PROCUREMENT Process Diagram for the Rutherford Initiative

PROCUREMENT Process Diagram for the Rutherford Initiative

PROCUREMENT Process Diagram for the Rutherford Initiative

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

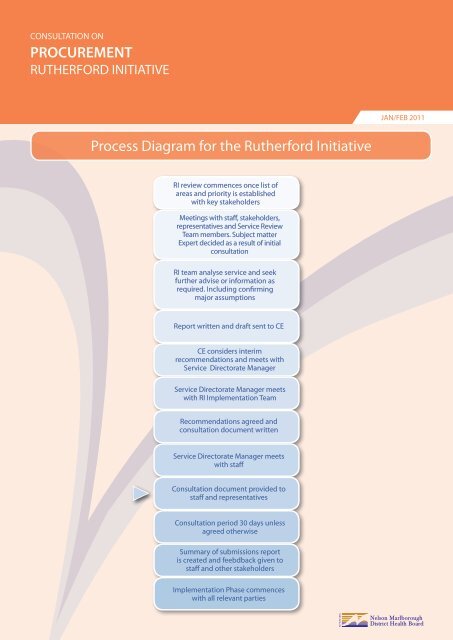

CONSULTATION ON<br />

<strong>PROCUREMENT</strong><br />

RUTHERFORD INITIATIVE<br />

<strong>Process</strong> <strong>Diagram</strong> <strong>for</strong> <strong>the</strong> Ru<strong>the</strong>r<strong>for</strong>d <strong>Initiative</strong><br />

RI review commences once list of<br />

areas and priority is established<br />

with key stakeholders<br />

Meetings with staff, stakeholders,<br />

representatives and Service Review<br />

Team members. Subject matter<br />

Expert decided as a result of initial<br />

consultation<br />

RI team analyse service and seek<br />

fur<strong>the</strong>r advise or in<strong>for</strong>mation as<br />

required. Including confirming<br />

major assumptions<br />

Report written and draft sent to CE<br />

CE considers interim<br />

recommendations and meets with<br />

Service Directorate Manager<br />

Service Directorate Manager meets<br />

with RI Implementation Team<br />

Recommendations agreed and<br />

consultation document written<br />

Service Directorate Manager meets<br />

with staff<br />

Consultation document provided to<br />

staff and representatives<br />

Consultation period 30 days unless<br />

agreed o<strong>the</strong>rwise<br />

Summary of submissions report<br />

is created and feebdback given to<br />

staff and o<strong>the</strong>r stakeholders<br />

Implementation Phase commences<br />

with all relevant parties<br />

JAN/FEB 2011

Ru<strong>the</strong>r<strong>for</strong>d <strong>Initiative</strong> – Procurement Consultation Document<br />

COST SAVING INITIATIVES<br />

<strong>Initiative</strong> 1<br />

Transfer management of consignment stock to Procurement and fully review<br />

consignment stock at Nelson and Wairau sites.<br />

Total estimated savings $468k, through a 15% reduction in costs.<br />

Rationale<br />

Consignment stock particularly in large organisations can be problematic. In brief,<br />

ownership of consignment stock is not transferred until it is used: invoicing is not<br />

immediate. Only after <strong>the</strong> DHB actually uses <strong>the</strong> consignment stock may an<br />

accounts payable be created. The nature of consignment inventory is that “change of<br />

ownership” is unrelated to <strong>the</strong> shipment/receipt processes. This is contrary to <strong>the</strong><br />

basic design of most inventory/accounting systems transactional processes.<br />

Because of this, most inventory systems do not handle consignment inventory very<br />

well. This <strong>for</strong>ces many businesses to manage consignment inventory with manual<br />

off-line processes (sending reports back and <strong>for</strong>th, maintaining data in spreadsheets,<br />

etc). Not only is this time consuming, but it also creates many opportunities <strong>for</strong> errors<br />

because <strong>the</strong> additional transactions necessary <strong>for</strong> consignment inventory can get<br />

ra<strong>the</strong>r complicated and are highly dependant on accurate in<strong>for</strong>mation sharing. If this<br />

process is not monitored closely, an organisation can end up in a situation where<br />

reconciling its consignment inventory becomes a nightmare. Having one point of<br />

accountability with <strong>the</strong> tools to manage and <strong>the</strong> following principles will result in cost<br />

reduction.<br />

Recommendations:<br />

• That all consignment stock is reviewed by Procurement alongside <strong>the</strong> relevant<br />

department manager;<br />

• That all consignment stock is managed by <strong>the</strong> Procurement service; and<br />

• That <strong>the</strong> level of consignment stock generally is reduced.<br />

Ownership<br />

Procurement Team Leader<br />

Page 1 of 9

<strong>Initiative</strong> 2<br />

Negotiate contracts with all suppliers costing $40k or more per annum<br />

Total estimated savings $217k<br />

Rationale<br />

Not all of NMDHB suppliers are covered by a contract <strong>for</strong> a variety of reasons - some<br />

suppliers have refused to enter into contracts.<br />

Increasing <strong>the</strong> number of suppliers with contracts will improve <strong>the</strong> administration of<br />

contracts.<br />

Recommendations:<br />

• Ensure Procurement staff have <strong>the</strong> time to focus on this aspect of<br />

procurement; and<br />

• Negotiate supply agreements as soon as practicable.<br />

Ownership<br />

Procurement Team Leader<br />

<strong>Initiative</strong> 3<br />

Review stock levels across ward stores, o<strong>the</strong>r stores and Nelson and Wairau<br />

stores<br />

Rationale<br />

There is not a clear point of accountability <strong>for</strong> stock locations.<br />

Recommendations:<br />

• That a thorough and systematic review of all store locations is undertaken,<br />

starting at <strong>the</strong> stores with higher stock levels;<br />

• That Charge Nurse Managers are accountable <strong>for</strong> <strong>the</strong>ir department’s stores;<br />

• That KPIs are established <strong>for</strong> stock in stores <strong>for</strong> HODs and CNMs;<br />

• That regular audits take place; and<br />

• That procurement teams with <strong>the</strong> assistance of <strong>the</strong> Quality team review <strong>the</strong><br />

Nelson and Wairau main stores.<br />

Ownership<br />

Procurement Team Leader<br />

Page 2 of 9

<strong>Initiative</strong> 4<br />

Shift undefined products to <strong>the</strong> catalogue<br />

Estimated total savings $132k. Savings are based on <strong>the</strong> assumption <strong>the</strong>re will be a<br />

reduction in current level of undefined products and a move to more cost effective<br />

products in <strong>the</strong> catalogue.<br />

Rationale<br />

NMDHB spends a considerable amount on products each year. The products fall into<br />

four categories:<br />

1. Capital items;<br />

2. Stock (in catalogue and held in store);<br />

3. Non stock (in catalogue but not held in store); and<br />

4. Undefined products (not in catalogue).<br />

The organisation spends approximately $20m a year on undefined products. This<br />

does not allow appropriate controls on purchasing.<br />

Recommendations:<br />

• Procurement service focuses on and accelerate processes to transfer<br />

agreed non defined product to <strong>the</strong> catalogue; and<br />

• That procurement aims <strong>for</strong> 95% of undefined stock being defined and if<br />

appropriate transferred onto catalogue.<br />

Ownership<br />

Procurement Team Leader<br />

<strong>Initiative</strong> 5<br />

Reduce purchase orders and process more purchases using TechOne<br />

Total estimated saving $83k through a reduction in <strong>the</strong> level of “no purchase orders”<br />

with a consequent saving through better administration and control of expenditure.<br />

Rationale<br />

At <strong>the</strong> time of review, of <strong>the</strong> total spend ($70m) on supplies/products, only 53% was<br />

raised by purchase order.<br />

The number of non purchase orders needs to reduce significantly to allow better<br />

management and control of spend.<br />

Page 3 of 9

Recommendations:<br />

• That a policy of “No Purchase Order No Payment” be developed; and<br />

• That <strong>the</strong> No Purchase Order NO Payment Policy be rolled out over a two<br />

year period with a target of 50% reduction.<br />

Ownership<br />

Procurement Team Leader<br />

CAPITAL PURCHASE INITIATIVE<br />

<strong>Initiative</strong> 6<br />

Greater involvement of Procurement in capex process<br />

Estimated total saving $180k.<br />

Rationale<br />

Managing costs and ensuring optimal supply is <strong>the</strong> strategic contribution that<br />

Procurement can make to <strong>the</strong> DHB’s success. By being fully involved fluidity and<br />

cost of supply chains are improved. This should also include capex.<br />

Recommendations:<br />

• That <strong>the</strong> business case template is reviewed with a worked example<br />

included;<br />

• Inclusion of a capex checklist <strong>for</strong> all capex procedures be developed;<br />

• Procurement's role be expanded to be included in capex decisions and to<br />

include working with BST by providing advice on budget setting, checking<br />

business case inputs, quoting or tendering, sign-off, placing <strong>the</strong> order and<br />

supplier per<strong>for</strong>mance management;<br />

• That with <strong>the</strong> exclusion of <strong>the</strong> Planning and Funding contracts, Procurement<br />

is involved at least from a probity perspective on all capex, clinical<br />

equipment and o<strong>the</strong>r capex greater than $100k;<br />

• That <strong>the</strong> use of a preferred equipment list <strong>for</strong> each service specialty is<br />

developed; and<br />

• That a capex review is completed with each service Directorate of capex<br />

requirements <strong>for</strong> <strong>the</strong> next 3 years and a capex plan <strong>for</strong> each service<br />

prepared.<br />

Ownership<br />

Infrastructure Manager<br />

Page 4 of 9

PROCESS INITIATIVES<br />

<strong>Initiative</strong> 7<br />

Reduce <strong>the</strong> number of suppliers<br />

Rationale<br />

In 2009/2010 <strong>the</strong>re was over 2600 suppliers to <strong>the</strong> DHB. Of <strong>the</strong>se 90% (1721<br />

Suppliers) are <strong>for</strong> less than $50k which in aggregate account <strong>for</strong> only 13% of <strong>the</strong><br />

total spend. All <strong>the</strong>se suppliers require some <strong>for</strong>m of administration and<br />

management. Reduction in <strong>the</strong> number of suppliers particularly in <strong>the</strong> 90% category<br />

will "free up" staff time, lower administration costs and could well result in reduction<br />

of supplier costs through consolidation.<br />

Recommendation:<br />

That wherever possible DHB wide all purchases are via Procurement through<br />

TechOne. This will facilitate supplier rationalisation and enable tighter management<br />

of supplier relationships.<br />

Ownership<br />

Procurement Team Leader<br />

<strong>Initiative</strong> 8<br />

Review Product Evaluation Committee<br />

Rationale<br />

The purpose of a Product Evaluation Committee is to control <strong>the</strong> introduction of new<br />

medical equipment and clinical consumables. Its role is to assist in <strong>the</strong> development<br />

of purchasing policy and <strong>the</strong> evaluation of equipment and consumable supplies.<br />

When considering <strong>the</strong> introduction of new equipment or consumables, <strong>the</strong> product<br />

evaluation process considers a range of issues, including clinical requirements,<br />

quality, cost, and standardisation with existing equipment and products, as well as<br />

ongoing educational requirements.<br />

Recommendation:<br />

That <strong>the</strong> Terms of Reference and membership <strong>for</strong> <strong>the</strong> Product Evaluation Committee<br />

is reviewed to ensure its purpose is fully met.<br />

Ownership<br />

Infrastructure Manager<br />

Page 5 of 9

<strong>Initiative</strong> 9<br />

Increase functional use of TechOne<br />

Rationale<br />

TechOne is not being utilised to its full potential. To help maximise efficiencies and<br />

savings from procurement, DHBs generally need to understand <strong>the</strong> demand <strong>for</strong>, and<br />

usage of, goods and services at <strong>the</strong> line item level. This knowledge can improve<br />

purchasing through a better understanding of what, why, when, how much<br />

purchasing is happening so that best practices can be implemented.<br />

Recommendation:<br />

That an appropriate staff member with comprehensive knowledge of TechOne and<br />

its functionality is assigned as project leader with <strong>the</strong> objective to increase <strong>the</strong> level<br />

of use of TechOne starting with Procurement and <strong>the</strong>n migrating to key users.<br />

Ownership<br />

Procurement Team Leader<br />

<strong>Initiative</strong> 10<br />

Regional and National <strong>Initiative</strong>s<br />

Rationale<br />

There are a number of National and Regional initiatives underway regarding<br />

Procurement which if implemented will result in increased efficiencies and benefits<br />

<strong>for</strong> <strong>the</strong> DHB through:<br />

• Exploiting economies of scale;<br />

• Partnering with o<strong>the</strong>r DHBs to share inventory management and distribution<br />

services; and<br />

• Aggregation of demand <strong>for</strong> medical equipment and consumables.<br />

Regional and National collaboration between DHBs is such that initiatives will take<br />

time to be developed and implemented. In <strong>the</strong> interim <strong>the</strong> DHB needs to focus on<br />

doing what it can internally. We need to be cognisant of developments and ensure it<br />

does not anyway hamper Regional and National <strong>Initiative</strong>s.<br />

Recommendation:<br />

That NMDHB maintains an active presence at all National & Regional <strong>for</strong>ums but<br />

aggressively addresses all aspects of Procurement as <strong>the</strong>re are potential savings<br />

regardless of National and Regional possible <strong>Initiative</strong>s.<br />

Ownership<br />

Infrastructure Manager<br />

Page 6 of 9

<strong>Initiative</strong> 11<br />

Increase <strong>the</strong> level of KPI reporting<br />

Rationale<br />

The <strong>for</strong>mer order system (JDE) was problematic and cumbersome. The recent<br />

installation of TechOne with its greater functionality has significantly improved<br />

Procurement’s ability to develop and monitor supply chain processes albeit some of<br />

<strong>the</strong>se processes are still in <strong>the</strong>ir infancy and need to be accelerated. Procurement<br />

produces a monthly purchasing and inventory report off TechOne. KPI reporting<br />

needs to be developed with regards to monitoring <strong>the</strong> Opex <strong>Initiative</strong>s, achieving<br />

targets etc.<br />

Recommendation:<br />

That a thorough review of per<strong>for</strong>mance measures takes place, generating<br />

per<strong>for</strong>mance measures as opposed to simply reporting historical and <strong>the</strong><br />

development of savings targets and mechanisms to monitor <strong>the</strong> efficiency of<br />

procurement and supply chain processes, and <strong>the</strong> savings delivered.<br />

Ownership<br />

Infrastructure Manager<br />

<strong>Initiative</strong> 12<br />

Improve Supplier Relationship Management<br />

Rationale<br />

There are three key areas where Procurement staff can contribute to a successful<br />

supply chain:<br />

• Visibility - Provide clinicians, nursing and management with spend data to<br />

detect and interpret supply and demand patterns, from which sourcing and<br />

stocking decisions can be made. For example, this visibility can help answer<br />

how many of a specific item, like a ca<strong>the</strong>ter, needs to be delivered. When are<br />

<strong>the</strong>y needed? Are <strong>the</strong>re any spikes in demand? Where are <strong>the</strong>y needed? How<br />

many suppliers are needed to mitigate supply risk? Which of <strong>the</strong>se suppliers<br />

are strategically important to <strong>the</strong> organisation? Data analysis can yield great<br />

examples of savings, such as dual/multiple sourcing strategies to ensure<br />

continuous supply, volume aggregation and item standardisation to drive<br />

volume discounts;<br />

• Supply Market Intelligence - Procurement should be continuously feeling <strong>the</strong><br />

pulse of <strong>the</strong> industry, as well as individual suppliers, to understand<br />

consolidation or separation, emergence of technologies, demographics and<br />

market changes; and<br />

• Supplier Per<strong>for</strong>mance Monitoring - Ongoing supplier per<strong>for</strong>mance<br />

management is paramount to guarantee optimal patient outcome. Without<br />

monitoring a supplier's key per<strong>for</strong>mance indicators such as on-time delivery,<br />

accurateness of supply and responsiveness in rush-order situations, parts of<br />

<strong>the</strong> Provider may find <strong>the</strong>mselves unable to optimally serve a patient.<br />

Page 7 of 9

There<strong>for</strong>e standards of care at <strong>the</strong> Provider are directly dependant upon<br />

strategic supplier management.<br />

There<strong>for</strong>e, central to greater efficiency in Procurement is <strong>the</strong> maintenance of user<br />

and supplier relationships. The DHB can secure its line of materials and can reduce<br />

transaction costs and <strong>for</strong>go extra costs and delays of finding new suppliers all <strong>the</strong><br />

time. Best in class DHBs meet regularly with <strong>the</strong>ir strategic suppliers to discuss<br />

supply and delivery improvements ranging from process to items upgrades.<br />

The number of key relationships and <strong>the</strong> level of relationship activity with suppliers<br />

should be increased and <strong>the</strong> nature of <strong>the</strong> supplier relationships become more<br />

strategic. Suppliers are not per<strong>for</strong>mance monitored nor is <strong>the</strong>re proactive meetings<br />

with suppliers given <strong>the</strong> level of expenditure with suppliers.<br />

Recommendations:<br />

• Develop an overall supplier management plan;<br />

• Broaden <strong>the</strong> number of key relationships;<br />

• Develop individual supplier management plans;<br />

• Introduce supplier KPIs;<br />

• Building key strategic relationships; and<br />

• Develop use of TechOne and Electronic Data Interface direct to suppliers’<br />

inventory.<br />

Ownership<br />

Procurement Team Leader<br />

<strong>Initiative</strong> 13<br />

Link with major suppliers through TechOne using electronic data interface<br />

Rationale<br />

TechOne is trialling with Hawke’s Bay DHB, Johnson & Johnson and Baxter an<br />

Electronic Data Interface which will enable <strong>the</strong> DHB to order direct from <strong>the</strong> suppliers<br />

inventory and match <strong>the</strong> invoice to products sourced with no human interface. The<br />

implications <strong>for</strong> greater efficiency, less procurement staff, increased speed of supply,<br />

reduction in inventory levels held at <strong>the</strong> DHB are significant.<br />

Recommendation:<br />

That if successful following suit as soon as practicable.<br />

Ownership<br />

Procurement Team Leader<br />

Page 8 of 9

<strong>Initiative</strong> 14<br />

Review Impresting Systems<br />

Rationale<br />

Currently Procurement staff physically imprest wards every few days in <strong>the</strong> ward<br />

stores. This process is cumbersome and time consuming. With <strong>the</strong> introduction of<br />

TechOne it is suggested that this impresting can become redundant as <strong>the</strong> wards<br />

<strong>the</strong>mselves could order via TechOne directly from <strong>the</strong> stores. However, this is not<br />

recommended at this stage as a cost saving initiative as <strong>the</strong>re are a number of o<strong>the</strong>r<br />

process changes that should first occur two of which is a complete review of ward<br />

stores across <strong>the</strong> DHB and instilling "ownership" of ward stores in <strong>the</strong> minds of <strong>the</strong><br />

Charge Nurse Managers.<br />

Recommendation:<br />

A full review of impresting process is completed after <strong>Initiative</strong> 3 is implemented.<br />

Ownership<br />

Procurement Team Leader<br />

Page 9 of 9

RUTHERFORD INITIATIVE CONSULTATION<br />

<strong>PROCUREMENT</strong><br />

FEEDBACK FORM<br />

In<strong>for</strong>mation about you: (Optional)<br />

Name:<br />

Address:<br />

Phone:<br />

Organisation represented: (if applicable)<br />

Option Feedback: 1: What do you think about <strong>the</strong> proposal to outsource Ophthalmology Services?<br />

What do you think about <strong>the</strong> consultation proposal?<br />

Additional comment (you may like to include an insert with your returned <strong>for</strong>m)<br />

SUBMISSIONS CLOSE AT 5 PM ON FRIDAY, 25 FEBRUARY 2011<br />

Written feedback is <strong>the</strong> preferred mechanism <strong>for</strong> submitting responses to <strong>the</strong> proposal.<br />

Submissions to <strong>the</strong> proposal should be emailed to: karen.lindsay@nmdhb.govt.nz<br />

Any hard copy submissions should be mailed to: Karen Lindsay, Human Resources, NMDHB, Private Bag 18, Nelson<br />

Any staff wishing to make a verbal submission should contact: Karen Lindsay. Staff feedback during <strong>the</strong><br />

consultation period will be taken into consideration in <strong>the</strong> final decision over <strong>the</strong>se proposed changes.