regardless of the procedure used, however, all drums should be empty (as defined by RCRA, 40 CFR<br />

§ 261.7) before they leave the <strong>TDI</strong> user’s facility. (6) (Note: Drums to be sent to a reconditioner may also need<br />

to be decontaminated. However, since reconditioners use a variety of different techniques to clean drums<br />

and to prepare them for reuse, the <strong>TDI</strong> user should consult with the reconditioner before using any drum<br />

decontamination procedure.)<br />

Drums destined for a scrap dealer, an incinerator, or a landfill should be decontaminated, then punctured or<br />

crushed to prevent reuse. (Note: Empty <strong>TDI</strong> drums can be decontaminated by filling them with water or a<br />

decontamination solution (5-10% sodium carbonate) and allowing them to stand unsealed for at least 48<br />

hours. Used decontamination solution and rinse water should be disposed of as hazardous wastes in strict<br />

accordance with all applicable federal, state, and local laws and regulations.)<br />

CAUTION: Remember, <strong>TDI</strong> is listed as a hazardous waste under Section 261.33(f) of EPA’s RCRA regulations<br />

and requires special handling for disposal. Additionally, shipments of RCRA empty drums are subject to DOT<br />

hazardous material regulations unless the container is completely cleaned and purged of the material so that<br />

no hazard exists. See 49 CFR § 173.29.<br />

Compliance with RCRA’s one-inch residue rule is not sufficient to meet DOT’s standard of “cleaned and<br />

purged.” If the container must be shipped with residue, then under DOT regulations, all labeling, marking,<br />

packaging, and shipping paper requirements and placarding must be followed.<br />

WARNING: Under no circumstances should empty drums be burned or cut open with a gas or electric torch, as toxic<br />

decomposition products may be liberated.<br />

(6) According to RCRA, 40 CFR § 261.7, an empty container is on that is “drip dry” - i.e., one that has been emptied of all materials which<br />

can be removed using the practices commonly employed to remove materials from that type of container; e.g., pouring, pumping, or<br />

aspirating. (Note that the “one inch” residue rule for determining whether a drum is empty applies only to nonflowable products, such<br />

as very viscous resins.) Drums which have contained an acutely hazardous waste must be triple rinsed.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

7

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

2.8 Recommended Formulations for Decontaminant Solutions<br />

Formulation 1 Weight or Volume %<br />

Water 90-95<br />

Concentrated ammonia 1 solution 3-8<br />

Liquid detergent 0.2-2<br />

Formulation 2 Weight or Volume %<br />

Water 90-95<br />

Sodium carbonate 5-10<br />

Liquid detergent 0.2-2<br />

For routine operations, for example, decontamination of protective equipment, tools and parts of machines, the following formulation<br />

is more effective. The solution is flammable and should be handled accordingly.<br />

Formulation 3 Weight or Volume %<br />

An alcohol (ethanol, isopropanol or butanol) 50<br />

Water 45<br />

Concentrated ammonia1 solution 5<br />

Formulation 4 Weight or Volume %<br />

Water 75<br />

Non-ionic surfactant 20<br />

n-propanol 5<br />

* Care should be taken when handling ammonia because it is a hazardous material.<br />

8 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 3: Safety Auditing of Tank Truck Carriers and Bulk Tank Operators<br />

3.1 Carrier’s Capability: Assessment and Control<br />

All <strong>TDI</strong> manufacturers should use the services of professional tank truck carriers for distributing their<br />

products. Manufacturers should be sure that the carriers employed are competent and operate to<br />

appropriate safety standards. Manufacturers should be aware that carriers sometimes will subcontract with<br />

another carrier. To ensure that a shipper is aware of any such arrangements, a shipper may include a<br />

provision in its motor carrier contract requiring the shipper’s consent to any subcontract, and establishing<br />

appropriate safety criteria.<br />

3.2 Carrier Safety Audits<br />

All shippers involved in transporting <strong>TDI</strong> should undertake safety audits of their tank truck carriers and bulk<br />

tank operations periodically. This will enable each shipper to verify that the motor carriers comply with<br />

applicable environmental and safety regulations and adhere to general industry safety standards. To protect<br />

against liability in the event of an accident, shippers should consider seeking an indemnity provision in the<br />

contract. This would indicate that they are to be indemnified by the carrier in the event the shipper is sued<br />

because of the carrier’s failure to comply with applicable regulations or general industry safety standards or<br />

guidelines.<br />

3.3 Carrier Safety Audit Procedure<br />

A carrier safety audit protocol and procedure has been produced by the <strong>American</strong> Chemistry Council to be<br />

utilized as a guideline in conducting safety evaluations of the carrier. This guideline may provide useful<br />

information that may be the basis of a carrier audit for those engaged in the transport of <strong>TDI</strong>.<br />

3.4 Meeting Safety and Regulatory Standards<br />

Auditing does not replace or diminish the basic responsibility of the carrier to ensure that his distribution<br />

practices meet the appropriate safety, health, and other regulatory standards and potentially hazardous<br />

substances are properly maintained as required by the various federal, state and local regulatory statutes and<br />

regulations.<br />

3.5 Scope<br />

While this section deals with bulk transportation, similar care is required in selecting competent carriers to<br />

transport intermediate bulk and non-bulk packaging. <strong>TDI</strong> suppliers may wish to consult the <strong>American</strong><br />

Chemistry Council Carrier Safety Assessment and Audit Protocol procedures for this purpose.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

9

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

10 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 4: Design and Construction of <strong>Transportation</strong> Equipment<br />

4.1 Rail Tank Cars (RTCs)<br />

Rail tank cars used for the transportation of <strong>TDI</strong> must meet the US Department of <strong>Transportation</strong>’s design<br />

and construction requirements for the transportation of hazardous materials. These requirements are found in<br />

49 CFR Part 179. The various sub-parts of Part 179 describe the requirements for construction material,<br />

welding, wall thickness, gaskets, valves, valve protection, and venting devices.<br />

Specific additional recommendations are as follows:<br />

• All fittings on rail tank cars should be clearly labeled.<br />

• Tanks should be thermally insulated to minimize temperature fluctuations and to provide extra protection<br />

in the event of fire or other accident.<br />

• Heating coils should be located on the exterior of the tank.<br />

• Tanks may be constructed of mild steel. The tanks may be internally lined.<br />

• Tanks should be fitted with 2-inch connections for vapor return lines.<br />

• Although the DOT’s Hazardous Materials Regulations permit bottom outlets, diisocyanate producers<br />

recommend only top unloading outlets.<br />

• Pressure relief valves should be present and should be set to 75% of the pressure rating of the tank car.<br />

• If present, vacuum relief valves should be utilized to prevent negative internal pressure and should be set<br />

at 1 psig.<br />

• External fittings should have rollover or crash protection so that the tank car will not leak when involved<br />

in an accident.<br />

• Thermowells for temperature measuring devices should be present and have the appropriate relief<br />

devices to prevent spraying of product in the event of a malfunction of the thermowell.<br />

• Fittings should be available for pressurizing the car with dry nitrogen or dry air to assist in unloading or<br />

to apply a blanket to prevent moisture ingress.<br />

• <strong>TDI</strong> should not come in contact with aluminum, brass, copper, zinc, or their alloys due to corrosion (loss<br />

of integrity).<br />

4.2 Cargo Tanks (Tank Trucks) and Inter-modal Bulk Tank Containers (ISOTainers)<br />

Cargo Tanks and ISOTainers used for the transport of <strong>TDI</strong> must meet the design and construction requirements<br />

of the US DOT. In addition, Cargo Tanks and ISOTainers should be designed and constructed in accordance<br />

with the following recommendations:<br />

• When <strong>TDI</strong> is shipped in a DOT specification container permitted by 49 CFR Part 173, it must conform to<br />

the applicable design specifications under Part 178.<br />

• Each tank must be fitted with a pressure relief device as prescribed in the appropriate section of the<br />

DOT’s regulations.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

11

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

• Each tank should be fitted with vacuum relief devices as prescribed in the appropriate section of DOT’s<br />

regulations.<br />

• Loading outlets must be equipped with valves and unloading outlets should terminate in a 2-inch<br />

diameter male quick connect fitting with proper closure cap.<br />

• The vapor return valves should be 2-inch diameter and terminate in a quick connect fitting with proper<br />

closure cap or plug.<br />

• The air-line valve should be 3/4-inch and terminate in a Chicago coupling with proper closure cap or plug.<br />

• It is very important to prevent atmospheric moisture from entering the tank during off-loading. Dry<br />

nitrogen is preferred for pressure off-loading. When dry nitrogen is not available, a tank may be<br />

pressurized using air from the tractor compressor or other source, provided it moves through a desiccant<br />

dryer at the proper CFM prior to entering the tank. The desiccant drier must be capable of drying the air<br />

to a dew point of -40°F. All customer-supplied air or nitrogen should be routed through the carrier’s<br />

desiccant dryer.<br />

• Heating systems, when used, should be external and equipped with a temperature-control device<br />

(manual or electronic).<br />

• Off-loading hoses should be 2-inch diameter, color-coded red, and stamped “For Diisocyanate Use<br />

Only.” Materials of construction should be suitable for diisocyanates. The hoses should be clean, dry<br />

and capped when not in use. Pressure testing is recommended prior to their first use and at least<br />

quarterly thereafter.<br />

4.3 Intermediate Bulk Containers (IBCs)<br />

Intermediate Bulk Containers may be used for the transportation of <strong>TDI</strong> by road, rail, sea, or inland waterway. If<br />

used, they must meet the DOT and IMDG design and construction requirements for the particular transport modes.<br />

DOT 51 is an approved portable tank for <strong>TDI</strong>. DOT 56 and 57 portable tanks manufactured after September<br />

30, 1996 can not be used. DOT 56 and 57 portable tanks manufactured prior to October 1, 1996 may<br />

continue in hazardous materials service for the commodities currently authorized as long as they meet the<br />

retest requirements in paragraph (e) of Section 173.32. These requirements are as follows:<br />

a. DOT 52, 53, 56 and 57 portable tanks are required to be retested every 2.5 years.<br />

b. DOT 51 portable tanks must be retested every 5 years.<br />

c. Dual marked portable tanks certified to both pre-October 1, 1996 DOT 56 or 57 specifications and the<br />

metal IBC standards must conform to the pre-October 1, 1996 retest requirements and the metal retest<br />

and inspection requirements adopted in the IBC final rule.<br />

In addition to the above requirements, IBCs should comply with the following suggestions:<br />

4.3.1 Filling Standards<br />

Before being filled and offered for transportation, each IBC and its service equipment must be visually<br />

inspected to ensure that it is free from any damage that would render it unsafe for transport. 49 CFR<br />

§ 173.35(b).<br />

12 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

When filling an IBC with liquids, sufficient ullage must be left to ensure that, at the mean bulk temperature<br />

of 50° C (122° F), the IBC is not filled to more than 98% of its water capacity. 49 CFR § 173.35(d).<br />

4.3.2 Construction and Performance Standards<br />

Section 178.705 specifies the construction requirements for authorized metal IBCs. Additionally,<br />

these containers must satisfy the following performance tests, which are detailed under sections<br />

178.810-815 and 178.819:<br />

• Vibration;<br />

• Bottom lift and/or top lift (depending on how the container is intended to be handled);<br />

• Stacking;<br />

• Leakproofness (liquids only);<br />

• Hydrostatic (liquids only); and,<br />

• Drop Tests.<br />

Each new container must be visually inspected and be leakproofness tested (if containing liquids)<br />

every 2.5 years from the date of manufacture. 49 CFR § 180.352.<br />

4.3.3 Recordkeeping<br />

The IBC owner or lessee must keep records of periodic retests and initial and periodic inspections.<br />

Records must include:<br />

• Design types and packaging specifications,<br />

• Test and inspection dates,<br />

• Names of tests and the names and addresses of test and inspection facilities,<br />

• Names of persons conducting tests or inspections, and;<br />

• Test or inspection specifics and results.<br />

Records must be kept for each packaging at each location where periodic tests are conducted. These<br />

records must be kept until such tests are successfully performed again, or for 2.5 years from the date<br />

of the last test.<br />

4.4 Drums<br />

<strong>TDI</strong> is classified as a hazardous material by the DOT. If <strong>TDI</strong> is shipped in drums, the drums must comply with<br />

the relevant modal transport regulations for road (49 CFR), rail (49 CFR), air (49 CFR or ICAO/IATA), sea<br />

(IMDG) or inland waterway (33 CFR). Drums must be constructed in conformance with the standards<br />

applicable for the particular material of construction. See 49 CFR §§ 178.504-509.<br />

Additionally, drums must meet the performance tests prescribed in the regulations. See 49 CFR §§ 178.600-<br />

178.608. These regulations also include a requirement that the drums bear certification marks indicating<br />

compliance with the UN performance oriented packaging standards to the appropriate product density and<br />

hazard level. 49 CFR § 178.503.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

13

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Drum material, including any fitting, must be compatible with the product. 49 CFR § 173.24(e) Drums must<br />

be inspected for integrity, tightness, dryness, cleanliness and lack of rust or foreign particles before filling.<br />

See 49 CFR § 173.22(a)(2). Additionally, all disocyanate producers agree that open head type drums should not<br />

be used for <strong>TDI</strong> due to the potential for leakage and/or contamination.<br />

4.4.1 Drum Specifications<br />

Drums used for the shipment of <strong>TDI</strong> must satisfy the specifications provided for in 49 CFR § 178.504-<br />

.506 & .508-.509. Additionally the drums must satisfy the performance tests indicated in 49 CFR<br />

§ 178.600-.608. <strong>TDI</strong> manufacturers do not recommend use of open-top drums for <strong>TDI</strong> or other<br />

materials containing <strong>TDI</strong>.<br />

4.4.2 Drum Handling<br />

Personal Protective Equipment<br />

Persons handling drums should have the proper personal protective equipment.<br />

Transporting Drums<br />

Drums should be transported by lifting, to avoid damage caused by sliding or rolling. Only<br />

equipment designed for handling drums should be used, such as fork-lift trucks equipped with<br />

“parrot beaks” or drum clamps. (CAUTION: Drum clamps should not be used on the Euro “W” style<br />

drum now used by many diisocyanate suppliers) Once loaded/unloaded, the responsible party should<br />

examine the drums to check for damage or leaks. If any drums are found to be leaking, the<br />

procedures for spill response should be followed.<br />

Emptying Drums<br />

Drums may be gravity discharged or emptied using a standard immersion pump. Air displaced from<br />

the receiving tank should be properly treated to ensure that <strong>TDI</strong> vapors are not released into the<br />

atmosphere. The drum should be vented to prevent collapse when pumping out material, or to<br />

facilitate flow when gravity feeding material. A small canister of silica gel (desiccant) should be<br />

installed in the drum’s vent opening to prevent atmospheric moisture from entering the drum as<br />

liquid is transferred out. The opening of drums should be minimized to reduce moisture<br />

contamination. Do not use pressure to unload drums.<br />

Caution: Contamination Problems<br />

Water contamination of drums should be avoided. <strong>TDI</strong> reacts with water to generate CO2 gas, which<br />

can cause a potentially dangerous pressure build-up in the container. This reaction is accelerated at<br />

high temperatures (120°F). Drums showing evidence of pressure build-up should be vented<br />

immediately with caution; otherwise, there is a potential for a violent drum rupture.<br />

14 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 5: HazMat Training<br />

5.1 Training Requirements<br />

Under 49 CFR §§ 172.700-704, all employees handling hazardous materials, including drivers, must be<br />

trained in each of the following areas:<br />

• General Awareness<br />

• Function Specific<br />

• Safety<br />

DOT requires that all persons involved in the preparation of hazardous materials for transport be trained in<br />

accordance with the hazardous materials regulations within 90 days of employment or a change in job<br />

function. Prior to training, an employee must be directly supervised by a trained individual. Refresher training<br />

every 3 years is required for all employees handling hazardous materials. Further, employees should be<br />

advised of changes in the law that occur during that time that affect their job performance.<br />

Records must be maintained on all personnel who receive DOT training, both supervisory and non-supervisory<br />

personnel. Each employee must have his or her own training log (the formal record) inclusive of the preceding three<br />

years. The employer must retain the training log for as long as that employee is employed and for 90 days thereafter.<br />

5.2 Specific Requirements for <strong>TDI</strong><br />

Because <strong>TDI</strong> is a DOT-regulated hazardous material, drivers must be specifically trained to understand the<br />

particular nature of the dangers that may arise during the transport of this material and how to handle an<br />

emergency. A guideline for drivers is contained in Appendix 2. Under DOT’s regulations, an employer whose<br />

employees are involved in handling hazardous materials is responsible for ensuring that they are properly<br />

trained. See 49 CFR §§ 172.700-704. This means that both shippers and carriers are independently<br />

responsible for ensuring compliance with the training requirements.<br />

5.3 Driver Criteria for Transporting <strong>TDI</strong><br />

Before a driver is allowed to transport a hazardous material like <strong>TDI</strong>, he must have:<br />

• Received training to the standard required by Federal, State and local regulation and obtained a<br />

Commercial Drivers License (CDL) and a Hazardous Materials endorsement on his/her license as<br />

required by 49 CFR §§ 383.71-383.155.<br />

• Received <strong>TDI</strong> specific training as part of his required function-specific training.<br />

5.4 Certified Drivers<br />

Before a shipper enlists a carrier he should:<br />

• Ensure that the carrier can document that all drivers transporting <strong>TDI</strong> have been trained in accordance<br />

with DOT’s regulations.<br />

• Include training as an item to be addressed in the carrier audit program mentioned in Sections 3.2 to 3.5.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

15

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

16 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 6: Personal Protective Equipment for Loading or Unloading <strong>TDI</strong><br />

When transferring <strong>TDI</strong>, personal protective equipment should be worn by employees and/or drivers engaged<br />

in these activities if the possibility of exposure exists. This may, depending upon conditions (i.e. <strong>TDI</strong> vapor<br />

exposure), consist of:<br />

• Self contained breathing apparatus or airline system with full face piece, operated in a pressure demand<br />

or positive mode, or an air-purifying respirator with an appropriate cartridge change-out schedule;<br />

• Chemical gloves, impervious to <strong>TDI</strong> (butyl rubber, nitrile rubber, PVA);*<br />

• Full body protection, impervious to <strong>TDI</strong>;*<br />

• Fitted boots made of material(s) impervious to <strong>TDI</strong>,* and;<br />

• Head protection, such as a close fitting hood, made of a material impervious to <strong>TDI</strong>.*<br />

Taking samples for quality control analysis during off-loading is not recommended because of the potential<br />

for exposure.<br />

The use of suitable respiratory equipment is required whenever there is a potential for exposure to airborne<br />

<strong>TDI</strong> levels in excess of permissible exposure limits (PEL 0.02ppm-ceiling, TLV 0.005ppm - 8hour TWA).<br />

For additional information on Personal Protective Equipment (PPE) refer to the manufacturer’s Material Safety<br />

Data Sheet.<br />

• See API Technical Bulletin - <strong>TDI</strong> User <strong>Guidelines</strong> for Chemical Protective Clothing Selection (AX-179) for protective glove/clothing<br />

permeation data.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

17

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

18 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 7: Loading Operations<br />

7.1 Compliance With Transport Regulations<br />

The shipper and the carrier should work together to ensure compliance with transport regulations.<br />

7.2 Criteria for Loading Facilities and Transport Equipment<br />

The act of filling any container with a hazardous material is potentially dangerous. It is therefore important<br />

that loading facilities and transport equipment be correctly designed and constructed, as well as properly<br />

used and well maintained.<br />

7.3 Design and Construction of Transport Equipment<br />

The design and construction of transport equipment is described in Section 4 of these <strong>Guidelines</strong>. Equipment<br />

used in the transportation of <strong>TDI</strong> is subject to periodic inspection and testing requirements by the carrier as<br />

specified in DOT’s regulations.<br />

7.4 Availability of Written Operating Instructions<br />

Written operating instructions should be made available covering the loading of <strong>TDI</strong> into bulk tank trucks,<br />

inter-modal tanks and containers, rail tank cars, multi-unit tank car tanks, intermediate bulk containers, and<br />

non-bulk packaging. Additionally, persons involved in shipping <strong>TDI</strong> must be fully trained in accordance with<br />

DOT’s hazardous materials regulations. Information regarding the specific hazards of <strong>TDI</strong> must be<br />

communicated to all individuals involved in the loading/unloading or transportation of <strong>TDI</strong>. 49 CFR § 172.600.<br />

Additionally, such persons must be trained in the proper procedures for the operation of the filling equipment<br />

in both normal operations and in any emergency situations (see Section 11.3 for further relevant details).<br />

Drivers also must be familiar with safety procedures, including the use of safety equipment at the loading<br />

point. See 49 CFR § 172.704(a)(3).<br />

7.5 Availability of Personal Protective Equipment<br />

Appropriate personal protective equipment must be available for loading operations and persons must be<br />

trained in the correct use of this equipment. See 29 CFR § 1910.132. Whenever the driver leaves his vehicle,<br />

he should take with him the appropriate personal protective equipment to ensure its availability in the event<br />

of an emergency. See Chapter 6.<br />

7.6 Inspection of the Bulk Transport Equipment<br />

These <strong>Guidelines</strong> do not attempt to set detailed operating instructions for filling <strong>TDI</strong> containers since these,<br />

of necessity, will depend upon local operating conditions. However, the operating instructions should specify<br />

that loading personnel inspect the bulk transport equipment before and after loading and that loading<br />

personnel attend the transfer process. This inspection does not replace or diminish the responsibility of the<br />

operator of bulk transport equipment to ensure that it is properly tested, maintained, fit for its intended<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

19

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

purpose and ready for loading. It is meant to ensure that the loading and unloading of <strong>TDI</strong> is conducted as<br />

safely as possible. The inspection list detailed in Appendix 6 is a guideline that loaders may use to check the<br />

condition of the bulk transport equipment before and after all filling operations. Individual companies should<br />

develop their own detailed operating instructions that include inspection procedures.<br />

7.6.1 Routine Inspection of Tank Trucks and IMO Containers at Loading<br />

Terminals<br />

Administrative procedures<br />

The shipper should verify that:<br />

1. The driver has a valid CDL certificate for the transport of hazardous materials.<br />

2. The driver has received <strong>TDI</strong>-specific training.<br />

3. The trailer/container capacity is adequate for the quantity to be loaded and, when loaded, the<br />

total gross weight is within regulatory limits.<br />

Before loading<br />

The carrier should have a comprehensive pre-loading procedure that includes, as a minimum,<br />

verification that:<br />

1. The unit is in compliance with all DOT required inspections, including:<br />

• DOT standard equipment; and,<br />

• Air-dryer, insulation, heating device, temperature gauge, safety relief valves (pressure and<br />

vacuum), vapor return connection, air valve and sampling valve, if required.<br />

2. All the valves, domes and manways are closed upon arrival.<br />

3. The correct caps or blind flanges have been fitted with all the necessary bolts and gaskets.<br />

4. The vehicle has all the necessary equipment in good working order.<br />

5. The person in charge of the operation has been notified of the quantity to be loaded.<br />

During loading<br />

1. Continuous monitoring of the loading operation is required.<br />

2. Ensure that the required filling levels are not exceeded.<br />

After loading<br />

The shipper and the driver should verify that:<br />

1. The maximum permitted gross weight for the vehicle and container has not been exceeded.<br />

2. All valves have been closed and blind flanges, caps, plugs, and domes have been properly secured.<br />

3. The exterior of the tank is clean and free from product residue.<br />

4. Proper toxic placards and U.N. identification numbers for <strong>TDI</strong> (UN-2078) are attached.<br />

5. The tank truck is equipped with all hoses and fittings required for unloading.<br />

20 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

7.6.2 Routine Inspection of Rail Tank Cars (RTCs)<br />

Administrative Procedures<br />

The shipper should verify that:<br />

1. The Rail Tank Car is DOT approved and authorized for <strong>TDI</strong> transport.<br />

2. The safety valve and tank test dates are current.<br />

3. The carrier has been provided with the appropriate shipping documentation and emergency<br />

response information.<br />

Before loading<br />

The shipper should have a comprehensive pre-loading procedure that includes, as a minimum,<br />

verification of the following:<br />

1. The Rail Tank Car is in good physical condition and is safe to transport <strong>TDI</strong>.<br />

2. All the valves and the manway are properly secured.<br />

3. The Rail Tank Car capacity is adequate for the quantity to be loaded.<br />

4. All valves function correctly and have passed a pressure test.<br />

During loading<br />

The shipper and/or carrier shall do the following:<br />

1. Monitor the loading operation continuously. (49 CFR § 174.67).<br />

2. Ensure that the required filling level is not exceeded.<br />

After loading<br />

The shipper should have a comprehensive post-loading audit procedure that includes, as a minimum,<br />

verification that:<br />

1. The car’s gross weight has not been exceeded.<br />

2. All valves, blind flanges, the manway lid and the valve cover hatch lid have been properly secured.<br />

3. All seals or locks are in place.<br />

4. The outside of the tank is clean and free of product residue.<br />

5. All appropriate hazardous material placards and the identification numbers for <strong>TDI</strong> (UN-2078)<br />

are affixed.<br />

7.6.3 Maintenance of Transport Equipment<br />

During operations, unscheduled maintenance of the transport equipment may be necessary. The<br />

chemical reaction of <strong>TDI</strong> with water in the atmosphere leads to the formation of urea, which could plug<br />

the valves and block the pressure relief valves and piping. Customers should be instructed to<br />

immediately report any difficulties to the shipper and to their maintenance department. One means of<br />

communicating is to attach an information tag that identifies problems to the returning transport<br />

equipment.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

21

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

7.7 Inspection List: Modifications<br />

The inspection list assumes that <strong>TDI</strong> is to be loaded and transported domestically. In circumstances where<br />

<strong>TDI</strong> is to be shipped internationally — in accordance with regulations that may differ from the requirements of<br />

the DOT — the inspection list should be modified as appropriate.<br />

22 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 8: Transport of <strong>TDI</strong> by Rail<br />

8.1 Responsibilities of Rail Tank Carrier<br />

Rail carriers are responsible for the safe transport by rail from dispatch siding to final reception siding. See<br />

49 CFR Part 174. The selection of the routes, intermediate stopping locations, and cessation of traffic<br />

because of severe weather conditions are matters to be decided by the railway authorities, and should be<br />

reported to the shipper.<br />

8.2 Emergency Intervention<br />

The relevant federal, state or local authorities may intervene in the event of a transport emergency involving<br />

rail tank cars containing <strong>TDI</strong>. Shippers must provide rail carriers with the appropriate emergency response<br />

information, along with a 24-hour contact number. See 49 CFR §§ 172.600-604.<br />

8.3 Inter-Modal Movements<br />

Where inter-modal (i.e., road/rail/road) movements are arranged that are not driver/tractor accompanied<br />

during the rail stage, particular attention must be given to ensuring that the motor carrier leg of the journey<br />

has the appropriate shipping and emergency response information.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

23

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

24 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 9: Transport of <strong>TDI</strong> by Road<br />

The carrier is responsible for the safe transport of <strong>TDI</strong> by road from the loading point to the discharge (unloading)<br />

point. The following summarizes basic regulatory provisions and highlights industry recommendations:<br />

9.1 Routing<br />

The route to be followed must be selected carefully by the carrier and should be given, upon request, to the<br />

shipper. Compliance with bridge, tunnel or local routing regulations and restrictions is the responsibility of the<br />

carrier. DOT requires carriers of hazardous chemicals to utilize routes that:<br />

• follow major highways and/or designated truck routes, and;<br />

• avoid areas of high population density.<br />

Exceptions to the above restrictions are permissible only where “there is no practicable alternative.” See 49<br />

CFR § 397.9.<br />

9.2 Safe Parking<br />

Motor vehicles containing hazardous materials (with the exception of explosives which are treated separately)<br />

must not be parked on or within five feet of the traveled portion of a public street except for brief periods when<br />

the “necessities of operation require the vehicle to be parked and make it impracticable to park the vehicle in any<br />

other place.” See 49 CFR § 397.7. A secure depot or secure factory premises should be used whenever possible.<br />

Preferably, parking should be in an isolated location that is illuminated at night. It is strongly recommended<br />

that receivers allow secure parking to vehicles that have arrived outside specific access times.<br />

9.3 Severe Weather Conditions<br />

When severe weather conditions exist (i.e., icy roads, snow or poor visibility) that may affect the ability of the<br />

driver to proceed safely with the shipment, the vehicle should stop at the first suitable parking place. The<br />

driver should not continue with the delivery until the weather conditions improve. See 49 CFR § 392.14.<br />

9.4 Delays or Accidents<br />

All delays during transport, whether caused by severe weather conditions, breakdown or any other reason, should<br />

be reported to the shipper as soon as possible. In the event of an accident involving the immobilization of the<br />

vehicle, product spillage, or threatened loss of containment, the driver must contact the 24-hour emergency<br />

contact number, and follow any procedures specified in the emergency response information provided by the<br />

shipper. In addition, details of the accident must be reported to DOT in accordance with DOT’s reporting<br />

requirements. See 49 CFR § 171.16.<br />

Also, the U.S. Environmental Protection Agency considers <strong>TDI</strong> an extremely hazardous substance. Thus, if<br />

more than 100 pounds of <strong>TDI</strong> is spilled or otherwise released into the environment, the shipper is responsible<br />

for immediately reporting the release to the National Response Center and the local 911 operator. See 40<br />

CFR §§ 302.6 and 355.40.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

25

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

9.5 Inspections During Transport<br />

Under the DOT’s regulations, a driver must examine the vehicle’s cargo and its load-securing devices within<br />

the first 25 miles after beginning a trip and make any adjustments to the cargo or load-securing devices<br />

(other than steel strapping) as may be necessary to maintain the security of the commercial motor vehicle’s<br />

load. 49 CFR § 392.9(b)(2). The truck driver then must periodically examine the vehicle’s cargo during the<br />

course of transportation as follows:<br />

• when the driver makes a change of duty,<br />

• after the vehicle has been driven for 3 hours, or;<br />

• after the vehicle has been driven 150 miles, whichever occurs first. 49 CFR § 392.9(b)(3).<br />

For the bulk transport of <strong>TDI</strong>, the temperature of the tank contents should be checked regularly (detailed above)<br />

and recorded manually or electronically. If the temperature of the tank contents should rise more than 10°F<br />

above that specified by the shipper, the driver should immediately telephone the shipper to seek instruction.<br />

26 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 10: Transport of <strong>TDI</strong> by Water Vessel<br />

10.1 Approved Containers<br />

<strong>Transportation</strong> of <strong>TDI</strong> by ocean vessel must be in accordance with the International Maritime Dangerous<br />

Goods Code (IMDG). To the extent permitted by the IMDG Code, <strong>TDI</strong> may can be transported as follows:<br />

• Inter-modal tank containers, by roll on/roll off chassis; use of a 40 foot drop-nose type is recommended.<br />

• Inter-modal tank containers that are lifted on/off of container vessels.<br />

• In bulk ocean tankers or inland waterway vessels (not covered by these guidelines. See Chapter 1.5).<br />

• In metal intermediate bulk containers that should be transported in freight containers.<br />

• In non-bulk packaging such as drums that should be transported in freight containers.<br />

10.2 Parties Involved<br />

Because of the nature of the activity, a number of different parties may be involved in transporting <strong>TDI</strong> from<br />

shipper to customer. These may include shipping companies, freight forwarders, port or harbor authorities,<br />

and carriers.<br />

10.3 Safety Audits<br />

The shipper should consider carrying out a safety audit of the following distribution operations:<br />

• Forwarding operators;<br />

• Loading and unloading facilities at container terminals; and,<br />

• Emergency handling within hazardous cargo yards and container terminals.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

27

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

28 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 11: Unloading Operations for Tank Trucks and Rail Tank Cars<br />

11.1 Criteria for Discharge Facilities<br />

The operation of discharging <strong>TDI</strong> from any bulk container may present risk of certain physical and health<br />

hazards. Consequently, it is important that discharge facilities be correctly designed and constructed, and<br />

properly used and maintained.<br />

11.2 Design, Location and Checks<br />

Discharging facilities should be designed and located for the handling requirements associated with <strong>TDI</strong>. A<br />

preventive maintenance program covering all equipment should be developed to ensure proper operation<br />

(See Appendix 2 & 3.)<br />

11.3 Criteria for Discharge Hoses<br />

All discharge hoses and vapor return hoses should be specifically selected for <strong>TDI</strong> service, be<br />

marked/labeled “For Diisocyanates Service Only”, and be equipped with a safe means of sealing the hose<br />

when not in use. Two-inch diameter hoses are the recommended industry standard for unloading <strong>TDI</strong> and for<br />

vapor exchange.<br />

11.4 Operating Procedures<br />

Written operating procedures should be prepared covering all aspects of the discharge of <strong>TDI</strong>. In the case of<br />

tank truck unloading, division of responsibilities between the driver and receiver should be clearly defined.<br />

For attendance requirements, see 49 CFR § 177.834 for tank truck unloading and 49 CFR § 174.67 for rail<br />

tank car unloading. See Appendix 2 for specific recommendations on the division of responsibilities between<br />

the tank truck driver and the receiver. See Appendix 3 for specific recommendations for unloading from a rail<br />

car.<br />

11.5 Protective Equipment for Operators<br />

All necessary personal protective equipment should be available for discharging operations (See Chapter 6<br />

for further details). It is the shippers’ responsibility to provide to his employees the proper personal protective<br />

equipment and to ensure that they are trained in its use. The carrier and the customer have the same responsibilities<br />

for their employees.<br />

11.6 Inspection of the Bulk Reception Facilities<br />

The customer is generally responsible for controlling the conditions of receipt. Customers should work with<br />

their suppliers to ensure that good safety standards have been developed for handling and storage. See<br />

Appendix 4 for a checklist of general industry recommendations that provides companies with guidelines for<br />

ensuring the safe handling and storage of <strong>TDI</strong>.<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

29

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

30 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Chapter 12: Required Shipping Information for <strong>TDI</strong><br />

12.1 <strong>TDI</strong>’s Hazardous Materials Classification<br />

When in transport, <strong>TDI</strong> is classified as a Division 6.1, Packing Group II toxic substance. This classification<br />

triggers a number of regulatory requirements when a company offers a material for either domestic or<br />

international shipment. The principles of DOT hazardous materials regulations are as follows:<br />

• A company offering <strong>TDI</strong> for transport must complete a shipping paper indicating the required shipping<br />

information for <strong>TDI</strong>. 49 CFR §§ 172.200-.203. This information varies slightly depending on whether the<br />

material is moving in domestic (U.S.) or international commerce. See subsection 12.2 below.<br />

• The shipping paper must include an emergency contact telephone number that is manned twenty-four<br />

hours a day. 49 CFR § 172.604. (Within the U.S., all major producers are members of a mutual aid<br />

program known as CHEMTREC, which is available through the <strong>American</strong> Chemistry Council). If shipping<br />

<strong>TDI</strong> as a waste, the Hazardous Waste Manifest must be completed as required. 49 CFR § 172.205.<br />

• The shipping paper must include the required shipper’s certification that the material is shipped in<br />

compliance with the regulations. See 49 CFR § 172.204.<br />

• Emergency response information must be included with the shipping paper and provided to the carrier.<br />

See 49 CFR §§ 172.600-602.<br />

• As required by DOT’s regulations, all <strong>TDI</strong> must be appropriately:<br />

– packaged (49 CFR § 173.202 (non bulk) or 49 CFR § 173.243 (bulk) and 49 CFR § Part 178);<br />

– marked (49 CFR §§ 172.300-338); and<br />

– labeled and placarded (49 CFR §§ 172.300-.338, 172.400-.448 and 172.500-.560).<br />

12.2 Summary of <strong>TDI</strong> Hazard Information*<br />

DOT<br />

Proper Shipping Name Toluene Diisocyanate<br />

Hazard Class 6.1<br />

U.N. Number U.N. 2078<br />

Packing Group II<br />

Reportable Quantity** 100 lbs.<br />

Label/placard toxic<br />

IMDG<br />

Proper Shipping Name Toluene Diisocyanate<br />

Hazard Class 6.1<br />

U.N. Number U.N. 2078<br />

Packing Group II<br />

Label/placard toxic<br />

Copyright 2002, <strong>American</strong> Plastics Council<br />

31

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

ICAO<br />

Proper Shipping Name Toluene Diisocyanate<br />

Hazard Class 6.1<br />

U.N. Number U.N. 2078<br />

Packing Group II<br />

Label/placard toxic<br />

Maximum Quantities per Package Refer to regulations or air carrier for guidance<br />

* Information in italics should be entered on the shipping paper in the order shown. Other information is provided for easy reference.<br />

** Shipments of <strong>TDI</strong> exceeding 100 lbs. in one container must have the letters “RQ” entered on the shipping paper and marked on the packaging.<br />

12.3 Preparedness and Emergency Response<br />

Companies should be prepared to provide on-scene assistance and expert advice in remedial action<br />

procedures. In cases where local, state or federal authorities are in control of the incident, the role of the<br />

company responders should be to:<br />

• Operate fully within the company’s Site Specific Emergency Response and Safety and Health Plan.<br />

• Assist in the establishment of an Incident Management System and provide technical advice based upon<br />

product knowledge to the On-Scene Command (OSC).<br />

• When conditions warrant, and as requested by the OSC, organize the provision of spare<br />

vehicles/pumps/hoses/other equipment for the cargo transfer, decontamination, and be prepared, on<br />

behalf of the OSC, to employ their technical expertise in conducting or supervising remedial action.<br />

12.4 Principles of Emergency Response Scheme<br />

The principles of the scheme should be:<br />

• If the producer cannot respond promptly to an incident that requires on-scene assistance, the producer<br />

may request a nearby chemical company to respond. If another company cannot respond, the shipper<br />

may seek a for-hire response company.<br />

• Only chemical companies and for-hire responders that are qualified to handle the hazards of <strong>TDI</strong><br />

involved in the incident will be requested to respond.<br />

• Response by a chemical company to another shipper’s incident is discretionary.<br />

• The producer will, upon request, reimburse the responding company for reasonable expenses, or pay a<br />

for-hire company in accordance with the current schedule of charges in effect under their contract.<br />

• All companies participating in these arrangements will make available such services and assistance as<br />

would be provided for their own <strong>TDI</strong>.<br />

12.5 Technical Communications<br />

Regular technical communications should be established between participating companies in order to<br />

recommend methods of resolving transportation/distribution incidents.<br />

32 Copyright 2002, <strong>American</strong> Plastics Council

<strong>TDI</strong> transportation<br />

g u i d e l i n e s<br />

Appendix 1: Sample Certificate of Receipt<br />

1 Part A: (To be completed by the receiver of bulk tank truck loads BEFORE discharge is started)<br />

I hereby certify that the following has occurred:<br />

• The <strong>TDI</strong> can be safely received by the storage facility.<br />

• The <strong>TDI</strong> to be received is the same as described on the bill of lading.<br />

• The unloading arm or hose is connected to the correct lines and/or piping and unloading may begin.<br />

• The storage tank(s) receiving the <strong>TDI</strong> have adequate space for the entire quantity being delivered.<br />

Signature ........................................................ Date ...................................<br />

1 Part B: (To be completed by the receiver of bulk loads AFTER discharge is started)<br />