Original Parts Brochure - GEA Westfalia Separator

Original Parts Brochure - GEA Westfalia Separator

Original Parts Brochure - GEA Westfalia Separator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

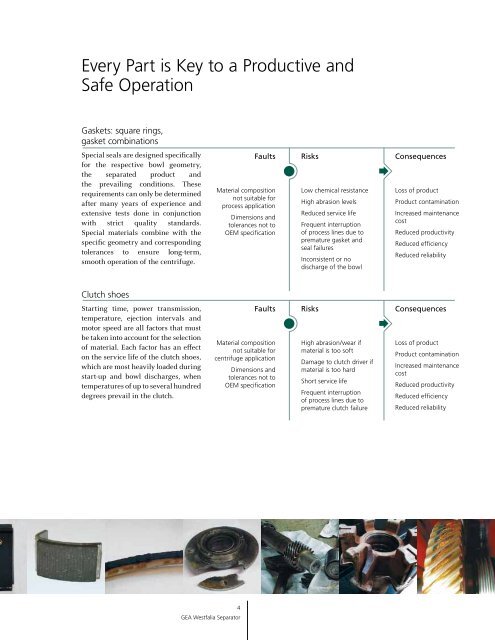

Every Part is Key to a Productive and<br />

Safe Operation<br />

Gaskets: square rings,<br />

gasket combinations<br />

Special seals are designed specifically<br />

for the respective bowl geometry,<br />

the separated product and<br />

the prevailing conditions. These<br />

requirements can only be determined<br />

after many years of experience and<br />

extensive tests done in conjunction<br />

with strict quality standards.<br />

Special materials combine with the<br />

specific geometry and corresponding<br />

tolerances to ensure long-term,<br />

smooth operation of the centrifuge.<br />

Clutch shoes<br />

Starting time, power transmission,<br />

temperature, ejection intervals and<br />

motor speed are all factors that must<br />

be taken into account for the selection<br />

of material. Each factor has an effect<br />

on the service life of the clutch shoes,<br />

which are most heavily loaded during<br />

start-up and bowl discharges, when<br />

temperatures of up to several hundred<br />

degrees prevail in the clutch.<br />

4<br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong><br />

Faults<br />

Material composition<br />

not suitable for<br />

process application<br />

Dimensions and<br />

tolerances not to<br />

OEM specification<br />

Faults<br />

Material composition<br />

not suitable for<br />

centrifuge application<br />

Dimensions and<br />

tolerances not to<br />

OEM specification<br />

Risks<br />

Low chemical resistance<br />

High abrasion levels<br />

Reduced service life<br />

Frequent interruption<br />

of process lines due to<br />

premature gasket and<br />

seal failures<br />

Inconsistent or no<br />

discharge of the bowl<br />

Risks<br />

High abrasion/wear if<br />

material is too soft<br />

Damage to clutch driver if<br />

material is too hard<br />

Short service life<br />

Frequent interruption<br />

of process lines due to<br />

premature clutch failure<br />

Consequences<br />

Loss of product<br />

Product contamination<br />

Increased maintenance<br />

cost<br />

Reduced productivity<br />

Reduced efficiency<br />

Reduced reliability<br />

Consequences<br />

Loss of product<br />

Product contamination<br />

Increased maintenance<br />

cost<br />

Reduced productivity<br />

Reduced efficiency<br />

Reduced reliability