Experience on axle defects

Experience on axle defects

Experience on axle defects

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

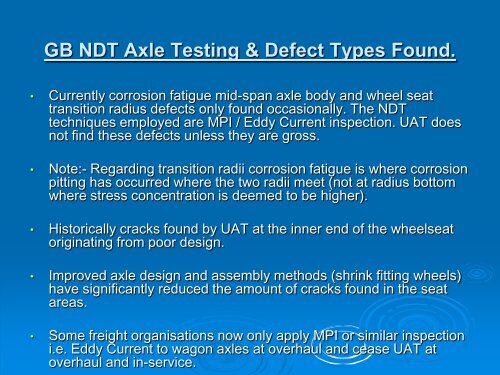

GB NDT Axle Testing & Defect Types Found.<br />

• Currently corrosi<strong>on</strong> fatigue mid-span <strong>axle</strong> body and wheel seat<br />

transiti<strong>on</strong> radius <strong>defects</strong> <strong>on</strong>ly found occasi<strong>on</strong>ally. The NDT<br />

techniques employed are MPI / Eddy Current inspecti<strong>on</strong>. UAT does<br />

not find these <strong>defects</strong> unless they are gross.<br />

• Note:- Regarding transiti<strong>on</strong> radii corrosi<strong>on</strong> fatigue is where corrosi<strong>on</strong><br />

pitting has occurred where the two radii meet (not at radius bottom<br />

where stress c<strong>on</strong>centrati<strong>on</strong> is deemed to be higher).<br />

• Historically cracks found by UAT at the inner end of the wheelseat<br />

originating from poor design.<br />

• Improved <strong>axle</strong> design and assembly methods (shrink fitting wheels)<br />

have significantly reduced the amount of cracks found in the seat<br />

areas.<br />

• Some freight organisati<strong>on</strong>s now <strong>on</strong>ly apply MPI or similar inspecti<strong>on</strong><br />

i.e. Eddy Current to wag<strong>on</strong> <strong>axle</strong>s at overhaul and cease UAT at<br />

overhaul and in-service.