EVA closed-cell foam and its effect on transmitted forces - Australian ...

EVA closed-cell foam and its effect on transmitted forces - Australian ...

EVA closed-cell foam and its effect on transmitted forces - Australian ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

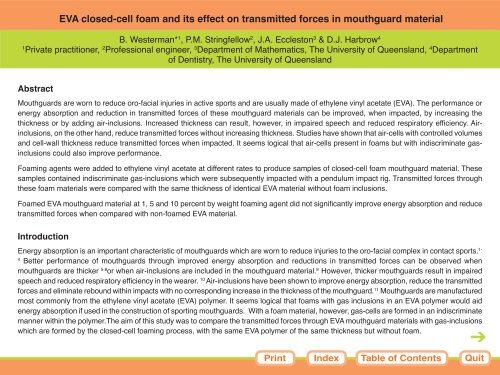

<str<strong>on</strong>g>EVA</str<strong>on</strong>g> <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>its</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>transmitted</strong> <strong>forces</strong> in mouthguard material<br />

B. Westerman* 1 , P.M. Stringfellow 2 , J.A. Ecclest<strong>on</strong> 3 & D.J. Harbrow 4<br />

1 Private practiti<strong>on</strong>er, 2 Professi<strong>on</strong>al engineer, 3 Department of Mathematics, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g>, 4 Department<br />

of Dentistry, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

Abstract<br />

Mouthguards are worn to reduce oro-facial injuries in active sports <str<strong>on</strong>g>and</str<strong>on</strong>g> are usually made of ethylene vinyl acetate (<str<strong>on</strong>g>EVA</str<strong>on</strong>g>). The performance or<br />

energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong> of these mouthguard materials can be improved, when impacted, by increasing the<br />

thickness or by adding air-inclusi<strong>on</strong>s. Increased thickness can result, however, in impaired speech <str<strong>on</strong>g>and</str<strong>on</strong>g> reduced respiratory efficiency. Airinclusi<strong>on</strong>s,<br />

<strong>on</strong> the other h<str<strong>on</strong>g>and</str<strong>on</strong>g>, reduce <strong>transmitted</strong> <strong>forces</strong> without increasing thickness. Studies have shown that air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s with c<strong>on</strong>trolled volumes<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>cell</str<strong>on</strong>g>-wall thickness reduce <strong>transmitted</strong> <strong>forces</strong> when impacted. It seems logical that air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s present in <str<strong>on</strong>g>foam</str<strong>on</strong>g>s but with indiscriminate gasinclusi<strong>on</strong>s<br />

could also improve performance.<br />

Foaming agents were added to ethylene vinyl acetate at different rates to produce samples of <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> mouthguard material. These<br />

samples c<strong>on</strong>tained indiscriminate gas-inclusi<strong>on</strong>s which were subsequently impacted with a pendulum impact rig. Transmitted <strong>forces</strong> through<br />

these <str<strong>on</strong>g>foam</str<strong>on</strong>g> materials were compared with the same thickness of identical <str<strong>on</strong>g>EVA</str<strong>on</strong>g> material without <str<strong>on</strong>g>foam</str<strong>on</strong>g> inclusi<strong>on</strong>s.<br />

Foamed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard material at 1, 5 <str<strong>on</strong>g>and</str<strong>on</strong>g> 10 percent by weight <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent did not significantly improve energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> reduce<br />

<strong>transmitted</strong> <strong>forces</strong> when compared with n<strong>on</strong>-<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> material.<br />

Introducti<strong>on</strong><br />

Energy absorpti<strong>on</strong> is an important characteristic of mouthguards which are worn to reduce injuries to the oro-facial complex in c<strong>on</strong>tact sports. 1-<br />

4 Better performance of mouthguards through improved energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> reducti<strong>on</strong>s in <strong>transmitted</strong> <strong>forces</strong> can be observed when<br />

mouthguards are thicker 5-8or when air-inclusi<strong>on</strong>s are included in the mouthguard material. 9 However, thicker mouthguards result in impaired<br />

speech <str<strong>on</strong>g>and</str<strong>on</strong>g> reduced respiratory efficiency in the wearer. 10 Air-inclusi<strong>on</strong>s have been shown to improve energy absorpti<strong>on</strong>, reduce the <strong>transmitted</strong><br />

<strong>forces</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> eliminate rebound within impacts with no corresp<strong>on</strong>ding increase in the thickness of the mouthguard. 11 Mouthguards are manufactured<br />

most comm<strong>on</strong>ly from the ethylene vinyl acetate (<str<strong>on</strong>g>EVA</str<strong>on</strong>g>) polymer. It seems logical that <str<strong>on</strong>g>foam</str<strong>on</strong>g>s with gas inclusi<strong>on</strong>s in an <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer would aid<br />

energy absorpti<strong>on</strong> if used in the c<strong>on</strong>structi<strong>on</strong> of sporting mouthguards. With a <str<strong>on</strong>g>foam</str<strong>on</strong>g> material, however, gas-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s are formed in an indiscriminate<br />

manner within the polymer.The aim of this study was to compare the <strong>transmitted</strong> <strong>forces</strong> through <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard materials with gas-inclusi<strong>on</strong>s<br />

which are formed by the <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing process, with the same <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer of the same thickness but without <str<strong>on</strong>g>foam</str<strong>on</strong>g>.<br />

Print<br />

Index<br />

Table of C<strong>on</strong>tents<br />

Quit

<str<strong>on</strong>g>EVA</str<strong>on</strong>g> <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>its</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>transmitted</strong> <strong>forces</strong> in mouthguard material<br />

B. Westerman* 1 , P.M. Stringfellow 2 , J.A. Ecclest<strong>on</strong> 3 & D.J. Harbrow 4<br />

1 Private practiti<strong>on</strong>er, 2 Professi<strong>on</strong>al engineer, 3 Department of Mathematics, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g>, 4 Department<br />

of Dentistry, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

Materials <str<strong>on</strong>g>and</str<strong>on</strong>g> Method<br />

• Transmitted <strong>forces</strong> measured through samples of <str<strong>on</strong>g>EVA</str<strong>on</strong>g> (4mm thick), with <str<strong>on</strong>g>and</str<strong>on</strong>g> without <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

• <str<strong>on</strong>g>EVA</str<strong>on</strong>g> had Shore A Hardness of 3<br />

• Test impacts all 4.4 joules <str<strong>on</strong>g>and</str<strong>on</strong>g> 3 meters per sec<strong>on</strong>d velocity<br />

• C<strong>on</strong>stant impacts produced by impact pendulum<br />

• Samples included 0, 1, 5, <str<strong>on</strong>g>and</str<strong>on</strong>g> 10 % <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent<br />

• Foaming agent Hydrocerol (citric acid/bicarb<strong>on</strong>ate of soda)<br />

• Flat circular impact head, 12.5 mm in diameter<br />

• 20 test impacts <strong>on</strong> each sample (different site each time)<br />

• Force sensor measured <strong>transmitted</strong> <strong>forces</strong><br />

• Minitab <str<strong>on</strong>g>and</str<strong>on</strong>g> Excel used for statistical analysis<br />

Results<br />

The cut surface of un<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> material showed a homogenous texture with little more than fine score marks from the razor’s edge as it<br />

secti<strong>on</strong>ed through the material. Additi<strong>on</strong> of <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent to the <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer mixture resulted in the formati<strong>on</strong> of irregular gas inclusi<strong>on</strong>s. <str<strong>on</strong>g>EVA</str<strong>on</strong>g><br />

material c<strong>on</strong>taining 1.0 % <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent had occasi<strong>on</strong>al inclusi<strong>on</strong>s of approximately 20 mm diameter. However with increasing c<strong>on</strong>centrati<strong>on</strong><br />

of <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent the inclusi<strong>on</strong>s became larger <str<strong>on</strong>g>and</str<strong>on</strong>g> more heterogenous in size. <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer material c<strong>on</strong>taining 10% <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent showed<br />

this <str<strong>on</strong>g>effect</str<strong>on</strong>g> the most clearly. The inclusi<strong>on</strong>s ranged in size from less than 100 mm diameter <str<strong>on</strong>g>and</str<strong>on</strong>g> regular in shape, to inclusi<strong>on</strong>s larger than 1.0mm<br />

diameter <str<strong>on</strong>g>and</str<strong>on</strong>g> irregular in shape. The large inclusi<strong>on</strong>s tended to be located in deeper regi<strong>on</strong>s of the disc material about 0.5 mm from the surface,<br />

with this regi<strong>on</strong> becoming more clearly defined with increasing c<strong>on</strong>centrati<strong>on</strong> of the <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent.<br />

Print<br />

Index<br />

Table of C<strong>on</strong>tents<br />

Quit

<str<strong>on</strong>g>EVA</str<strong>on</strong>g> <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>its</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>transmitted</strong> <strong>forces</strong> in mouthguard material<br />

B. Westerman* 1 , P.M. Stringfellow 2 , J.A. Ecclest<strong>on</strong> 3 & D.J. Harbrow 4<br />

1 Private practiti<strong>on</strong>er, 2 Professi<strong>on</strong>al engineer, 3 Department of Mathematics, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g>, 4 Department<br />

of Dentistry, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

The different mean maximum <strong>transmitted</strong> <strong>forces</strong> through the various materials are shown in Table 1. The <str<strong>on</strong>g>EVA</str<strong>on</strong>g> material without <str<strong>on</strong>g>foam</str<strong>on</strong>g> <strong>transmitted</strong><br />

a force of 4.04 kN. Of the <str<strong>on</strong>g>foam</str<strong>on</strong>g>ed materials, the best energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> least <strong>transmitted</strong> force occurred with the ten percent-by-weight<br />

<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed polymer which <strong>transmitted</strong> a force of 3.88 kN. Figure 1 illustrates the mean maximum <strong>transmitted</strong> <strong>forces</strong> graphically.<br />

A <strong>on</strong>e-way analysis of variance was completed <strong>on</strong> the test data. The maximum <strong>transmitted</strong> force for each set of five impacts per sample were<br />

averaged for each test material <str<strong>on</strong>g>and</str<strong>on</strong>g> the c<strong>on</strong>trol. Analysis was performed <strong>on</strong> these averages <str<strong>on</strong>g>and</str<strong>on</strong>g> no significant differences were found between<br />

the tested samples. Although there were small differences between the various levels of <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing, these were not statistically significant.<br />

Discussi<strong>on</strong><br />

The impact results from the indiscriminate additi<strong>on</strong> of gas by <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing in <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g>s can be compared with other air-inclusi<strong>on</strong>s in<br />

mouthguard materials. A previous study identified the reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong> through samples made from Stay-guard material (Rudolf<br />

Gunz <str<strong>on</strong>g>and</str<strong>on</strong>g> Co., Sydney). This commercially available <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer with a Shore A Hardness of 85 <str<strong>on</strong>g>and</str<strong>on</strong>g> the same thickness of 4mm showed<br />

more than 30 percent reducti<strong>on</strong> in <strong>transmitted</strong> force when impacted with a similar force. This compares with a reducti<strong>on</strong> of 4.96 percent in the<br />

<strong>transmitted</strong> force with the present study of <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g>.<br />

The earlier study featured air-inclusi<strong>on</strong>s in which the air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s were all the same dimensi<strong>on</strong> throughout the test samples. The volumes of the air<str<strong>on</strong>g>cell</str<strong>on</strong>g>s<br />

were also c<strong>on</strong>stant at either 8 cubic millimeters (2x2x2mm) or 18 cubic millimeters (3x3x2 mm). The wall thickness between air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s was<br />

also c<strong>on</strong>trolled at either <strong>on</strong>e or two millimeters. This c<strong>on</strong>trasts with the <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> where the formati<strong>on</strong> of gas-inclusi<strong>on</strong>s provided variable<br />

<str<strong>on</strong>g>cell</str<strong>on</strong>g> volume <str<strong>on</strong>g>and</str<strong>on</strong>g> wall thickness.<br />

There was also a slight difference in the Shore A Hardness of the polymers in the two studies with the different air or gas inclusi<strong>on</strong>s. The early<br />

study used an <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer with a Shore A Hardness of 85 while the latter showed a Shore A Hardness of 83. It would be expected that the<br />

harder material (85) would transmit more force because of <str<strong>on</strong>g>its</str<strong>on</strong>g> greater hardness <str<strong>on</strong>g>and</str<strong>on</strong>g> reduced elasticity. However, the <strong>transmitted</strong> <strong>forces</strong> through<br />

the air-inclusi<strong>on</strong> material with fixed air-<str<strong>on</strong>g>cell</str<strong>on</strong>g> volume <str<strong>on</strong>g>and</str<strong>on</strong>g> wall thickness were reduced by 32 percent when compared with the <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer<br />

Print<br />

Index<br />

Table of C<strong>on</strong>tents<br />

Quit

<str<strong>on</strong>g>EVA</str<strong>on</strong>g> <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>its</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>transmitted</strong> <strong>forces</strong> in mouthguard material<br />

B. Westerman* 1 , P.M. Stringfellow 2 , J.A. Ecclest<strong>on</strong> 3 & D.J. Harbrow 4<br />

1 Private practiti<strong>on</strong>er, 2 Professi<strong>on</strong>al engineer, 3 Department of Mathematics, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g>, 4 Department<br />

of Dentistry, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

without air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s. In c<strong>on</strong>trast, <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer showed a 4.96 percent reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong> compared with <str<strong>on</strong>g>EVA</str<strong>on</strong>g> without<br />

the gas inclusi<strong>on</strong>s. The reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong> under the same c<strong>on</strong>diti<strong>on</strong>s (magnitude of test impact force, thickness of test samples<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> similar air-c<strong>on</strong>diti<strong>on</strong>ed envir<strong>on</strong>ment) <str<strong>on</strong>g>and</str<strong>on</strong>g> with similar <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymers showed that the improvements in the <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer were <strong>on</strong>ly <strong>on</strong>e<br />

sixth of those shown with the more c<strong>on</strong>trolled air-inclusi<strong>on</strong>s with regular volume <str<strong>on</strong>g>and</str<strong>on</strong>g> wall thickness.<br />

C<strong>on</strong>clusi<strong>on</strong>s<br />

The additi<strong>on</strong> of <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent to the <str<strong>on</strong>g>EVA</str<strong>on</strong>g> ( Shore A Hardness 83) comm<strong>on</strong>ly used in mouthguard materials produced <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g>s which<br />

showed small increases in energy absorpti<strong>on</strong>, when impacted, compared with the same material without <str<strong>on</strong>g>foam</str<strong>on</strong>g>. Reducti<strong>on</strong>s of close to 5 percent<br />

in <strong>transmitted</strong> <strong>forces</strong> in these <str<strong>on</strong>g>foam</str<strong>on</strong>g> materials c<strong>on</strong>trasted with the larger air-inclusi<strong>on</strong>s with fixed air-<str<strong>on</strong>g>cell</str<strong>on</strong>g> volume <str<strong>on</strong>g>and</str<strong>on</strong>g> wall thickness which<br />

dem<strong>on</strong>strated a 32 percent reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong>.<br />

Closed-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>EVA</str<strong>on</strong>g> plastics with up to 10 percent by weight <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent <str<strong>on</strong>g>and</str<strong>on</strong>g> with indiscriminate gas-inclusi<strong>on</strong>s do not provide statistically<br />

significant improvements in energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> reducti<strong>on</strong>s in <strong>transmitted</strong> <strong>forces</strong> when compared with n<strong>on</strong>-<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymers.<br />

Acknowledgments<br />

This study was supported by a grant from the <strong>Australian</strong> Dental Research Foundati<strong>on</strong> Inc.<br />

The authors also thank Frank <str<strong>on</strong>g>and</str<strong>on</strong>g> John Oskam for their assistance in preparing the <str<strong>on</strong>g>foam</str<strong>on</strong>g> materials.<br />

References<br />

Wood AW. Head protecti<strong>on</strong>- cranial, facial <str<strong>on</strong>g>and</str<strong>on</strong>g> dental in c<strong>on</strong>tact sports. Oral Health 62:23-33, 1972<br />

Wei SH. Preventi<strong>on</strong> of injuries to anterior teeth. Int Dent J 24:30-49, 1974<br />

Gar<strong>on</strong> MW, Merckle A, Wright JT. Mouth protectors <str<strong>on</strong>g>and</str<strong>on</strong>g> oral trauma: a study of adolescent football players. J Am Dent Assoc 12:663-6, 1986<br />

Print<br />

Index<br />

Table of C<strong>on</strong>tents<br />

Quit

<str<strong>on</strong>g>EVA</str<strong>on</strong>g> <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>its</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>transmitted</strong> <strong>forces</strong> in mouthguard material<br />

B. Westerman* 1 , P.M. Stringfellow 2 , J.A. Ecclest<strong>on</strong> 3 & D.J. Harbrow 4<br />

1 Private practiti<strong>on</strong>er, 2 Professi<strong>on</strong>al engineer, 3 Department of Mathematics, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g>, 4 Department<br />

of Dentistry, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

Hickey JC, Morris AL, Caels<strong>on</strong> LD, Seward TE. The relati<strong>on</strong> of mouth protectors to cranial pressure <str<strong>on</strong>g>and</str<strong>on</strong>g> deformati<strong>on</strong>. J Am Dent Assoc 74:735-<br />

40, 1967<br />

De Wijn JR, Vrijhoef MMA, Versteegh PA, Strassen HP, Linn EW. A mechanical investigati<strong>on</strong> to the functi<strong>on</strong>ing of mouthguards.<br />

Biomedics:Principles <str<strong>on</strong>g>and</str<strong>on</strong>g> applicati<strong>on</strong>s. The Hague:Martinus Nijhoff Publishers, 1982.<br />

Park JB, Shaull KL, Overt<strong>on</strong> B, D<strong>on</strong>ly KJ. Improving mouthguards. J Prosthet Dent 72:373-380, 1994<br />

Going RE, Loehman RE, Ming Sam Chan. Mouthguard materials: their physical <str<strong>on</strong>g>and</str<strong>on</strong>g> mechanical properties. J Am Dent Assoc 88:132-8, 1974<br />

Westerman B, Stringfellow PM, Ecclest<strong>on</strong> JA. Forces <strong>transmitted</strong> through <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard matterials of different types <str<strong>on</strong>g>and</str<strong>on</strong>g> thickness. Aust<br />

Dent J 40:389-391, 1995<br />

Westerman B, Stringfellow PM, Ecclest<strong>on</strong> JA. An improved mouthguard material. Aust Dent J 42:189-191, 1997<br />

Francis KT, Brasher J. Physical <str<strong>on</strong>g>effect</str<strong>on</strong>g>s of wearing mouthguards. Br J Sports Med 25(4):227-31, 1991<br />

Westerman B, Sringfellow PM, Ecclest<strong>on</strong> JA. The beneficial <str<strong>on</strong>g>effect</str<strong>on</strong>g>s of air-inclusi<strong>on</strong>s <strong>on</strong> mouthguard performance. Submitted for publicati<strong>on</strong><br />

2001.<br />

Print<br />

Index<br />

Table of C<strong>on</strong>tents<br />

Quit

<str<strong>on</strong>g>EVA</str<strong>on</strong>g> <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>its</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>transmitted</strong> <strong>forces</strong> in mouthguard material<br />

B. Westerman* 1 , P.M. Stringfellow 2 , J.A. Ecclest<strong>on</strong> 3 & D.J. Harbrow 4<br />

1 Private practiti<strong>on</strong>er, 2 Professi<strong>on</strong>al engineer, 3 Department of Mathematics, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g>, 4 Department<br />

of Dentistry, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

Table 1. Mean maximum <strong>transmitted</strong> <strong>forces</strong> through <str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>and</str<strong>on</strong>g> n<strong>on</strong>-<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard material (kN)<br />

<strong>transmitted</strong> force (kN)<br />

Foaming agent <strong>transmitted</strong> <strong>forces</strong> st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard deviati<strong>on</strong><br />

(% weight) (kN)<br />

0.0 (c<strong>on</strong>trol) 4.04 0.21<br />

1.0 4.12 0.08<br />

5.0 4.08 0.10<br />

10.0 3.88 0.16<br />

Figure 1. Mean maximum <strong>transmitted</strong> <strong>forces</strong> (kN) in <str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>and</str<strong>on</strong>g> n<strong>on</strong>-<str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard material - percentage <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent<br />

5.00E+00<br />

4.00E+00<br />

3.00E+00<br />

2.00E+00<br />

1.00E+00<br />

0.00E+00<br />

-1.00E+00<br />

1<br />

153<br />

305<br />

457<br />

609<br />

761<br />

913<br />

time (0.001sec<strong>on</strong>ds)<br />

Print<br />

0% <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

1% <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

5% <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

10% <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

Index<br />

Table of C<strong>on</strong>tents<br />

Quit

<str<strong>on</strong>g>EVA</str<strong>on</strong>g> <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>its</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <strong>on</strong> <strong>transmitted</strong> <strong>forces</strong> in mouthguard<br />

material<br />

B. Westerman* 1, P.M. Stringfellow 2, J.A. Ecclest<strong>on</strong> 3 & D.J. Harbrow 4<br />

1Private practiti<strong>on</strong>er<br />

2Professi<strong>on</strong>al engineer<br />

3Department of Mathematics, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

4Department of Dentistry, The University of Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g><br />

ABSTRACT: Mouthguards are worn to reduce oro-facial injuries in active sports <str<strong>on</strong>g>and</str<strong>on</strong>g> are usually made of<br />

ethylene vinyl acetate (<str<strong>on</strong>g>EVA</str<strong>on</strong>g>). The performance or energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong> of these<br />

mouthguard materials can be improved, when impacted, by increasing the thickness or by adding air-inclusi<strong>on</strong>s.<br />

Increased thickness can result, however, in impaired speech <str<strong>on</strong>g>and</str<strong>on</strong>g> reduced respiratory efficiency. Air-inclusi<strong>on</strong>s, <strong>on</strong><br />

the other h<str<strong>on</strong>g>and</str<strong>on</strong>g>, reduce <strong>transmitted</strong> <strong>forces</strong> without increasing thickness. Studies have shown that air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s with<br />

c<strong>on</strong>trolled volumes <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>cell</str<strong>on</strong>g>-wall thickness reduce <strong>transmitted</strong> <strong>forces</strong> when impacted. It seems logical that air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s<br />

present in <str<strong>on</strong>g>foam</str<strong>on</strong>g>s but with indiscriminate gas-inclusi<strong>on</strong>s could also improve performance.<br />

Foaming agents were added to ethylene vinyl acetate at different rates to produce samples of <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

mouthguard material. These samples c<strong>on</strong>tained indiscriminate gas-inclusi<strong>on</strong>s which were subsequently impacted<br />

with a pendulum impact rig. Transmitted <strong>forces</strong> through these <str<strong>on</strong>g>foam</str<strong>on</strong>g> materials were compared with the same<br />

thickness of identical <str<strong>on</strong>g>EVA</str<strong>on</strong>g> material without <str<strong>on</strong>g>foam</str<strong>on</strong>g> inclusi<strong>on</strong>s.<br />

Foamed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard material at 1, 5 <str<strong>on</strong>g>and</str<strong>on</strong>g> 10 percent by weight <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent did not significantly<br />

improve energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> reduce <strong>transmitted</strong> <strong>forces</strong> when compared with n<strong>on</strong>-<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> material.<br />

INTRODUCTION: Energy absorpti<strong>on</strong> is an important characteristic of mouthguards which are worn to reduce<br />

injuries to the oro-facial complex in c<strong>on</strong>tact sports. 1-4 Better performance of mouthguards through improved energy<br />

absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> reducti<strong>on</strong>s in <strong>transmitted</strong> <strong>forces</strong> can be observed when mouthguards are thicker 5-8or when airinclusi<strong>on</strong>s<br />

are included in the mouthguard material. 9 However, thicker mouthguards result in impaired speech <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

reduced respiratory efficiency in the wearer. 10 Air-inclusi<strong>on</strong>s have been shown to improve energy absorpti<strong>on</strong>,<br />

reduce the <strong>transmitted</strong> <strong>forces</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> eliminate rebound within impacts with no corresp<strong>on</strong>ding increase in the<br />

thickness of the mouthguard. 11 Mouthguards are manufactured most comm<strong>on</strong>ly from the ethylene vinyl acetate<br />

(<str<strong>on</strong>g>EVA</str<strong>on</strong>g>) polymer. It seems logical that <str<strong>on</strong>g>foam</str<strong>on</strong>g>s with gas inclusi<strong>on</strong>s in an <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer would aid energy absorpti<strong>on</strong> if<br />

used in the c<strong>on</strong>structi<strong>on</strong> of sporting mouthguards. With a <str<strong>on</strong>g>foam</str<strong>on</strong>g> material, however, gas-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s are formed in an<br />

indiscriminate manner within the polymer.The aim of this study was to compare the <strong>transmitted</strong> <strong>forces</strong> through<br />

<str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard materials with gas-inclusi<strong>on</strong>s which are formed by the <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing process, with the<br />

same <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer of the same thickness but without <str<strong>on</strong>g>foam</str<strong>on</strong>g>.<br />

MATERIALS AND METHOD:<br />

• Transmitted <strong>forces</strong> measured through samples of <str<strong>on</strong>g>EVA</str<strong>on</strong>g> (4mm thick), with <str<strong>on</strong>g>and</str<strong>on</strong>g> without <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

• <str<strong>on</strong>g>EVA</str<strong>on</strong>g> had Shore A Hardness of 3<br />

• Test impacts all 4.4 joules <str<strong>on</strong>g>and</str<strong>on</strong>g> 3 meters per sec<strong>on</strong>d velocity<br />

• C<strong>on</strong>stant impacts produced by impact pendulum<br />

• Samples included 0, 1, 5, <str<strong>on</strong>g>and</str<strong>on</strong>g> 10 % <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent<br />

• Foaming agent Hydrocerol (citric acid/bicarb<strong>on</strong>ate of soda)<br />

• Flat circular impact head, 12.5 mm in diameter<br />

• 20 test impacts <strong>on</strong> each sample (different site each time)<br />

• Force sensor measured <strong>transmitted</strong> <strong>forces</strong><br />

• Minitab <str<strong>on</strong>g>and</str<strong>on</strong>g> Excel used for statistical analysis<br />

RESULTS: The cut surface of un<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> material showed a homogenous texture with little more than fine<br />

score marks from the razor’s edge as it secti<strong>on</strong>ed through the material. Additi<strong>on</strong> of <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent to the <str<strong>on</strong>g>EVA</str<strong>on</strong>g><br />

polymer mixture resulted in the formati<strong>on</strong> of irregular gas inclusi<strong>on</strong>s. <str<strong>on</strong>g>EVA</str<strong>on</strong>g> material c<strong>on</strong>taining 1.0 % <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent<br />

had occasi<strong>on</strong>al inclusi<strong>on</strong>s of approximately 20 μm diameter. However with increasing c<strong>on</strong>centrati<strong>on</strong> of <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing<br />

agent the inclusi<strong>on</strong>s became larger <str<strong>on</strong>g>and</str<strong>on</strong>g> more heterogenous in size. <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer material c<strong>on</strong>taining 10%<br />

<str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent showed this <str<strong>on</strong>g>effect</str<strong>on</strong>g> the most clearly. The inclusi<strong>on</strong>s ranged in size from less than 100 μm diameter<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> regular in shape, to inclusi<strong>on</strong>s larger than 1.0mm diameter <str<strong>on</strong>g>and</str<strong>on</strong>g> irregular in shape. The large inclusi<strong>on</strong>s tended<br />

to be located in deeper regi<strong>on</strong>s of the disc material about 0.5 mm from the surface, with this regi<strong>on</strong> becoming<br />

more clearly defined with increasing c<strong>on</strong>centrati<strong>on</strong> of the <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent.<br />

The different mean maximum <strong>transmitted</strong> <strong>forces</strong> through the various materials are shown in Table 1. The <str<strong>on</strong>g>EVA</str<strong>on</strong>g><br />

material without <str<strong>on</strong>g>foam</str<strong>on</strong>g> <strong>transmitted</strong> a force of 4.04 kN. Of the <str<strong>on</strong>g>foam</str<strong>on</strong>g>ed materials, the best energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

least <strong>transmitted</strong> force occurred with the ten percent-by-weight <str<strong>on</strong>g>foam</str<strong>on</strong>g>ed polymer which <strong>transmitted</strong> a force of 3.88<br />

kN. Figure 1 illustrates the mean maximum <strong>transmitted</strong> <strong>forces</strong> graphically.

A <strong>on</strong>e-way analysis of variance was completed <strong>on</strong> the test data. The maximum <strong>transmitted</strong> force for each set<br />

of five impacts per sample were averaged for each test material <str<strong>on</strong>g>and</str<strong>on</strong>g> the c<strong>on</strong>trol. Analysis was performed <strong>on</strong> these<br />

averages <str<strong>on</strong>g>and</str<strong>on</strong>g> no significant differences were found between the tested samples. Although there were small<br />

differences between the various levels of <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing, these were not statistically significant.<br />

DISCUSSION: The impact results from the indiscriminate additi<strong>on</strong> of gas by <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing in <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g>s can<br />

be compared with other air-inclusi<strong>on</strong>s in mouthguard materials. A previous study identified the reducti<strong>on</strong> in<br />

<strong>transmitted</strong> <strong>forces</strong> through samples made from Stay-guard material (Rudolf Gunz <str<strong>on</strong>g>and</str<strong>on</strong>g> Co., Sydney). This<br />

commercially available <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer with a Shore A Hardness of 85 <str<strong>on</strong>g>and</str<strong>on</strong>g> the same thickness of 4mm showed<br />

more than 30 percent reducti<strong>on</strong> in <strong>transmitted</strong> force when impacted with a similar force. This compares with a<br />

reducti<strong>on</strong> of 4.96 percent in the <strong>transmitted</strong> force with the present study of <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g>.<br />

The earlier study featured air-inclusi<strong>on</strong>s in which the air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s were all the same dimensi<strong>on</strong> throughout the test<br />

samples. The volumes of the air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s were also c<strong>on</strong>stant at either 8 cubic millimeters (2x2x2mm) or 18 cubic<br />

millimeters (3x3x2 mm). The wall thickness between air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s was also c<strong>on</strong>trolled at either <strong>on</strong>e or two millimeters.<br />

This c<strong>on</strong>trasts with the <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> where the formati<strong>on</strong> of gas-inclusi<strong>on</strong>s provided variable <str<strong>on</strong>g>cell</str<strong>on</strong>g> volume <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

wall thickness.<br />

There was also a slight difference in the Shore A Hardness of the polymers in the two studies with the different<br />

air or gas inclusi<strong>on</strong>s. The early study used an <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer with a Shore A Hardness of 85 while the latter showed<br />

a Shore A Hardness of 83. It would be expected that the harder material (85) would transmit more force because<br />

of <str<strong>on</strong>g>its</str<strong>on</strong>g> greater hardness <str<strong>on</strong>g>and</str<strong>on</strong>g> reduced elasticity. However, the <strong>transmitted</strong> <strong>forces</strong> through the air-inclusi<strong>on</strong> material<br />

with fixed air-<str<strong>on</strong>g>cell</str<strong>on</strong>g> volume <str<strong>on</strong>g>and</str<strong>on</strong>g> wall thickness were reduced by 32 percent when compared with the <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer<br />

without air-<str<strong>on</strong>g>cell</str<strong>on</strong>g>s. In c<strong>on</strong>trast, <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer showed a 4.96 percent reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong><br />

compared with <str<strong>on</strong>g>EVA</str<strong>on</strong>g> without the gas inclusi<strong>on</strong>s. The reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong> under the same c<strong>on</strong>diti<strong>on</strong>s<br />

(magnitude of test impact force, thickness of test samples <str<strong>on</strong>g>and</str<strong>on</strong>g> similar air-c<strong>on</strong>diti<strong>on</strong>ed envir<strong>on</strong>ment) <str<strong>on</strong>g>and</str<strong>on</strong>g> with<br />

similar <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymers showed that the improvements in the <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymer were <strong>on</strong>ly <strong>on</strong>e sixth of those shown<br />

with the more c<strong>on</strong>trolled air-inclusi<strong>on</strong>s with regular volume <str<strong>on</strong>g>and</str<strong>on</strong>g> wall thickness.<br />

CONCLUSIONS: The additi<strong>on</strong> of <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent to the <str<strong>on</strong>g>EVA</str<strong>on</strong>g> ( Shore A Hardness 83) comm<strong>on</strong>ly used in<br />

mouthguard materials produced <str<strong>on</strong>g>closed</str<strong>on</strong>g>-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g>s which showed small increases in energy absorpti<strong>on</strong>, when<br />

impacted, compared with the same material without <str<strong>on</strong>g>foam</str<strong>on</strong>g>. Reducti<strong>on</strong>s of close to 5 percent in <strong>transmitted</strong> <strong>forces</strong> in<br />

these <str<strong>on</strong>g>foam</str<strong>on</strong>g> materials c<strong>on</strong>trasted with the larger air-inclusi<strong>on</strong>s with fixed air-<str<strong>on</strong>g>cell</str<strong>on</strong>g> volume <str<strong>on</strong>g>and</str<strong>on</strong>g> wall thickness which<br />

dem<strong>on</strong>strated a 32 percent reducti<strong>on</strong> in <strong>transmitted</strong> <strong>forces</strong>.<br />

Closed-<str<strong>on</strong>g>cell</str<strong>on</strong>g> <str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>EVA</str<strong>on</strong>g> plastics with up to 10 percent by weight <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent <str<strong>on</strong>g>and</str<strong>on</strong>g> with indiscriminate gasinclusi<strong>on</strong>s<br />

do not provide statistically significant improvements in energy absorpti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> reducti<strong>on</strong>s in <strong>transmitted</strong><br />

<strong>forces</strong> when compared with n<strong>on</strong>-<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> polymers.<br />

ACKNOWLEDGEMENTS: This study was supported by a grant from the <strong>Australian</strong> Dental Research<br />

Foundati<strong>on</strong> Inc.<br />

The authors also thank Frank <str<strong>on</strong>g>and</str<strong>on</strong>g> John Oskam for their assistance in preparing the <str<strong>on</strong>g>foam</str<strong>on</strong>g> materials.<br />

REFERENCES:<br />

1. Wood AW. Head protecti<strong>on</strong>- cranial, facial <str<strong>on</strong>g>and</str<strong>on</strong>g> dental in c<strong>on</strong>tact sports. Oral Health 62:23-33, 1972<br />

2. Wei SH. Preventi<strong>on</strong> of injuries to anterior teeth. Int Dent J 24:30-49, 1974<br />

3. Gar<strong>on</strong> MW, Merckle A, Wright JT. Mouth protectors <str<strong>on</strong>g>and</str<strong>on</strong>g> oral trauma: a study of adolescent football<br />

players. J Am Dent Assoc 12:663-6, 1986<br />

4. Hickey JC, Morris AL, Caels<strong>on</strong> LD, Seward TE. The relati<strong>on</strong> of mouth protectors to cranial pressure <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

deformati<strong>on</strong>. J Am Dent Assoc 74:735-40, 1967<br />

5. De Wijn JR, Vrijhoef MMA, Versteegh PA, Strassen HP, Linn EW. A mechanical investigati<strong>on</strong> to the<br />

functi<strong>on</strong>ing of mouthguards. Biomedics:Principles <str<strong>on</strong>g>and</str<strong>on</strong>g> applicati<strong>on</strong>s. The Hague:Martinus Nijhoff<br />

Publishers, 1982.<br />

6. Park JB, Shaull KL, Overt<strong>on</strong> B, D<strong>on</strong>ly KJ. Improving mouthguards. J Prosthet Dent 72:373-380, 1994<br />

7. Going RE, Loehman RE, Ming Sam Chan. Mouthguard materials: their physical <str<strong>on</strong>g>and</str<strong>on</strong>g> mechanical<br />

properties. J Am Dent Assoc 88:132-8, 1974<br />

8. Westerman B, Stringfellow PM, Ecclest<strong>on</strong> JA. Forces <strong>transmitted</strong> through <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard matterials of<br />

different types <str<strong>on</strong>g>and</str<strong>on</strong>g> thickness. Aust Dent J 40:389-391, 1995<br />

9. Westerman B, Stringfellow PM, Ecclest<strong>on</strong> JA. An improved mouthguard material. Aust Dent J 42:189-<br />

191, 1997<br />

10. Francis KT, Brasher J. Physical <str<strong>on</strong>g>effect</str<strong>on</strong>g>s of wearing mouthguards. Br J Sports Med 25(4):227-31, 1991<br />

11. Westerman B, Sringfellow PM, Ecclest<strong>on</strong> JA. The beneficial <str<strong>on</strong>g>effect</str<strong>on</strong>g>s of air-inclusi<strong>on</strong>s <strong>on</strong> mouthguard<br />

performance. Submitted for publicati<strong>on</strong> 2001.

Table 1. Mean maximum <strong>transmitted</strong> <strong>forces</strong> through <str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>and</str<strong>on</strong>g> n<strong>on</strong>-<str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard material (kN)<br />

Foaming agent <strong>transmitted</strong> <strong>forces</strong> st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard deviati<strong>on</strong><br />

(% weight) (kN)<br />

0.0 (c<strong>on</strong>trol) 4.04 0.21<br />

1.0<br />

4.12 0.08<br />

5.0 4.08 0.10<br />

10.0<br />

3.88 0.16<br />

Figure 1. Mean maximum <strong>transmitted</strong> <strong>forces</strong> (kN) in <str<strong>on</strong>g>foam</str<strong>on</strong>g>ed <str<strong>on</strong>g>and</str<strong>on</strong>g> n<strong>on</strong>-<str<strong>on</strong>g>foam</str<strong>on</strong>g> <str<strong>on</strong>g>EVA</str<strong>on</strong>g> mouthguard material -<br />

percentage <str<strong>on</strong>g>foam</str<strong>on</strong>g>ing agent<br />

<strong>transmitted</strong> force (kN)<br />

5.00E+00<br />

4.00E+00<br />

3.00E+00<br />

2.00E+00<br />

1.00E+00<br />

0.00E+00<br />

-1.00E+00<br />

1<br />

153<br />

305<br />

457<br />

609<br />

761<br />

913<br />

time (0.001sec<strong>on</strong>ds)<br />

0% <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

1% <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

5% <str<strong>on</strong>g>foam</str<strong>on</strong>g><br />

10% <str<strong>on</strong>g>foam</str<strong>on</strong>g>