Martin Industries, LLC. ? 800.366.5817 13

Martin Industries, LLC. ? 800.366.5817 13

Martin Industries, LLC. ? 800.366.5817 13

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

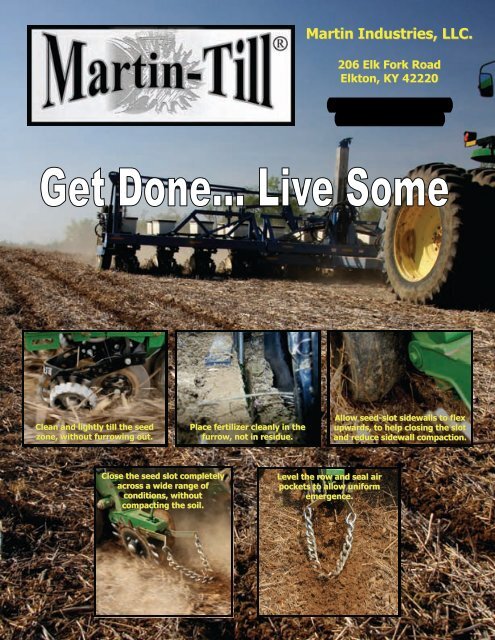

Clean and lightly till the seed<br />

zone, without furrowing out.<br />

Close the seed slot completely<br />

across a wide range of<br />

conditions, without<br />

compacting the soil.<br />

Place fertilizer cleanly in the<br />

furrow, not in residue.<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>.<br />

Level the row and seal air<br />

pockets to allow uniform<br />

emergence.<br />

206 Elk Fork Road<br />

Elkton, KY 42220<br />

Phone 800-366 800 366-5817 5817<br />

Fax 270-265 270 265-9896 9896<br />

Allow seed-slot seed slot sidewalls to flex<br />

upwards, to help closing the slot<br />

and reduce sidewall compaction.

Consider this.<br />

Each year, more and more farmers turn to the <strong>Martin</strong>-Till system to help widen their<br />

planting window. Being able to return to the field a day or two sooner after each rain<br />

allows more acres to be planted on time. Having the option of reducing or<br />

eliminating tillage lets them focus on planting, which creates opportunities for<br />

expansion without the need for additional costly equipment.<br />

Increased nitrate levels within streams and rivers will soon bring tighter regulations<br />

with regards to quantity and timing of nitrogen applications. This brings both<br />

challenges and opportunities, because research clearly illustrates that banding<br />

fertilizer close to the seed row can increase early plant health (especially in no-till<br />

conditions) plus boost the overall recovery % of fertilizer applications. Our UMO-100<br />

fertilizer opener mounts to the face plate of the planter unit and cleanly positions<br />

fertilizer consistently alongside the row. The UMO-100 can also be installed within<br />

our new <strong>13</strong>60 floating row cleaners to achieve the benefits of residue clearing and<br />

fertilizer placement at the same time.<br />

<strong>Martin</strong> <strong>Industries</strong> remains committed to the task of discovering and developing more<br />

ways to help our customers achieve better stands, yields and profits.<br />

Howard <strong>Martin</strong><br />

Founder, <strong>Martin</strong> <strong>Industries</strong>

Contents<br />

Page<br />

<strong>Martin</strong> WA <strong>13</strong>60 Floating Row Cleaners 6-9<br />

<strong>Martin</strong> Fixed Row Cleaners 10-<strong>13</strong><br />

<strong>Martin</strong> UMO-100 Fertilizer Openers 14-15<br />

<strong>Martin</strong> Reduced Inner Diameter Gauge Wheel Tires 16-17<br />

<strong>Martin</strong> Closing Wheel Systems 18-25<br />

<strong>Martin</strong> Twisted Drag Chains 26-27<br />

<strong>Martin</strong> John Deere Grain Drill and Air-Seeder<br />

Closing Systems 28-29<br />

<strong>Martin</strong> Spring Spacers For John Deere Drill and<br />

Air-Seeders 30<br />

Warranty Information 31<br />

®

The 5 Step <strong>Martin</strong>-Till <strong>Martin</strong> Till ® Planting System<br />

4<br />

Step 2.<br />

Place fertilizer in soil, not on trash or<br />

planter.<br />

Use our <strong>Martin</strong> Unit-Mounted Fertilizer<br />

Openers to cleanly position liquid or dry<br />

fertilizer precisely in a band beside the row.<br />

Pages 14 - 15<br />

Step 1.<br />

Clean and lightly till the seed<br />

zone without furrowing out.<br />

Use <strong>Martin</strong> Row Cleaners to remove<br />

excess residue and clods from the<br />

row without furrowing.<br />

Pages 6 - <strong>13</strong><br />

Step 3.<br />

Let the seed discs lift part of the<br />

sidewall.<br />

Use our Reduced Inner Diameter<br />

Gauge Tires to open the seed trench<br />

with a minimum amount of sidewall<br />

compaction.<br />

Pages 16 - 17

Step 4.<br />

Close the slot without compacting the soil surface and slowing emergence.<br />

Select the best <strong>Martin</strong> closing system for your soils and moisture level.<br />

20 point dimples, single 15” and a pair of <strong>13</strong>” spiked closing wheels are all available<br />

to install on most planters to close and/or fracture the sidewalls.<br />

Pages 18 - 25<br />

Step 5.<br />

Level the row and seal air<br />

pockets.<br />

Finally, use our Twisted Drag<br />

Chain to drag a hand-full of soil.<br />

This technique helps level and<br />

lightly firm the row to promote<br />

more consistent emergence.<br />

Pages 26 - 27<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 5

<strong>Martin</strong> WA <strong>13</strong>60 Floating Row Cleaners<br />

6<br />

WA <strong>13</strong>60 Floating Row Cleaner Features:<br />

Heavy Duty frame<br />

3/8" thick, heat treated T-1 right and left toothed<br />

wheels with diamond shaped points<br />

Stationary triple-lip seals<br />

Heavy-gauge dust caps<br />

Double tapered bearings<br />

Greaseable hubs<br />

Available for most planter models<br />

WA <strong>13</strong>60 Floating Row Cleaners<br />

Floating row cleaners allow residue to<br />

be consistently cleared from the seed<br />

zone across a wide range of different<br />

soil types, residue levels and<br />

topographies. The Image to the left<br />

illustrates a WA <strong>13</strong>60 floating row<br />

cleaner helping to no-till corn into<br />

wheat stubble in Kentucky.<br />

The image to the left illustrates a set<br />

of WA <strong>13</strong>60 floating row cleaners<br />

mounted on a John Deere 1770 in<br />

Kansas, no-tilling corn into soybean<br />

residue. Floating row cleaners excel in<br />

fields with topographic variations, different<br />

soil types or areas with wide<br />

ranging residue levels.<br />

The image to the left illustrates a WA<br />

<strong>13</strong>60 floating row cleaner mounted on<br />

a White 8000 series planter no-tilling<br />

corn into grain sorghum residue. A<br />

set of internal deflectors (scrapers)<br />

are strongly encouraged for damp<br />

residue conditions.

WA <strong>13</strong>60 Floating Row Cleaners - Options<br />

STW-04 Side Treader Wheels.<br />

Aluminum Side Treader wheels are purchased on over 95% of<br />

WA <strong>13</strong>60 floating row cleaners and are designed to prevent the<br />

row cleaner wheels trenching within soft soils. They also provide<br />

traction to help keep the row cleaners turning in heavy residue.<br />

CA Cam Adjust.<br />

Clearing Residue<br />

WA <strong>13</strong>60 floating row cleaners are designed<br />

to follow the contours of the soil surface,<br />

consistently moving residue clear of the<br />

path of the gauge wheels. This allows the<br />

gauge wheels to run in the cleared zone to<br />

promote uniform depth control and facilitate<br />

quicker soil warming and rapid emergence.<br />

The image to the left shows a Kentucky<br />

grower no-tilling corn back into previous 200<br />

bu/ac corn residue. When no-tilling into Bt<br />

cornstalks (especially within high yielding<br />

and/or irrigated environments) we strongly<br />

suggest adding at least one pair of wheel<br />

weights (see below).<br />

Cam adjusters are available for all WA <strong>13</strong>60 row cleaners and<br />

they speed up the process of changing the working depth of the<br />

row cleaner frames. They are especially beneficial for growers<br />

who frequently switch from no-till to conventional soils.<br />

WW-04 Wheel Weights (sold as a pair)<br />

Wheel weights are strongly recommended when no-tilling into<br />

heavy residue (such as heavy corn or wheat residue). Each pair<br />

adds 10lb of weight per row. Two pairs can be added per row<br />

for extremely heavy residue such as heavy Bt cornstalks.<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong><br />

<strong>Martin</strong> WA <strong>13</strong>60 Floating Row Cleaners<br />

<strong>Martin</strong> WA <strong>13</strong>60 Floating Row Cleaners<br />

7

<strong>Martin</strong> WA <strong>13</strong>60 Floating Row Cleaners<br />

8<br />

John Deere Mounts<br />

BDC <strong>13</strong>60* This mount attaches to John Deere<br />

7200 (and later) series planters with a<br />

John Deere unit mounted no-till<br />

coulter. It will also install behind the<br />

John Deere single disc fertilizer opener<br />

(with extended parallel arms) and the<br />

Moeller Fertilizer Knife. Measures 21”<br />

from planter face plate to front of row<br />

cleaner wheels.<br />

BD <strong>13</strong>60* This mount attaches to John Deere<br />

7200 (and later) series planters<br />

without No-till coulters. Measures 19”<br />

from planter face plate to front of row<br />

cleaner wheels.<br />

* If equipping the rear units of a John Deere 1790 with <strong>13</strong>60 row<br />

cleaners, long parallel arms all the way across the rear units are<br />

strongly encouraged, especially when operating in heavy residue.<br />

Kinze Mounts<br />

BKC <strong>13</strong>60** This mount attaches to Kinze 2000<br />

and 3000 series planters with a unit<br />

mounted no-till coulter. Measures 21”<br />

from planter face plate to front of row<br />

cleaner wheels.<br />

BK <strong>13</strong>60 This mount attaches to Kinze 2000<br />

and 3000 series planters without a<br />

unit mounted no-till coulter. Measures<br />

19” from planter face plate to front of<br />

row cleaner wheels.<br />

** If installing WA <strong>13</strong>60 row cleaners on Kinze Twinline planters<br />

with no-till coulters, unit set back kits will be required behind the<br />

transport wheels on the rear units. Unit set-back kits (USB-70)<br />

are available from <strong>Martin</strong> <strong>Industries</strong> (see box to the right).

Case IH Mounts<br />

BCIH <strong>13</strong>60*** This mount attaches to Case IH<br />

planters without frame mounted no-till<br />

coulters. Measures 22” forward from<br />

the mounting frog.<br />

*** Please note the BCIH <strong>13</strong>60 will not fit on Case planters that<br />

have the hexagonal drive shaft under the parallel arms (There is<br />

not enough upward clearance above the BCIH <strong>13</strong>60 and below<br />

the parallel arms to allow the frame to float sufficiently).<br />

White Mounts<br />

BW <strong>13</strong>60**** This mount attaches to White 6000<br />

and 8000 series planters without a<br />

no-till coulter. Measures 19” from<br />

planter face plate to front of the row<br />

cleaner wheels.<br />

**** If installing BW <strong>13</strong>60 row cleaners on White planters,<br />

make sure there is enough clearance between the top of the BW<br />

<strong>13</strong>60 frame and the bottom of the planter drive shaft. Some<br />

planters may have interference problems when the row cleaners<br />

raise up on undulating ground.<br />

Unit Set Back Kits<br />

USB 70 Unit set back kit for John Deere 7000 series<br />

and Kinze planters. This kit moves the unit<br />

back 6” to allow more clearance when<br />

installing floating row cleaners around<br />

certain no-till coulter configurations.<br />

USB 72 Unit set back kit for John Deere 7200 series<br />

through to John Deere 1700 series planters.<br />

Moves the unit back 6” to allow more<br />

clearance when placing floating row cleaners<br />

around no-till coulter configurations.<br />

<strong>Martin</strong> WA <strong>13</strong>60 Floating Row Cleaners<br />

<strong>Martin</strong> WA <strong>13</strong>60 Floating Row Cleaners<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 9

<strong>Martin</strong> C-125 C 125 and Fixed Row Cleaners<br />

10<br />

WA 1532<br />

WA 1532 Features<br />

Rigidly mounted directly to<br />

planter unit face plate<br />

Easily adjustable in 1/4"<br />

increments with lift assist<br />

handle and spring<br />

Patent #5,507,351<br />

Heavy duty cast 4-bolt hub<br />

Double tapered bearings<br />

Triple lip seals<br />

<strong>Martin</strong> C-125<br />

We still offer the proven C-125. The C-125 is a<br />

floating row cleaner with 2 x <strong>13</strong>” row cleaner<br />

wheels, heavy duty hubs, double tapered<br />

bearings and optional aluminum side treader<br />

wheels.<br />

C-125 was superseded by the WA <strong>13</strong>60 but this<br />

model can install on planter types not previously<br />

included within this product guide. If in doubt,<br />

please call us to help you configure the best row<br />

cleaner configuration for your planting system.<br />

<strong>Martin</strong> WA 1532 Fixed Row Cleaners<br />

The <strong>Martin</strong> original style row cleaner clears the<br />

widest path of any tooth wheel row cleaner on<br />

the market.<br />

The 15" diameter, 3/8” thick T-1 heat treated<br />

wheels are made left and right in order to shed<br />

the residue better. The axles are located to the<br />

rear of the adjustable stem in order to insure a<br />

simultaneous stretching and cutting of the<br />

residue.<br />

The teeth on the cleaning wheels actually reach<br />

past the edge of the planter gauge wheel rubber.<br />

This guarantees a clear path for planter operation<br />

even at reduced speeds. The space between the<br />

teeth is wider than any competitor’s to enable soil<br />

to remain in place as residue is raked aside. The<br />

teeth intersect in order to reach the entire row<br />

middle and to aid in cleaning one another.<br />

GWS-01 Optional Gauge Wheel Shield<br />

Attaches to the side of the gauge wheel to<br />

smooth out the flow of residue between unit<br />

and transport wheels. Two required per row.

WA <strong>13</strong>32<br />

WA <strong>13</strong>34<br />

WA <strong>13</strong>20N<br />

<strong>Martin</strong> WA<strong>13</strong>32 and WA<strong>13</strong>34 Row Cleaners<br />

• Rigidly mounted directly to planter unit face plate<br />

• Easily adjustable in 1/4" increments with lift assist<br />

handle and spring<br />

• Movable axles with the <strong>Martin</strong> Exclusive D-Lock<br />

System allow for several mounting positions<br />

(intersect, offset, retracted)<br />

• <strong>13</strong>" diameter toothed steel wheels with diamond<br />

shaped points allow plenty of upward adjustment in<br />

loosely worked soils<br />

WA <strong>13</strong>32 Row Cleaner comes complete with 1 1/2”<br />

stem wheel assembly. (For use with all pin adjust<br />

brackets which accept 1 1/2” stems).<br />

WA <strong>13</strong>34 Row Cleaner are specifically desiogned for<br />

IH Early-Riser planters which require extra tilt. (for<br />

use with all pin adjust brackets which accept 2”<br />

stems).<br />

<strong>Martin</strong> WA <strong>13</strong>20N Row Cleaners<br />

The <strong>Martin</strong> Narrow Row Cleaner Model WA<strong>13</strong>20N is<br />

designed to clean residue from the vital seed trench<br />

area with less total disturbance than regular models.<br />

Two wheels are used to insure that residue is<br />

removed from the row center and not just dragged<br />

across the row which may occur with single wheel<br />

models.<br />

This model is recommended for 20" planters that<br />

have all units on one bar operating in moderate<br />

residue. Because the cleaning teeth reach their<br />

maximum depth nearer the row than other models,<br />

the seed trench is more easily opened and the trench<br />

walls are more likely to crumble. The planter path will<br />

retain more moisture where this model is used than<br />

where the regular width cleaners are operated.<br />

<strong>Martin</strong> Fixed Row Cleaners<br />

<strong>Martin</strong> Fixed Row Cleaners<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 11

<strong>Martin</strong> Fixed Row Cleaners And Brackets<br />

12<br />

<strong>Martin</strong> B4<strong>13</strong> Row Cleaner<br />

For use only on White Frame Mounted<br />

Double Arm Coulter.<br />

• 3/8" thick, right and left <strong>13</strong>" diameter<br />

toothed steel wheels with diamond<br />

shaped points<br />

• Side treader wheels are standard on this<br />

model to create a larger gripping surface<br />

for the toothed wheels<br />

• Mounting bracket included<br />

Pin Adjust Brackets For Fixed Row Cleaners<br />

MT385 Attaches to Deutz-Allis (now Landoll) Quadra Disk<br />

planting unit. Accepts 1 1/2” tube wheel assembly.<br />

MT512 Attaches to White 5000 Series planters. Bolts<br />

directly to planter using existing holes. Accepts<br />

1 1/2” wheel assembly.<br />

MT610 Attaches to White 6000 Series planters with heavy<br />

duty down pressure springs. Accepts 1 1/2” wheel<br />

assembly.<br />

MT810 Attaches to White 8000 Series planters.<br />

Accepts 1 1/2” wheel assembly.

MT892 Attaches to Case IH 800 and 900 series planters.<br />

For 2” tube wheel assemblies (Additional mounting<br />

kit required for early 800 series planters).<br />

MT1250 Attaches to Case IH 1200 and 1250 series planters<br />

For 2” tube wheel assemblies. Will not work with<br />

pneumatic down force systems.<br />

MT772 - Rear Position<br />

Uses two position bolt-in receiver tube to fit all<br />

MaxEmerge, Kinze, and White 6000 series<br />

planters. Shown in rear position as used on JD<br />

MaxEmerge, early Kinze. Also, some JD Early<br />

MaxEmerge 2 series (7200, 7240, 7300).<br />

Accepts 1 1/2” tube wheel assembly.<br />

MT772 - Forward Position<br />

Shown with receiver tube in forward position<br />

as used on late MaxEmerge 2 series to<br />

MaxEmerge Plus, late Kinze, early White 6000<br />

series (except with heavy down pressure<br />

springs). Accepts 1 1/2” tube wheel assembly.<br />

<strong>Martin</strong> Fixed Row Cleaner Brackets<br />

<strong>Martin</strong> Fixed Row Cleaner Brackets<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> <strong>13</strong>

<strong>Martin</strong> Unit Mounted Fertilizer Openers<br />

14<br />

The <strong>Martin</strong> UMO-100 fertilizer opener mounts<br />

directly to the planting unit and is compact<br />

enough to be mounted within our <strong>13</strong>60 floating<br />

row cleaners.<br />

Because the opener mounts directly to the<br />

planter unit, the fertilizer is always precisely the<br />

same distance from the seed, even when<br />

planting on the contour. The lateral spacing<br />

from the seed can be 1", 2", or 3", and there<br />

are also three vertical settings that allow<br />

fertilizer to be placed 3/4" above, even with, or<br />

3/4" below seed depth. We like the way it<br />

consistently places the fertilizer in the ground<br />

without splattering it on the planter.<br />

Image above shows the UMO-100<br />

placing fertilizer in a band alongside<br />

the row for maximum uptake.<br />

Many no-till producers are placing<br />

1/3 to 1/2 of their nitrogen down<br />

in a band alongside the row at<br />

planting time. Research shows<br />

banded placement of the nutrient<br />

allows for increased uptake, more<br />

consistent early growth and an<br />

increased rate of total nitrogen<br />

recovery (compared to broadcast<br />

nitrogen applications).<br />

UMO-100 Features<br />

Sturdy compact design<br />

Double tapered bearing hub<br />

5mm thick (0.197") blade<br />

Adjustable furrow control device<br />

Can be set to place liquids 1", 2", or 3" from<br />

seed row<br />

Can also be set to place liquids 3/4" above,<br />

Even with, or 3/4" below seed depth<br />

Fits Deere 7000 - 1700 series planters, Kinze<br />

and White 6000 & 8000 series planters<br />

• Patent Number 7,481,171

BD-UMO<br />

<strong>13</strong>60 floating row cleaner with UMO-100<br />

combination. Designed to install on 7200 (and<br />

later) John Deere planter units. Measures 25” from<br />

face plate to front of row cleaner assembly.<br />

BK-UMO<br />

<strong>13</strong>60 floating row cleaner with UMO-100<br />

combination. Designed to install on 2000 and 3000<br />

series Kinze planter units and John Deere 7000<br />

series planters. Measures 25” from face plate to<br />

front of row cleaner assembly.<br />

BCIH-UMO*<br />

<strong>13</strong>60 floating row cleaner with UMO-100<br />

combination. Designed to install on Case IH<br />

planter units without frame mounted no-till<br />

coulters.<br />

* Requires heavy duty lower parallel arms.<br />

BW-UMO<br />

<strong>13</strong>60 floating row cleaner with UMO-100<br />

combination. Designed to install on White 6000 and<br />

8000 series planter units without frame mounted no<br />

-till coulters. Measures 25” from face plate to front<br />

of row cleaner assembly<br />

<strong>Martin</strong> Unit Mounted Fertilizer Openers<br />

<strong>Martin</strong> Unit Mounted Fertilizer Openers<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 15

<strong>Martin</strong> Reduced Inner Diameter Gauge Wheel Tires<br />

16<br />

Left side shows where the<br />

standard gauge wheel tire<br />

was used. Notice the<br />

compacted soil and sidewall.<br />

Right side shows how the<br />

RID-01 tire allows the<br />

sidewall to flex upwards<br />

and fracture, reducing<br />

sidewall compaction and<br />

helping with row closure.

Reduced Inner Diameter Gauge Wheel Tires are an important<br />

addition to a no-till planting system, especially if the soils are<br />

wet at planting time. The benefits of reduced inner diameter<br />

gauge wheel tires can be seen in the images to the left<br />

where both a standard gauge wheel tire and a reduced inner<br />

diameter tire are both installed on the same row unit. Notice<br />

how the standard tire (left) compressed the sidewall,<br />

increasing the risk of sidewall compaction and reduced yields.<br />

The reduced inner diameter gauge wheel tire (right) allows<br />

the sidewall to flex upwards, reducing soil compression within<br />

the seed zone.<br />

A second and perhaps more significant benefit of the reduced<br />

inner diameter gauge wheel tires is their ability to leave the<br />

soil either side of the row looser and this helps improve the<br />

closing action of both factory and <strong>Martin</strong>-Till closing systems.<br />

RID-01 are not for use on John Deere XP series row units.<br />

RID - 01 Tire<br />

Many different reduced inner diameter gauge wheel tires are available on the<br />

market, however, our research has concluded that the most effective tire is one<br />

which includes a softer, more flexible compound. Softer compounds enable tires<br />

to better shed wet soil plus offer greater terrain following ability by absorbing<br />

more shock through the softer tire. Our tire is the one illustrated at the top of the<br />

two tires (with a weight of 7.4lb). Other tires on the market have a harder and<br />

less flexible compound and they can be identified by their increased weight.<br />

<strong>Martin</strong> Reduced Inner Diameter Gauge Wheel Tires<br />

<strong>Martin</strong> Reduced Inner Diameter Gauge Wheel Tires<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 17

<strong>Martin</strong> Closing Systems<br />

18<br />

<strong>Martin</strong> Paired <strong>13</strong>” Spading Closing Wheels<br />

<strong>Martin</strong> Spading Closing wheels move soil toward the seed at planting depth, while<br />

lifting and fracturing the surface layer to achieve compaction free closing of the<br />

seed trench in wet, hard, or sod conditions. With soil firmed around the seed<br />

from each side and the surface layer loosened, crops emerge sooner and planting<br />

can be done at the proper depth, even in wetter conditions, without fear of<br />

crushed soil above the seed preventing emergence.<br />

Our Spading-Closing Wheels do not attempt to close the seed trench by a<br />

crushing action from the top down. The soil is wedged toward the seed from<br />

either side at seeding depth by a pair of <strong>Martin</strong> Row Cleaner wheels. The ends of<br />

the teeth have full bevels cut on them. The beveled sides of the teeth on each<br />

wheel are placed toward the row and the narrow edge enters the soil first<br />

producing a wedging action. As the teeth on the wheels rotate up out of the soil,<br />

a slight lifting and crumbling occurs in the surface layer. The area on either side<br />

of the seed and immediately above it is not fractured, and because of the shape<br />

and spacing of the teeth on these wheels, wet soil does not bind to them.

Spading Wheels - Specific Advantages<br />

Speeds up warming of the row area<br />

Closing wheel arm pressure can be greatly reduced<br />

Seed trench is closed in the most severe conditions<br />

Seed depth does not have to be raised to insure emergence<br />

Soil above the seed is loose and slightly mounded allowing quicker emergence<br />

in a compaction-free environment<br />

Sidewall compaction is greatly reduced<br />

In the past we thought the only way to grow no-till crops successfully was to<br />

wait until the soil was dry enough for the planter’s smooth closing wheels to<br />

crumble the soil over the seed. Our long-standing struggle with the problem<br />

prompted us to find a solution that we have since patented.<br />

Customers around the country are praising it.<br />

<strong>Martin</strong> Closing Systems<br />

<strong>Martin</strong> Closing Systems<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 19

<strong>Martin</strong> Paired <strong>13</strong>” Spading Closing Wheels<br />

20<br />

SCW<strong>13</strong>41 Spading Closing<br />

Wheels<br />

For planters with roll-pin attached<br />

hubs: Deere 7000 & 7100 series,<br />

early Kinze series planters<br />

3/8" thick, <strong>13</strong>" diameter right and<br />

left toothed steel wheels with<br />

diamond shaped points<br />

Cast hubs<br />

Adaptor axles<br />

Two 17mm I.D. bearings<br />

SCW<strong>13</strong>43 Spading Closing<br />

Wheels<br />

For Deere 7200-7300 series planters<br />

3/8" thick, <strong>13</strong>" diameter right and<br />

left toothed steel wheels with<br />

diamond shaped points<br />

Cast hubs<br />

Two 17mm I.D. bearings<br />

SCW<strong>13</strong>44 Spading Closing<br />

Wheels<br />

For planters with bolt-on hubs: Deere<br />

1700 series, Kinze & White 6000 &<br />

8000<br />

3/8" thick, <strong>13</strong>" diameter right and<br />

left toothed steel wheels with<br />

diamond shaped points<br />

HU44-B2 cast hubs with long life<br />

50mm 5203 bearing<br />

SCW <strong>13</strong>44 Spading Closing<br />

Wheels pictured on a John<br />

Deere 1700 series closing wheel<br />

SCW <strong>13</strong>44 Spading Closing<br />

Wheels pictured on a John<br />

Deere 1700 series closing wheel<br />

arm with optional drop-down<br />

brackets. Drop down brackets<br />

are designed for paired <strong>13</strong>”<br />

wheels and they help maintain a<br />

level closing wheel arm<br />

assembly in loose soils. See the<br />

following page for more<br />

information.

Maximizing The Performance Of A<br />

Pair Of <strong>13</strong>” Spading Closing Wheels.<br />

Most producers are good at centering their<br />

closing wheel arm assembly above the<br />

seed slot, however, its surprising to see<br />

how many producers don't adjust their<br />

closing wheel arm to run level when<br />

planting, especially with a pair of <strong>13</strong>”<br />

spading closing wheels.<br />

A <strong>13</strong>” spading closing wheel is 1” greater<br />

in diameter than a standard smooth<br />

closing wheel, this is by design to allow<br />

the wheels to engage the soil and<br />

effectively close the seed slot as previously<br />

discussed.<br />

When working in looser soils, they<br />

frequently engage the soil deeper than<br />

within firmer soils, so to help reduce this<br />

excessive soil engagement, down pressure<br />

may need to be reduced (sometimes to a<br />

minimum setting).<br />

Greater down pressure settings tend to<br />

lower the rear of the closing wheel arm<br />

assembly, which reduces the gathering<br />

action of the two spading wheels.<br />

The images to the right illustrate the<br />

problem. Look closely at how the angle of<br />

the closing wheel arm assembly influences<br />

the gathering action of the spading closing<br />

wheels.<br />

A closing wheel arm assembly can be<br />

leveled slightly on a 3000 series Kinze by<br />

adjusting the eccentric bolts which attach<br />

the arm to the planter, but John Deere and<br />

White cannot be adjusted this way.<br />

Low Closing Wheel Arm Rear<br />

Negative Closing Action<br />

Level Closing Wheel Arm<br />

Positive Closing Action<br />

<strong>Martin</strong> Paired <strong>13</strong>” Spading Closing Wheels<br />

<strong>Martin</strong> Paired <strong>13</strong>” Spading Closing Wheels<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 21

<strong>Martin</strong> Single 15” Spading Closing Wheels<br />

22<br />

SCW1541 Spading Closing<br />

Wheels<br />

For planters with roll-pin attached<br />

hubs: Deere 7000 & 7100 series,<br />

early Kinze series planters<br />

3/8" thick, 15" diameter right and<br />

left toothed steel wheels with<br />

diamond shaped points<br />

Cast hubs<br />

Adaptor axles<br />

Two 17mm I.D. bearings<br />

SCW1543 Spading Closing<br />

Wheels<br />

For Deere 7200-7300 series planters<br />

3/8" thick, 15" diameter right and<br />

left toothed steel wheels with<br />

diamond shaped points<br />

Cast hubs<br />

Two 17mm I.D. bearings<br />

SCW1544 Spading Closing<br />

Wheels<br />

For planters with bolt-on hubs: Deere<br />

1700 series, Kinze, plus White 6000<br />

& 8000 series.<br />

3/8" thick, 15" diameter right and<br />

left toothed steel wheels with<br />

diamond shaped points<br />

HU44-B2 cast hubs with long life<br />

50mm 5203 bearing<br />

Single SCW1544 spading closing<br />

wheels don’t close the seed slot as<br />

well as a pair of correctly leveled <strong>13</strong>”<br />

spading closing wheels, but they do<br />

perform significantly better than a<br />

pair of smooth factory closing wheels<br />

in higher moisture no-till soils.<br />

The above two photos were taken<br />

from the same pass of a 3600 Kinze<br />

planter while no-tilling corn into<br />

higher moisture soybean residue.<br />

While down pressure could be<br />

increased on the unit with the<br />

smooth closing wheels, the amount<br />

of sidewall compaction would be<br />

severe.

SCW<strong>13</strong>41D Closing Wheels<br />

For planters with roll-pin attached<br />

hubs: Deere 7000 & 7100 series,<br />

early Kinze series planters<br />

1/2 thick, heat treated T-1<br />

material wheels with 20 rounded<br />

points<br />

Cast hubs<br />

Adaptor axles<br />

Two 17mm I.D. bearings<br />

SCW<strong>13</strong>43D Closing Wheels<br />

For Deere 7200-7300 series planters<br />

1/2 thick, heat treated T-1<br />

material wheels with 20 rounded<br />

points<br />

Cast hubs<br />

Two 17mm I.D. bearings<br />

SCW<strong>13</strong>44D Closing Wheels<br />

For planters with bolt-on hubs: Deere<br />

1700 series, Kinze, plus White 6000<br />

& 8000 series.<br />

1/2 thick, heat treated T-1<br />

material wheels with 20 rounded<br />

points<br />

HU44-B2 cast hubs with long life<br />

50mm 5203 bearing<br />

The SCW<strong>13</strong>44D, 20 point dimple<br />

wheels are a sound choice for<br />

producers who plant most of their<br />

crops from medium moisture to dry<br />

conditions.<br />

Their 20 rounded points help this<br />

closing system performs well in hard<br />

sod conditions plus they frequently<br />

outperform factory closing systems in<br />

minimum till soil conditions.<br />

<strong>Martin</strong> Paired 20 Point Dimple Wheels<br />

<strong>Martin</strong> Paired 20 Point Dimple Wheels<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 23

<strong>Martin</strong> Spading Closing Wheels For Early Model White Planters<br />

24<br />

These closing wheels can be added<br />

to the White 5000 or 6000 series<br />

planters that have single closing<br />

tires. The <strong>Martin</strong> Spading Closing<br />

Wheels enhance closing of the seed<br />

trench while the smooth wheel<br />

gently tamps the surface.<br />

Moist soil is moved toward the seed<br />

at seeding depth, even in wet, hard<br />

or sod conditions. In wet conditions,<br />

the soil is prevented from forming a<br />

continuous ribbon by the lifting<br />

action of the teeth as they rotate up<br />

out of the soil.<br />

Other benefits include:<br />

Closing wheel arm pressure can<br />

be greatly reduced<br />

Seed trench is closed in the most<br />

severe conditions<br />

Seeding depth does not have to<br />

be raised to insure emergence<br />

Soil above the seed is loose,<br />

allowing quicker emergence in a<br />

compaction free environment<br />

Sidewall compaction is eliminated<br />

SCW51 Spading Closing Wheels<br />

Double <strong>13</strong>" diameter left and right<br />

hand toothed steel wheels with<br />

diamond shaped points<br />

Single 2-row ball bearing<br />

Left and right angled brackets<br />

Fits White 5100 planters with single<br />

closing wheels<br />

Does not change planters’ overall<br />

length<br />

SCW61 Spading Closing Wheels<br />

Double <strong>13</strong>" diameter left and right<br />

toothed steel wheels with diamond<br />

shaped points<br />

Single 2-row ball bearing<br />

Left and right angled brackets<br />

Fits White 6000 series planters with<br />

single closing wheels<br />

Does not change planters overall<br />

length

The SCW899 guarantees a closed<br />

seed trench, while the smooth<br />

wheel gently tamps the surface.<br />

These specially designed toothed<br />

wheels replace the regular closing<br />

disk.<br />

Moist soil is moved toward the seed<br />

at seeding depth even in wet, hard<br />

or sod conditions. In wet conditions,<br />

the soil is prevented from forming a<br />

continuous ribbon by the lifting<br />

action of the teeth as they rotate up<br />

out of the soil.<br />

Other benefits include:<br />

Closing wheel arm pressure can<br />

be greatly reduced<br />

Seed trench is closed in the most<br />

severe conditions<br />

Seeding depth does not have to<br />

be raised to insure emergence<br />

Soil above the seed is loose<br />

allowing quicker emergence in a<br />

compaction free environment<br />

Sidewall compaction is eliminated<br />

SCW899 Closing Wheels<br />

9" diameter toothed steel wheels and<br />

ball bearing hubs<br />

Replaces closing disk on Case IH<br />

800, 900, 1200 and 1250 planters;<br />

for use on offset closing wheel arm<br />

only<br />

Also fits Deere and Kinze shallow<br />

closing systems<br />

Model SCW899. Nine-inch diameter<br />

spikes replace covering disc on IH<br />

planters. Not available for units without<br />

offset covering disc arm (for example<br />

the Early 800 series).<br />

<strong>Martin</strong> Spading Closing Wheels For Case Planters<br />

<strong>Martin</strong> Spading Closing Wheels For Case Planters<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 25

<strong>Martin</strong> Twisted Drag Chain<br />

26<br />

Following behind the Spading Closing<br />

Wheels our Twisted Drag Chain helps to<br />

further crumble and level the soil. This helps<br />

even out the rate of drying and insures the<br />

soil does not dry past seed depth.<br />

This is a low cost, low maintenance way to<br />

help increase uniform emergence in the drier<br />

parts of the field and is a must when using<br />

the spading closing wheels in minimum till.<br />

By the way, some of our customers still feel<br />

the need for some shallow tillage in the<br />

spring and the spading closing wheels and<br />

drag chain combination do an excellent job<br />

in that situation.<br />

DCK-01 Drag Chain Kit<br />

<strong>Martin</strong> Twisted Drag Chains<br />

are designed to follow a pair<br />

of <strong>13</strong>” spading closing wheels,<br />

a pair of 20 point dimple<br />

wheels and a single 15”<br />

spading closing wheel.<br />

Heavy square edge cross chain and brackets<br />

Bolts to all Max-Emerge units<br />

Fits Kinze and White units with bolt-on wheels<br />

Kinze units with roll pin attached closing wheels will need<br />

holes drilled for mounting

The <strong>Martin</strong> Twisted Drag Chain Kit can be seen following a pair of<br />

<strong>13</strong>” Spading Closing Wheels on a John Deere 1770 planter. Notice in<br />

the above photo how the drag chain pulls a handful of soil along<br />

which helps smooth and fill in any unclosed areas of the seed slot.<br />

In combination with a pair RID-01 gauge wheel tires, the seed zone<br />

is left slightly elevated to reduced ponding and crusting.<br />

<strong>Martin</strong> Twisted Drag Chain<br />

<strong>Martin</strong> Twisted Drag Chain<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 27

<strong>Martin</strong> Closing Systems For John Deere Grain Drills and Air Seeders<br />

28<br />

SCW75B4 Spading-Closing<br />

Wheels<br />

3/8" thick, <strong>13</strong>" diameter right<br />

and left toothed steel wheel<br />

with diamond shaped points<br />

Single 2-row ball bearing<br />

Double threaded specially<br />

designed axle<br />

Fits Deere 750 and 1850<br />

drills<br />

Completely aerates above<br />

seed<br />

Creates a miniature ridge<br />

that sheds water and helps<br />

maintain a warmer seed<br />

environment<br />

SCW75B4D-20 Dimple<br />

Closing Wheels<br />

1/2" thick, <strong>13</strong>" diameter steel<br />

wheel with 20 rounded<br />

points<br />

Single 2-row ball bearing<br />

Double threaded specially<br />

designed axle<br />

Fits Deere 750 and 1850<br />

drills<br />

Firms soil at rounded points<br />

while leaving looser area<br />

between points<br />

Less aggressive than<br />

SCW75B4

SCW1564 Spading Closing<br />

Wheels<br />

3/8" thick, <strong>13</strong>" diameter right<br />

and left toothed steel wheel<br />

with diamond shaped points<br />

Fits 1560, 1860, 1590, and<br />

1890 drills<br />

Completely aerates above<br />

seed<br />

Creates a miniature ridge<br />

that sheds water and helps<br />

maintain a warmer seed<br />

environment<br />

Mounts on existing closing<br />

wheel arm<br />

SCW1564D-20 Dimple<br />

Closing Wheels<br />

Fits Deere 1560, 1860, 1590,<br />

and 1890 drills<br />

1/2" thick, <strong>13</strong>" diameter steel<br />

wheel with 20 rounded<br />

points<br />

Firms soil at rounded points<br />

while leaving looser area<br />

between points<br />

Less aggressive than spading<br />

closing wheels<br />

Mounts on existing closing<br />

wheel arm<br />

<strong>Martin</strong> Closing Systems For John Deere Grain Drills and Air Seeders<br />

<strong>Martin</strong> Closing Systems For John Deere Grain Drills and Air Seeders<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 29

<strong>Martin</strong> Spring Spacers For John Deere Drills and Air-Seeders<br />

Air Seeders<br />

30<br />

Key Benefits:<br />

<strong>Martin</strong> Spring Spacers are available for John Deere 50 series and 60/90<br />

series openers installed on No-Till Grain Drills and Air-Seeders.<br />

These 3/8” spacers are easily installed within the spring assembly and<br />

increase the opener down pressure by approximately 75 lb.<br />

Designed to be installed behind air-cart wheels or tractor wheels, where<br />

additional down pressure is frequently required.<br />

Can be paired up. When a pair of spring spacers are added in tandem, they<br />

can provide an additional 150 lb of down force per opener. This<br />

configuration is especially suitable for heavy air-carts which leave<br />

compacted and lowered wheel tracks, which present penetration difficulties.<br />

SS-50 Designed to install within all<br />

50 series John Deere openers.<br />

SS-60 Designed to install within all<br />

60 and 90 series openers.

<strong>Martin</strong> Warranty<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong> warranties its product to be free from defects in<br />

materials and in workmanship for one full year from date of sale to the<br />

original user.<br />

The warranty is valid provided defective part(s) is received within twenty<br />

days of discovery.<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong> has the option to either repair or replace any parts<br />

that were determined to be defective due to material or workmanship.<br />

Any improper use, including operation after discovery of defective or<br />

worn parts, operation beyond rated capacity, or substitution of parts not<br />

approved by <strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. shall void this warranty.<br />

No dealer, employee, or representative is authorized to change this<br />

warranty in any way or grant any other warranty unless such change is in<br />

writing and signed by an officer of <strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong> at its home<br />

office.<br />

<strong>Martin</strong> Warranty<br />

<strong>Martin</strong> Warranty<br />

<strong>Martin</strong> <strong>Industries</strong>, <strong>LLC</strong>. • <strong>800.366.5817</strong> 31