Research on method for determination of amylose content in rice

Research on method for determination of amylose content in rice

Research on method for determination of amylose content in rice

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Proceedmas <strong>of</strong> the 7 th Iniemaiumai Worktng C<strong>on</strong>ference <strong>on</strong> Stored-product Protecti<strong>on</strong>. - Yolurne 2<br />

<strong>of</strong> <strong>rice</strong> <strong>amylose</strong> c<strong>on</strong>tent was provided m this research, it<br />

should not exceed 0.5 % while <strong>amylose</strong> c<strong>on</strong>tent <strong>of</strong> nee IS less<br />

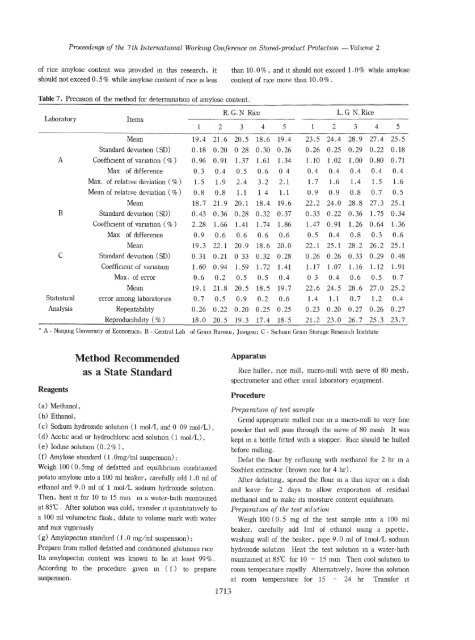

Table 7. Precisi<strong>on</strong> <strong>of</strong> the <strong>method</strong> <strong>for</strong> determmati<strong>on</strong> <strong>of</strong> <strong>amylose</strong> c<strong>on</strong>tent.<br />

Laboratory<br />

A<br />

B<br />

C<br />

Statistical<br />

Analysis<br />

than 10.0%, and It should not exceed 1.0% wlule <strong>amylose</strong><br />

c<strong>on</strong>tent <strong>of</strong> nee more than 10.0 % .<br />

R.G.N Rice 1. G N. Rice<br />

Items<br />

1 2 3 4 5 1 2 3 4 5<br />

Standard<br />

Mean<br />

deviati<strong>on</strong> (SD)<br />

19.4<br />

0.18<br />

21.6<br />

0.20<br />

20.5<br />

o 28<br />

18.6<br />

0.30<br />

19.4<br />

0.26<br />

23.5<br />

0.26<br />

24.4<br />

0.25<br />

28.9<br />

0.29<br />

27.4<br />

0.22<br />

25.5<br />

0.18<br />

Coefficient<br />

Max<br />

<strong>of</strong> vanatr<strong>on</strong><br />

<strong>of</strong> difference<br />

(%) 0.96<br />

0.3<br />

0.91<br />

0.4<br />

1.37<br />

0.5<br />

1.61<br />

0.6<br />

1.34<br />

o 4<br />

1.10<br />

0.4<br />

1.02<br />

0.4<br />

1.00<br />

0.4<br />

0.80<br />

0.4<br />

0.71<br />

0.4<br />

Max. <strong>of</strong> relative deviati<strong>on</strong> ( % ) 1.5 1.9 2.4 3.2 2.1 1.7 1.6 1.4 1.5 1.6<br />

Mean <strong>of</strong> relative deviati<strong>on</strong> (%) 0.8 0.8 1.1 1 4 1.1 0.9 0.9 0.8 0.7 0.5<br />

Mean 18.7 21.9 20.1 18.4 19.6 22.2 24.0 28.8 27.3 25.1<br />

Standard deviati<strong>on</strong> (SD) 0.43 0.36 0.28 0.32 0.37 0.33 0.22 0.36 1. 75 0.34<br />

Coeffrcient <strong>of</strong> vanati<strong>on</strong> (%) 2.28 1.66 1.41 1. 74 1.86 1.47 0.91 1.26 0.64 1.36<br />

Max <strong>of</strong> difference 0.9 0.6 0.6 0.6 0.6 0.5 0.4 0.8 0.3 0.6<br />

Standard<br />

Mean<br />

deviati<strong>on</strong> (SD)<br />

19.3<br />

0.31<br />

22.1<br />

0.21<br />

20.9<br />

o 33<br />

18.6<br />

0.32<br />

20.0<br />

0.28<br />

22.1<br />

0.26<br />

25.1<br />

0.26<br />

28.2<br />

0.33<br />

26.2<br />

0.29<br />

25.1<br />

0.48<br />

Coefficien t <strong>of</strong> vana n<strong>on</strong><br />

Max. <strong>of</strong> error<br />

1.60<br />

0.6<br />

0.94<br />

0.2<br />

1.59<br />

0.5<br />

1. 72<br />

0.5<br />

1.41<br />

0.4<br />

1.17<br />

o 3<br />

1.07<br />

0.4<br />

1.16<br />

0.6<br />

1.12<br />

0.5<br />

1.91<br />

0.7<br />

Mean 19.1 21.8 20.5 18.5 19.7 22.6 24.5 28.6 27.0 25.2<br />

error am<strong>on</strong>g laborat<strong>on</strong>es 0.7 0.5 0.9 0.2 0.6 1.4 1.1 0.7 1.2 0.4<br />

Repea tabih ty 0.26 0.22 0.20 0.25 0.25 0.23 0.20 0.27 0.26 0.27<br />

Reproducibility ( % ) 18.0 20.5 19.3 17.4 18.5 21.2 23.0 26.7 25.3 23.7<br />

* A - Nanjmg University <strong>of</strong> Ec<strong>on</strong>omics. B - Central Lab <strong>of</strong> Gram Bureau, Iiangsu, C - Sichuan Gram Storage <str<strong>on</strong>g>Research</str<strong>on</strong>g> Institute<br />

Method Recommended<br />

as a State Standard<br />

Apparatus<br />

RIce huller, nee null, micro-null WIth SIeve <strong>of</strong> 80 mesh,<br />

spectrometer and other usual laboratory equipment.<br />

Reagents<br />

Procedure<br />

(a) Methanol,<br />

Preparati<strong>on</strong>. <strong>of</strong> test sample<br />

(b) Ethanol,<br />

Gnnd appropnate milled nee m a micro-mill to very fme<br />

(c) Sodium hydroxide soluti<strong>on</strong> (1 mollL and 0 09 mol/L) ,<br />

powder that Will pass through the SIeve <strong>of</strong> 80 mesh It was<br />

(d) Acetic acid or hydrochl<strong>on</strong>c acid soluti<strong>on</strong> (1 mol/L) ,<br />

kept m a bottle fitted WIth a stopper. RIce should be hulled<br />

(e) Iodme soluti<strong>on</strong> (0.2%),<br />

be<strong>for</strong>e null<strong>in</strong>g.<br />

(0 Amylose standard (1. Omg/ml suspensi<strong>on</strong>) :<br />

Defat the flour by refluxmg WIth methanol <strong>for</strong> 2 hr <strong>in</strong> a<br />

Weigh 100 (0. 5mg <strong>of</strong> defatted and equilibrium c<strong>on</strong>diti<strong>on</strong>ed Soxhlex extractor (brown nee <strong>for</strong> 4 hr ):<br />

potato <strong>amylose</strong> mto a 100 ml beaker, carefully add 1.0 ml <strong>of</strong> After defattmg, spread the flour m a thm layer <strong>on</strong> a dish<br />

ethanol and 9.0 ml <strong>of</strong> 1 mollL sodium hydroxide soluti<strong>on</strong>. and leave <strong>for</strong> 2 days to allow evaporati<strong>on</strong> <strong>of</strong> residual<br />

Then, heat It <strong>for</strong> 10 to 15 m<strong>in</strong> m a water-bath mamtamed methanol and to make ItS moisture c<strong>on</strong>tent equihbnum.<br />

at 85°C. After soluti<strong>on</strong> was cold, transfer It quantitatively to Preparatwn <strong>of</strong> the test soluti<strong>on</strong><br />

a 100 ml volumetnc flask, dilute to volume mark WIth water Weigh 100 ( 0.5 mg <strong>of</strong> the test sample mto a 100 ml<br />

and mIX VIgorously<br />

beaker, carefully add l.ml <strong>of</strong> ethanol us<strong>in</strong>g a pipette,<br />

(g) Amylopect<strong>in</strong> standard (1.0 mg/ml suspensi<strong>on</strong>}.<br />

wash<strong>in</strong>g wall <strong>of</strong> the beaker, pipe 9.0 ml <strong>of</strong> 1molIL sodium<br />

Prepare from milled defatted and c<strong>on</strong>diti<strong>on</strong>ed glutmous nee hydroxide soluti<strong>on</strong> Heat the test soluti<strong>on</strong> <strong>in</strong> a water-bath<br />

Its amylopectm c<strong>on</strong>tent was known to be at least 99%. mamtamed at 85°C <strong>for</strong> 10 - 15 nun Then cool soluti<strong>on</strong> to<br />

Accordmg to the procedure given m (f) to prepare room temperature rapidly Alternatively, leave tlus soluti<strong>on</strong><br />

suspensi<strong>on</strong>.<br />

at<br />

1713<br />

room temperature <strong>for</strong> 15 - 24 hr Transfer It