PA30IS Series Powered Air-Purifying Respirator PA3IS ... - Bullard

PA30IS Series Powered Air-Purifying Respirator PA3IS ... - Bullard

PA30IS Series Powered Air-Purifying Respirator PA3IS ... - Bullard

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mounting and Replacing Cartridges on the Blower Unit<br />

The useful life of a chemical cartridge for vapors and gases will vary with the<br />

concentration and nature of the contaminant, the breathing rate of the respirator<br />

wearer, and ambient temperature and humidity.<br />

The Occupational Safety and Health Administration (OSHA) regulations 29 CFR<br />

1910.134 require that the employer must implement a change schedule when<br />

using <strong>Air</strong>-<strong>Purifying</strong> respirators for protection against gases and vapors, if there<br />

is no end-of-service-life indicator on the cartridges. The change schedule must<br />

be based on objective data that will ensure that the cartridges are replaced<br />

before the end of their service life. Factors to consider include workplace conditions<br />

such as contaminant concentration, relative humidity, temperature, work<br />

activities, respirator use pattern (e.g., continuous or intermittent use), presence<br />

of other contaminants, potential for contaminant migration/desorption, health<br />

effects of the gas or vapor, and the presence of any warning properties. Contact<br />

<strong>Bullard</strong> for further information on change-out schedules.<br />

High efficiency particulate filters must be replaced when retained particles clog<br />

the filters and reduce air flow below acceptable levels, as indicated by testing<br />

with the <strong>Air</strong> Flow Indicator.<br />

To Replace Cartridges<br />

Remove the air-purifying element from its packaging, and inspect for damage. If<br />

in doubt do not use.<br />

Check that the air-purifying element has not exceeded its “use-by” date and that<br />

the connecting thread is in good condition.<br />

Check that the air-purifying element is appropriate to the hazard. If in doubt<br />

consult your respirator program administrator or supervisor.<br />

Check that the threads in the blower unit port are in good condition and clear of<br />

contaminant.<br />

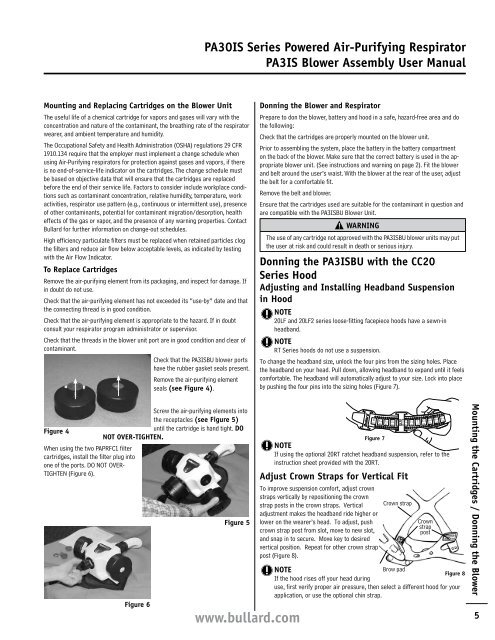

Check that the <strong>PA3IS</strong>BU blower ports<br />

have the rubber gasket seals present.<br />

Remove the air-purifying element<br />

seals (see Figure 4).<br />

Screw the air-purifying elements into<br />

the receptacles (see Figure 5)<br />

Figure 4<br />

until the cartridge is hand tight. DO<br />

NOT OVER-TIGHTEN.<br />

When using the two PAPRFC1 filter<br />

cartridges, install the filter plug into<br />

one of the ports. DO NOT OVER-<br />

TIGHTEN (Figure 6).<br />

Figure 6<br />

<strong>PA30IS</strong> <strong>Series</strong> <strong>Powered</strong> <strong>Air</strong>-<strong>Purifying</strong> <strong>Respirator</strong><br />

<strong>PA3IS</strong> Blower Assembly User Manual<br />

Figure 5<br />

www.bullard.com<br />

Donning the Blower and <strong>Respirator</strong><br />

Prepare to don the blower, battery and hood in a safe, hazard-free area and do<br />

the following:<br />

Check that the cartridges are properly mounted on the blower unit.<br />

Prior to assembling the system, place the battery in the battery compartment<br />

on the back of the blower. Make sure that the correct battery is used in the appropriate<br />

blower unit. (See instructions and warning on page 2). Fit the blower<br />

and belt around the user’s waist. With the blower at the rear of the user, adjust<br />

the belt for a comfortable fit.<br />

Remove the belt and blower.<br />

Ensure that the cartridges used are suitable for the contaminant in question and<br />

are compatible with the <strong>PA3IS</strong>BU Blower Unit.<br />

WARNING<br />

The use of any cartridge not approved with the <strong>PA3IS</strong>BU blower units may put<br />

the user at risk and could result in death or serious injury.<br />

Donning the <strong>PA3IS</strong>BU with the CC20<br />

<strong>Series</strong> Hood<br />

Adjusting and Installing Headband Suspension<br />

in Hood<br />

NOTE<br />

20LF and 20LF2 series loose-fitting facepiece hoods have a sewn-in<br />

headband.<br />

NOTE<br />

RT <strong>Series</strong> hoods do not use a suspension.<br />

To change the headband size, unlock the four pins from the sizing holes. Place<br />

the headband on your head. Pull down, allowing headband to expand until it feels<br />

comfortable. The headband will automatically adjust to your size. Lock into place<br />

by pushing the four pins into the sizing holes (Figure 7).<br />

Figure 7<br />

NOTE<br />

If using the optional 20RT ratchet headband suspension, refer to the<br />

instruction sheet provided with the 20RT.<br />

Adjust Crown Straps for Vertical Fit<br />

To improve suspension comfort, adjust crown<br />

straps vertically by repositioning the crown<br />

strap posts in the crown straps. Vertical<br />

adjustment makes the headband ride higher or<br />

lower on the wearer’s head. To adjust, push<br />

crown strap post from slot, move to new slot,<br />

and snap in to secure. Move key to desired<br />

vertical position. Repeat for other crown strap<br />

post (Figure 8).<br />

NOTE<br />

Brow pad<br />

Figure 8<br />

If the hood rises off your head during<br />

use, first verify proper air pressure, then select a different hood for your<br />

application, or use the optional chin strap.<br />

8<br />

64<br />

7 63<br />

7 62<br />

7 61<br />

SIZE<br />

7 60<br />

7 59<br />

7 58<br />

7/8 3/4 5/8 1/2 3/8 1/8<br />

Crown strap<br />

7<br />

57<br />

6 56<br />

7/8<br />

6 55<br />

Crown<br />

strap<br />

post<br />

6 54<br />

6 53<br />

3/4 5/8 1/2<br />

Mounting the Cartridges / Donning the Blower<br />

5