acrobat JSPD 8 - The Centre for Sustainable Design

acrobat JSPD 8 - The Centre for Sustainable Design

acrobat JSPD 8 - The Centre for Sustainable Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

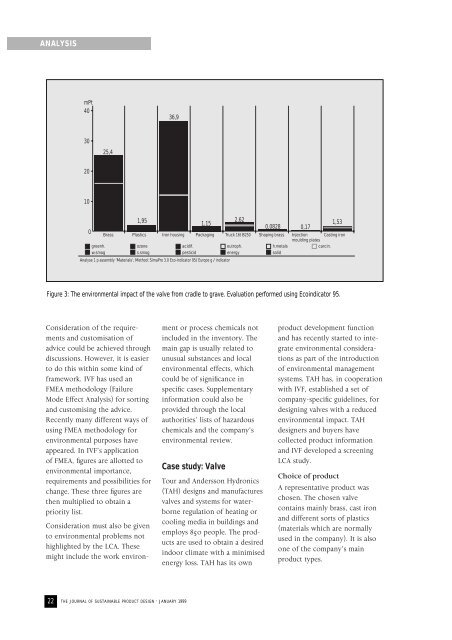

ANALYSIS<br />

mPt<br />

40<br />

30<br />

20<br />

10<br />

0<br />

25,4<br />

1,95<br />

Figure 3: <strong>The</strong> environmental impact of the valve from cradle to grave. Evaluation per<strong>for</strong>med using Ecoindicator 95.<br />

Consideration of the requirements<br />

and customisation of<br />

advice could be achieved through<br />

discussions. However, it is easier<br />

to do this within some kind of<br />

framework. IVF has used an<br />

FMEA methodology (Failure<br />

Mode Effect Analysis) <strong>for</strong> sorting<br />

and customising the advice.<br />

Recently many different ways of<br />

using FMEA methodology <strong>for</strong><br />

environmental purposes have<br />

appeared. In IVF’s application<br />

of FMEA, figures are allotted to<br />

environmental importance,<br />

requirements and possibilities <strong>for</strong><br />

change. <strong>The</strong>se three figures are<br />

then multiplied to obtain a<br />

priority list.<br />

Consideration must also be given<br />

to environmental problems not<br />

highlighted by the LCA. <strong>The</strong>se<br />

might include the work environ-<br />

36,9<br />

22 THE JOURNAL OF SUSTAINABLE PRODUCT DESIGN · JANUARY 1999<br />

1,15<br />

ment or process chemicals not<br />

included in the inventory. <strong>The</strong><br />

main gap is usually related to<br />

unusual substances and local<br />

environmental effects, which<br />

could be of significance in<br />

specific cases. Supplementary<br />

in<strong>for</strong>mation could also be<br />

provided through the local<br />

authorities’ lists of hazardous<br />

chemicals and the company’s<br />

environmental review.<br />

Case study: Valve<br />

2,62<br />

Tour and Andersson Hydronics<br />

(TAH) designs and manufactures<br />

valves and systems <strong>for</strong> waterborne<br />

regulation of heating or<br />

cooling media in buildings and<br />

employs 850 people. <strong>The</strong> products<br />

are used to obtain a desired<br />

indoor climate with a minimised<br />

energy loss. TAH has its own<br />

0,0828 0,17<br />

Brass Plastics Iron housing Packaging Truck 16t B250 Shaping brass Injection<br />

moulding plates<br />

Casting iron<br />

greenh.<br />

ozone<br />

acidif.<br />

eutroph.<br />

h.metals<br />

carcin.<br />

w.smog<br />

s.smog<br />

pesticid<br />

energy<br />

solid<br />

Analyse 1 p assembly ‘Materials’; Method: SimaPro 3.0 Eco-indicator 95/ Europe g / indicator<br />

1,53<br />

product development function<br />

and has recently started to integrate<br />

environmental considerations<br />

as part of the introduction<br />

of environmental management<br />

systems. TAH has, in cooperation<br />

with IVF, established a set of<br />

company-specific guidelines, <strong>for</strong><br />

designing valves with a reduced<br />

environmental impact. TAH<br />

designers and buyers have<br />

collected product in<strong>for</strong>mation<br />

and IVF developed a screening<br />

LCA study.<br />

Choice of product<br />

A representative product was<br />

chosen. <strong>The</strong> chosen valve<br />

contains mainly brass, cast iron<br />

and different sorts of plastics<br />

(materials which are normally<br />

used in the company). It is also<br />

one of the company’s main<br />

product types.